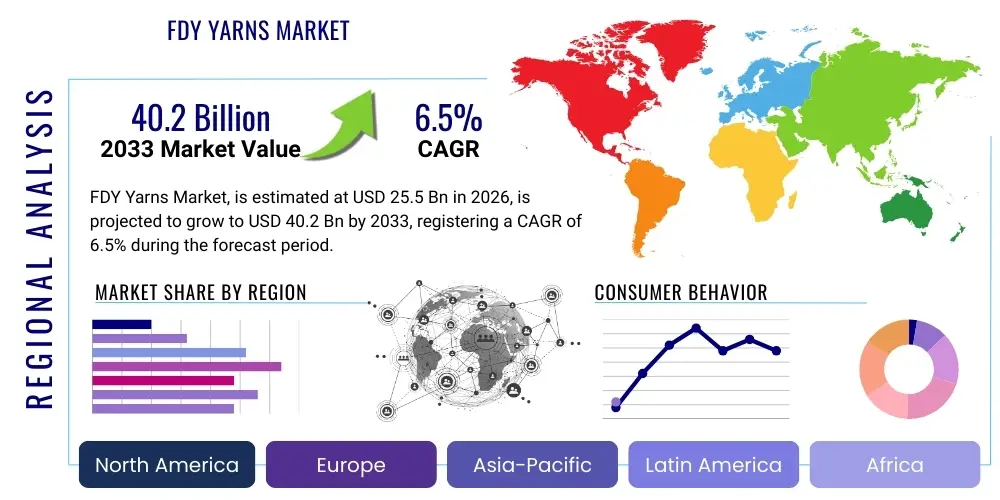

FDY Yarns Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438838 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

FDY Yarns Market Size

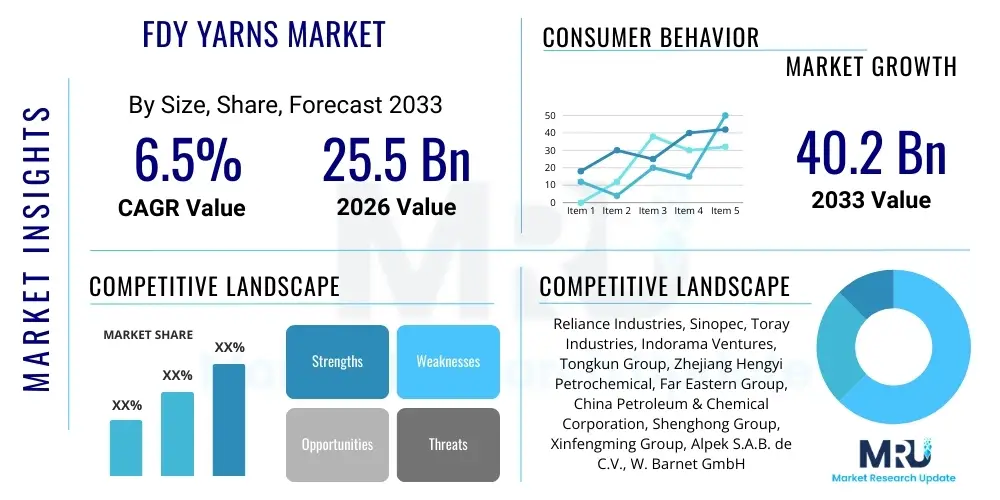

The FDY Yarns Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 25.5 Billion in 2026 and is projected to reach USD 40.2 Billion by the end of the forecast period in 2033.

FDY Yarns Market introduction

The Fully Drawn Yarn (FDY) market encompasses the production and distribution of continuous filament yarns that have undergone drawing processes during the spinning stage, resulting in high tenacity, low elongation, and complete orientation. These yarns, predominantly manufactured from polyester, nylon, and polypropylene, are characterized by their smooth surface and high luster, making them suitable for direct use in high-speed weaving and knitting operations without requiring further texturizing or processing. This inherent efficiency and readiness for downstream applications significantly drive their demand across global textile manufacturing hubs.

FDY yarns serve as critical inputs across a multitude of sectors, including apparel, where they are essential for producing fine fabrics, sportswear, and fashion garments due to their excellent drape and color fastness. Beyond apparel, they find extensive use in home textiles for bedsheets, curtains, and upholstery, offering durability and aesthetic appeal. Furthermore, their superior mechanical properties position them favorably within industrial applications such as automotive interiors, conveyor belts, and technical textiles requiring strength and resilience.

The growth trajectory of the FDY Yarns Market is intrinsically linked to global population growth, rising disposable incomes in emerging economies, and the rapid expansion of the fast-fashion industry which demands large volumes of consistent, high-quality yarn. Key driving factors include technological advancements in spinning processes leading to higher yields and reduced production costs, coupled with a growing consumer preference for durable and easy-care textile products. Moreover, the increasing adoption of dope-dyed FDY yarns, which reduces water consumption during the textile dyeing process, aligns with global sustainability trends and further stimulates market expansion.

FDY Yarns Market Executive Summary

The global FDY Yarns market is exhibiting robust growth, propelled primarily by significant capacity additions and technological advancements concentrated within the Asia Pacific region, particularly China and India, which act as the global manufacturing core for textiles. Business trends indicate a strong movement towards backward integration among major players, aiming to control the entire value chain from petrochemical feedstock (PTA/MEG) to final yarn production, thereby ensuring supply stability and optimizing costs. Furthermore, there is an accelerating strategic pivot towards sustainable production methods, including the increasing use of recycled polyester (rPET) for FDY production and the promotion of dope-dyed products to meet stringent environmental regulations and consumer demand for eco-friendly textiles.

Regionally, Asia Pacific maintains overwhelming dominance due to low operational costs, established textile ecosystems, and massive domestic and export market requirements. North America and Europe, while slower in volume growth, are focusing on high-performance and specialty FDY products tailored for technical textiles, automotive, and high-end sportswear, emphasizing innovation and functional differentiation over mass production. Latin America and MEA are emerging markets showing promising growth driven by localized apparel production and infrastructural development, leading to increased demand for home and industrial textiles.

Segment trends highlight the overwhelming market share held by Polyester FDY due to its versatility, cost-effectiveness, and strength, though Nylon FDY maintains a critical niche in high-performance applications like hosiery and specialized outdoor gear. The application segment sees Apparel continuing to be the largest consumer, but Industrial Textiles, encompassing geotextiles and non-wovens, is projected to experience the fastest CAGR, reflecting global infrastructure spending and the increasing technical requirements of modern manufacturing. Strategic focus remains on efficiency improvements, raw material cost management, and diversification into specialty yarns that command higher margins.

AI Impact Analysis on FDY Yarns Market

Users frequently inquire about how Artificial Intelligence and advanced machine learning are being deployed to mitigate the traditionally volatile nature of textile raw material pricing, streamline complex spinning operations, and enhance product quality consistency in FDY manufacturing. Key themes include the implementation of predictive maintenance to reduce costly downtime of high-speed spinning machines, optimizing energy consumption in polymerization and drawing processes, and improving supply chain transparency from monomer sourcing to finished yarn inventory. Consumers and industry stakeholders expect AI integration to drive down operational costs, enable personalized product mixes (e.g., specific deniers or cross-sections), and ensure quicker response times to market shifts, ultimately leading to a more efficient, less wasteful production cycle for FDY yarns.

- AI-driven Predictive Maintenance: Utilizing sensor data from spinning machines to forecast equipment failure, dramatically reducing unplanned downtime and maintenance costs.

- Optimized Process Control: Machine learning algorithms fine-tuning temperature, pressure, and speed parameters in real-time during polymerization and spinning for flawless yarn quality and consistency (e.g., titer, tenacity).

- Supply Chain and Inventory Management: AI systems predicting demand fluctuations and optimizing raw material procurement (PTA/MEG), minimizing expensive inventory holdings and mitigating commodity price risks.

- Quality Assurance Automation: Employing computer vision and deep learning for automatic defect detection in high-speed FDY winding, ensuring compliance with strict textile standards faster than traditional manual checks.

- Energy Consumption Reduction: Using AI to model and manage optimal energy use during the heating and cooling phases of the FDY production line, leading to significant reductions in operational expenditure and carbon footprint.

DRO & Impact Forces Of FDY Yarns Market

The dynamics of the FDY Yarns market are influenced by a complex interplay of internal and external forces summarized by Drivers, Restraints, and Opportunities (DRO). Major drivers include robust demand from the global fast-fashion industry, coupled with infrastructural development in emerging economies boosting the technical textile sector. The continuous innovation in polymerization and spinning technologies allows manufacturers to produce higher quality yarn at increased speeds, further enhancing market supply and accessibility. Additionally, governmental incentives promoting textile manufacturing in key Asian countries provide substantial momentum to market expansion and capacity upgrades.

However, the market faces significant restraints. The most critical is the intense volatility in the price of raw materials, specifically Purified Terephthalic Acid (PTA) and Monoethylene Glycol (MEG), which are petrochemical derivatives. These fluctuations directly impact profit margins and pricing strategies across the value chain. Furthermore, escalating environmental concerns regarding the textile industry's high water and energy consumption, coupled with regulatory pressure on wastewater discharge, necessitate costly investments in sustainable manufacturing processes, posing a barrier for smaller players. Intense competition and overcapacity, particularly in the Chinese market, lead to constant downward pressure on pricing.

Opportunities for growth are abundant, primarily focused on the shift towards sustainable FDY production, including the scaling up of recycled polyester (rPET) FDY and bio-based alternatives. The market also benefits from the expanding applications in high-performance technical textiles, such as filtration media, industrial reinforcements, and specialized automotive components, which demand superior durability and specific functional properties. The adoption of advanced dope-dyeing techniques not only addresses environmental concerns but also offers manufacturers a competitive edge through reduced production cycles and enhanced color fastness, presenting a strong avenue for future market penetration and differentiation.

Segmentation Analysis

The FDY Yarns market is comprehensively segmented based on raw material type, application, and color technology, reflecting the diverse industrial and consumer needs it serves globally. The segmentation by raw material, primarily Polyester, Nylon, and others (like Polypropylene), dictates the fundamental mechanical properties and cost structure of the yarn, with Polyester FDY dominating due to its superior strength-to-cost ratio and versatility across applications. Application segmentation—Apparel, Home Textiles, Automotive, and Industrial—highlights the varied end-use requirements, driving specific product innovations related to denier size, luster, and functional finishes.

A crucial segmentation factor is the type of coloring, categorized mainly into Raw White and Dope Dyed. Dope-dyed FDY, where color pigments are added before spinning, is experiencing rapid growth as it offers significant environmental benefits by eliminating the need for subsequent wet processing, aligning with industry trends towards sustainable manufacturing practices and resource conservation.

- By Raw Material

- Polyester FDY

- Nylon FDY

- Polypropylene (PP) FDY

- Others (e.g., specialty polymers)

- By Application

- Apparel (Knitting and Weaving)

- Home Textiles (Bedding, Upholstery, Curtains)

- Industrial Textiles (Conveyor Belts, Tarpaulins, Ropes)

- Automotive Textiles (Interior Fabric, Seat Belts)

- Others (Medical, Filtration)

- By Color Technology

- Raw White FDY

- Dope Dyed (Colored) FDY

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East & Africa (MEA)

Value Chain Analysis For FDY Yarns Market

The FDY Yarns value chain is characterized by high capital intensity and significant integration, starting deep within the petrochemical industry. The upstream segment involves the production of key monomers: Purified Terephthalic Acid (PTA) and Monoethylene Glycol (MEG) for polyester, or Caprolactam for Nylon. Producers in the midstream sector, often large integrated chemical companies, convert these raw materials into polymer chips and then execute the high-speed melt spinning and drawing processes to manufacture the final FDY yarn. The efficiency and cost-competitiveness at this stage are crucial, heavily relying on advanced machinery and economies of scale.

The distribution channel involves both direct and indirect routes. Major textile conglomerates often engage in direct sales, supplying large volumes of FDY to their captive weaving/knitting units or to large, long-term apparel and home textile manufacturers. Indirect channels utilize specialized yarn distributors, agents, and traders who bridge the gap between large producers and smaller downstream textile mills, providing essential inventory management and logistics services, especially across international borders.

The downstream sector comprises the actual end-users: textile mills, knitters, weavers, and garment manufacturers. Their demand dictates the specifications (denier, color, luster) required from FDY producers. The final consumer purchasing decisions for apparel or home goods ultimately drive the entire chain. Due to the high cost of raw materials and the scale of production, vertical integration—where the same company controls petrochemical production, polymerization, and spinning—is a prevalent strategy aimed at stabilizing costs and increasing margin capture across the complex value chain.

FDY Yarns Market Potential Customers

The primary consumers and end-users of FDY yarns are globally distributed companies operating within the textile, apparel, and technical fabric manufacturing sectors. These customers require yarns with stringent quality specifications, including consistent denier, high tenacity, excellent dye uptake (or pre-coloring in the case of dope-dyed yarns), and low levels of filament breakage to ensure efficiency on high-speed downstream processing equipment. The procurement decision is typically driven by a balance between unit cost, reliable supply volume, and the ability of the yarn to meet specific performance requirements like UV resistance or moisture-wicking properties.

The largest volume buyers are the large-scale apparel manufacturers and their integrated supply chain partners, particularly those focused on mass-market fashion and sportswear, which rely heavily on polyester FDY for cost-effective and high-volume production. Home textile producers, including those making bedding, curtains, and carpets, constitute another significant customer base, valuing the durability and aesthetic finishes FDY provides. Moreover, the automotive industry requires specialized, high-performance FDY for interior fabrics and safety components like airbags and seatbelts, demanding suppliers adhere to strict safety and quality certifications, making them premium customers.

Emerging segments of potential customers include manufacturers of technical textiles such as geotextiles used in civil engineering, industrial filtration media, and sophisticated composite materials. These end-users demand customized FDY products, often requiring specialized coatings or specific polymer bases (like high-tenacity Nylon FDY), indicating a shift towards value-added, rather than purely commodity, procurement. These technical applications represent the highest growth potential in terms of revenue per unit, although volume remains lower than the mass-market apparel segment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 25.5 Billion |

| Market Forecast in 2033 | USD 40.2 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Reliance Industries, Sinopec, Toray Industries, Indorama Ventures, Tongkun Group, Zhejiang Hengyi Petrochemical, Far Eastern Group, China Petroleum & Chemical Corporation, Shenghong Group, Xinfengming Group, Alpek S.A.B. de C.V., W. Barnet GmbH & Co. KG, Bombay Dyeing, Filatex India Limited, Sateri (Royal Golden Eagle Group), Polyplex Corporation, Lotte Chemical Corporation, Formosa Taffeta Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

FDY Yarns Market Key Technology Landscape

The manufacturing of FDY yarns is highly dependent on continuous innovation in spinning and automation technology to maintain cost-competitiveness and quality consistency. A primary technological focus is on high-speed spinning (HSS) and ultra-high-speed spinning (UHSS) systems, which allow for increased production output and reduced energy consumption per kilogram of yarn. These modern spinning lines integrate advanced automatic doffing systems and sophisticated quality control mechanisms, minimizing human error and maximizing efficiency. Furthermore, the integration of melt-filtering technologies ensures higher quality polymer flow, reducing yarn breaks and improving the overall uniformity and tenacity of the final FDY product, which is crucial for high-speed downstream processing.

Another significant area of technological advancement is in color application through Dope Dyeing or solution dyeing. This process involves incorporating the color pigment directly into the polymer melt before extrusion, creating inherently colored filaments. This technology is preferred over traditional piece dyeing methods because it offers superior color fastness, reduces water usage by up to 90%, and significantly lowers energy requirements. The adoption of advanced metering and mixing systems ensures precise color consistency across batches, addressing a major quality challenge in the textile industry and aligning with the industry’s push towards environmentally sustainable manufacturing practices (Green Chemistry).

Furthermore, automation and digitization, facilitated by technologies like the Industrial Internet of Things (IIoT) and advanced sensors, are becoming standard in modern FDY plants. These tools enable real-time monitoring of machine parameters, temperature profiles, and yarn tension, allowing for immediate corrective action. This level of process control not only enhances product quality but also enables greater flexibility in manufacturing smaller lots of specialty yarns with specific functional attributes, such as antimicrobial or flame-retardant properties, allowing manufacturers to move beyond commodity markets into high-margin niches.

Regional Highlights

The FDY Yarns market exhibits pronounced regional disparities in terms of production capacity, consumption rate, and technological focus, primarily influenced by localized textile industry ecosystems and economic development.

- Asia Pacific (APAC)

- APAC is the undisputed global leader in both production and consumption of FDY yarns, driven by countries like China, India, and Southeast Asian nations (Indonesia, Vietnam).

- China alone accounts for the majority of global production capacity, capitalizing on mature supply chains, significant economies of scale, and readily available petrochemical feedstock.

- Growth in the region is fueled by the massive domestic appetite for fast fashion and home textiles, coupled with strong export activities catering to global apparel brands.

- A major trend is the ongoing shift towards advanced, sustainable manufacturing, including large-scale investments in rPET FDY and dope-dyed yarn facilities to meet international compliance standards.

- Europe

- Europe is a mature market characterized by slower volume growth but a high focus on high-performance and specialty FDY yarns.

- The primary demand stems from technical textiles, high-end automotive interiors, and premium sportswear, requiring stringent quality specifications like high tenacity Nylon FDY.

- Manufacturers in countries like Italy and Germany prioritize advanced functional finishes, sustainability certifications, and localized, specialized production to maintain competitiveness against low-cost imports.

- North America

- North America is a net importer of FDY yarns, though domestic production exists, largely focused on niche, high-value technical and industrial textiles, particularly for defense and safety applications.

- Consumption is driven by the robust automotive sector, protective apparel, and composite materials, emphasizing durability, fire resistance, and specific functional attributes.

- Market growth is also supported by the increasing consumer trend towards sustainable and recycled materials in athletic wear and home furnishings.

- Latin America (LATAM)

- LATAM presents moderate growth potential, tied directly to the development of local apparel manufacturing industries, particularly in Brazil and Mexico.

- Demand is concentrated in standard polyester FDY for domestic market consumption of basic apparel and home textiles, often relying on imports from APAC due to limited domestic polymerization capacity.

- Middle East & Africa (MEA)

- The MEA market is gradually expanding, fueled by infrastructure projects (increasing demand for industrial textiles) and governmental efforts to diversify economies through textile manufacturing, especially in Turkey and the UAE.

- Investments are focused on creating modern, energy-efficient production facilities, with a strong emphasis on meeting the region’s specialized needs for heavy-duty outdoor and protective fabrics.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the FDY Yarns Market.- Reliance Industries Limited

- Sinopec (China Petroleum & Chemical Corporation)

- Tongkun Group Co., Ltd.

- Indorama Ventures Public Company Limited (IVL)

- Toray Industries, Inc.

- Zhejiang Hengyi Petrochemical Co., Ltd.

- Shenghong Group (Jiangsu Shenghong Chemical Fiber Co., Ltd.)

- Far Eastern Group

- Xinfengming Group Co., Ltd.

- Alpek S.A.B. de C.V.

- Lotte Chemical Corporation

- Polyplex Corporation Ltd.

- W. Barnet GmbH & Co. KG

- Bombay Dyeing and Manufacturing Co. Ltd.

- Filatex India Limited

- Formosa Taffeta Co., Ltd.

- Sateri (Royal Golden Eagle Group)

- Shandong Ruyi Group

- Jiangsu Hualian International Group

- Lealea Group

Frequently Asked Questions

Analyze common user questions about the FDY Yarns market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between FDY, POY, and DTY yarns?

FDY (Fully Drawn Yarn) is ready for direct use in weaving/knitting as it is drawn during spinning, offering high strength and low elongation. POY (Partially Oriented Yarn) requires further drawing or texturizing. DTY (Draw Textured Yarn) is a textured yarn derived from POY, characterized by bulkiness and stretch, contrasting with the smooth texture of FDY.

How does the volatile price of raw materials impact the FDY market profitability?

Profitability in the FDY market is highly sensitive to the cost fluctuations of petrochemical derivatives like PTA and MEG. Since raw materials constitute a significant portion of the total production cost, sudden price spikes force manufacturers to adjust pricing or absorb costs, often leading to margin compression, especially for non-integrated producers.

What role does sustainability play in the future growth of FDY yarns?

Sustainability is a crucial growth driver, pushing the adoption of eco-friendly alternatives. This includes a major shift towards Recycled Polyester (rPET) FDY, manufactured from post-consumer plastic waste, and Dope Dyeing technology, which drastically reduces water and chemical usage compared to traditional dyeing methods, meeting global regulatory and brand requirements.

Which application segment holds the largest market share for FDY yarns?

The Apparel segment remains the largest consumer of FDY yarns globally, driven by continuous demand from the fast-fashion industry and the need for durable, low-cost synthetic fabrics in sportswear and general clothing. However, the Industrial Textiles segment is projected to show the fastest growth rate.

Which region dominates the global production and consumption of Fully Drawn Yarn?

Asia Pacific (APAC), spearheaded by China and India, dominates both the production capacity and consumption of FDY yarns, benefiting from extensive raw material access, low labor costs, significant investments in high-speed spinning technology, and a massive integrated textile manufacturing base.

The market for FDY yarns continues to evolve rapidly, driven by technological enhancements that increase production speed and efficiency, coupled with shifting global demands for greater sustainability. Manufacturers are heavily investing in automation and digitalization to optimize resource consumption and ensure consistent, high-quality output, thereby solidifying the market's trajectory towards higher specialization and environmental responsibility. The push towards dope-dyed technology represents a crucial turning point, moving the industry away from water-intensive traditional dyeing, which is vital for long-term growth and compliance in major export markets.

Future competitive advantage in the FDY sector will be secured not only through economies of scale, traditionally mastered by APAC giants, but increasingly through product differentiation in functional textiles—such as yarns with enhanced thermal regulation, moisture management, or specialized fire-retardant properties. Regional strategies are bifurcating: APAC focusing on mass volume and sustainable innovation, while North America and Europe target highly specialized, high-margin technical applications. Successfully navigating raw material cost volatility through hedging strategies and vertical integration remains paramount for sustaining robust profit margins throughout the forecast period.

Furthermore, the integration of advanced data analytics and AI into inventory and demand forecasting is revolutionizing supply chain resilience, allowing producers to adapt more swiftly to unpredictable market cycles. This analytical capability minimizes overproduction and waste, ensuring that the global textile value chain, which heavily relies on FDY, operates with maximum agility and minimal environmental footprint, thereby ensuring stable long-term growth prospects for the market.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- FDY Yarns Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- FDY Yarns Market Statistics 2025 Analysis By Application (Home Textiles, Apparel, Automotive Fabrics), By Type (Row White, Semi Dull, Trilobal Bright), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager