Flame Retardant Adhesives Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439730 | Date : Jan, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Flame Retardant Adhesives Market Size

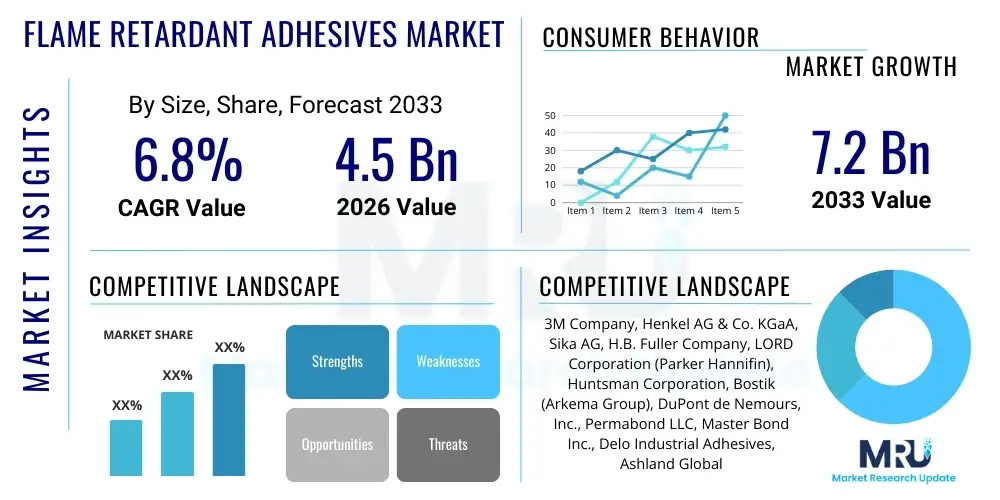

The Flame Retardant Adhesives Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 3.10 Billion by the end of the forecast period in 2033.

Flame Retardant Adhesives Market introduction

The Flame Retardant Adhesives Market encompasses specialized adhesive formulations designed to inhibit or slow down the spread of fire. These adhesives play a crucial role in enhancing the safety and structural integrity of various products and infrastructures by offering increased resistance to ignition and flame propagation. Their primary function is to provide a protective barrier or to release fire-suppressing agents when exposed to heat, thereby minimizing fire hazards and complying with stringent fire safety regulations across industries.

These products include a diverse range of chemistries such as epoxy, polyurethane, silicone, and acrylic formulations, each tailored for specific performance requirements and application environments. Depending on the intended use, they can be halogenated or, increasingly, halogen-free, to meet environmental and health standards. Major applications span critical sectors like building and construction, where they are used in insulation and cladding; automotive and aerospace, for interior components and structural bonding; and electronics, for encapsulating sensitive components and securing wiring. The core benefit of flame retardant adhesives is the significant reduction in fire risk, protecting lives and assets, and enabling manufacturers to meet mandatory safety certifications.

Driving factors for market growth include the continuously evolving and tightening global fire safety standards, particularly in high-risk sectors such as transportation and electronics. The increasing demand for advanced materials in sustainable building practices, coupled with a rising consumer and industry awareness regarding fire safety, further fuels market expansion. Technological advancements leading to more effective, durable, and environmentally friendly flame retardant adhesive solutions are also pivotal in shaping the market landscape.

Flame Retardant Adhesives Market Executive Summary

The Flame Retardant Adhesives Market is characterized by robust growth, driven primarily by escalating global fire safety regulations and the expanding application scope in critical industries. Business trends highlight a strong focus on innovation, particularly in the development of halogen-free and sustainable adhesive solutions to address environmental concerns and regulatory shifts. Key players are investing heavily in research and development to enhance product performance, durability, and ease of application, alongside strategic collaborations and acquisitions to expand their market footprint and technological capabilities. This competitive landscape is evolving rapidly, with companies striving to differentiate through superior fire resistance properties, adhesion strength, and compliance with diverse international standards.

Regional trends indicate significant market expansion across all major geographies. Asia Pacific is poised to maintain its dominance, propelled by rapid industrialization, burgeoning construction activities, and the growth of electronics manufacturing in countries like China and India. North America and Europe are also experiencing substantial growth, underpinned by rigorous fire safety codes, a strong emphasis on worker safety, and the increasing adoption of flame retardant materials in the automotive and aerospace sectors. Emerging markets in Latin America, the Middle East, and Africa present significant opportunities due to ongoing infrastructure development and rising awareness about industrial safety, albeit from a lower base. Each region's unique regulatory environment and industrial development trajectory influence the adoption patterns and market dynamics for flame retardant adhesives.

Segment trends underscore the increasing demand for high-performance and specialized flame retardant adhesives. The building and construction sector remains a major consumer, with a growing preference for adhesives that contribute to overall structural fire integrity. In the automotive industry, the drive towards lightweighting and enhanced passenger safety is boosting the uptake of these adhesives in interior and under-the-hood applications. The electronics segment shows consistent demand for non-halogenated solutions due to stricter environmental directives and the need for thermal management. Furthermore, the rising adoption of electric vehicles (EVs) is creating new niches for flame retardant adhesives, particularly for battery pack assembly and cable management, given the inherent fire risks associated with high-voltage battery systems. The shift towards solvent-free and water-based formulations is also a prominent trend across various segments, driven by health and environmental considerations.

AI Impact Analysis on Flame Retardant Adhesives Market

The integration of Artificial Intelligence (AI) is poised to revolutionize the Flame Retardant Adhesives Market by addressing some of its most complex challenges, from material discovery to application optimization. Users frequently question how AI can accelerate the notoriously slow and resource-intensive R&D processes for new fire-resistant formulations. There's significant interest in AI's potential to predict the fire performance of novel adhesive compositions without extensive physical testing, thereby reducing costs and time-to-market. Additionally, concerns around supply chain resilience and efficiency, particularly regarding raw material sourcing and quality control, are expected to be mitigated by AI-driven analytics. Users also anticipate AI's role in personalizing adhesive solutions for highly specific industrial applications and in ensuring continuous compliance with rapidly evolving global safety standards.

- AI accelerates material discovery and design of novel flame retardant additives and polymer matrices.

- Predictive modeling with AI enables accurate forecasting of adhesive fire performance, reducing physical prototyping.

- Optimized formulation development using AI minimizes trial-and-error, improving efficiency and cost-effectiveness.

- AI-driven analytics enhance supply chain management, from raw material sourcing to inventory optimization.

- Automated quality control and defect detection systems improve manufacturing consistency and product reliability.

- Personalized adhesive solutions tailored for specific end-use requirements can be rapidly developed using AI algorithms.

- AI assists in navigating complex regulatory landscapes by identifying compliant formulations and material combinations.

- Monitoring and predicting equipment maintenance needs in adhesive manufacturing processes for enhanced operational efficiency.

DRO & Impact Forces Of Flame Retardant Adhesives Market

The Flame Retardant Adhesives Market is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, collectively shaping its growth trajectory and strategic direction. Stricter global fire safety regulations across various industries, particularly in construction, automotive, and electronics, serve as a primary driver, compelling manufacturers to integrate fire-resistant materials into their products. Concurrently, the increasing demand from high-growth end-use sectors seeking to enhance product safety and longevity, coupled with a heightened public and industrial awareness of fire hazards, further stimulates market expansion. These adhesives offer significant benefits in terms of enhanced safety, reduced property damage, and compliance with mandatory certifications, making them indispensable components in modern industrial applications. The continuous innovation in polymer science and material engineering also contributes to the development of more effective and versatile flame retardant adhesive solutions.

However, the market faces significant restraints that temper its growth. The high initial research and development costs associated with developing new flame retardant formulations, especially those that are halogen-free and environmentally friendly, pose a considerable barrier for smaller players. Furthermore, the volatility in raw material prices, including specialized polymers and flame retardant additives, can impact manufacturing costs and ultimately influence product pricing and market accessibility. The complex and often conflicting regulatory landscape across different regions presents challenges for manufacturers seeking to standardize products globally. Additionally, achieving an optimal balance between flame retardancy, adhesive performance (such as bond strength and durability), and other material properties (like flexibility or clarity) can be technically demanding, sometimes leading to performance trade-offs that limit broader adoption. Disposal challenges for certain flame retardant chemistries also remain a concern, pushing for more sustainable alternatives.

Despite these challenges, substantial opportunities exist for market participants. The most prominent opportunity lies in the development and commercialization of eco-friendly, halogen-free flame retardant adhesives, driven by increasing environmental consciousness and regulatory pressures such as REACH in Europe. The emergence of new applications, particularly in electric vehicles (EVs) for battery thermal management and structural integrity, and in renewable energy infrastructure, offers significant growth avenues. Moreover, ongoing technological advancements in nanotechnology and smart materials present opportunities for developing next-generation adhesives with superior fire resistance, lighter weight, and multi-functional properties. Market expansion into developing regions, characterized by rapid urbanization, industrialization, and improving safety standards, also provides fertile ground for growth. Strategic collaborations between adhesive manufacturers and end-use industries can further unlock specialized applications and accelerate innovation.

Segmentation Analysis

The Flame Retardant Adhesives Market is extensively segmented to reflect the diverse applications, chemical compositions, and technological advancements driving its evolution. Understanding these segments is crucial for identifying key growth areas, market dynamics, and competitive landscapes. The market is primarily categorized by resin type, which dictates the adhesive's base properties and performance characteristics; by technology, referring to the curing mechanism or form; by chemistry, distinguishing between halogenated and halogen-free solutions; by end-use industry, which defines the application sectors; and by application, specifying the function of the adhesive within those industries. This comprehensive segmentation allows for a detailed analysis of market trends and consumer preferences across the global landscape.

- By Resin Type

- Epoxy

- Polyurethane

- Silicone

- Acrylic

- Cyanoacrylate

- Others (e.g., Phenolic, Polyamide)

- By Technology

- Water-based

- Solvent-based

- Hot Melt

- Reactive (e.g., UV-curing, two-component)

- By Chemistry

- Halogenated

- Halogen-free (e.g., Phosphorus-based, Nitrogen-based, Inorganic)

- By End-use Industry

- Building & Construction

- Automotive

- Aerospace

- Electronics

- Marine

- Textiles

- Others (e.g., Furniture, Appliances, Wire & Cable)

- By Application

- Bonding

- Sealing

- Laminating

- Encapsulation

- Potting

Value Chain Analysis For Flame Retardant Adhesives Market

The value chain for the Flame Retardant Adhesives Market is a multi-tiered structure, commencing with upstream activities centered around raw material procurement. This stage involves the sourcing of essential chemicals such as various polymers (e.g., epoxy resins, polyols, silicones, acrylic monomers), flame retardant additives (e.g., phosphorus compounds, nitrogen compounds, metal hydroxides, antimony oxides), catalysts, fillers, and solvents from a diverse base of chemical suppliers. The quality, availability, and pricing of these foundational components significantly influence the final product's performance and cost-effectiveness. Innovations in raw material synthesis, particularly for sustainable and halogen-free alternatives, are crucial at this stage, dictating the environmental profile and regulatory compliance of subsequent products.

Moving downstream, these raw materials are transformed by flame retardant adhesive manufacturers through formulation, blending, and processing into finished adhesive products. This stage involves extensive research and development to achieve the desired balance of flame retardancy, adhesive strength, thermal stability, and application-specific properties. Manufacturers often specialize in particular chemistries or application areas, developing a proprietary portfolio of solutions. Following manufacturing, the distribution channel plays a vital role in connecting manufacturers with their diverse end-user base. This includes a mix of direct sales efforts by manufacturers to large industrial clients and the utilization of indirect channels through a network of distributors, wholesalers, and specialized chemical suppliers who provide regional market access, technical support, and logistics services. Online platforms are also emerging as a significant, albeit smaller, direct and indirect distribution channel for specific product types.

The final stage of the value chain involves the end-users who apply these adhesives in their respective industries, such as construction companies, automotive OEMs, aerospace manufacturers, and electronics assembly plants. The efficiency of the distribution channel, including inventory management and timely delivery, directly impacts the satisfaction of these end-users. The interplay between direct and indirect channels is strategically managed by manufacturers; direct sales offer greater control and deeper customer relationships for large-volume, highly technical applications, while indirect channels provide broader market reach and cater to smaller, diverse customer needs. Each stage of this value chain adds value through specialized expertise, technological input, and logistical efficiency, ultimately delivering a critical safety component to a wide array of industrial applications.

Flame Retardant Adhesives Market Potential Customers

The potential customers for flame retardant adhesives span a broad spectrum of industries that prioritize safety, regulatory compliance, and high-performance material solutions. These end-users, or buyers, are typically manufacturers, contractors, and assemblers integrating these specialized adhesives into their products or construction projects. In the building and construction sector, customers include general contractors, insulation manufacturers, and facade system providers who use these adhesives for bonding insulation panels, fire-rated doors, wall claddings, and flooring, ensuring structural integrity and meeting strict fire codes. The automotive industry represents a significant customer base, comprising original equipment manufacturers (OEMs) and their suppliers, who utilize flame retardant adhesives for interior components like seating, dashboards, and headliners, as well as for under-the-hood applications and battery assemblies in electric vehicles to enhance passenger safety and mitigate fire risks.

The aerospace industry also constitutes a critical customer segment, including aircraft manufacturers and component suppliers, for applications in cabin interiors, structural bonding, and wire harnessing, where extreme safety standards and lightweighting are paramount. Within the electronics sector, manufacturers of circuit boards, consumer electronics, and industrial equipment are key buyers, employing these adhesives for encapsulation, potting, and bonding sensitive components to prevent short circuits and fire propagation. Furthermore, the marine industry relies on these adhesives for shipbuilding and maintenance, particularly for fire-resistant bulkheads and interior fittings. Textile manufacturers, appliance makers, and companies involved in wire and cable production also represent viable customer segments, each requiring specialized flame retardant adhesive formulations tailored to their specific material substrates and performance requirements. The diverse needs across these sectors drive continuous innovation and market demand for advanced flame retardant adhesive solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 3.10 Billion |

| Growth Rate | CAGR 7.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Henkel AG & Co. KGaA, 3M Company, H.B. Fuller Company, Sika AG, Arkema S.A., Dow Inc., Huntsman Corporation, Bostik (Arkema Group), Ashland Global Holdings Inc., DuPont de Nemours, Inc., Momentive Performance Materials Inc., Master Bond Inc., ITW Performance Polymers, Permabond LLC, LORD Corporation (Parker Hannifin), Dymax Corporation, Resinlab, Avery Dennison Corporation, Illinois Tool Works Inc., Hexion Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Flame Retardant Adhesives Market Key Technology Landscape

The Flame Retardant Adhesives Market is continuously evolving, driven by innovations in material science and engineering aimed at enhancing fire safety without compromising performance or environmental sustainability. A pivotal technology trend is the widespread adoption and advancement of halogen-free formulations. This shift is a response to increasing regulatory pressures and growing health concerns associated with traditional halogenated flame retardants, which can release toxic and corrosive gases during combustion. Manufacturers are increasingly focusing on phosphorus-based, nitrogen-based, and inorganic compounds (like metal hydroxides) as alternative flame retardant additives, developing sophisticated chemistries that achieve high levels of fire resistance while maintaining desirable adhesive properties and meeting stringent environmental standards. These new formulations often employ intumescent mechanisms, forming a protective char layer when exposed to heat, thereby insulating the substrate and preventing flame spread.

Another significant technological development involves the integration of nanotechnology and advanced polymer chemistry. Nanocomposites, utilizing materials such as carbon nanotubes or nanoclay, are being incorporated into adhesive formulations to enhance mechanical strength, thermal stability, and flame retardancy at lower additive loadings, leading to lighter and more efficient products. Furthermore, the market is witnessing a surge in solvent-free and water-based adhesive technologies. These advancements reduce volatile organic compound (VOC) emissions, contributing to safer working environments and improved environmental footprints, aligning with global sustainability initiatives. UV-curing and other reactive adhesive systems are also gaining traction due to their rapid cure times, which enhance manufacturing efficiency and reduce energy consumption, particularly in high-volume production settings like electronics assembly.

The development of multi-functional flame retardant adhesives represents another frontier, where products are engineered to provide not just fire resistance but also additional benefits such as improved thermal conductivity, electrical insulation, acoustic damping, or enhanced structural integrity. This allows for consolidated material solutions, reducing complexity and cost for end-users. Research into bio-based and recyclable flame retardant components is also a growing area, reflecting the industry's commitment to circular economy principles. These technological advancements collectively aim to provide smarter, safer, and more sustainable adhesive solutions that cater to the evolving demands of diverse industrial applications, ensuring adherence to the most stringent safety protocols while driving innovation.

Regional Highlights

- North America: This region demonstrates strong market growth driven by rigorous fire safety codes, particularly in the construction, automotive, and aerospace industries. The U.S. and Canada are prominent consumers, with significant R&D investments in high-performance, halogen-free solutions. The automotive sector's shift towards electric vehicles (EVs) is a key driver for specialized flame retardant adhesives in battery management and interior components.

- Europe: Characterized by stringent environmental regulations such as REACH, Europe is a leader in adopting halogen-free and eco-friendly flame retardant adhesives. Countries like Germany, France, and the UK show high demand from the building and construction sector, as well as the robust automotive and electronics industries, necessitating compliance with EU directives for fire safety and material sustainability.

- Asia Pacific (APAC): The largest and fastest-growing market, APAC's expansion is fueled by rapid industrialization, burgeoning construction activities, and the booming electronics and automotive manufacturing sectors in countries like China, India, Japan, and South Korea. Increasing disposable incomes and growing awareness of fire safety standards are contributing to the widespread adoption of these adhesives, especially in residential and commercial infrastructure.

- Latin America: This region presents an emerging market with significant growth potential, driven by infrastructure development projects and increasing foreign investments in manufacturing. Countries like Brazil and Mexico are witnessing rising demand from the construction and automotive industries, though market penetration is still evolving compared to developed regions.

- Middle East and Africa (MEA): The MEA region is experiencing steady growth, primarily supported by large-scale construction projects, particularly in the GCC countries, and growing investments in industrial and manufacturing sectors. Increasing regulatory enforcement for fire safety in new developments is boosting the demand for flame retardant adhesives in these emerging economies.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Flame Retardant Adhesives Market.- Henkel AG & Co. KGaA

- 3M Company

- H.B. Fuller Company

- Sika AG

- Arkema S.A.

- Dow Inc.

- Huntsman Corporation

- Bostik (Arkema Group)

- Ashland Global Holdings Inc.

- DuPont de Nemours, Inc.

- Momentive Performance Materials Inc.

- Master Bond Inc.

- ITW Performance Polymers

- Permabond LLC

- LORD Corporation (Parker Hannifin)

- Dymax Corporation

- Resinlab

- Avery Dennison Corporation

- Illinois Tool Works Inc.

- Hexion Inc.

Frequently Asked Questions

What are Flame Retardant Adhesives and why are they important?

Flame Retardant Adhesives are specialized bonding agents designed to resist ignition and inhibit the spread of fire. They are crucial for enhancing safety in products and structures by slowing combustion, preventing flame propagation, and ensuring compliance with stringent fire safety regulations across industries like construction, automotive, and electronics.

What are the primary applications of Flame Retardant Adhesives?

Key applications include bonding insulation panels, fire-rated doors, and cladding in building & construction; securing interior components and battery packs in automotive (especially EVs); aerospace cabin interiors and structural bonding; encapsulating electronic components; and various uses in marine, textile, and appliance manufacturing to enhance fire safety.

What is the difference between halogenated and halogen-free flame retardant adhesives?

Halogenated adhesives contain bromine or chlorine compounds, effective but can release toxic gases when burned. Halogen-free adhesives use phosphorus, nitrogen, or inorganic compounds, offering a safer and more environmentally friendly alternative, driven by increasingly strict regulations and health concerns, particularly in Europe and for electronic applications.

Which factors are driving the growth of the Flame Retardant Adhesives Market?

Key drivers include increasingly strict global fire safety regulations, rising demand for high-performance and safe materials in end-use industries (e.g., EVs, smart buildings), growing awareness about fire hazards, and continuous innovation in eco-friendly and advanced adhesive formulations.

What are the major challenges faced by the Flame Retardant Adhesives Market?

Challenges include high R&D costs for new, sustainable formulations, volatility in raw material prices, complex and varying regional regulatory landscapes, and the technical difficulty of balancing superior flame retardancy with other crucial adhesive performance attributes like bond strength and durability without trade-offs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager