Hand Trucks And Dollies Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436344 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Hand Trucks And Dollies Market Size

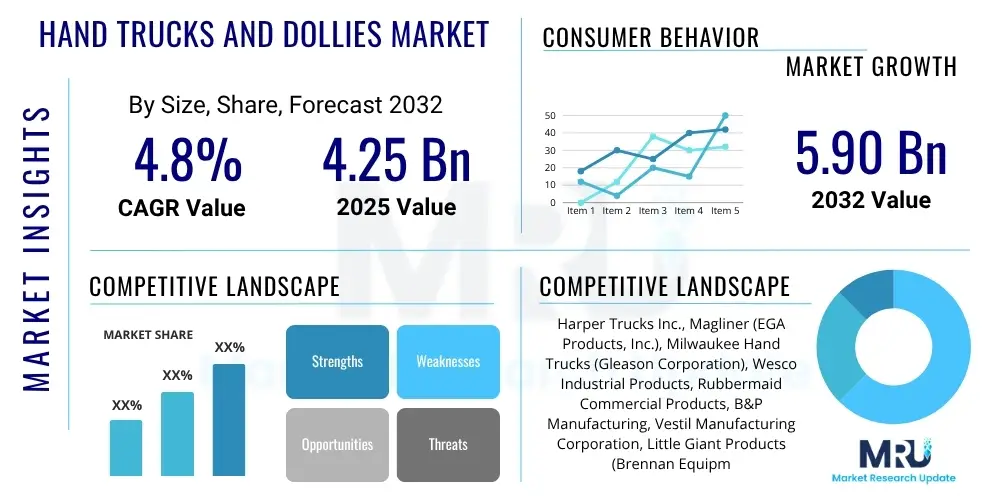

The Hand Trucks And Dollies Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $7.5 billion in 2026 and is projected to reach $11.1 billion by the end of the forecast period in 2033.

Hand Trucks And Dollies Market introduction

The Hand Trucks And Dollies Market encompasses the manufacturing, distribution, and sales of material handling equipment designed for the manual or semi-automated transport of goods within short distances. This essential segment of the logistics and warehousing industry includes a variety of products such as two-wheeled hand trucks (or sack trucks), multi-purpose convertible hand trucks, four-wheeled platform dollies, and specialty carts engineered for specific load types. The market’s fundamental importance lies in optimizing workflow efficiency, reducing the physical strain on workers, and ensuring the safe movement of materials across diverse commercial and industrial environments, ranging from small retail outlets to expansive e-commerce fulfillment centers and large-scale manufacturing plants.

Product descriptions vary significantly based on intended use and load capacity. Hand trucks typically feature a strong frame, wheels, and a small platform (nose plate) that slides under the object to be moved. Modern variations incorporate ergonomic designs, lightweight yet durable materials like aluminum alloys, and specialized wheel types (e.g., puncture-proof or stair-climbing wheels) to enhance functionality and versatility. Dollies, generally flat platforms resting on casters, are crucial for moving heavy, bulky, or irregularly shaped items horizontally. The major applications for these tools span logistics, retail, food and beverage distribution, postal services, and construction, making them indispensable components of supply chain operations globally.

The primary driving factors propelling market expansion include the exponential growth of the global e-commerce sector, which necessitates efficient last-mile delivery solutions and rapid internal warehouse movement capabilities. Furthermore, stringent occupational safety regulations focusing on manual handling risks are driving companies to invest in ergonomic and powered material handling aids. The benefit derived from adopting high-quality hand trucks and dollies extends beyond mere movement; it involves significant labor cost reduction, minimizing product damage during transit, and overall improvement in operational throughput. The continuous introduction of technologically advanced features, such as integrated weighing scales and electric assistance, further solidifies the market's positive trajectory.

Hand Trucks And Dollies Market Executive Summary

The Hand Trucks And Dollies Market is witnessing robust expansion driven primarily by shifts in global business trends, notably the pervasive influence of digitalization and automation across logistics networks. Business trends indicate a strong move toward lightweight, durable materials like aerospace-grade aluminum to maximize maneuverability and capacity while minimizing operator fatigue. Key manufacturers are focusing on integrating modular designs that allow users to convert standard hand trucks into platform dollies or specialized carts quickly. This adaptability meets the dynamic needs of modern distribution channels, which frequently handle varying package sizes and weights. Investment in battery-powered and motorized dollies represents a significant market shift, addressing heavy lifting requirements and enhancing efficiency in high-volume settings, positioning these products as precursors to full robotic automation.

Regionally, the market exhibits divergent growth patterns. Asia Pacific (APAC) stands out as the fastest-growing region, fueled by massive investment in infrastructure development, the rapid expansion of third-party logistics (3PL) providers, and the enormous scale of e-commerce markets in China and India. North America and Europe maintain substantial market shares due to established warehousing industries and a higher adoption rate of advanced, ergonomic, and powered equipment, largely mandated by stringent worker safety regulations. The competitive landscape in these regions emphasizes product quality, compliance with ISO standards, and the provision of integrated handling solutions, including IoT-enabled asset tracking for high-value equipment.

Segmentation trends highlight the dominance of the Manual Hand Trucks segment in terms of volume, owing to their cost-effectiveness and versatility, particularly in small businesses and retail settings. However, the Powered Hand Trucks and Specialty Dollies segments are projected to record the highest CAGR, reflecting increasing operational scale and the necessity for handling extremely heavy loads (over 1,000 lbs) efficiently. The material segment shows a gradual transition from traditional steel toward lightweight aluminum and composite materials, especially in applications requiring frequent movement or use in temperature-controlled environments. Ultimately, market growth is characterized by a balance between mass-market, budget-friendly manual solutions and high-specification, technology-enabled powered units tailored for large-scale, automated logistical operations.

AI Impact Analysis on Hand Trucks And Dollies Market

User queries regarding the impact of AI on the Hand Trucks And Dollies Market frequently revolve around the integration of autonomous navigation into traditional equipment, the potential displacement of manual labor, and the optimization of material flow paths within complex environments. Users are keen to understand if AI will render simple, non-powered equipment obsolete, or if it will primarily enhance powered units. The key themes emerging include the future of manually operated equipment in smart warehouses, the role of predictive maintenance enabled by AI, and how AI-driven route optimization can improve the efficiency of existing dolly fleets. Concerns often center on the capital expenditure required for AI integration and the training needs for warehouse personnel transitioning to semi-autonomous handling systems, while expectations focus on achieving unparalleled inventory accuracy and reduced operational bottlenecks.

- AI-powered route optimization algorithms enhance the efficiency of existing fleets of hand trucks and dollies by determining the shortest and safest paths for operators, especially in large warehouses.

- Predictive maintenance analytics, driven by AI monitoring equipment usage and sensor data, significantly extends the lifespan of powered dollies and reduces unexpected downtime by forecasting component failure.

- Integration of Computer Vision systems allows standard dollies, when equipped with small sensors, to report asset location and inventory status accurately, improving real-time inventory management.

- AI-driven automation facilitates the transition from basic powered dollies to semi-autonomous guided carts (AGCs), which can handle repetitive, long-distance hauling tasks without constant human intervention.

- AI assists in ergonomic design refinement by analyzing human-machine interaction data from existing hand truck usage, leading to the development of safer and less fatiguing manual handling equipment.

- Data generated by smart hand trucks informs warehouse management systems (WMS) about traffic flow patterns, enabling continuous layout optimization and reducing congestion in high-traffic zones.

DRO & Impact Forces Of Hand Trucks And Dollies Market

The market dynamics are governed by a complex interplay of Drivers, Restraints, and Opportunities (DRO), underpinned by significant Impact Forces. A major driver is the accelerating demand from the e-commerce sector, which requires rapid, reliable, and versatile internal transport solutions to manage escalating order fulfillment volumes efficiently. Simultaneously, global attention to worker welfare and the implementation of stricter safety standards (such as OSHA guidelines in the US and equivalent directives in the EU) push companies toward investing in ergonomic, easily maneuverable, and often powered equipment, further stimulating market growth for high-end dollies and hand trucks. The necessity for quick stock movement within increasingly automated but still human-centric warehouses dictates the fundamental role of these tools.

However, the market faces notable restraints. The primary impediment is the relatively high initial capital expenditure associated with advanced, battery-powered hand trucks and specialized ergonomic dollies, particularly problematic for small and medium-sized enterprises (SMEs) operating on tight budgets. Additionally, the proliferation of large, fully autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) in mega-warehouses poses a long-term competitive challenge, potentially displacing the high-end powered dolly segment. Operational restraints also exist in highly constrained or unusually shaped physical environments where larger, automated equipment cannot function effectively, forcing reliance on manual, albeit specialized, hand trucks.

Opportunities for expansion are primarily centered on innovation. The development and deployment of ultra-lightweight, durable composite materials present a significant avenue for creating highly portable and high-capacity equipment. Furthermore, the burgeoning demand for specialized handling solutions in niche markets—such as cleanroom dollies for semiconductor manufacturing or heavy-duty trucks for construction sites—offers premium pricing opportunities. The strongest impact forces shaping the market include ongoing technological advancement (especially in battery technology and electric motors), stringent governmental regulations dictating safety and material standards, and fluctuating raw material costs (steel and aluminum), which directly affect manufacturing overheads and end-product pricing structure.

Segmentation Analysis

The Hand Trucks And Dollies Market is comprehensively segmented based on product type, material composition, load capacity, and diverse end-user applications, reflecting the wide spectrum of usage requirements across global industries. Understanding these segments is crucial for manufacturers to tailor product specifications—for instance, focusing on high-load capacity steel units for manufacturing versus lightweight aluminum models for last-mile delivery. The segmentation analysis reveals the heterogeneous demand structure, where manual equipment dominates volume sales due to versatility and low cost, while powered and specialty equipment drive revenue growth and technological innovation, catering to the efficiency demands of modern logistics operations. Application-based segmentation provides insight into sector-specific needs, such as the need for anti-microbial coatings in food service dollies or non-marking wheels in institutional settings.

- By Product Type:

- Manual Hand Trucks (Two-Wheeled Hand Trucks, Convertible Hand Trucks)

- Powered Hand Trucks (Electric, Battery-Operated)

- Platform Dollies (Flatbed Carts, Four-Wheeled Dollies)

- Specialty Dollies (Appliance Trucks, Drum Dollies, Pallet Dollies, Stair Climbers)

- By Material:

- Steel

- Aluminum

- Plastic & Composites (Polyethylene, Fiberglass)

- By Load Capacity:

- Light Duty (Up to 300 lbs)

- Medium Duty (301 to 600 lbs)

- Heavy Duty (601 lbs and Above)

- By Application/End-User:

- Logistics, Warehousing & Distribution

- Retail & E-commerce Fulfillment

- Manufacturing & Industrial (Automotive, Machinery)

- Food & Beverage (Including Cold Chain)

- Institutional (Hospitals, Libraries, Offices)

- Construction & Field Services

Value Chain Analysis For Hand Trucks And Dollies Market

The value chain for the Hand Trucks And Dollies Market begins with upstream activities involving the sourcing of primary raw materials, predominantly steel, aluminum, and various polymers for wheels and plastic components. Price volatility in global metal markets, particularly for specialty aluminum alloys that offer a high strength-to-weight ratio, directly impacts manufacturing costs. Upstream suppliers are focused on adhering to quality standards and providing materials that meet specific structural integrity and corrosion resistance requirements. Key partnerships are often formed between manufacturers and specialized component suppliers for items such as high-grade casters, ergonomic handles, and durable electric motors used in powered units, emphasizing reliability and longevity to justify higher product prices.

Manufacturing and assembly form the central link, where raw materials are converted into finished products through processes like cutting, welding, molding, and powder coating. Efficiency in manufacturing—often achieved through lean production techniques and automated welding processes—is vital for maintaining competitive pricing, especially for high-volume manual hand trucks. Downstream activities involve the robust distribution network, which is segmented into direct sales to large corporate accounts (e.g., major retailers or 3PL giants) and indirect sales through specialized industrial distributors, material handling equipment wholesalers, and burgeoning online marketplaces. The efficacy of the distribution channel is paramount, as customers often require immediate availability of these tools to maintain operational continuity.

Direct distribution allows manufacturers to offer customized solutions, high-volume discounts, and specialized after-sales service and maintenance for complex powered equipment. Indirect channels, including e-commerce platforms and regional suppliers, ensure market penetration into smaller businesses and diverse geographical locations, offering convenience and broad product choice. Service providers, including maintenance and repair shops specializing in industrial equipment, play a crucial role in extending the functional life of powered and heavy-duty hand trucks. The entire value chain is currently being optimized through digital inventory management and predictive logistics to ensure that the final product reaches the end-user efficiently, reducing lead times which is a competitive differentiator in the logistics sector.

Hand Trucks And Dollies Market Potential Customers

The potential customer base for hand trucks and dollies is highly diversified, spanning nearly every sector that involves the movement of physical goods. The largest segment of end-users comprises logistics, warehousing, and distribution centers, including third-party logistics (3PL) providers and in-house logistics departments of multinational corporations. These entities require a constant supply of both high-volume manual equipment for sorting and loading and advanced powered dollies for heavy lifting and long-haul tasks within large facilities. The rapid expansion of e-commerce has made fulfillment centers significant buyers, demanding specialized equipment that interfaces seamlessly with conveyor systems and optimizes final packaging stages, prioritizing speed and maneuverability.

Retail environments, from hypermarkets to small convenience stores, represent another core customer group. Retailers utilize hand trucks for moving inventory from storage areas to the sales floor, receiving incoming shipments, and managing seasonal stock surges. In this sector, light-duty, folding, and aesthetically pleasing hand trucks are often preferred. Furthermore, the manufacturing industry, particularly in automotive, aerospace, and general machinery, relies heavily on heavy-duty, specialty dollies and carts designed to move large, irregularly shaped components across production lines safely, often requiring anti-static or cleanroom specifications, demonstrating a need for highly customized solutions.

Institutional and service sectors also constitute a significant buyer base. This includes hospitals and healthcare facilities needing specialized carts for laundry, medical supplies, and hazardous waste; hotels and food service operations requiring durable, easy-to-clean dollies for catering and housekeeping; and construction companies utilizing rugged, pneumatic-tired hand trucks for moving materials across rough terrain. The purchasing decision for these various customer types hinges on factors such as load capacity, ergonomic features to prevent worker injury, durability under specific environmental conditions (e.g., wet or cold), and regulatory compliance, making specialization a key purchasing determinant across end-user verticals.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $7.5 billion |

| Market Forecast in 2033 | $11.1 billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hyster-Yale Materials Handling, Crown Equipment Corporation, Toyota Industries Corporation, KION Group, Jungheinrich AG, Prestar, Magliner, Harper Trucks, Milwaukee Hand Trucks, Wesco Industrial Products, Vestil Manufacturing, B&P Manufacturing, Little Giant Products, Rubbermaid Commercial Products, Dutro Company, Ekko Material Handling, Akro-Mils, Lakeside Manufacturing, Gleason Industrial, Ballymore. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hand Trucks And Dollies Market Key Technology Landscape

The technological landscape of the Hand Trucks And Dollies Market is rapidly evolving beyond simple mechanical aids, incorporating advanced materials science and smart technologies. A key area of innovation is the development of next-generation power systems for powered hand trucks, moving toward lighter, faster-charging lithium-ion batteries that offer extended operational cycles compared to traditional lead-acid alternatives. This enhancement directly addresses user demand for equipment that minimizes downtime. Furthermore, sophisticated electric motors and optimized gearboxes are being utilized to maximize torque and speed while reducing overall unit weight, significantly improving the efficacy of stair-climbing hand trucks and heavy-duty platform carts.

Material innovation is another vital technological driver. Manufacturers are increasingly utilizing advanced composite materials, reinforced polymers, and high-strength aluminum alloys. These materials not only reduce the ergonomic strain on the operator by lowering the inherent weight of the equipment but also provide enhanced resistance to corrosion, impact, and chemical exposure, crucial for sectors like pharmaceuticals and food processing. Furthermore, modular design technologies are gaining prominence, allowing components like handles, nose plates, and wheel assemblies to be quickly interchanged or upgraded, offering a single piece of equipment versatility across multiple handling tasks and maximizing return on investment for end-users.

The most transformative technology permeating this market is the integration of IoT (Internet of Things) and sensor technology. Smart hand trucks and dollies are now being equipped with RFID tags, GPS trackers, and acceleration sensors. These integrated technologies enable real-time asset tracking, utilization monitoring, and preventive maintenance alerts, funneling critical data back to centralized warehouse management systems (WMS). This integration turns simple movement equipment into data-gathering assets, facilitating precise inventory tracking, preventing theft or loss, and providing historical usage data to inform future purchasing and deployment strategies, positioning them as essential elements within the broader Smart Logistics ecosystem.

Regional Highlights

- Asia Pacific (APAC): APAC represents the fastest-growing region globally, propelled by burgeoning e-commerce giants and substantial investment in infrastructural and logistics development, particularly in emerging economies like India, Southeast Asia, and China. High population density and rising consumer spending necessitate efficient, scalable, and low-cost material handling solutions. While the market sees high consumption of cost-effective manual units, the adoption of advanced powered and specialty dollies is accelerating, driven by the establishment of sophisticated mega-warehouses by global and domestic 3PL providers. Standardization of logistics processes across vast distances is also creating demand for durable, standardized equipment fleets.

- North America: North America holds a mature and technologically advanced market share. Growth here is characterized by high demand for ergonomic, safety-compliant, and high-capacity equipment, influenced heavily by stringent OSHA regulations requiring reduced manual strain. The primary growth drivers include the dominance of major retailers and fulfillment centers investing in electric and highly modular hand trucks. Integration of smart logistics features, such as integrated scales and IoT tracking capabilities, is prevalent among high-end users, seeking maximum operational transparency and efficiency in their supply chain operations across the US and Canada.

- Europe: The European market is highly regulated, focusing intensely on worker safety and environmental sustainability. This drives substantial demand for premium, lightweight aluminum hand trucks and electrically assisted dollies that minimize physical exertion and adhere to strict CE certifications. Western European nations, such as Germany and the UK, are early adopters of advanced handling solutions, often incorporating telematics into their dolly fleets. Eastern European countries, experiencing rapid growth in warehousing and distribution infrastructure, are driving volume demand, seeking a balance between cost-effectiveness and EU regulatory compliance.

- Latin America (LATAM): The LATAM region is characterized by fragmented logistics infrastructure and growing industrialization. Demand is robust but often price-sensitive, leading to a focus on durable, multi-purpose manual steel hand trucks. However, increasing foreign direct investment in retail and manufacturing is gradually introducing the need for more sophisticated, medium-duty equipment, especially in countries like Brazil and Mexico. Challenges related to varied terrain and infrastructure quality necessitate equipment featuring high-durability wheels and robust framing capable of withstanding demanding operational environments.

- Middle East and Africa (MEA): Market growth in the MEA region is strongly tied to large-scale infrastructure projects, rapid urbanization, and significant investment in oil and gas logistics. The UAE and Saudi Arabia are pivotal markets due to ambitious logistics hub development. The region requires highly durable equipment capable of operating efficiently in extreme temperature conditions (e.g., specialized lubricants and ruggedized construction). Demand is balanced between heavy-duty specialty dollies for industrial applications and general-purpose hand trucks for the burgeoning retail and consumer goods distribution sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hand Trucks And Dollies Market.- Hyster-Yale Materials Handling

- Crown Equipment Corporation

- Toyota Industries Corporation

- KION Group

- Jungheinrich AG

- Prestar

- Magliner

- Harper Trucks

- Milwaukee Hand Trucks

- Wesco Industrial Products

- Vestil Manufacturing

- B&P Manufacturing

- Little Giant Products

- Rubbermaid Commercial Products

- Dutro Company

- Ekko Material Handling

- Akro-Mils

- Lakeside Manufacturing

- Gleason Industrial

- Ballymore

Frequently Asked Questions

Analyze common user questions about the Hand Trucks And Dollies market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the current growth of the Hand Trucks And Dollies Market?

The predominant driver is the exponential expansion of the global e-commerce and retail sector, which necessitates rapid, efficient, and versatile internal logistics solutions for handling increasing volumes of packaged goods in distribution centers and last-mile delivery operations.

How are advancements in battery technology influencing the Powered Hand Trucks segment?

The transition to advanced lithium-ion battery technology significantly enhances the utility of powered hand trucks by providing lighter power sources, extended operational hours per charge, and faster recharging times, thereby reducing operational downtime and increasing productivity in heavy-duty applications.

Which geographical region exhibits the highest growth potential for dollies and hand trucks?

Asia Pacific (APAC) is projected to record the highest compound annual growth rate (CAGR), primarily fueled by rapid urbanization, massive investment in warehousing infrastructure, and the maturation of regional e-commerce markets, particularly in China and India.

What are the key benefits of choosing specialty dollies made from composite or aluminum materials?

Specialty dollies made from lightweight materials like aluminum or composites offer superior ergonomic benefits, reducing worker fatigue. They also provide excellent resistance to rust and corrosion, making them ideal for regulated environments such as cleanrooms, food processing, and cold chain logistics.

How does IoT technology integrate with modern hand trucks and dollies?

IoT integration involves embedding sensors and trackers (GPS/RFID) into equipment, allowing for real-time asset visibility, tracking utilization rates, facilitating proactive maintenance alerts, and providing crucial data inputs to optimize centralized warehouse management systems (WMS) flow efficiency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager