Hand Trucks and Dollies Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428293 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Hand Trucks and Dollies Market Size

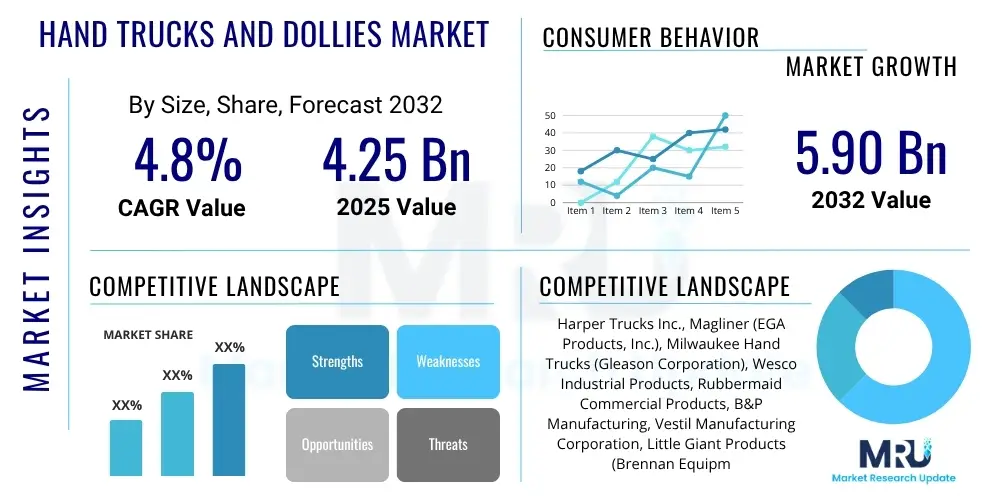

The Hand Trucks and Dollies Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032. The market is estimated at USD 4.25 Billion in 2025 and is projected to reach USD 5.90 Billion by the end of the forecast period in 2032.

Hand Trucks and Dollies Market introduction

The Hand Trucks and Dollies market encompasses a wide array of manual material handling equipment designed to facilitate the efficient transportation of goods across various industrial, commercial, and residential settings. These essential tools, ranging from traditional two-wheeled hand trucks to versatile four-wheeled dollies and specialized models, are engineered to enhance productivity, reduce physical strain on workers, and optimize logistical operations. Their fundamental role lies in providing mechanical assistance to move heavy or bulky items that would otherwise be difficult or impossible for an individual to handle, thereby improving safety and operational efficiency within numerous sectors.

Key product types include upright hand trucks for vertical stacking, platform dollies for horizontal movement of larger items, convertible models offering dual functionality, and specialized stair climbers designed for challenging environments. Major applications span across logistics and warehousing, retail, manufacturing, construction, food and beverage, and healthcare industries. The inherent benefits of these devices, such as improved ergonomics, enhanced worker safety by minimizing manual lifting, and increased speed of material transfer, solidify their indispensable position in modern supply chains. The market's growth is predominantly driven by the relentless expansion of e-commerce, the intensification of global logistics activities, ongoing industrialization in emerging economies, and the continuous demand for operational efficiency and labor productivity improvements across diverse end-use sectors.

These devices are critical components in streamlining workflows, reducing turnaround times, and preventing workplace injuries associated with manual handling. As businesses continue to prioritize operational agility and cost-effectiveness, the demand for robust, ergonomic, and application-specific hand trucks and dollies remains strong. Innovations in material science, design, and integration with complementary technologies further enhance their utility and broaden their market applicability, ensuring their continued relevance in evolving material handling landscapes. Their simple yet effective design contributes to their widespread adoption, making them foundational tools for efficient goods movement.

Hand Trucks and Dollies Market Executive Summary

The Hand Trucks and Dollies market is experiencing robust expansion driven by dynamic shifts in global business trends, including the exponential growth of e-commerce and the associated intensification of warehousing and logistics operations. Companies are increasingly investing in efficient material handling solutions to meet escalating consumer demands for faster delivery and optimized inventory management. This surge in demand directly translates into higher adoption rates for a wide variety of hand trucks and dollies, crucial for navigating complex supply chains and improving last-mile delivery capabilities. Furthermore, the imperative for enhanced workplace safety and reduced manual labor costs continues to bolster market growth, as ergonomic and specialized designs gain prominence in industrial settings.

Regionally, Asia Pacific is emerging as a dominant force, propelled by rapid industrialization, burgeoning manufacturing sectors, and expanding retail landscapes in countries like China and India. North America and Europe also maintain significant market shares, characterized by advanced logistics infrastructure and a strong focus on automation and worker welfare, which fuels demand for more sophisticated and specialized material handling equipment. Latin America, the Middle East, and Africa are demonstrating promising growth trajectories, supported by increasing investments in infrastructure development and the modernization of their supply chain networks. These regional dynamics highlight a diversified market landscape with varying drivers and opportunities tailored to local economic and industrial conditions.

From a segmentation perspective, the market is characterized by diverse product types, materials, load capacities, and end-use industries. Upright hand trucks and platform dollies remain foundational, while convertible and stair climbing models are gaining traction due to their versatility and utility in niche applications. The trend towards lightweight yet durable materials like aluminum and high-strength plastics is noticeable, addressing the need for both portability and robust performance. Furthermore, the retail and logistics & warehousing sectors continue to be the largest end-users, with significant growth observed in manufacturing and construction as well. This diverse segmentation underscores the adaptability and essential nature of hand trucks and dollies across virtually all commercial and industrial activities.

AI Impact Analysis on Hand Trucks and Dollies Market

Common user inquiries concerning the impact of Artificial Intelligence on the Hand Trucks and Dollies Market often revolve around how AI could enhance efficiency, improve safety, and potentially automate tasks currently performed by manual equipment. Users express curiosity about the integration of AI in route optimization for material movement, predictive maintenance for equipment longevity, and ergonomic design improvements driven by AI-powered data analysis. There is a palpable interest in whether AI will lead to the development of "smart" hand trucks that can autonomously navigate warehouses or assist operators more intuitively, alongside concerns about the potential for job displacement and the cost implications of implementing such advanced technologies within traditional manual handling operations.

The prevailing themes indicate an expectation for AI to augment, rather than entirely replace, human-operated hand trucks and dollies in the near to mid-term. Stakeholders are particularly keen on understanding how AI can provide actionable insights into material flow, optimize load distribution, and identify bottlenecks in logistical processes, thereby making manual handling more intelligent and less labor-intensive. The discussion also frequently touches upon the role of AI in quality control for manufacturing hand trucks, ensuring higher product reliability and consistency. This suggests a forward-looking perspective where AI is seen as a tool for evolutionary improvement rather than revolutionary disruption in this mature market segment, with a strong focus on practical, implementable enhancements that deliver tangible benefits to operators and businesses alike.

Moreover, there are expectations regarding AI's ability to analyze vast amounts of operational data to inform better design choices for future hand trucks and dollies. This includes optimizing weight distribution for easier handling, developing more intuitive braking systems, and creating predictive models for common wear and tear issues, ultimately extending the lifespan of equipment and reducing operational downtime. The market anticipates AI will contribute to a new generation of more responsive, durable, and user-friendly material handling tools that can adapt to dynamic warehouse environments and varied operational demands, solidifying their critical role in an increasingly data-driven supply chain ecosystem.

- AI-powered route optimization for efficient material movement within facilities.

- Predictive maintenance schedules for hand trucks, reducing downtime and extending lifespan.

- Ergonomic design improvements based on AI analysis of user interaction and strain.

- Integration with warehouse management systems for intelligent inventory tracking.

- Potential for semi-autonomous or collaborative hand trucks assisting operators.

- Enhanced safety features through AI-driven collision avoidance and load stability monitoring.

- Optimization of manufacturing processes for hand trucks, improving quality and reducing costs.

- Data analytics to identify bottlenecks and inefficiencies in manual handling workflows.

DRO & Impact Forces Of Hand Trucks and Dollies Market

The Hand Trucks and Dollies market is significantly influenced by a confluence of driving forces, opportunities, and restraining factors, alongside broader impact forces shaping its trajectory. Key drivers include the relentless expansion of the e-commerce sector, necessitating efficient and rapid material handling for last-mile delivery and intricate warehouse operations. The continuous growth of global logistics and supply chain networks also bolsters demand, as goods require constant movement and transfer across various stages. Furthermore, industrialization in emerging economies and the imperative for improved labor efficiency and reduced manual handling injuries are compelling businesses to invest in ergonomic and robust material handling solutions, directly fueling market growth.

However, the market also faces notable restraints. The initial capital investment for higher-end, specialized, or semi-automated hand trucks and dollies can be a barrier for smaller businesses. The increasing adoption of advanced automated systems, such as Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs), presents a competitive challenge, particularly in large-scale warehouses where complete automation is viable. Additionally, ergonomic concerns related to prolonged manual operation and the physical demands on workers, even with assistive devices, can sometimes lead to a preference for fully automated solutions in certain contexts. The rising awareness regarding environmental impact also pushes for sustainable material choices, potentially increasing production costs.

Opportunities abound for market players. Customization and specialization of hand trucks to meet niche industry requirements, such as those in healthcare or food processing, offer avenues for market differentiation and growth. The development of 'smart' hand trucks equipped with IoT sensors for tracking, load management, and predictive maintenance represents a significant innovation opportunity. Furthermore, targeting emerging markets with growing industrial and retail infrastructures presents substantial untapped potential. The demand for sustainable and lightweight materials in manufacturing also creates opportunities for product innovation and eco-friendly solutions. Overall, the market is shaped by technological advancements, evolving regulatory landscapes concerning worker safety, and the inherent volatility and disruptions within global supply chains, all of which mandate adaptive strategies from market participants to capitalize on the opportunities while mitigating the restraints.

Segmentation Analysis

The Hand Trucks and Dollies market is extensively segmented to reflect the diverse applications, designs, and capacities required by various end-users. This granular segmentation allows for a detailed understanding of market dynamics, consumer preferences, and technological advancements across different product categories. The primary bases for segmentation typically include product type, the material used in manufacturing, the load capacity of the equipment, and the specific end-use industry that deploys these handling solutions. Each segment is characterized by unique demand drivers, design considerations, and competitive landscapes, catering to specific operational needs and budgetary constraints of businesses.

Product type segmentation distinguishes between the fundamental designs such as upright hand trucks, which are ideal for stacking and moving individual boxes; platform dollies, favored for transporting multiple items horizontally; versatile convertible hand trucks that adapt to different tasks; and specialized stair climbers designed for challenging environments. Material segmentation highlights the shift towards lighter yet durable options like aluminum and high-strength plastics, alongside traditional steel, each offering distinct advantages in terms of weight, corrosion resistance, and cost. Load capacity segmentation, from light-duty to heavy-duty, addresses the varied weight requirements across different industries, ensuring that equipment matches the scale of the handling task efficiently and safely.

The end-use industry segmentation provides crucial insights into where demand is concentrated, identifying key sectors such as retail, logistics & warehousing, manufacturing, food & beverage, construction, and healthcare. Each of these sectors has unique material handling challenges and regulatory compliance requirements that drive the adoption of specific types of hand trucks and dollies. For instance, the food & beverage industry might prioritize stainless steel options for hygiene, while construction would favor robust, heavy-duty models. This comprehensive segmentation framework is critical for market players to develop targeted product offerings, tailor marketing strategies, and identify emerging growth opportunities within the expansive and essential material handling equipment landscape.

- Product Type:

- Upright Hand Trucks (Two-Wheelers)

- Platform Dollies (Four-Wheelers)

- Convertible Hand Trucks

- Stair Climber Hand Trucks

- Specialty Hand Trucks (e.g., Appliance, Keg, Furniture)

- Material:

- Steel

- Aluminum

- Plastic

- Hybrid/Composite

- Load Capacity:

- Light Duty (Up to 100 kg)

- Medium Duty (101-250 kg)

- Heavy Duty (Above 250 kg)

- End-Use Industry:

- Retail

- Logistics & Warehousing

- Manufacturing

- Food & Beverage

- Construction

- Healthcare

- Commercial

- Residential

Value Chain Analysis For Hand Trucks and Dollies Market

The value chain for the Hand Trucks and Dollies Market begins with upstream activities involving the sourcing and processing of raw materials. This includes procuring various grades of steel, aluminum, and plastics, as well as rubber for wheels, and other components like bearings and fasteners. Suppliers in this segment are crucial for ensuring the quality, cost-effectiveness, and sustainability of the primary inputs. Manufacturers engage in design and engineering, focusing on ergonomics, durability, and functionality, followed by fabrication processes such as cutting, welding, molding, and assembly. This stage adds significant value through precision manufacturing, quality control, and innovative product development, aiming to meet diverse market demands for load capacity, material type, and specialized features.

Moving downstream, the distribution channel plays a pivotal role in connecting manufacturers with the end-users. This involves a mix of direct and indirect channels. Direct sales typically occur for large industrial clients or through manufacturers' own online platforms, allowing for custom orders and direct customer service. Indirect channels are more prevalent and include a network of wholesalers, distributors, industrial supply companies, hardware stores, and e-commerce retailers. These intermediaries are critical for market penetration, inventory management, and providing localized sales and support. They often handle logistics, warehousing, and fragmented order fulfillment, ensuring broad availability of products to a diverse customer base, from small businesses to individual consumers.

The final stages of the value chain involve post-sales services, including warranty provisions, repair, and replacement parts, which contribute to customer satisfaction and brand loyalty. The efficiency and effectiveness of the entire value chain are significantly influenced by logistics, inventory management, and strategic partnerships. A well-optimized value chain ensures a smooth flow from raw material procurement to product delivery and after-sales support, reducing costs, enhancing speed to market, and maintaining competitive pricing. This holistic approach, from upstream material suppliers to downstream distribution networks, is essential for sustained success in the dynamic Hand Trucks and Dollies market.

Hand Trucks and Dollies Market Potential Customers

The potential customer base for Hand Trucks and Dollies is remarkably broad and diverse, encompassing virtually any entity or individual involved in the movement of goods, materials, or equipment. At its core, any business or operational setting requiring manual assistance for lifting, pushing, or pulling items too heavy or bulky for direct handling represents a direct opportunity. This includes a wide spectrum of commercial, industrial, and even residential users who prioritize efficiency, worker safety, and the protection of goods during transit. The essential nature of these tools ensures a perennially robust demand across various economic sectors, making them fundamental to countless daily operations.

Key end-users include businesses within the expansive logistics and warehousing sector, where hand trucks and dollies are indispensable for sorting, picking, packing, and loading operations in distribution centers and fulfillment hubs. The retail industry, encompassing supermarkets, hardware stores, department stores, and e-commerce giants, relies heavily on these devices for stock replenishment, moving merchandise from back rooms to sales floors, and facilitating last-mile delivery. Manufacturing facilities utilize them for transporting raw materials, work-in-progress, and finished goods across production lines. Furthermore, the construction industry deploys heavy-duty variants for moving building materials, tools, and equipment on job sites, significantly enhancing operational fluidity and reducing manual strain in demanding environments.

Beyond these major industrial and commercial applications, the food & beverage sector uses specialized, often corrosion-resistant, hand trucks for moving cases, kegs, and appliances, ensuring hygiene and operational efficiency. Healthcare facilities find them vital for transporting medical supplies, equipment, and laundry, while commercial establishments like hotels, offices, and schools use them for various internal logistics. Even residential users and small businesses frequently purchase hand trucks for moving furniture, appliances, or garden supplies. This extensive range of applications underscores the universal utility of hand trucks and dollies, solidifying their position as critical, foundational equipment for efficient and safe material handling across almost every facet of the modern economy.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.25 Billion |

| Market Forecast in 2032 | USD 5.90 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Harper Trucks Inc., Magliner (EGA Products, Inc.), Milwaukee Hand Trucks (Gleason Corporation), Wesco Industrial Products, Rubbermaid Commercial Products, B&P Manufacturing, Vestil Manufacturing Corporation, Little Giant Products (Brennan Equipment & Manufacturing), Cotterman Company, Raymond Corporation, Hallowell, Escalate, Palleon, Bay State Hand Truck, R&M Materials Handling, Southworth Products Corp., Koke Inc., Lift Safe, Easy Movers, Presto Lifts Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hand Trucks and Dollies Market Key Technology Landscape

The Hand Trucks and Dollies market, while rooted in simple mechanical principles, is continuously evolving through technological advancements that enhance efficiency, ergonomics, and durability. Material science plays a pivotal role, with ongoing research and development focusing on lighter yet stronger alloys of aluminum and steel, as well as advanced composite plastics. These innovations aim to reduce the overall weight of the equipment, making it easier for operators to maneuver, while simultaneously increasing load capacity and resistance to wear and tear. Furthermore, the integration of specialized wheels and caster technologies, such as puncture-proof tires, non-marking wheels, and precision bearings, significantly improves mobility, reduces rolling resistance, and extends product lifespan across diverse terrains and indoor environments.

Ergonomic design principles are increasingly being applied, leveraging engineering and biomechanical studies to create hand trucks and dollies that minimize operator strain and prevent injuries. This includes features like adjustable handles, cushioned grips, improved weight distribution, and foot-assist mechanisms for easier tilting. The incorporation of braking systems, particularly on platform dollies, enhances safety during transport on inclines or when handling heavy loads. For specialized applications, technologies like electric motor assistance for stair climbers or hydraulic lift mechanisms for platform trucks are transforming manual handling into semi-automated processes, vastly improving efficiency and safety for extremely heavy or challenging loads.

The emerging landscape also sees the nascent integration of smart technologies, albeit on a smaller scale compared to fully automated systems. This includes IoT sensors for real-time tracking of equipment location, usage patterns, and predictive maintenance alerts. Such features can optimize fleet management, ensure timely servicing, and provide valuable data for process improvement in large-scale logistics operations. While fully autonomous hand trucks are still a niche, the trend is towards intelligent assistance and data-driven design, making traditional material handling tools smarter, safer, and more aligned with the demands of modern, data-centric supply chains. These technological strides ensure that hand trucks and dollies remain relevant and competitive alongside more complex automated solutions.

Regional Highlights

The Hand Trucks and Dollies market exhibits diverse characteristics and growth trajectories across different geographical regions, each influenced by unique economic, industrial, and logistical factors. Understanding these regional dynamics is crucial for market participants to tailor their strategies and capitalize on localized opportunities. The global market is broadly segmented into North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa, with each contributing significantly to the overall market landscape through varying demand patterns, regulatory environments, and technological adoption rates.

North America and Europe represent mature markets characterized by well-established logistics infrastructure, high labor costs, and stringent safety regulations. This leads to a strong demand for ergonomic, durable, and often specialized hand trucks and dollies designed to enhance worker welfare and operational efficiency. The continuous expansion of e-commerce, particularly in the US and Germany, further drives market growth, with a focus on quick and efficient material handling within warehouses and for last-mile delivery. Innovation in these regions often centers on advanced materials, smart features, and improved ergonomic designs to maintain competitiveness against automated solutions.

Asia Pacific is undeniably the fastest-growing region, propelled by rapid industrialization, burgeoning manufacturing sectors in China, India, and Southeast Asia, and the massive scale of e-commerce operations. The region benefits from a large labor force and increasing investments in infrastructure development, leading to a high demand for both basic and advanced material handling equipment. Latin America, the Middle East, and Africa are emerging markets with significant growth potential, driven by urbanization, expanding retail sectors, and improving supply chain networks. While initial adoption may focus on more cost-effective solutions, there is a gradual shift towards more sophisticated and efficient equipment as these economies develop and integrate further into global trade. These regional nuances underscore the global reach and localized importance of hand trucks and dollies in facilitating material movement.

- North America: A mature market with high adoption rates, driven by a robust e-commerce sector, extensive logistics networks, and a strong emphasis on worker safety and ergonomic designs. The United States and Canada are key contributors.

- Europe: Characterized by stringent labor laws and a focus on operational efficiency, leading to demand for high-quality, durable, and specialized hand trucks. Germany, the UK, and France are prominent markets.

- Asia Pacific (APAC): The fastest-growing region due to rapid industrialization, expanding manufacturing bases, and booming e-commerce markets in countries like China, India, and Japan. Significant infrastructure development supports market expansion.

- Latin America: Emerging market with increasing industrialization and retail expansion. Growth is driven by investments in logistics and warehousing, particularly in Brazil and Mexico.

- Middle East and Africa (MEA): Growing market influenced by infrastructure projects, economic diversification, and increasing trade activities. Demand is rising from construction, retail, and oil & gas sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hand Trucks and Dollies Market.- Harper Trucks Inc.

- Magliner (EGA Products, Inc.)

- Milwaukee Hand Trucks (Gleason Corporation)

- Wesco Industrial Products

- Rubbermaid Commercial Products

- B&P Manufacturing

- Vestil Manufacturing Corporation

- Little Giant Products (Brennan Equipment & Manufacturing)

- Cotterman Company

- Raymond Corporation

- Hallowell

- Escalate

- Palleon

- Bay State Hand Truck

- R&M Materials Handling

- Southworth Products Corp.

- Koke Inc.

- Lift Safe

- Presto Lifts Inc.

- Akro-Mils

Frequently Asked Questions

What factors are primarily driving the growth of the Hand Trucks and Dollies market?

The market's growth is largely fueled by the exponential expansion of global e-commerce, the increasing complexity of logistics and warehousing operations, rapid industrialization in emerging economies, and a persistent demand for enhanced labor efficiency and worker safety across various industries.

How is the e-commerce sector impacting the demand for hand trucks and dollies?

The e-commerce boom necessitates faster and more efficient material handling for order fulfillment, inventory management, and last-mile delivery. This directly increases the demand for hand trucks and dollies to streamline the movement of goods within warehouses, distribution centers, and during transportation.

What are the key types of hand trucks and dollies available in the market?

The market offers diverse types including upright hand trucks for vertical loads, platform dollies for horizontal movement of bulkier items, versatile convertible hand trucks, specialized stair climber hand trucks, and various specialty models tailored for specific items like appliances or furniture.

What role does the material of construction play in hand truck and dolly performance?

The choice of material, such as steel, aluminum, or plastic, significantly impacts a hand truck's weight, durability, load capacity, corrosion resistance, and overall lifespan. Lightweight materials like aluminum enhance maneuverability, while steel offers superior strength for heavy-duty applications.

How are technological advancements improving the safety and efficiency of hand trucks and dollies?

Technological advancements include ergonomic designs to reduce operator strain, integration of durable and smooth-rolling wheels for better maneuverability, enhanced braking systems for stability, and the use of lighter yet stronger materials. Emerging smart features like IoT sensors for tracking and predictive maintenance also contribute to improved efficiency and safety.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager