Harmonic Drive Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438391 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Harmonic Drive Market Size

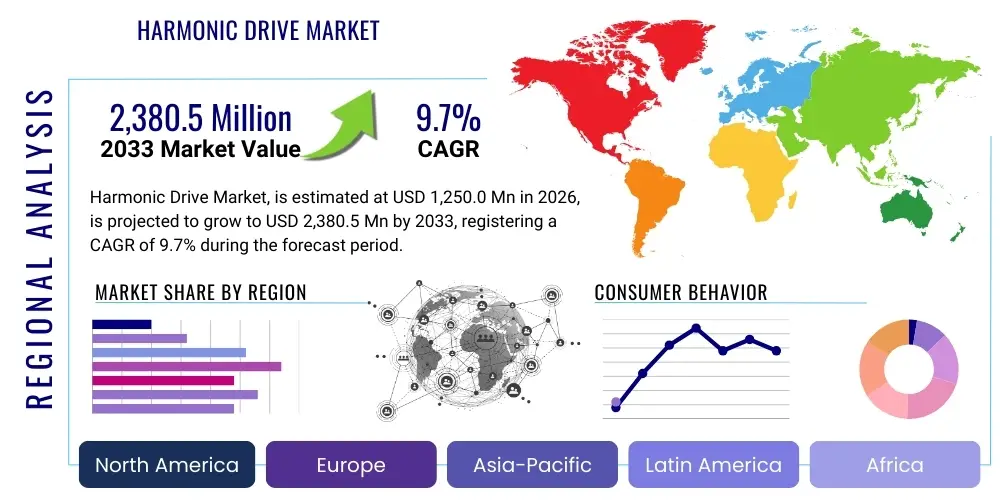

The Harmonic Drive Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.7% between 2026 and 2033. The market is estimated at USD 1,250.0 Million in 2026 and is projected to reach USD 2,380.5 Million by the end of the forecast period in 2033.

Harmonic Drive Market introduction

The Harmonic Drive Market encompasses high-precision speed reducers utilizing the principles of strain wave gearing. These devices, characterized by their compact size, lightweight construction, high torque capacity, and exceptional positioning accuracy, are fundamental components in advanced motion control systems. A standard harmonic drive mechanism consists of three primary components: the Circular Spline, the Flexspline, and the Wave Generator. This unique operating principle allows for zero backlash and high reduction ratios in a single stage, features critically required in sophisticated mechanical and robotic systems where precision and repeatability are paramount. The product description centers on high-reliability transmissions essential for tasks ranging from surgical assistance to space exploration.

Major applications of harmonic drives are concentrated in fields demanding extremely tight motion tolerance. Robotics is the single largest consumer, spanning industrial automation (collaborative robots, SCARA robots), surgical robots, and prosthetics. Beyond robotics, harmonic drives are indispensable in aerospace and defense systems, particularly in satellite antenna positioning and flight control surfaces, due to their lightweight nature and robustness. Furthermore, precision machine tools, semiconductor manufacturing equipment, and advanced optical tracking systems rely heavily on the non-existent backlash and high stiffness offered by these gears. The benefits derived from harmonic drive utilization include enhanced system efficiency, reduced power consumption, minimized mechanical vibration, and increased lifespan of complex machinery.

The market growth is primarily driven by the exponential expansion of the industrial automation sector globally, fueled by Industry 4.0 initiatives. The surging adoption of collaborative robots (cobots) in small and medium enterprises (SMEs) demands lighter, safer, and more precise actuation components, directly boosting the demand for harmonic drives. Additionally, significant investments in electric vehicle (EV) battery manufacturing and advanced medical devices (such as MRI machines and robotic surgical platforms) contribute substantially to market expansion. Technical advancements leading to higher torque-density designs and improved material science also serve as crucial catalysts driving market penetration across previously underserved industrial segments.

Harmonic Drive Market Executive Summary

The Harmonic Drive Market is experiencing robust expansion, fundamentally underpinned by the global push towards automation and precision engineering. Current business trends indicate a shift towards customization, with end-users demanding application-specific gearing solutions that can integrate seamlessly with lightweight robot arms and advanced servo motors. Key industry players are focusing on developing drives with enhanced load capacity and smaller footprints while maintaining high torsional stiffness, addressing the constraints faced in compact manufacturing environments and payload-sensitive applications like UAVs. Furthermore, strategic mergers and acquisitions, coupled with significant R&D spending on materials like ceramics and advanced alloys, are defining the competitive landscape, aiming to reduce production costs and improve resistance to harsh operating conditions, thereby strengthening the long-term viability and performance of harmonic drive units across diverse industries.

Regionally, the Asia Pacific (APAC) stands out as the dominant and fastest-growing market, primarily due to the colossal manufacturing base in China, Japan, and South Korea, which are rapidly integrating automation technologies across automotive, electronics, and semiconductor industries. Japan, being the hub of advanced robotics technology and home to key industry leaders, continues to be a crucial innovation center. Europe and North America maintain significant market shares, driven by high adoption rates in medical robotics, aerospace, and specialized industrial machinery, coupled with stringent quality requirements that mandate the use of high-precision gearing systems. Emerging markets in Southeast Asia and Latin America are showing accelerating demand, stimulated by foreign direct investment and localized manufacturing initiatives aimed at improving supply chain resilience and reducing labor costs through enhanced automation.

Segment-wise, the Cup type harmonic drive dominates the market due to its versatility, low-profile design, and ease of integration into standard robotic joints and actuator modules. However, the Pancake type is gaining traction, particularly in applications requiring extremely short axial length, such as surgical instruments and sophisticated camera gimbals. By application, the Robotics segment remains the largest revenue generator, correlating directly with the industrial automation boom. The Medical and Healthcare segment is projected to exhibit the highest CAGR, propelled by the increasing deployment of sophisticated surgical robots, patient rehabilitation equipment, and high-precision diagnostic imaging systems. These trends necessitate gear systems that offer unparalleled accuracy and long-term reliability under intermittent or continuous high-stress operations.

AI Impact Analysis on Harmonic Drive Market

Common user questions regarding AI's impact on the Harmonic Drive Market often center on how Artificial Intelligence (AI) and Machine Learning (ML) optimize gear design, predict component failure, and enhance manufacturing processes. Users frequently inquire if AI-driven simulation tools can lead to lighter, yet stronger, harmonic drive designs, or if ML algorithms are being utilized to optimize the complex meshing patterns of the Flexspline and Circular Spline for reduced friction and increased efficiency. Another key concern relates to predictive maintenance: users want to know if integrating sensor data from harmonic drives (torque, temperature, vibration) into AI models can reliably forecast wear and tear, thereby minimizing unexpected downtime in critical robotic and aerospace applications.

AI’s influence is profound, primarily manifesting in three areas: accelerated design, predictive maintenance, and optimized manufacturing. Generative AI tools are being deployed by leading manufacturers to explore thousands of potential geometric configurations for harmonic drive components (such as tooth profiles and material thicknesses) that would be impossible to manually test, resulting in next-generation drives that offer superior torque density and extended operational lifespan. This capability is vital for meeting the ever-increasing demand for smaller, more powerful actuators in fields like collaborative robotics and advanced surgical systems. Furthermore, AI-enhanced quality control systems utilize computer vision to inspect subtle imperfections in component surface finishing, ensuring every unit meets the zero-backlash specification necessary for high-precision applications.

The integration of AI directly impacts the competitiveness of harmonic drive offerings. By embedding smart sensors (IoT capabilities) within the drive units, manufacturers can collect real-time operational data. This data feeds into ML models which not only predict potential failure points days or weeks in advance but also suggest optimal operational parameters (speed, load cycles) to maximize component longevity. This transition from reactive to predictive servicing drastically reduces total cost of ownership for end-users, particularly those operating large fleets of industrial robots or critical aerospace hardware. Ultimately, AI transforms the harmonic drive from a passive mechanical component into an intelligent, self-optimizing system, ensuring peak performance and reliable operation across demanding industrial ecosystems.

- AI-driven topology optimization reduces material usage and enhances the torque-to-weight ratio of the drive system.

- Machine Learning algorithms predict component wear and lubrication breakdown based on real-time acoustic and vibration data, facilitating proactive maintenance.

- Generative design techniques accelerate the development cycle for application-specific drive ratios and sizes.

- AI enhances quality assurance by automating micro-defect inspection of gear teeth profiles, ensuring zero-backlash performance.

- Integration of smart sensors and IoT capabilities turns harmonic drives into intelligent assets within Industry 4.0 frameworks.

- Optimized robot path planning and smoother motion control achieved through real-time feedback loop processing enabled by embedded AI.

DRO & Impact Forces Of Harmonic Drive Market

The dynamics of the Harmonic Drive Market are defined by a strong interplay between compelling growth drivers, significant technological and economic restraints, and latent opportunities that promise future expansion. The primary drivers revolve around the massive scale-up of automated manufacturing globally, particularly in countries aiming for competitive labor cost reduction and enhanced production quality. The increasing complexity of tasks assigned to robotics, requiring multi-axis articulation and extremely fine control, directly necessitates the adoption of high-precision, zero-backlash gearing systems. Simultaneously, the restraints, largely technical and economic, involve the inherent high manufacturing cost associated with the precise machining required for harmonic drives and their relatively limited tolerance to continuous high-speed operation and shock loads compared to traditional gearboxes. The market is constantly impacted by the pressure to reduce the price point while simultaneously improving performance metrics such as torsional stiffness and lifespan.

Key opportunities for market expansion lie in the burgeoning segments of collaborative robotics and exoskeleton technology. Cobots, designed to work alongside humans, require actuators that are lightweight, safe, and easily controlled—attributes where harmonic drives excel. The rapid advancement of surgical and medical robotics presents another lucrative avenue, as these applications place the highest demand on precision, reliability, and sterilization compatibility. Furthermore, the space exploration sector, driven by new commercial space ventures and increased satellite deployment, requires miniaturized, radiation-resistant harmonic drives. The ability of manufacturers to successfully develop and commercialize standardized, modular harmonic drive units at a competitive price point for mid-range automation will be crucial for unlocking broader market potential and offsetting current restraints related to cost and complexity.

Impact forces currently influencing the market include intense competition among a few dominant, highly specialized global players, forcing constant innovation in material science (e.g., utilizing PEEK composites or specialized ceramics) to reduce weight without sacrificing strength. Regulatory standards for safety in collaborative robotics (ISO/TS 15066) dictate specific torque limitations and joint design, which inherently favor the high control accuracy provided by harmonic drives. Economic factors, such as volatile raw material prices for high-grade steel and fluctuations in global semiconductor supply (essential for the servo motors paired with the drives), introduce external market volatility. Overall, the market propulsion remains strong, primarily driven by the unstoppable global trajectory toward pervasive automation across all industrial and consumer-facing sectors, ensuring sustained long-term demand for high-precision transmission solutions.

Segmentation Analysis

The Harmonic Drive Market segmentation provides a detailed structural view of the industry, categorized primarily by Product Type, Component, Application, and End-User Industry. This granular analysis is crucial for understanding specific market dynamics and identifying high-growth niches. Segmentation by Product Type (Cup, Hat, Pancake) helps manufacturers tailor designs to spatial requirements—for example, Cup types are favored for standard robotic joints due to their balance of size and torque, while Pancake types address stringent axial space limitations. Component segmentation (Flexspline, Circular Spline, Wave Generator) is essential for aftermarket services and understanding the specialized manufacturing processes for these critical parts.

Application-based segmentation is perhaps the most defining characteristic of the market, differentiating the demand volume and technical requirements across diverse sectors. Robotics is the volume leader, but aerospace, demanding extreme reliability under temperature variation, and medical, requiring precision and biocompatibility, drive value growth. The End-User Industry perspective highlights the varying buying power and integration cycles across Automotive, Semiconductor, and Defense sectors. The automotive sector, specifically in EV manufacturing, demands high throughput and durability, whereas semiconductor fabrication equipment requires ultra-clean, vibration-free performance, often influencing material choice and overall drive encapsulation design.

The strategic purpose of segment analysis is to enable companies to prioritize investments in R&D and manufacturing capacity aligned with the fastest-growing application areas, such as surgical robotics and high-end industrial automation. Understanding the geographical distribution of these segments—for instance, the heavy concentration of semiconductor manufacturing demand in APAC versus the high R&D intensity of aerospace demand in North America and Europe—allows for optimized supply chain and sales strategies, ensuring products meet localized performance standards and regulatory compliance requirements.

- By Product Type:

- Cup Type Harmonic Drive

- Hat Type Harmonic Drive

- Pancake Type Harmonic Drive

- By Component:

- Flexspline

- Circular Spline

- Wave Generator

- Bearings and Housings

- By Application:

- Industrial Robotics (Articulated, SCARA, Delta, Collaborative)

- Aerospace and Defense (Antenna Positioning, Actuators, UAVs)

- Medical Robotics and Equipment (Surgical Systems, Imaging Devices)

- Machine Tools and Equipment

- Semiconductor Manufacturing Equipment

- Optical and Tracking Systems

- By End-User Industry:

- Automotive

- Electronics and Semiconductor

- Healthcare and Pharmaceutical

- Manufacturing and Automation

- Defense and Space

- By Reduction Ratio:

- Low Ratio (50:1 to 100:1)

- Medium Ratio (100:1 to 160:1)

- High Ratio (160:1 and above)

Value Chain Analysis For Harmonic Drive Market

The value chain for the Harmonic Drive Market begins with the highly specialized upstream analysis involving the sourcing and processing of raw materials. This stage is critical, requiring high-grade alloys such as specialized tool steel (e.g., Chromium-Molybdenum steel) and advanced ceramics, which must possess superior wear resistance and fatigue strength to ensure the zero-backlash requirement is maintained over the drive’s lifetime. Key upstream activities include metallurgical refinement, precision casting, and forging. The integration of high-precision bearing manufacturers and specialized lubrication suppliers further defines this stage. Given the critical tolerances, supplier relationships are often long-term and collaborative, focusing on mutual quality standards and material traceability, which significantly impacts the final cost structure of the harmonic drive unit.

The manufacturing stage is characterized by high capital intensity and proprietary technology, where the complex components—the flexible spline, circular spline, and wave generator—are produced using ultra-precision CNC grinding, electrical discharge machining (EDM), and complex heat treatments. Quality control, involving non-contact measurement systems and environmental testing, is paramount to ensure the required sub-micron accuracy. Downstream analysis focuses on integration. Harmonic drive manufacturers often sell their products directly to Original Equipment Manufacturers (OEMs) in the robotics, aerospace, and medical sectors. These OEMs integrate the drives into sophisticated assemblies like robot joints, surgical manipulators, or flight control systems, often requiring customized housing and interface specifications, leading to a strong business-to-business (B2B) sales model.

Distribution channels for harmonic drives are typically direct, facilitating technical support and application engineering expertise required by high-tech end-users. Direct sales teams work closely with OEM engineers during the product design phase, ensuring the drive is optimally selected and integrated. Indirect distribution occurs through specialized technical distributors and value-added resellers (VARs), particularly for standard, off-the-shelf models or for serving smaller industrial automation integrators. The market success relies heavily on the strength of the service and after-sales support provided, including maintenance scheduling, repair, and genuine spare parts supply, especially concerning high-reliability components like the Flexspline, which is subject to high operational stress. This integrated approach ensures technical superiority and customer loyalty.

Harmonic Drive Market Potential Customers

Potential customers for the Harmonic Drive Market are diverse but share a common need for high-precision motion control where space and weight constraints are critical. The primary end-users are Original Equipment Manufacturers (OEMs) specializing in advanced automation and mechanical systems. Within the industrial sector, major buyers include manufacturers of multi-axis articulated robots, collaborative robots (cobots), and high-throughput production machinery for sectors like automotive welding and electronics assembly. These customers seek compact drives capable of maintaining accuracy under continuous, high-cycle operation, maximizing production efficiency and minimizing positional error accumulation in dynamic processes.

Beyond traditional manufacturing, the aerospace and defense industries represent a high-value customer base. These end-users, including satellite manufacturers, defense contractors, and aircraft component producers, require drives that function reliably under extreme environmental conditions (vacuum, radiation, temperature variation) and must adhere to rigorous quality certifications (e.g., AS9100). The specific demands often necessitate customized harmonic drive solutions, including specialized materials and sealed designs, which translates into higher price points and longer contractual relationships, focusing heavily on proven reliability and redundancy testing.

Finally, the medical and semiconductor sectors are emerging as critical customer segments. Hospitals and medical device companies purchase harmonic drives for integration into surgical robotic arms (e.g., Da Vinci systems), diagnostic imaging equipment, and patient rehabilitation devices, prioritizing exceptional smoothness of motion and sterility compliance. Semiconductor fabrication equipment manufacturers require drives for wafer handling and lithography systems, where minimal vibration and sub-micron positioning accuracy are absolutely non-negotiable for chip manufacturing yield. These end-users are willing to invest significantly in harmonic drive technology due to the direct correlation between drive precision and the successful outcome of their highly sensitive processes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1,250.0 Million |

| Market Forecast in 2033 | USD 2,380.5 Million |

| Growth Rate | 9.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Harmonic Drive Systems Inc., HDSI (Harmonic Drive AG), Curtiss-Wright Corporation (NuVinci), Cone Drive Operations Inc., Sumitomo Drive Technologies (Cyclo Drive), Nidec Shimpo Corporation, Nabtesco Corporation, Zhejiang Shuanghuan Driveline Co., Ltd., Leaderdrive (Suzhou) Co., Ltd., Ningbo Zhenyu Technology Co., Ltd., Beijing CTKM Harmonic Drive Co., Ltd., Shinano Kenshi Co., Ltd., REDEX Group, Sango Automation Technology, and Electromate Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Harmonic Drive Market Key Technology Landscape

The technological landscape of the Harmonic Drive Market is rapidly evolving, driven by the need to increase torque density, improve efficiency, and reduce weight, particularly for mobile and collaborative applications. A primary area of innovation is in material science, moving beyond traditional steel alloys to incorporate advanced materials such as high-strength aluminum alloys, specialized titanium composites, and high-performance polymers for the Flexspline and housing components. These material choices aim to drastically reduce the overall inertia of the drive system, crucial for high-dynamic response applications like pick-and-place robots. Furthermore, manufacturers are investing heavily in surface treatment technologies, including specialized coatings and nitriding processes, to enhance wear resistance and friction reduction between the engaging gear teeth, thereby extending operational life and minimizing maintenance requirements.

Another significant technological focus is on optimizing the gear tooth geometry and profile. Utilizing advanced finite element analysis (FEA) and computational fluid dynamics (CFD) simulations, engineers are designing tooth shapes that distribute load more evenly across the contact area, increasing load capacity while maintaining the characteristic zero-backlash performance. This includes refining the design of the Wave Generator, often through incorporating elliptical or tri-lobed cams, to optimize the deformation of the Flexspline and achieve smoother, quieter operation. Miniaturization technology is equally critical, enabling the production of micro harmonic drives essential for surgical instruments, micro-robotics, and sophisticated camera payloads where size and weight must be minimized without compromising on the high reduction ratio capability.

The integration of smart technology is also redefining the landscape. Modern harmonic drives are increasingly designed to be "smart" components, incorporating integrated sensors for real-time monitoring of critical parameters such as torque, temperature, and vibration. This IoT-enabled capability allows for precise condition monitoring and facilitates predictive maintenance strategies, essential for maximizing uptime in high-cost industrial and aerospace environments. Advanced manufacturing techniques, specifically 3D printing (Additive Manufacturing), are being explored, particularly for prototyping and producing complex internal structures of the housing and customized components, leading to faster iteration cycles and potential simplification of the overall assembly process. The combination of material innovation, geometric optimization, and embedded intelligence defines the current frontier of harmonic drive technology.

Regional Highlights

Regional dynamics within the Harmonic Drive Market are highly differentiated by levels of industrial automation maturity, investment in advanced manufacturing, and the presence of dominant end-user sectors like aerospace and medical device production. Asia Pacific (APAC) holds the largest market share and is projected to exhibit the highest growth rate during the forecast period. This dominance is attributed to the massive scale of manufacturing operations, particularly in China (the world’s largest consumer of industrial robots) and the technological prowess of Japan and South Korea in robotics and semiconductor equipment manufacturing. Government initiatives like "Made in China 2025" and similar automation mandates across the region heavily stimulate the demand for high-precision, domestically manufactured, or imported harmonic drives. The rapid expansion of EV production in APAC further solidifies its leading position.

North America is a mature market characterized by high-value applications, including advanced aerospace and defense contracts, and a dominant presence in medical robotics. The United States, being a global leader in both commercial spaceflight and complex surgical systems, drives the demand for highly customized, ultra-reliable harmonic drives. The regional focus is less on sheer volume and more on specialized performance requirements, such as radiation resistance, temperature stability, and extended mean time between failures (MTBF). Strong government funding for defense modernization and robust private investment in R&D across technology hubs ensure continuous demand for cutting-edge harmonic drive technology used in sensitive applications and cutting-edge research equipment.

Europe represents another key region, driven by the highly advanced industrial sectors in Germany, Italy, and Scandinavia. Germany, in particular, with its strong emphasis on Industry 4.0 and machine tool excellence, remains a critical consumer. The region leads in the adoption of collaborative robotics and specialized automation solutions for complex assembly tasks. European market growth is supported by a stringent regulatory environment that encourages investments in safety and precision, favoring high-quality, zero-backlash gearing systems. Furthermore, major European aerospace entities contribute significantly to the demand for certified, high-performance harmonic drives, particularly those engineered for long operational life and maintenance-free use.

Latin America and the Middle East & Africa (MEA) currently represent smaller but rapidly growing markets. Growth in Latin America is concentrated in automotive manufacturing and packaging automation, particularly in Brazil and Mexico, as these countries modernize their production lines. In the MEA region, investments in defense, oil and gas automation, and smart city infrastructure (requiring sophisticated monitoring and control systems) are slowly stimulating the adoption of harmonic drives. While the cost sensitivity is higher in these regions, the increasing need for high-reliability systems in critical infrastructure projects promises sustained, albeit gradual, market penetration over the forecast period, often relying on imported solutions from established North American, European, and Japanese manufacturers.

- Asia Pacific (APAC): Dominates the market due to massive robotic integration in China and Japan, particularly across automotive and electronics supply chains.

- North America: High-value market focused on specialized aerospace, defense, and advanced surgical robotics applications, prioritizing reliability and customization.

- Europe: Driven by Industry 4.0, machine tool precision, and collaborative robot adoption, with Germany serving as a major hub for technical excellence.

- Latin America: Emerging demand fueled by modernization of automotive manufacturing and packaging automation infrastructure.

- Middle East & Africa (MEA): Growth tied to defense modernization, oil and gas sector automation, and emerging smart city projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Harmonic Drive Market.- Harmonic Drive Systems Inc.

- HDSI (Harmonic Drive AG)

- Curtiss-Wright Corporation (NuVinci)

- Cone Drive Operations Inc.

- Sumitomo Drive Technologies (Cyclo Drive)

- Nabtesco Corporation

- Nidec Shimpo Corporation

- Leaderdrive (Suzhou) Co., Ltd.

- Zhejiang Shuanghuan Driveline Co., Ltd.

- Ningbo Zhenyu Technology Co., Ltd.

- Beijing CTKM Harmonic Drive Co., Ltd.

- Shinano Kenshi Co., Ltd.

- Sango Automation Technology

- REDEX Group

- Electromate Inc.

- Schaeffler Technologies AG & Co. KG

- Tsubakimoto Chain Co.

- Dürr AG (through automation divisions)

- WITTENSTEIN SE

- Bonfiglioli Riduttori S.p.A.

Frequently Asked Questions

Analyze common user questions about the Harmonic Drive market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of a harmonic drive compared to traditional gearboxes?

The primary advantage is the implementation of strain wave gearing which results in zero or near-zero backlash, extremely high reduction ratios in a single stage, and a significantly compact, lightweight form factor ideal for robotic joints and precision machinery.

Which application segment drives the largest demand for harmonic drives globally?

The Industrial Robotics segment generates the largest market demand, fueled by the global acceleration of factory automation, the increasing deployment of collaborative robots (cobots), and the requirement for highly accurate motion control in multi-axis systems.

How does the high cost of harmonic drives impact market adoption in emerging economies?

The high unit manufacturing cost, driven by the required ultra-precision machining, acts as a primary restraint, particularly in cost-sensitive emerging markets. However, the superior lifespan and reduced maintenance associated with harmonic drives often justify the higher initial investment for critical operations.

What are the limitations of harmonic drives regarding operational performance?

Key limitations include reduced efficiency at very high speeds, sensitivity to continuous shock loading, and a specialized manufacturing process that makes customization and repair expensive. They are typically optimized for low-to-medium speed, high-torque applications.

How is AI influencing the future design and maintenance of harmonic drive systems?

AI facilitates generative design for optimal torque density and geometry, reduces time-to-market for specialized units, and, crucially, enables predictive maintenance through embedded sensors, drastically increasing operational uptime and component longevity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Harmonic Drive Precision Gear Reducers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Harmonic Drive Reduction Gear Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Harmonic Drive Market Size Report By Type (Cup Style, Hat Style, Pancake Style), By Application (Industry Robots, Semiconductor Manufacturing Systems, Flat Panel Display Manufacturing Systems, Machine Tools, Optical Machines, Printing, Bookbinding and Paper Machines, Metalworking Machines, Medical Equipment, Space Equipment), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Harmonic Drive Market Statistics 2025 Analysis By Application (Industry Robot, Semiconductor Equipment, Flat Panel Equipment, Machine Tools, Optical Machine, Printing, Bookbinding and Paper Machine, Metal Working Machine, Medical Equipment, Space Equipment), By Type (Cup, Hat, Pancake), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager