High Purity Copper Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434294 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

High Purity Copper Market Size

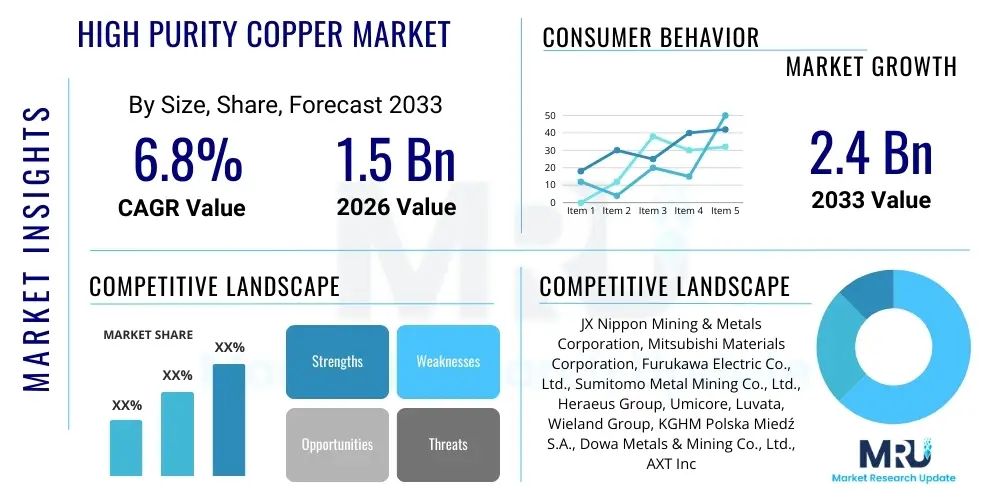

The High Purity Copper Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.4 Billion by the end of the forecast period in 2033.

High Purity Copper Market introduction

The High Purity Copper (HPC) market encompasses materials characterized by purity levels ranging from 99.99% (4N) up to 99.99999% (7N). This advanced material is critical for applications demanding superior electrical and thermal conductivity, minimal impurity interference, and exceptional corrosion resistance. Products range from sputtering targets used in thin-film deposition to advanced wiring harnesses, ensuring optimal signal integrity and energy efficiency in sensitive electronic systems. The market is segmented primarily by purity grade, form (ingots, wire, powder), and end-use application, with 5N and 6N grades forming the core demand structure due to their extensive use in cutting-edge semiconductor manufacturing and high-performance electronics.

Major applications of HPC span critical industries including semiconductors, photovoltaic (PV) cells, advanced automotive systems (especially Electric Vehicles or EVs), and specialized aerospace components. In semiconductor fabrication, ultra-high purity copper (typically 6N or higher) is essential for producing interconnects and microchip wiring where even trace impurities can severely compromise device performance and longevity. The benefits derived from using HPC include reduced signal attenuation, increased power handling capacity, and greater operational reliability across extreme temperature ranges, directly addressing the stringent requirements of modern technological advancements such as 5G infrastructure deployment and high-density data centers.

Driving factors for sustained market expansion include the exponential growth in demand for complex electronic devices, the global transition towards renewable energy sources necessitating high-efficiency PV technology, and the rapid proliferation of electric vehicle manufacturing. EVs require substantial volumes of highly conductive and reliable copper for battery management systems, motor windings, and charging infrastructure, where the purity level directly impacts overall vehicle efficiency and range. Furthermore, continuous investment in R&D for miniaturization technologies in consumer electronics pushes manufacturers to adopt higher purity grades to maintain performance benchmarks in increasingly compact designs, thereby sustaining the premium pricing structure within the HPC market landscape.

High Purity Copper Market Executive Summary

The global High Purity Copper market demonstrates robust growth, primarily propelled by geopolitical focus on domestic semiconductor manufacturing capabilities and the accelerated energy transition initiatives across developed and developing economies. Business trends indicate a strategic vertical integration among leading producers, aiming to control the highly specialized purification processes and secure raw material supply chains against increasing volatility. Furthermore, a discernible shift toward advanced grades (6N and 7N) is occurring, driven by the computational demands of Artificial Intelligence and Machine Learning applications, which require pristine materials for advanced packaging and high-speed data transfer components. Investment in novel refining techniques, such as continuous electrorefining and advanced zone melting, is a key focus area for competitive advantage.

Regionally, Asia Pacific (APAC) maintains its undisputed dominance, primarily due to the concentration of the world’s largest semiconductor foundries, consumer electronics manufacturing hubs, and extensive solar panel production facilities in countries like China, South Korea, Japan, and Taiwan. However, North America and Europe are showing significant revitalization, spurred by massive governmental subsidies (e.g., the U.S. CHIPS Act) aimed at re-establishing domestic high-end manufacturing capabilities, leading to forecasted high CAGR in these regions for the specialized 6N and 7N segments. The market dynamics are also influenced by environmental regulations mandating sustainable production practices, prompting investments in energy-efficient purification methods.

Segment trends confirm that the Application segment dominated by Semiconductors and Electronics remains the largest revenue generator, demanding the highest purity specifications. Within the Grade segmentation, while 4N and 5N copper satisfy standard electronic requirements, the 6N+ segment is experiencing the fastest growth rate, reflecting the technical trajectory of next-generation microprocessors and memory chips. The form factor segment is seeing increased demand for highly uniform copper powders used in additive manufacturing (3D printing) of complex electronic parts and specialized interconnects, alongside the traditional prevalence of sputtering targets and large ingots used for wire drawing and sheet formation.

AI Impact Analysis on High Purity Copper Market

Users frequently inquire about how the exponential scaling of AI data centers and generative AI workloads affects the raw material supply chain, particularly for high-purity metals like copper. Common questions revolve around the increased demand for high-speed interconnects, advanced thermal management solutions (liquid cooling utilizing high-conductivity materials), and the purity requirements for specialized AI accelerator chips. Key themes emerging from this analysis include the expectation that AI deployment will significantly accelerate the demand curve for 6N and 7N copper, not just for the chips themselves, but also for the underlying infrastructure supporting massive power consumption and heat dissipation. Concerns focus on whether existing purification capacity can meet this sudden, high-specification demand spike without inflating prices substantially or causing supply bottlenecks for lower-grade users.

The influence of AI extends beyond simple demand generation; Machine Learning models are increasingly utilized within the production sector for optimizing the complex and energy-intensive high-purity copper refining process. AI algorithms analyze data streams from electrorefining cells, zone melting equipment, and chemical purification steps to predict impurity concentrations, adjust operating parameters (temperature, current density), and minimize energy usage while maximizing yield and consistency. This capability is crucial for consistently achieving 6N and 7N standards, where maintaining purity levels is extremely challenging. By increasing efficiency and reducing waste, AI helps manufacturers stabilize the supply of ultra-premium copper needed for AI hardware.

- AI-driven data center expansion creates explosive demand for 6N copper interconnects and power distribution systems, requiring superior conductivity and minimal signal loss.

- Advanced cooling systems for high-density AI servers necessitate high-purity copper heat sinks and liquid cooling components for optimal thermal transfer efficiency.

- Machine Learning optimization enhances the yield and purity consistency of complex copper refining processes (e.g., zone melting and electrorefining), increasing 7N availability.

- AI modeling assists in material simulation and testing, accelerating the development of new high-performance copper alloys used in power electronics for AI infrastructure.

- Automation via AI and robotics in specialized fabrication facilities ensures minimal human contamination, vital for maintaining ultra-high purity standards in final products like sputtering targets.

DRO & Impact Forces Of High Purity Copper Market

The High Purity Copper market is significantly influenced by a unique set of drivers, restraints, and opportunities that collectively determine market trajectory and profitability. Key drivers include the overwhelming global demand for semiconductors, driven by IoT, 5G, and advanced computing (AI/ML), necessitating ultra-reliable interconnects. Restraints largely center on the prohibitively high capital expenditure required for establishing and maintaining ultra-pure production facilities and the massive energy consumption associated with advanced purification techniques like zone melting. Opportunities arise from technological breakthroughs in solid-state battery technology and the expansion of space exploration programs, both of which require materials with unparalleled performance characteristics and purity. These forces create a highly competitive environment where only specialized firms with robust technological expertise can effectively operate.

The primary driving force remains the relentless pursuit of device miniaturization coupled with enhanced performance across the electronics value chain. As transistors shrink, the density of interconnects increases dramatically, making purity paramount to prevent electromigration and resistance issues which plague nanoscale circuits. The parallel surge in Electric Vehicle adoption acts as another macroeconomic driver, shifting large volumes of demand toward reliable, 5N grade copper for powertrain components and charging infrastructure. These macroeconomic shifts exert substantial impact forces on pricing and required production capacity, forcing market consolidation and strategic joint ventures between refiners and technology end-users to secure supply.

Conversely, the major restraint involves the stringent certification and validation processes required by end-users, especially in aerospace and semiconductor fabrication, which impose extremely high barriers to entry for new players. Furthermore, geopolitical instability affecting base copper supply chains poses an indirect risk, as disruptions in mining and smelting activities raise the cost of the already expensive input material used for ultra-refining. Opportunities for growth lie significantly in the development of 7N and beyond purity levels, catering to experimental quantum computing applications and the development of next-generation photonics devices, offering significant potential for market differentiation and premiumization in the coming decade.

Segmentation Analysis

The High Purity Copper market is systematically segmented to analyze specific demand drivers and consumption patterns across various dimensions, primarily by purity grade, product form, and key application areas. This detailed segmentation allows manufacturers to tailor production capabilities and marketing strategies to niche requirements, particularly differentiating between the high volume demand for 4N copper in standard electrical wiring and the low volume, ultra-premium demand for 6N and 7N materials essential for advanced microelectronics. The complexity of refining means each segment operates under different cost structures and regulatory scrutiny, reflecting the specialized end-use environments.

The Grade segment (4N, 5N, 6N, 7N) fundamentally dictates market value, with pricing escalating exponentially as the purity percentage increases due to the complexity and time required for advanced purification methods like vacuum melting and zone refining. The application segment provides the clearest view of market growth, with semiconductors consistently demanding the highest specifications and driving innovation in material properties. Meanwhile, the Form segment highlights the manufacturing requirements of end-users, distinguishing between massive inputs (ingots) and highly processed intermediate products (sputtering targets and ultrafine powder), which command significant added value.

- By Grade: 4N (99.99%), 5N (99.999%), 6N (99.9999%), 7N (99.99999%)

- By Form: Ingots/Billets, Wires, Powder, Sheets/Foils, Sputtering Targets

- By Application: Semiconductors and Electronics, Solar/Photovoltaics (PV), Automotive (EVs and traditional), Aerospace and Defense, Medical Devices, High-Energy Physics

- By Region: North America, Europe, Asia Pacific (APAC), Latin America, Middle East and Africa (MEA)

Value Chain Analysis For High Purity Copper Market

The value chain for High Purity Copper is intricate, starting from the extraction of base copper and extending through highly specialized refining stages before reaching the sophisticated end-user. Upstream analysis involves traditional copper mining and smelting, followed by initial electrolytic refining to produce standard LME-grade cathodes. The most critical step in this value chain is the subsequent ultra-purification, where specialized refiners take standard copper and subject it to multiple advanced processes (e.g., continuous casting, vacuum induction melting, zone refining, or proprietary chemical processes) to remove trace elements like Oxygen, Sulfur, Iron, and Bismuth down to parts per billion (ppb) levels. This refining step represents the highest value-addition point due to the technical expertise and infrastructure required.

The midstream involves secondary processing, where the ultra-pure ingots are converted into specific forms required by the end-user, such as sputtering targets (using vacuum bonding and machining), fine wires (using specialized drawing processes), or uniform powders. This stage is crucial for ensuring the material's structural integrity and geometric precision align with stringent manufacturing tolerances, particularly for semiconductor and aerospace components. Distribution channels are typically short and tightly controlled due to the material's high value and sensitivity. Direct sales channels are prevalent, connecting specialized refiners directly with large-scale end-users like integrated device manufacturers (IDMs) and solar cell producers.

Downstream analysis focuses on the integration of HPC into final products. For instance, in the semiconductor industry, sputtering targets are utilized in physical vapor deposition (PVD) to create thin film layers in microchips. The indirect channel involves distributors or specialized material suppliers who might handle logistics and smaller volume orders for research institutions or medium-sized electronics assembly firms. Due to the high criticality of purity, end-users often impose strict supplier qualification processes, making long-term supply agreements and strong vendor relationships vital components of the competitive landscape, ensuring that the integrity of the material is maintained from purification to final integration.

High Purity Copper Market Potential Customers

Potential customers and end-users of High Purity Copper are highly specialized corporations operating in technology-intensive sectors where material reliability and performance are non-negotiable. The largest consumer base resides within the integrated device manufacturing (IDM) and foundry segments of the semiconductor industry, which demand 6N and 7N purity for critical interconnects in microprocessors, memory chips (DRAM/NAND), and advanced logic circuits. These buyers require materials compliant with strict SEMI standards and often audit the refiner's entire process chain to ensure consistency and prevent contamination. Consistency in purity is prioritized over cost in this sector.

The second major group includes manufacturers in the renewable energy sector, specifically large-scale photovoltaic (PV) cell producers. While they typically utilize 4N or 5N copper for busbars and wiring within solar modules, their high volume requirements significantly influence the market for these mid-range purity grades. Automotive Original Equipment Manufacturers (OEMs) and their Tier 1 suppliers constitute a rapidly expanding customer segment, driven by the shift towards electric mobility. These customers demand robust 5N copper wire and sheets for battery packs, power electronics, and high-voltage cabling where thermal management and efficiency are key performance indicators.

Other crucial customers include aerospace and defense contractors, who require ultra-pure materials for sensitive navigational equipment, radar systems, and specialized wiring in harsh environments where reliability under stress is critical. Additionally, research institutions and governmental laboratories involved in fusion energy research (e.g., superconducting magnets) and high-energy physics are persistent, albeit lower volume, buyers of the highest purity grades (6N and 7N) due to the unique cryogenic and electrical demands of their experimental apparatus.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.4 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | JX Nippon Mining & Metals Corporation, Mitsubishi Materials Corporation, Furukawa Electric Co., Ltd., Sumitomo Metal Mining Co., Ltd., Heraeus Group, Umicore, Luvata, Wieland Group, KGHM Polska Miedź S.A., Dowa Metals & Mining Co., Ltd., AXT Inc., Materion Corporation, Mitsui Mining & Smelting Co., Ltd., Anglo American plc, Aurubis AG, CPMEC, S.A. Argor-Heraeus, Tanaka Holdings Co., Ltd., Pioneer Materials, Inc., Global Advanced Metals. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

High Purity Copper Market Key Technology Landscape

The achievement of ultra-high purity copper relies on sophisticated refining technologies that go far beyond conventional electrorefining. Key technological processes include Zone Refining, which involves slowly melting a section of an ingot and moving the molten zone down the length, thereby concentrating impurities at one end due to differential solubility. This technique is often used in combination with vacuum induction melting (VIM) to minimize gas inclusion and achieve 6N and 7N levels required for advanced semiconductor targets. Technological innovation in this field is focused on optimizing the efficiency, speed, and energy consumption of these inherently slow and capital-intensive processes, ensuring cost-effective production of premium grades.

Another crucial technology is advanced electroplating and continuous casting, specifically tailored to maintain extremely low oxygen content (Oxygen-Free High-Conductivity Copper, or OFHC). Furthermore, Physical Vapor Deposition (PVD) targets, a primary form factor for HPC, require specialized bonding and machining techniques to ensure the integrity of the copper surface is not compromised by contamination during manufacturing. New entrants are exploring plasma purification and chemical vapor deposition (CVD) techniques for niche applications, which promise even greater control over trace impurities but currently face scalability challenges for bulk production.

The trend towards miniaturization in electronics is driving the development of highly uniform copper nanopowders, necessitating advancements in chemical precipitation and gas atomization techniques to control particle size and morphology precisely. Technological breakthroughs in additive manufacturing also depend on the purity and consistency of these fine powders. Overall, the technological landscape is characterized by high investment in closed-loop systems, advanced analytics (often AI-assisted) for contamination monitoring, and proprietary methods that differentiate the few companies capable of consistently producing 6N and 7N copper materials for demanding applications like next-generation quantum computing hardware.

Regional Highlights

The global High Purity Copper market exhibits stark regional disparities driven by manufacturing concentrations and geopolitical strategic investments.

- Asia Pacific (APAC): Dominates the market both in terms of production capacity and consumption volume, primarily fueled by the concentration of leading semiconductor fabrication facilities (TSMC, Samsung, SK Hynix) and the vast solar energy industry located in China, South Korea, Taiwan, and Japan. This region is the primary consumer of 5N and 6N copper for advanced memory and logic chips, and also the largest end-user of 4N and 5N copper for consumer electronics assembly and large-scale PV projects.

- North America: Experiencing rapid market acceleration, particularly in the 6N and 7N segments. This growth is heavily supported by government initiatives (like the CHIPS and Science Act) aimed at reshoring semiconductor manufacturing, leading to massive investments in new fabrication plants (fabs) that require secured, high-purity material supply chains. Demand is also robust from the aerospace/defense sectors and pioneering EV manufacturers.

- Europe: Characterized by strong demand from the premium automotive sector, particularly for EV battery and charging components, and specialized industrial electronics. Key European players focus intensely on sustainable and green copper refining processes. Germany and France are central hubs for advanced materials research and high-end industrial machinery that utilize HPC.

- Latin America (LATAM): Primarily functions as a crucial upstream supplier of base copper concentrate and cathodes, but lacks significant downstream ultra-purification capacity. Local market demand for HPC is generally focused on standard electronics and infrastructure projects.

- Middle East and Africa (MEA): Emerging market, with increasing infrastructure spending driving moderate demand for 4N copper in specialized power transmission and high-reliability data center projects, especially in Gulf Cooperation Council (GCC) countries. Ultra-pure consumption remains low but is expected to grow with regional efforts to diversify into technology manufacturing.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the High Purity Copper Market.- JX Nippon Mining & Metals Corporation

- Mitsubishi Materials Corporation

- Furukawa Electric Co., Ltd.

- Sumitomo Metal Mining Co., Ltd.

- Heraeus Group

- Umicore

- Luvata

- Wieland Group

- KGHM Polska Miedź S.A.

- Dowa Metals & Mining Co., Ltd.

- AXT Inc.

- Materion Corporation

- Mitsui Mining & Smelting Co., Ltd.

- Anglo American plc

- Aurubis AG

- CPMEC (China Precision Materials Electronic Components)

- S.A. Argor-Heraeus

- Tanaka Holdings Co., Ltd.

- Pioneer Materials, Inc.

- Global Advanced Metals

Frequently Asked Questions

Analyze common user questions about the High Purity Copper market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between 4N, 5N, and 6N High Purity Copper, and where are they used?

The difference lies in the level of trace impurities, measured in nines (N). 4N copper is 99.99% pure, used for standard electronics and automotive wiring. 5N (99.999%) is used for advanced cabling and high-efficiency PV cells. 6N (99.9999%) is critical for semiconductor interconnects and sputtering targets where ultra-low impurity levels prevent performance degradation and electromigration in microchips.

How does the growth of Electric Vehicles (EVs) specifically drive the demand for High Purity Copper?

EVs significantly increase demand because their high-voltage battery packs, power electronics, motor windings, and charging systems require materials with exceptional electrical conductivity and thermal stability. High purity copper (typically 5N grade) minimizes energy losses, reduces resistance, and ensures the long-term reliability required for electric powertrains, making it an indispensable material for mass EV manufacturing.

What major technological hurdle restricts the scalable production of 7N High Purity Copper?

The primary hurdle is the extreme complexity and energy intensity of ultra-purification processes like advanced zone refining and multi-stage vacuum melting. Removing impurities down to parts per billion requires extremely controlled environments, long processing times, and specialized, high-cost equipment. Furthermore, maintaining purity during subsequent handling and fabrication into final forms (like sputtering targets) poses continuous technical challenges.

Which geographical region holds the largest market share in the High Purity Copper market, and why?

Asia Pacific (APAC) holds the largest market share, driven by its established dominance in global electronics manufacturing and semiconductor fabrication. Countries like China, Taiwan, South Korea, and Japan house the world's leading semiconductor foundries and consumer electronics assembly plants, creating massive, localized demand for ultra-high purity materials, particularly 6N copper for microchips.

What role does the High Purity Copper market play in the burgeoning Artificial Intelligence (AI) sector?

HPC is foundational to the AI sector through two main channels: advanced AI hardware and infrastructure. It provides 6N+ materials for high-speed interconnects and specialized packaging in AI accelerator chips, ensuring high data throughput. Secondly, it is vital for advanced thermal management (cooling systems) in large-scale data centers powering AI models, where its superior thermal conductivity is necessary for mitigating extreme heat generation.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- High Purity Copper Powder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- High Purity Copper Sulfate Solution Market Statistics 2025 Analysis By Application (Electronic Component, Chemical Copper, Surface Finishing), By Type ( 99.99%, 98.00%~99.99%), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Copper Sputtering Target Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Low Purity Copper Sputtering Target, High Purity Copper Sputtering Target, Ultra High Purity Copper Sputtering Target), By Application (Semiconductors, Solar cell, LCD Displays, Other), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

- High Purity Copper Cathode Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Purity =99.99%, Purity =99.97%, Others), By Application (Power Generation, Telecommunications, Electronic Circuits, Electrical Equipment, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager