High Purity Ethyl Trifluoroacetate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440272 | Date : Jan, 2026 | Pages : 245 | Region : Global | Publisher : MRU

High Purity Ethyl Trifluoroacetate Market Size

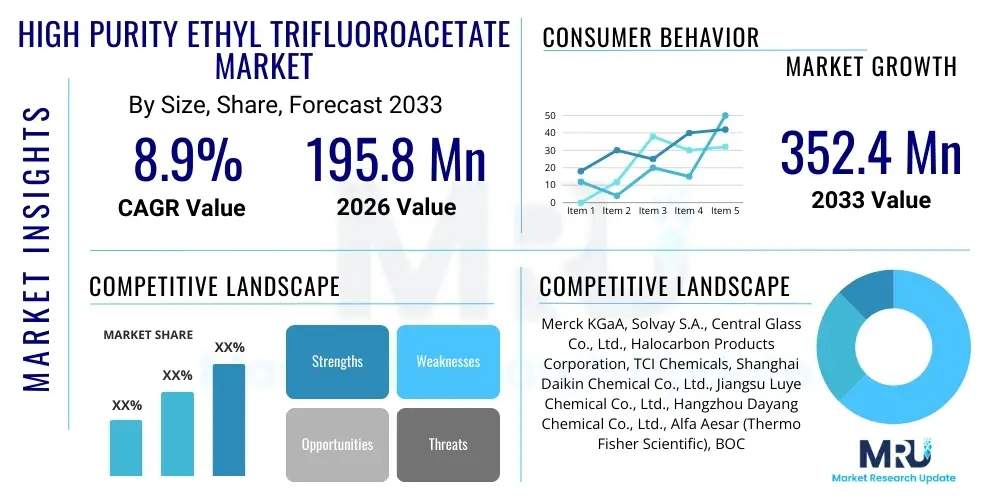

The High Purity Ethyl Trifluoroacetate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 480 Million in 2026 and is projected to reach USD 860 Million by the end of the forecast period in 2033.

High Purity Ethyl Trifluoroacetate Market introduction

High Purity Ethyl Trifluoroacetate (HPETF) is a vital chemical compound characterized by its unique trifluoromethyl group and ester functionality, offering exceptional chemical properties that render it indispensable across a multitude of advanced industries. As a trifluoroacetic acid derivative, HPETF exhibits excellent reactivity, thermal stability, and low toxicity, making it a preferred choice for intricate chemical syntheses. Its high purity, typically exceeding 99%, ensures minimal interference from impurities, which is crucial for sensitive applications where product integrity and consistency are paramount. This compound serves as a versatile building block and solvent, particularly in areas demanding precise chemical transformations and the introduction of fluorine atoms into complex molecules, thus contributing significantly to the performance and efficacy of end-products.

The primary applications of HPETF span across pharmaceutical synthesis, agrochemical manufacturing, and advanced electronics. In pharmaceuticals, it is a key reagent for synthesizing active pharmaceutical ingredients (APIs), intermediates, and chiral compounds, facilitating the development of novel drugs with enhanced therapeutic profiles. The agrochemical sector leverages HPETF for creating high-performance herbicides, insecticides, and fungicides, contributing to improved crop protection and agricultural productivity. Within electronics, its role as an etchant or cleaning agent for semiconductors and electronic components is growing, driven by the demand for miniaturization and enhanced device performance. The benefits derived from HPETF include superior reaction selectivity, high yield in synthesis, and the ability to impart unique properties like lipophilicity or increased metabolic stability to target molecules. Driving factors for its market expansion include the burgeoning global demand for specialized chemicals in healthcare and agriculture, continuous innovation in material science, and the increasing complexity of chemical syntheses requiring high-purity reagents.

High Purity Ethyl Trifluoroacetate Market Executive Summary

The High Purity Ethyl Trifluoroacetate market is currently experiencing robust growth, propelled by a confluence of evolving business trends, significant regional dynamics, and distinct segmental shifts. Globally, business trends indicate a strong push towards advanced manufacturing technologies, with a particular emphasis on green chemistry principles and sustainable production methods to mitigate environmental impact. There is also a notable trend of vertical integration among key players seeking to control the supply chain from raw material sourcing to end-product distribution, aiming for greater efficiency, cost reduction, and quality assurance. Furthermore, strategic alliances, mergers, and acquisitions are increasingly common as companies look to expand their product portfolios, enhance technological capabilities, and strengthen their market presence in a highly competitive landscape.

Regionally, the Asia Pacific (APAC) continues to emerge as the dominant growth engine for the HPETF market, driven by rapid industrialization, burgeoning pharmaceutical and agrochemical industries, and significant investments in electronic manufacturing across countries like China, India, and South Korea. North America and Europe, while more mature markets, exhibit stable demand, particularly from advanced R&D initiatives and stringent regulatory frameworks that necessitate high-purity reagents. In terms of segments, the pharmaceutical application segment maintains its lead, fueled by global healthcare expenditure and the continuous development of new drug molecules requiring sophisticated fluorinated intermediates. The agrochemical segment also shows consistent growth, attributed to the need for enhanced crop protection solutions and sustainable agricultural practices. Emerging applications in specialty polymers and advanced materials are also contributing to market diversification and presenting new growth avenues, indicating a healthy and dynamic market trajectory overall.

AI Impact Analysis on High Purity Ethyl Trifluoroacetate Market

The integration of Artificial Intelligence (AI) and machine learning technologies is poised to significantly transform the High Purity Ethyl Trifluoroacetate market by optimizing various stages of its lifecycle, from research and development to production and supply chain management. User inquiries about AI's impact frequently center on its potential to accelerate the discovery and synthesis of novel fluorinated compounds, enhance process efficiency, improve product quality, and establish more resilient supply chains. There is keen interest in how AI algorithms can predict reaction outcomes, identify optimal synthesis pathways, and even design new molecules that leverage HPETF's unique properties, thereby shortening development cycles and reducing costs. Concerns often revolve around the initial investment required for AI infrastructure, data privacy, and the need for a skilled workforce capable of implementing and managing these advanced systems effectively. Overall, users anticipate AI will drive significant advancements in precision manufacturing, predictive analytics for market demand, and the overall competitiveness of HPETF production.

- AI-driven molecular design and drug discovery accelerate the identification of new compounds requiring HPETF as a key intermediate.

- Predictive analytics optimize chemical reaction conditions, improving yield, purity, and efficiency in HPETF synthesis.

- AI-powered process control systems enhance manufacturing precision, reducing waste and ensuring consistent high purity levels.

- Machine learning algorithms enable real-time quality assurance by analyzing spectroscopic data for impurities.

- AI optimizes supply chain logistics, forecasting demand, managing inventory, and mitigating disruptions in raw material sourcing and distribution.

- Robotics and automation, often AI-controlled, are increasingly utilized in HPETF production for handling hazardous materials and repetitive tasks, boosting safety and throughput.

- Data analytics platforms provide deeper insights into market trends, customer behavior, and competitive landscapes, informing strategic business decisions.

DRO & Impact Forces Of High Purity Ethyl Trifluoroacetate Market

The High Purity Ethyl Trifluoroacetate market is shaped by a complex interplay of various Drivers, Restraints, and Opportunities, which collectively define its growth trajectory and competitive landscape. Key drivers include the escalating global demand from the pharmaceutical sector, where HPETF is critical for synthesizing advanced APIs and intermediates for new drug formulations, particularly in oncology, cardiovascular, and neurological treatments. Furthermore, the expanding agrochemical industry, driven by the need for enhanced crop yields and protection against evolving pests and diseases, consistently fuels demand for HPETF as a building block for efficient herbicides and pesticides. The rapid advancements and miniaturization in the electronics industry also contribute significantly, with HPETF serving as a crucial component in the manufacturing of high-performance semiconductors and specialized electronic materials. Continuous innovation and R&D activities in these end-user industries further bolster the market by creating novel applications and requiring higher purity standards for chemical reagents.

Despite these strong drivers, the market faces several significant restraints. The high production cost associated with HPETF, largely due to complex synthesis processes, specialized equipment, and the cost of raw materials like trifluoroacetic acid, poses a considerable barrier, especially for new entrants. Stringent environmental regulations and safety protocols governing the production and handling of fluorinated chemicals add to operational complexities and compliance costs, which can limit market expansion in certain regions. Moreover, the availability and price volatility of key raw materials can impact production stability and profitability. Opportunities within the market are abundant, however, including the exploration of new niche applications in areas like advanced materials, specialty polymers, and next-generation refrigerants, which can open up untapped revenue streams. Developing sustainable and greener synthesis methodologies presents an opportunity to address environmental concerns and reduce production costs in the long term, enhancing the market's appeal. Additionally, penetrating emerging economies, particularly in Asia Pacific and Latin America, which are experiencing robust industrial growth and increasing healthcare expenditures, offers significant potential for market expansion and increased sales volumes.

Segmentation Analysis

The High Purity Ethyl Trifluoroacetate market is comprehensively segmented to provide granular insights into its diverse components, allowing for a detailed understanding of market dynamics across various categories. These segmentations are critical for identifying specific growth pockets, understanding competitive pressures, and tailoring strategic approaches for different product types, applications, and regional demands. The market is primarily segmented based on purity level, which directly impacts its suitability for specific applications, as well as by its wide array of applications in key industries like pharmaceuticals, agrochemicals, and electronics, reflecting the end-use demand patterns. Further segmentation includes regional analysis, which highlights geographical consumption and production trends.

- By Purity Level

- >99%

- >99.5%

- >99.9%

- By Application

- Pharmaceuticals

- API Synthesis

- Intermediates

- Chiral Compounds

- Agrochemicals

- Herbicides

- Insecticides

- Fungicides

- Electronics

- Etchants

- Cleaning Agents

- Precursors

- Specialty Chemicals

- Polymers

- Flavors & Fragrances

- Dyes

- Others (e.g., Research & Development)

- Pharmaceuticals

- By End-User Industry

- Pharmaceutical & Biotechnology Companies

- Agrochemical Manufacturers

- Electronic Component Manufacturers

- Chemical Companies

- Academic & Research Institutions

- By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Value Chain Analysis For High Purity Ethyl Trifluoroacetate Market

The value chain for the High Purity Ethyl Trifluoroacetate market encompasses a series of interconnected activities, beginning from the sourcing of raw materials to the ultimate delivery to end-users, highlighting the critical stages that add value and define profitability. The upstream segment of the value chain involves the procurement and processing of key raw materials, primarily trifluoroacetic acid and ethanol. Suppliers of these precursors play a crucial role, as their quality, availability, and pricing directly influence the overall production cost and purity of the final HPETF product. Manufacturers often forge long-term relationships with reliable raw material suppliers to ensure a consistent supply of high-grade inputs, which is paramount for maintaining the high purity standards required for HPETF. Research and development activities, including process optimization and new synthesis route development, are also a significant part of the upstream value addition, enhancing efficiency and reducing environmental impact.

Moving downstream, the value chain involves the synthesis, purification, and formulation of HPETF, followed by its distribution to various end-use industries. HPETF manufacturers employ sophisticated chemical processes and rigorous purification techniques, such as fractional distillation and chromatography, to achieve the stringent purity specifications demanded by pharmaceutical, agrochemical, and electronics applications. Post-production, the product moves through various distribution channels, which can be direct or indirect. Direct sales typically involve large manufacturers selling directly to major pharmaceutical companies or specialized chemical formulators, often involving custom orders and technical support. Indirect channels involve distributors, agents, and specialized chemical suppliers who cater to a broader customer base, including smaller enterprises and research institutions, providing logistical support, inventory management, and regional market access. The efficiency and reliability of these distribution networks are critical for timely delivery, minimizing supply chain disruptions, and maintaining customer satisfaction in a global market.

High Purity Ethyl Trifluoroacetate Market Potential Customers

The High Purity Ethyl Trifluoroacetate market serves a diverse range of potential customers, primarily comprised of industries that require high-specification fluorinated intermediates for their advanced chemical synthesis and material production needs. These end-users are characterized by their stringent quality requirements, demand for consistent product performance, and often, adherence to complex regulatory frameworks. Pharmaceutical and biotechnology companies represent a significant customer segment, relying on HPETF for the synthesis of active pharmaceutical ingredients (APIs), key intermediates for drug discovery, and chiral molecules crucial for developing enantiopure drugs. Their continuous innovation in new drug development and demand for high-purity, low-impurity reagents drives a steady and growing consumption of HPETF.

Another major group of potential customers includes agrochemical manufacturers who utilize HPETF as a building block for creating advanced pesticides, herbicides, and fungicides. These companies seek HPETF to develop products with improved efficacy, reduced environmental impact, and enhanced selective toxicity, critical for modern agricultural practices aimed at increasing crop yields and ensuring food security. The electronics industry, particularly manufacturers of semiconductors, displays, and specialized electronic components, also constitutes a vital customer base. They leverage HPETF as an etchant, cleaning agent, or precursor for depositing fluorinated films, requiring exceptional purity to prevent contamination and ensure the performance and reliability of sensitive electronic devices. Additionally, specialty chemical companies, academic research institutions, and laboratories engaged in advanced materials science or organic synthesis also represent significant, albeit sometimes smaller, end-user segments, consuming HPETF for the development of novel polymers, flavors, fragrances, and for experimental research purposes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 480 Million |

| Market Forecast in 2033 | USD 860 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Merck KGaA, Solvay S.A., Lanxess AG, AGC Inc., Daicel Corporation, Honeywell International Inc., Alfa Aesar (Thermo Fisher Scientific), TCI Chemicals (India) Pvt. Ltd., Nippon Shokubai Co., Ltd., Arkema S.A., Jiangsu Sainty Chemical Co., Ltd., Zhejiang Kangli Pharmaceutical Co., Ltd., Fluorochem Ltd., Wuxi Accel Chemical Co., Ltd., Shandong Head Co., Ltd., Central Glass Co., Ltd., Sinochem Group, Stella Chemifa Corporation, Fluorine Compounds Ltd., Nantong Baokai Chemical Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

High Purity Ethyl Trifluoroacetate Market Key Technology Landscape

The production of High Purity Ethyl Trifluoroacetate relies on a sophisticated technology landscape that encompasses various synthesis methods, advanced purification techniques, and stringent quality control protocols, all aimed at achieving the exacting standards required by critical end-use applications. Traditional synthesis typically involves the esterification of trifluoroacetic acid with ethanol, a process that has been continually refined over decades to improve yield and reduce impurities. However, modern manufacturing increasingly leverages more advanced and efficient methodologies, such as continuous flow chemistry, which offers enhanced reaction control, safer operation, and higher throughput compared to traditional batch processes. This shift is driven by the need for greater sustainability, reduced waste generation, and faster production cycles to meet escalating market demand. Furthermore, enzymatic catalysis and organocatalysis are emerging as greener alternatives, providing highly selective reactions under milder conditions, thereby minimizing energy consumption and hazardous byproducts.

Beyond synthesis, the technology landscape is heavily influenced by state-of-the-art purification techniques essential for delivering high-purity HPETF. Techniques like multi-stage fractional distillation, extractive distillation, and advanced chromatography (e.g., preparative HPLC) are employed to meticulously remove trace impurities, ensuring the product meets the stringent specifications for pharmaceutical and electronic grades. For example, for semiconductor applications, HPETF often requires purity levels exceeding 99.9%, necessitating ultra-fine purification processes and specialized handling to prevent contamination. Quality control is maintained through a suite of analytical technologies, including Gas Chromatography-Mass Spectrometry (GC-MS), Nuclear Magnetic Resonance (NMR) spectroscopy, Fourier-transform infrared (FTIR) spectroscopy, and Karl Fischer titration, which accurately quantify purity, identify impurities, and measure water content. These integrated technological advancements enable manufacturers to consistently produce HPETF that meets the diverse and demanding requirements of its high-value applications, ensuring both efficacy and safety in downstream processes.

Regional Highlights

- North America: This region is characterized by robust R&D activities, particularly within the pharmaceutical and biotechnology sectors, driving consistent demand for HPETF as a high-purity reagent. The presence of leading chemical manufacturers and a strong focus on advanced materials also contribute significantly to market stability and innovation.

- Europe: Europe is a mature market with established pharmaceutical and agrochemical industries, where stringent regulatory environments often necessitate the use of high-quality and well-characterized chemical intermediates like HPETF. Germany, France, and Switzerland are key contributors, known for their advanced chemical manufacturing capabilities and innovation in specialty chemicals.

- Asia Pacific (APAC): APAC represents the fastest-growing region, fueled by rapid industrialization, expanding manufacturing bases in China and India, and significant investments in pharmaceutical, agrochemical, and electronics sectors. The increasing demand for generic drugs, crop protection solutions, and electronic devices propels the consumption of HPETF, with local production capacities also on the rise.

- Latin America: This region is an emerging market for HPETF, primarily driven by the growth of its agricultural sector and increasing investments in healthcare infrastructure. Countries like Brazil and Mexico are witnessing a gradual rise in demand for advanced agrochemicals and pharmaceutical intermediates.

- Middle East and Africa (MEA): The MEA market for HPETF is relatively nascent but shows potential, largely influenced by growing investments in pharmaceutical manufacturing, agricultural development projects, and the expanding chemical industry in some Gulf Cooperation Council (GCC) countries. Demand is currently more focused on specific niche applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the High Purity Ethyl Trifluoroacetate Market.- Merck KGaA

- Solvay S.A.

- Lanxess AG

- AGC Inc.

- Daicel Corporation

- Honeywell International Inc.

- Alfa Aesar (Thermo Fisher Scientific)

- TCI Chemicals (India) Pvt. Ltd.

- Nippon Shokubai Co., Ltd.

- Arkema S.A.

- Jiangsu Sainty Chemical Co., Ltd.

- Zhejiang Kangli Pharmaceutical Co., Ltd.

- Fluorochem Ltd.

- Wuxi Accel Chemical Co., Ltd.

- Shandong Head Co., Ltd.

- Central Glass Co., Ltd.

- Sinochem Group

- Stella Chemifa Corporation

- Fluorine Compounds Ltd.

- Nantong Baokai Chemical Co., Ltd.

Frequently Asked Questions

What is High Purity Ethyl Trifluoroacetate (HPETF) primarily used for?

HPETF is primarily used as a vital chemical intermediate and building block in the synthesis of active pharmaceutical ingredients (APIs), advanced agrochemicals (herbicides, insecticides), and as a specialized reagent or etchant in the electronics industry for semiconductor manufacturing.

Which factors are driving the growth of the HPETF market?

Key drivers include the expanding pharmaceutical industry's demand for novel drug molecules, the increasing need for effective agrochemicals to boost crop yields, and the growing electronics sector requiring high-purity reagents for miniaturized components. Continuous R&D and technological advancements also play a significant role.

What are the main challenges facing HPETF manufacturers?

Manufacturers face challenges such as the high production cost due to complex synthesis and specialized raw materials, stringent regulatory compliance, and potential volatility in raw material prices. Ensuring consistent ultra-high purity also requires significant investment in advanced purification technologies.

How is Artificial Intelligence (AI) impacting the HPETF market?

AI is influencing the HPETF market by accelerating molecular design, optimizing synthesis pathways for improved yield and purity, enhancing quality control through predictive analytics, and improving supply chain efficiency by forecasting demand and managing inventory, ultimately reducing costs and development cycles.

Which geographical region holds the largest share in the HPETF market, and why?

The Asia Pacific (APAC) region currently holds the largest market share due to its rapid industrialization, significant growth in pharmaceutical and agrochemical manufacturing, and substantial investments in the electronics sector, particularly in countries like China and India, leading to high consumption and production of HPETF.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager