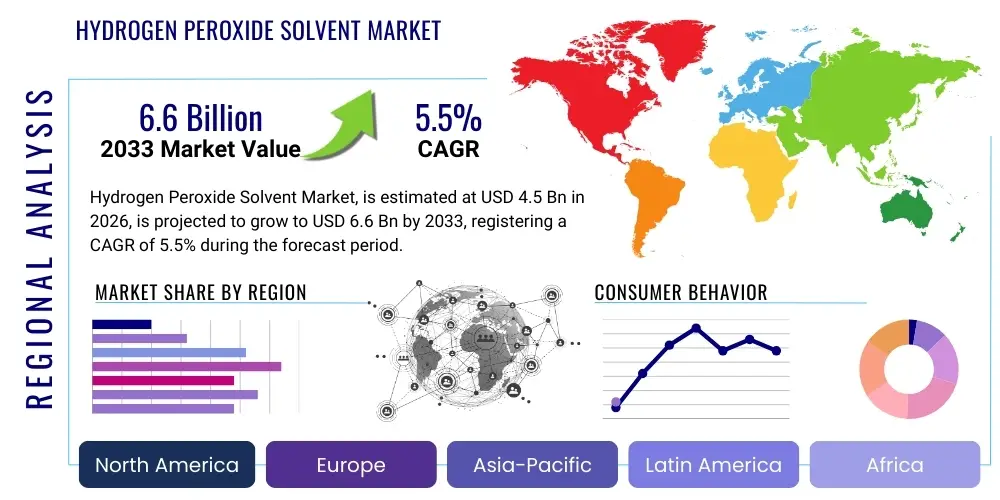

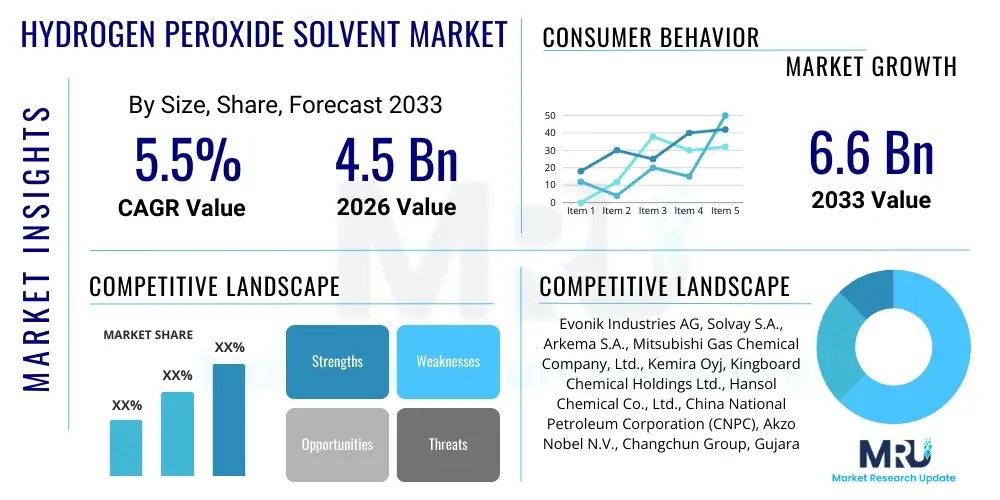

Hydrogen Peroxide Solvent Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439988 | Date : Jan, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Hydrogen Peroxide Solvent Market Size

The Hydrogen Peroxide Solvent Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 3.2 Billion in 2026 and is projected to reach USD 4.8 Billion by the end of the forecast period in 2033.

Hydrogen Peroxide Solvent Market introduction

The hydrogen peroxide solvent market encompasses the production, distribution, and application of hydrogen peroxide (H2O2) specifically for its solvent properties across various industrial sectors. While primarily known as a powerful oxidizer, disinfectant, and bleaching agent, hydrogen peroxide exhibits significant solvent capabilities, particularly in green chemistry, advanced oxidation processes, and the electronics industry where traditional organic solvents are being phased out due to environmental and health concerns. Its unique molecular structure allows it to dissolve a range of organic and inorganic compounds, making it a valuable, albeit specialized, solvent choice for specific applications.

The product, hydrogen peroxide, is a highly versatile chemical compound with the formula H2O2. It is characterized by its colorless nature, slight viscosity, and its decomposition into water and oxygen, rendering it an environmentally benign option. As a solvent, hydrogen peroxide is particularly effective in aqueous solutions, leveraging its polarity and ability to form hydrogen bonds. Its solvent role is distinct from its oxidative function, though often the two properties are utilized synergistically in processes such as chemical synthesis and material cleaning.

Major applications where hydrogen peroxide's solvent properties are increasingly valued include the precision cleaning of semiconductor wafers, where it dissolves photoresists and contaminants without leaving toxic residues; advanced wastewater treatment, where it facilitates the dissolution and degradation of recalcitrant organic pollutants; and in certain specialized chemical synthesis pathways as a reaction medium. Benefits of using hydrogen peroxide as a solvent include its non-toxic decomposition products, high efficiency in specific dissolution tasks, and its contribution to cleaner production methods, aligning with global sustainability initiatives. Driving factors for this market segment include growing environmental regulations pushing for eco-friendly alternatives, technological advancements in electronics and water purification, and increasing adoption of green chemistry principles in chemical manufacturing.

Hydrogen Peroxide Solvent Market Executive Summary

The Hydrogen Peroxide Solvent Market is experiencing dynamic shifts influenced by overarching business trends, evolving regional demands, and specific segmental developments. A key business trend is the strong push towards sustainable and environmentally friendly chemical processes, which inherently favors hydrogen peroxide due to its clean decomposition into water and oxygen. This trend is driving innovation in manufacturing processes, including research into more energy-efficient and direct synthesis methods, and fostering strategic collaborations among chemical producers, technology providers, and end-users to develop novel applications and optimized delivery systems. Furthermore, market consolidation through mergers and acquisitions is shaping the competitive landscape, aiming to enhance production capacities, expand geographic reach, and diversify product portfolios to meet specialized solvent demands.

Regionally, the Asia Pacific (APAC) market continues to be a dominant force, characterized by rapid industrialization, particularly in the electronics and textile sectors, and a burgeoning demand for advanced materials and cleaner manufacturing. Countries like China, India, and South Korea are witnessing significant investments in semiconductor fabrication and chemical industries, fueling the need for high-purity hydrogen peroxide solvents. North America and Europe, while mature markets, are experiencing growth driven by stringent environmental regulations, a strong focus on circular economy principles, and continuous innovation in high-tech industries such as aerospace and advanced composites, where precision cleaning and specific dissolution tasks require high-performance, eco-friendly solvents. Emerging economies in Latin America, the Middle East, and Africa are also showing potential as industrial development and water infrastructure projects advance.

Segmental trends highlight a notable increase in demand for electronic grade hydrogen peroxide, driven by the expanding semiconductor industry and the critical need for ultra-high purity solvents for wafer cleaning and etching processes. The water treatment segment is also exhibiting robust growth, with hydrogen peroxide increasingly employed not just as an oxidizer but also as a solubilizing agent for complex pollutants in advanced oxidation processes. Furthermore, the pharmaceutical and healthcare sectors are contributing to demand for medical and sterile grade hydrogen peroxide for cleaning and disinfection applications where its solvent properties assist in removing organic residues. The focus across segments is on higher purity, tailored concentrations, and improved stability to meet specialized application requirements, thereby distinguishing the solvent market from general hydrogen peroxide uses.

AI Impact Analysis on Hydrogen Peroxide Solvent Market

Artificial intelligence is poised to significantly transform the hydrogen peroxide solvent market by introducing unprecedented levels of efficiency, precision, and innovation across its entire value chain. Common user questions related to AI's impact often revolve around how AI can optimize production processes to reduce costs and environmental footprint, enhance product quality and purity, improve safety protocols in handling and storage, accelerate research and development for new applications, and streamline supply chain logistics. Users are keen to understand if AI can predict market demand more accurately, enabling better inventory management, and if it can aid in discovering novel solvent applications or improving existing ones through predictive modeling of chemical interactions. The overarching theme is an expectation for AI to drive smarter, safer, and more sustainable operations within the industry.

In production, AI-driven systems can analyze vast datasets from sensors and operational parameters to optimize reactor conditions, minimize energy consumption, and reduce waste generated during the anthraquinone auto-oxidation process or emerging direct synthesis methods. Predictive analytics can forecast equipment failures, enabling proactive maintenance and preventing costly downtime. This leads to higher operational efficiency and more consistent product quality, especially crucial for high-purity solvent grades demanded by the electronics industry. AI algorithms can also fine-tune process controls to achieve specific hydrogen peroxide concentrations and stabilize solutions, addressing critical requirements for solvent applications.

Beyond manufacturing, AI will significantly impact R&D, supply chain management, and safety. Machine learning models can analyze molecular structures and reaction pathways to identify new compounds that can be effectively dissolved by hydrogen peroxide, thereby expanding its application scope as a green solvent. For logistics, AI optimizes routing, inventory levels, and demand forecasting, ensuring timely and cost-effective delivery of a sensitive chemical product. Furthermore, AI-powered surveillance and monitoring systems can enhance safety by detecting anomalies in storage facilities, predicting potential leaks or hazardous conditions, and providing real-time alerts, thus mitigating risks associated with handling highly concentrated hydrogen peroxide solutions.

- Enhanced process optimization and efficiency in hydrogen peroxide manufacturing.

- Predictive maintenance for production equipment, reducing downtime and operational costs.

- Improved quality control and consistency for high-purity solvent grades through AI-driven analytics.

- Accelerated discovery and development of new hydrogen peroxide solvent applications.

- Optimized supply chain logistics, including demand forecasting and inventory management.

- Advanced safety monitoring and risk mitigation in handling and storage.

- Reduced environmental footprint through AI-guided waste minimization and energy efficiency.

- Personalized formulation and concentration recommendations for specific industrial applications.

DRO & Impact Forces Of Hydrogen Peroxide Solvent Market

The Hydrogen Peroxide Solvent Market is shaped by a complex interplay of drivers, restraints, opportunities, and broader impact forces that influence its growth trajectory and competitive landscape. A primary driver is the escalating demand for environmentally friendly chemicals and sustainable industrial practices across the globe. Hydrogen peroxide's decomposition into benign products (water and oxygen) makes it a preferred alternative to many conventional, often toxic, organic solvents. This aligns with increasingly stringent environmental regulations and corporate sustainability goals, pushing industries like electronics, water treatment, and pulp and paper to adopt cleaner solvent solutions. Furthermore, the continuous growth in key end-use industries, particularly the booming semiconductor manufacturing sector and the expanding need for advanced wastewater treatment, directly fuels the demand for high-purity hydrogen peroxide as a specialized solvent.

However, the market also faces significant restraints. The relatively high production cost of certain ultra-high purity grades required for advanced solvent applications, coupled with logistical challenges associated with handling and transporting concentrated hydrogen peroxide due to its reactive nature and safety considerations, can impede broader adoption. Fluctuation in raw material prices, such as hydrogen and energy, can also impact manufacturing costs and profitability. Additionally, the availability and continuous development of alternative green solvents or advanced cleaning technologies, while promoting sustainability, could pose a competitive threat to hydrogen peroxide's market share in specific niche applications. Economic downturns or industrial slowdowns in major end-user sectors can also temporarily dampen demand for industrial chemicals like hydrogen peroxide.

Despite these challenges, substantial opportunities exist for market expansion. Emerging applications in green chemistry, particularly in the synthesis of fine chemicals and pharmaceuticals where hydrogen peroxide can act as both a solvent and an oxidant, present significant growth avenues. The rapid technological advancements in semiconductor manufacturing, requiring ever-more precise and residue-free cleaning agents, solidify hydrogen peroxide's role as an indispensable solvent. Furthermore, the increasing global focus on water scarcity and quality issues drives innovation in advanced oxidation processes for industrial and municipal wastewater treatment, where hydrogen peroxide's dual solvent-oxidant properties are highly beneficial. Developing economies, undergoing industrialization and urbanization, also represent untapped markets with growing demand for water treatment, textiles, and basic chemicals, offering long-term growth prospects for hydrogen peroxide solvent applications.

Segmentation Analysis

The Hydrogen Peroxide Solvent Market is intricately segmented across various dimensions, providing a granular view of its diverse applications and market dynamics. This segmentation helps in understanding specific demand patterns, technological requirements, and competitive landscapes within distinct market niches. Key segmentation categories include the grade or concentration of hydrogen peroxide, its specific application as a solvent, the end-use industry utilizing it, and the manufacturing process employed, each reflecting unique value propositions and market drivers.

- By Grade/Concentration

- Technical Grade

- Food Grade

- Cosmetic Grade

- Electronic Grade

- Medical Grade

- Reagent Grade

- By Application

- Bleaching (Pulp & Paper, Textiles)

- Disinfectant/Antiseptic

- Oxidizer

- Solvent (Environmental Remediation, Chemical Synthesis, Electronics Cleaning, Surface Treatment)

- Etching Agent

- Sterilant

- Decontaminant

- By End-Use Industry

- Pulp & Paper

- Textile

- Water Treatment (Industrial, Municipal)

- Chemical Industry (Specialty Chemicals, Pharma)

- Electronics & Semiconductor

- Healthcare & Personal Care

- Food & Beverages

- Mining

- Environmental (Soil Remediation, Air Treatment)

- By Manufacturing Process

- Anthraquinone Auto-oxidation Process

- Electrolysis Process

- Direct Synthesis Process

- Peroxide from Hydrogen and Oxygen

Value Chain Analysis For Hydrogen Peroxide Solvent Market

The value chain for the Hydrogen Peroxide Solvent Market begins with the upstream sourcing of crucial raw materials, primarily hydrogen, oxygen, and derivatives of anthraquinone (for the dominant auto-oxidation process), or other catalysts for alternative synthesis methods. Key suppliers in the upstream segment focus on ensuring a stable and cost-effective supply of these foundational components, often involving industrial gas companies for hydrogen and oxygen, and specialized chemical manufacturers for anthraquinone. Energy, particularly electricity, is also a significant input cost, impacting the overall production economics. Efficiency in raw material conversion and energy management at the manufacturing stage is critical for producers to maintain competitive pricing and profitability.

Further along the value chain, the hydrogen peroxide is produced and then refined into various grades and concentrations, including technical, food, cosmetic, electronic, and medical grades, each tailored for specific solvent applications. This processing involves purification, stabilization, and concentration steps to meet stringent quality standards, especially for high-purity solvent applications in electronics and healthcare. Downstream analysis reveals a diverse customer base spanning multiple industries, each with unique requirements for hydrogen peroxide as a solvent. These include semiconductor manufacturers for precision cleaning and etching, pulp and paper mills for delignification and brightening, textile industries for bleaching and desizing, and water treatment facilities for advanced oxidation and pollutant solubilization.

The distribution channel for hydrogen peroxide solvents is multifaceted, involving both direct sales and indirect channels. Large-volume industrial consumers, such as major chemical companies or semiconductor fabs, often engage in direct supply agreements with hydrogen peroxide manufacturers, ensuring consistent supply and technical support. Indirect channels, involving a network of specialized chemical distributors and logistics providers, cater to smaller or geographically dispersed customers. These distributors play a crucial role in breaking bulk, providing regional warehousing, and offering specialized transportation and handling services for hydrogen peroxide, which is classified as a hazardous material. The efficiency and safety of this distribution network are paramount, impacting product availability, cost-effectiveness, and customer satisfaction across the entire market.

Hydrogen Peroxide Solvent Market Potential Customers

Potential customers for hydrogen peroxide in its solvent applications span a wide array of industrial sectors, each leveraging its unique properties for specific cleaning, dissolving, or reaction medium requirements. The electronics and semiconductor industry represents a significant and growing customer base, where ultra-high purity hydrogen peroxide is indispensable for precision cleaning of silicon wafers, etching photoresists, and preparing surfaces before deposition. Manufacturers of memory chips, processors, and other microelectronic components rely on its ability to remove organic and metallic contaminants without leaving harmful residues, which is critical for device performance and yield.

Another major segment comprises the water and wastewater treatment industries. Municipalities and industrial facilities increasingly utilize hydrogen peroxide as a solvent and oxidant in advanced oxidation processes (AOPs) to break down and solubilize persistent organic pollutants, remove odors, and disinfect water. Its efficacy in dissolving complex organic compounds and enhancing biodegradability makes it a valuable tool for environmental remediation efforts, catering to concerns about water scarcity and quality. Furthermore, the chemical manufacturing sector uses hydrogen peroxide as a green solvent in various synthesis reactions, particularly in the production of epoxides, caprolactam, and propylene oxide, aligning with sustainable chemistry principles.

Beyond these core industries, the healthcare and personal care sectors are significant buyers, employing medical-grade hydrogen peroxide as a solvent for sterilizing medical devices, disinfecting surfaces, and as an active ingredient in various antiseptic solutions. Food and beverage processors use it for sterile packaging and as a disinfectant, leveraging its non-toxic decomposition. The pulp and paper industry also remains a foundational customer, though primarily for its bleaching properties, its role in dissolving lignin enhances its overall utility. Lastly, research institutions and laboratories represent a consistent demand source for reagent-grade hydrogen peroxide for various analytical and experimental solvent applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.2 Billion |

| Market Forecast in 2033 | USD 4.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Arkema S.A., Evonik Industries AG, Solvay S.A., FMC Corporation, BASF SE, Kemira Oyj, Aditya Birla Chemicals, Hansol Chemical, Mitsubishi Gas Chemical Company Inc., National Peroxide Limited, Gujarat Alkalies and Chemicals Limited, Thai Peroxide Co. Ltd., OCI Company Ltd., Nouryon, Hawkins, Inc., S.P.C.P. (Changshu) Co., Ltd., Christeyns, Shandong Huatai Paper Co., Ltd., China National Chemical Corporation (ChemChina), Dongguan City Dongpu Chemical Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Hydrogen Peroxide Solvent Market Key Technology Landscape

The key technology landscape for the Hydrogen Peroxide Solvent Market is characterized by a blend of established industrial processes and emerging innovative methods, all aimed at enhancing production efficiency, purity, and sustainability. The dominant technology remains the anthraquinone auto-oxidation (AO) process, which accounts for the vast majority of global hydrogen peroxide production. This multi-step process involves the hydrogenation of an anthraquinone derivative, followed by oxidation with air to yield hydrogen peroxide and regenerate the anthraquinone derivative. While highly established, continuous research focuses on optimizing catalyst performance, improving energy efficiency, and reducing solvent losses to enhance its environmental and economic profile, especially for producing high-purity grades required for solvent applications.

Beyond the conventional AO process, significant technological advancements are being made in direct synthesis methods, which represent a greener and potentially more cost-effective alternative. Direct synthesis involves reacting hydrogen and oxygen directly to form hydrogen peroxide, typically over a precious metal catalyst (e.g., palladium, gold) in a solvent medium. This technology promises to eliminate the need for complex anthraquinone derivatives and large-scale infrastructure, potentially enabling on-site production and reducing transportation costs and risks. Challenges remain in achieving high selectivity, stability, and catalyst longevity, but ongoing R&D is progressively overcoming these hurdles, indicating its future prominence, particularly for specialized, high-purity solvent markets.

Furthermore, advanced purification techniques are crucial for hydrogen peroxide used in solvent applications, especially in the electronics and medical sectors. Technologies such as distillation, ion exchange, and membrane filtration are employed to remove impurities, organic residues, and metallic contaminants, ensuring the ultra-high purity required for sensitive processes like semiconductor wafer cleaning. Innovations in stabilization technologies are also vital to prevent decomposition during storage and transport, maintaining product efficacy. Additionally, the development of specialized equipment for on-site generation, particularly relevant for smaller-scale or remote applications, contributes to the evolving technological ecosystem, offering enhanced flexibility and reduced logistics for end-users requiring hydrogen peroxide as a solvent.

Regional Highlights

- North America: A mature market driven by stringent environmental regulations and high demand from the electronics, chemical, and water treatment sectors. Innovation in sustainable chemistry and advanced manufacturing processes fuel the need for high-purity hydrogen peroxide solvents.

- Europe: Characterized by strong regulatory support for green chemicals and significant investment in R&D for sustainable technologies. The region's focus on circular economy principles and advanced industrial applications, particularly in pharmaceuticals and specialty chemicals, boosts demand for hydrogen peroxide as an eco-friendly solvent.

- Asia Pacific (APAC): The largest and fastest-growing market, propelled by rapid industrialization, burgeoning electronics manufacturing (semiconductors), and increasing investments in water treatment infrastructure in countries like China, India, South Korea, and Japan. Economic expansion and rising environmental awareness drive the adoption of hydrogen peroxide solvents.

- Latin America: An emerging market with growing industrial activities, particularly in pulp & paper, mining, and water treatment. Increasing environmental concerns and infrastructure development are creating new opportunities for hydrogen peroxide solvent applications.

- Middle East and Africa (MEA): Showing nascent growth in demand, primarily linked to industrial diversification, expanding chemical manufacturing bases, and growing investment in water purification projects. Regional development initiatives are expected to gradually increase the uptake of hydrogen peroxide as a versatile solvent.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Hydrogen Peroxide Solvent Market.- Arkema S.A.

- Evonik Industries AG

- Solvay S.A.

- FMC Corporation

- BASF SE

- Kemira Oyj

- Aditya Birla Chemicals

- Hansol Chemical

- Mitsubishi Gas Chemical Company Inc.

- National Peroxide Limited

- Gujarat Alkalies and Chemicals Limited

- Thai Peroxide Co. Ltd.

- OCI Company Ltd.

- Nouryon

- Hawkins, Inc.

- S.P.C.P. (Changshu) Co., Ltd.

- Christeyns

- Shandong Huatai Paper Co., Ltd.

- China National Chemical Corporation (ChemChina)

- Dongguan City Dongpu Chemical Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Hydrogen Peroxide Solvent market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications of hydrogen peroxide as a solvent?

Hydrogen peroxide is primarily utilized as a solvent in specialized applications such as precision cleaning and etching in the electronics and semiconductor industry, advanced oxidation processes for wastewater treatment to solubilize pollutants, and as a reaction medium in green chemical synthesis. Its ability to dissolve specific organic and inorganic compounds, coupled with its non-toxic decomposition, makes it valuable for environmentally sensitive processes.

Why is hydrogen peroxide considered a 'green' solvent?

Hydrogen peroxide is considered a green solvent because its decomposition products are water and oxygen, which are non-toxic and environmentally benign. This contrasts sharply with many traditional organic solvents that are often volatile, flammable, or toxic, contributing to air and water pollution. Its use helps reduce the environmental footprint of industrial processes.

What purity grades of hydrogen peroxide are critical for solvent applications?

For solvent applications, particularly in high-tech industries, ultra-high purity grades like Electronic Grade and Medical Grade hydrogen peroxide are critical. These grades undergo extensive purification to remove metallic ions, organic impurities, and other contaminants that could interfere with sensitive processes such as semiconductor manufacturing or pharmaceutical production, ensuring optimal performance and preventing damage to delicate components.

How does AI impact the efficiency and safety of hydrogen peroxide solvent production and use?

AI significantly enhances efficiency by optimizing manufacturing processes, predicting equipment maintenance needs, and improving quality control for specific solvent grades. For safety, AI-powered systems can monitor storage conditions, detect potential hazards in real-time, and provide predictive risk assessments, thereby mitigating the inherent risks associated with handling concentrated hydrogen peroxide solutions.

What are the key drivers for the growth of the hydrogen peroxide solvent market?

The key drivers include increasing global demand for eco-friendly chemicals and sustainable industrial practices, stringent environmental regulations pushing for cleaner solvent alternatives, the rapid expansion of high-tech industries like electronics and semiconductor manufacturing, and the growing need for advanced water treatment solutions. These factors collectively stimulate demand for hydrogen peroxide's unique solvent properties.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager