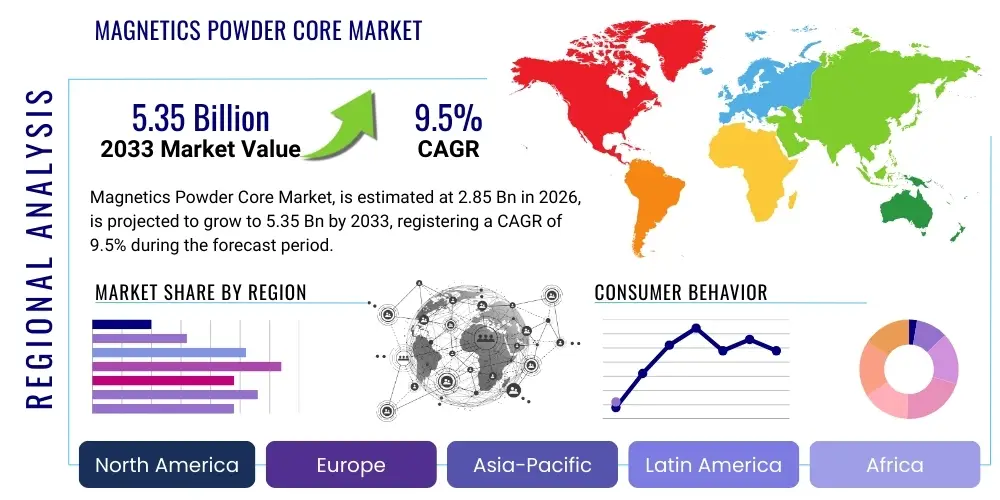

Magnetics Powder Core Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439523 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Magnetics Powder Core Market Size

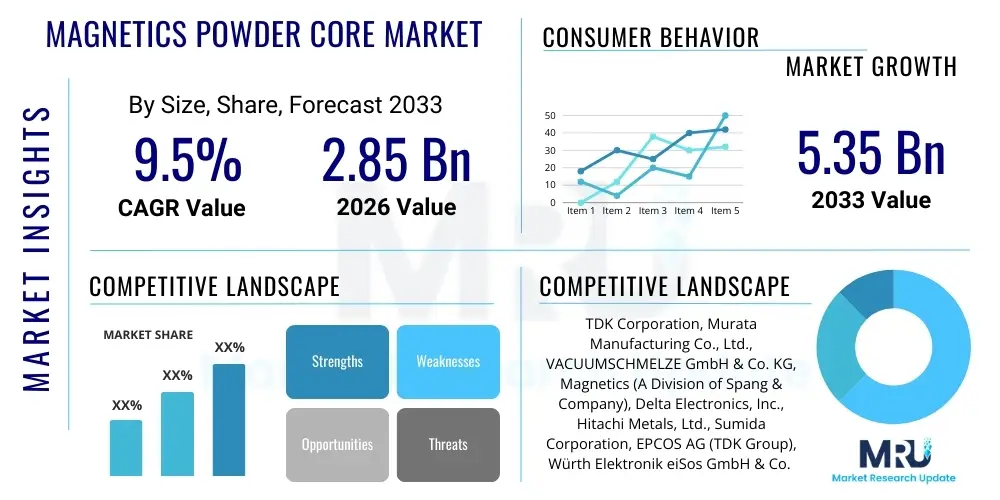

The Magnetics Powder Core Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2026 and 2033. The market is estimated at USD 2.85 billion in 2026 and is projected to reach USD 5.35 billion by the end of the forecast period in 2033.

Magnetics Powder Core Market introduction

The Magnetics Powder Core Market encompasses a critical segment of the electronics industry, providing essential components for power conversion, energy storage, and electromagnetic interference (EMI) filtering. Magnetics powder cores are composite materials consisting of fine metallic or alloy particles, insulated from each other and compacted into a solid form. This unique structure creates a distributed air gap within the core, which results in a soft magnetic material with excellent magnetic properties, including high saturation flux density, low core losses, and stable permeability across varying temperatures and frequencies. These characteristics make them indispensable in modern power electronics applications where efficiency, reliability, and miniaturization are paramount.

Major applications for magnetics powder cores span across diverse sectors, including automotive electronics, especially in electric vehicles (EVs) and hybrid electric vehicles (HEVs) for onboard chargers and DC-DC converters; consumer electronics such as laptops, smartphones, and gaming consoles for power inductors and chokes; renewable energy systems like solar inverters and wind turbine converters; industrial power supplies and motor drives; and telecommunications infrastructure including 5G base stations. The primary benefits derived from using powder cores include enhanced energy efficiency, reduced component size and weight, improved thermal management, and superior performance in high-frequency switching applications. These benefits directly contribute to the compact, efficient, and robust design of electronic devices across various industries.

The market is driven by several significant factors. The global push for energy efficiency and the stringent regulatory standards for power consumption are compelling manufacturers to adopt high-performance magnetic components. The rapid growth in the electric vehicle market, fueled by environmental concerns and government incentives, is a major catalyst, as EVs heavily rely on efficient power conversion and filtering. Furthermore, the expansion of renewable energy installations worldwide demands sophisticated power management solutions. The proliferation of 5G technology, IoT devices, and data centers also contributes substantially to market growth, as these technologies require highly reliable and compact power management systems, where magnetics powder cores play a vital role in ensuring optimal performance and stability.

Magnetics Powder Core Market Executive Summary

The Magnetics Powder Core Market is experiencing robust growth driven by the accelerating demand for energy-efficient power conversion solutions across various high-growth industries. Key business trends indicate a strong focus on material innovation, with manufacturers investing heavily in developing advanced alloy powder materials and composite structures that offer higher saturation, lower core losses, and improved temperature stability. There is also a discernible trend towards customization, as end-use industries require tailor-made magnetic components to meet specific performance requirements and form factors for increasingly complex electronic designs. Strategic partnerships and mergers and acquisitions are also playing a role in market consolidation and expanding technological capabilities among leading players, enhancing their competitive edge and market reach.

Regionally, the Asia Pacific continues to dominate the global magnetics powder core market, primarily due to the region's status as a manufacturing hub for consumer electronics, automotive components, and renewable energy equipment, particularly in countries like China, Japan, South Korea, and Taiwan. North America and Europe are also exhibiting significant growth, propelled by the increasing adoption of electric vehicles, advancements in industrial automation, and substantial investments in data center infrastructure and advanced power electronics research and development. Emerging economies in Latin America and the Middle East & Africa are showing nascent but promising growth, driven by infrastructure development and increasing industrialization, suggesting future expansion opportunities for market players seeking diversification.

In terms of segment trends, the market for high-frequency and high-flux powder cores is witnessing accelerated demand, especially for applications in DC-DC converters and power factor correction circuits that operate at higher switching frequencies. Iron powder cores remain a foundational segment due to their cost-effectiveness and versatility, while advanced alloy powder cores such as Sendust, MPP (Molybdenum Permalloy Powder), and High Flux materials are gaining traction owing to their superior performance characteristics crucial for high-efficiency, high-power-density applications. The automotive and renewable energy sectors are the fastest-growing end-use segments, demanding higher volumes of specialized magnetics powder cores designed to withstand harsh operating conditions and ensure long-term reliability in critical systems. This ongoing evolution in material science and application-specific demands underscores the dynamic nature of the market.

AI Impact Analysis on Magnetics Powder Core Market

User questions regarding AI's impact on the Magnetics Powder Core Market frequently center on how artificial intelligence can revolutionize the design, manufacturing, and application of these critical components. Common inquiries probe into AI's role in optimizing material properties, accelerating product development, enhancing manufacturing efficiency, and creating new demand avenues through its integration into advanced electronic systems. Users are keenly interested in understanding if AI can lead to the discovery of novel magnetic materials, improve the precision and quality of core production, enable predictive maintenance in production lines, and drive the need for specialized magnetic cores in AI hardware, such as data centers and edge computing devices. The overarching themes suggest an expectation that AI will bring about significant advancements in performance, cost-effectiveness, and new market opportunities within the magnetics industry.

- AI-driven material discovery and optimization: AI algorithms can analyze vast datasets of material properties to predict and design new magnetic alloys with superior characteristics, such as higher saturation, lower losses, and improved temperature stability, significantly shortening R&D cycles for advanced powder cores.

- Enhanced manufacturing process control: AI and machine learning can be integrated into powder core manufacturing processes for real-time monitoring, predictive maintenance, and adaptive control, optimizing parameters like pressing force, sintering temperature, and coating thickness, leading to higher yield, consistent quality, and reduced waste.

- Optimized core design for specific applications: AI tools can simulate and optimize the geometric and material properties of powder cores for specific end-use applications (e.g., EV chargers, 5G base stations) to maximize efficiency, minimize size, and reduce heat generation, leading to custom solutions tailored for peak performance.

- Predictive analytics for supply chain management: AI can forecast demand fluctuations, optimize inventory levels, identify potential supply chain disruptions, and manage raw material procurement more efficiently, ensuring a stable and cost-effective supply of materials for powder core production.

- Increased demand from AI hardware: The proliferation of AI accelerators, high-performance computing (HPC) systems, data centers, and edge AI devices creates a growing demand for highly efficient and compact power management components, including specialized magnetics powder cores, to power these energy-intensive systems.

- Improved quality assurance and fault detection: AI-powered vision systems and data analytics can perform rapid and precise quality inspections of powder cores, identifying defects that might be missed by traditional methods, thereby enhancing overall product reliability and reducing warranty claims.

- Acceleration of product development cycles: By automating simulation, testing, and optimization processes, AI enables faster iteration and validation of new powder core designs, bringing innovative products to market more quickly and responsively to evolving industry demands.

DRO & Impact Forces Of Magnetics Powder Core Market

The Magnetics Powder Core Market is influenced by a dynamic interplay of drivers, restraints, opportunities, and external impact forces. A primary driver is the burgeoning demand for highly efficient power conversion systems across various sectors, including electric vehicles (EVs), renewable energy infrastructure, and 5G telecommunications. The global imperative to reduce energy consumption and meet stringent environmental regulations also compels industries to adopt advanced magnetic materials that minimize energy losses. Furthermore, the ongoing trend towards miniaturization in electronic devices necessitates compact, high-performance magnetic components that can operate effectively in limited spaces while delivering optimal power density and thermal management. These factors collectively create a robust demand landscape for magnetics powder cores, positioning them as essential components in modern electronics.

Despite significant growth drivers, the market faces several restraints. Volatility in the prices and availability of key raw materials such as iron, nickel, molybdenum, and cobalt can impact manufacturing costs and supply chain stability, posing challenges for producers. The complex and energy-intensive manufacturing processes involved in producing high-quality powder cores, including powder metallurgy and precise heat treatments, require substantial capital investment and specialized expertise, which can limit market entry for new players and pressure profit margins. Additionally, competition from alternative magnetic materials, while often not directly interchangeable for all applications, can present a threat in certain segments, requiring continuous innovation from powder core manufacturers. Design challenges associated with achieving very high-frequency operation while maintaining low losses also represent a technical hurdle that manufacturers must consistently address.

Opportunities within the market are abundant, particularly in the development of novel materials and advanced composite structures that offer even better performance characteristics, such as ultra-low core losses and higher saturation flux densities at elevated frequencies and temperatures. Emerging applications in advanced power systems, wireless charging technologies for consumer electronics and EVs, smart grid infrastructure, and medical devices present new avenues for market expansion. The increasing adoption of gallium nitride (GaN) and silicon carbide (SiC) power semiconductors, which enable higher switching frequencies, creates a strong pull for compatible magnetics powder cores capable of operating efficiently under these advanced conditions. Geographically, untapped emerging markets, particularly in developing economies with growing industrialization and electrification needs, also offer significant growth prospects for manufacturers willing to invest in regional expansion.

Impact forces on the market include technological advancements, which constantly redefine performance benchmarks and open new application possibilities for magnetics powder cores. Economic shifts, such as global economic growth rates, industrial output, and consumer spending patterns, directly influence demand for electronics across end-use sectors. Environmental regulations, particularly those related to energy efficiency and material sustainability, necessitate continuous innovation in greener manufacturing processes and more eco-friendly materials. Geopolitical factors, including trade policies, tariffs, and international relations, can affect raw material sourcing, manufacturing locations, and global supply chains, thereby influencing market dynamics. These external forces require market participants to remain agile and adaptable in their strategies to maintain competitiveness and seize new opportunities.

Segmentation Analysis

The Magnetics Powder Core Market is comprehensively segmented to provide a detailed understanding of its diverse landscape, categorizing products and applications based on material type, end-use industry, and specific functionalities. This segmentation allows for a granular analysis of market trends, growth drivers, and competitive dynamics within each sub-segment, aiding manufacturers in strategic planning and product development. By dissecting the market along these lines, stakeholders can identify niche opportunities, understand specific customer needs, and tailor their offerings to address the unique requirements of different industrial applications, ranging from high-power automotive systems to sensitive medical electronics.

- By Material Type

- Iron Powder Cores

- Sendust (Kool Mµ) Cores

- MPP (Molybdenum Permalloy Powder) Cores

- High Flux Cores

- Alloy Powder Cores (e.g., XFlux, High-Perm)

- Ferrite Cores (sometimes included for comparative analysis due to similar applications but distinct material properties)

- Composite Powder Cores

- By Application

- Inductors (Power Inductors, SMD Inductors)

- Chokes (Common Mode Chokes, Differential Mode Chokes)

- Transformers (Pulse Transformers, Flyback Transformers)

- EMI/RFI Filters

- Power Factor Correction (PFC) Inductors

- Energy Storage

- Current Sensors

- By End-Use Industry

- Automotive (EV/HEV, Infotainment, Engine Control Units)

- Consumer Electronics (Smartphones, Laptops, TVs, Gaming Consoles)

- Industrial (Motor Drives, Power Supplies, Automation Equipment, Robotics)

- Renewable Energy (Solar Inverters, Wind Power Converters, Energy Storage Systems)

- Telecommunications (5G Base Stations, Data Centers, Networking Equipment)

- Medical Devices (Imaging Equipment, Diagnostic Tools)

- Aerospace and Defense

- LED Lighting

Value Chain Analysis For Magnetics Powder Core Market

The value chain for the Magnetics Powder Core Market begins with the upstream sourcing of critical raw materials. This stage involves the extraction and processing of various metals and alloys, including iron, nickel, molybdenum, silicon, aluminum, and cobalt, which form the base powders. These raw materials undergo meticulous purification and pulverization processes to achieve the required particle size and purity necessary for manufacturing high-performance magnetic cores. The quality and consistency of these initial materials are paramount, as they directly influence the magnetic properties and overall performance of the final powder core product. Key players in this segment include specialized metal and alloy suppliers who provide these refined powders to core manufacturers, ensuring the foundational quality for the entire production process.

Further along the value chain, these processed powders are then supplied to magnetics powder core manufacturers. These manufacturers employ sophisticated powder metallurgy techniques, involving processes such as mixing the various metallic powders with insulating binders, compacting them under high pressure into desired shapes (toroids, E-cores, block cores), and subsequently subjecting them to specialized heat treatments (annealing, sintering). Advanced coating technologies are also often applied to the cores to enhance insulation and manage thermal properties. This stage is highly technology-intensive, requiring significant investment in machinery, process control, and material science expertise to produce cores with precise magnetic characteristics, minimal losses, and robust mechanical integrity. Innovation at this stage, particularly in material composition and manufacturing processes, is critical for competitive advantage.

The downstream segment of the value chain involves the integration of these magnetics powder cores into finished electronic components and systems. This includes component manufacturers who use powder cores to produce inductors, chokes, transformers, and EMI filters. These components are then supplied to original equipment manufacturers (OEMs) across various end-use industries such as automotive, consumer electronics, industrial automation, renewable energy, and telecommunications. Distribution channels for magnetics powder cores and the components they enable are multifaceted, encompassing both direct sales from core manufacturers to large-volume OEM customers and indirect channels through a network of specialized distributors and electronic component suppliers. Direct channels facilitate close collaboration on custom designs, while indirect channels provide broader market reach and support for smaller volume orders or diverse product ranges. Both channels are vital for ensuring efficient market penetration and meeting varied customer demands globally.

Magnetics Powder Core Market Potential Customers

The potential customers for magnetics powder cores are diverse and span across nearly every sector of modern electronics, driven by the universal need for efficient power management, signal integrity, and electromagnetic compatibility. Fundamentally, any industry or application that relies on power conversion, energy storage, or filtering of electrical signals represents a potential buyer. These customers are typically manufacturers or integrators of electronic systems that require inductors, chokes, and transformers to function optimally. The increasing complexity and performance demands of electronic devices mean that the need for high-quality, application-specific powder cores continues to expand across a broad spectrum of end-user segments. Understanding these key customer groups is crucial for market players to tailor their product development, sales, and marketing strategies effectively to capture maximum market share.

One of the largest segments of potential customers includes manufacturers in the automotive industry, particularly those involved in developing electric vehicles (EVs), hybrid electric vehicles (HEVs), and advanced driver-assistance systems (ADAS). These companies require robust and efficient magnetic components for onboard chargers, DC-DC converters, motor drive inverters, and various control units that must operate reliably under harsh automotive conditions. Another significant customer base resides within the consumer electronics sector, encompassing companies that produce smartphones, laptops, tablets, gaming consoles, smart home devices, and LED lighting. These manufacturers demand compact, high-efficiency powder cores for power inductors, voltage regulators, and EMI filters to ensure the performance, battery life, and miniaturization of their products, meeting consumer expectations for sleek and powerful devices.

Furthermore, the industrial and renewable energy sectors represent substantial potential customers. Industrial equipment manufacturers developing motor drives, industrial power supplies, automation systems, and robotics rely on powder cores for their high-power handling capabilities and stability in demanding environments. In the renewable energy segment, inverter manufacturers for solar power systems, wind turbines, and grid-scale energy storage solutions are critical customers, requiring high-efficiency chokes and inductors that can withstand high currents and voltages while minimizing energy losses. The telecommunications industry, driven by the rollout of 5G infrastructure and the expansion of data centers, also represents a growing customer segment, seeking advanced powder cores for power supplies and filtering in base stations, servers, and networking equipment to ensure reliable and efficient data transmission. Lastly, the medical device industry, aerospace and defense sectors, and specialized power supply manufacturers also constitute important, albeit often niche, customer groups due to their stringent requirements for reliability, precision, and performance in critical applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.85 billion |

| Market Forecast in 2033 | USD 5.35 billion |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | TDK Corporation, Murata Manufacturing Co., Ltd., VACUUMSCHMELZE GmbH & Co. KG, Magnetics (A Division of Spang & Company), Delta Electronics, Inc., Hitachi Metals, Ltd., Sumida Corporation, EPCOS AG (TDK Group), Würth Elektronik eiSos GmbH & Co. KG, Bourns, Inc., Chilisin Electronics Corp., Micrometals, Inc., Cosmo Ferrites Limited, Changsung Corporation, CSC Group (Cosmo Core Technology), POCO Magnetic, Acme Electric Corporation (A Standex Company), Arnold Magnetic Technologies, Dongbu HiTek Co., Ltd., Shenzhen Sunlord Electronics Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Magnetics Powder Core Market Key Technology Landscape

The Magnetics Powder Core Market is characterized by a dynamic and evolving technology landscape, with continuous advancements aimed at enhancing performance, efficiency, and cost-effectiveness. Central to this landscape are sophisticated powder metallurgy techniques, which involve the precise control of powder particle size, shape, and distribution. Innovations in powder production, such as gas atomization and mechanical alloying, enable the creation of highly uniform and fine metallic or alloy powders. These powders are then mixed with specialized insulating binders and compacted using high-pressure presses, followed by carefully controlled heat treatments like annealing and sintering. These processes are critical for achieving the desired magnetic properties, including high saturation flux density, low core loss, and stable permeability, ensuring optimal performance across a wide range of operating conditions and frequencies. The refinement of these core manufacturing processes is a continuous focus for market leaders.

Material science advancements represent another crucial pillar of the technology landscape. Research and development efforts are concentrated on developing novel alloy compositions and composite materials that offer superior magnetic characteristics. This includes the exploration of nanocrystalline and amorphous alloys for higher frequency applications due to their exceptional low-loss properties, as well as the creation of advanced composite powder cores that combine different material types to leverage their individual strengths. For instance, hybrid cores blending metallic alloys with specialized ferrites are emerging to achieve a balance of high saturation and low high-frequency losses. Furthermore, advancements in specialized surface coatings and insulation technologies are vital for reducing eddy current losses, improving thermal management, and enhancing the dielectric strength of the cores, enabling them to operate reliably in high-power and high-temperature environments. These material innovations are directly driven by the demands of new applications like wide-bandgap (WBG) semiconductor-based power converters.

Beyond material and processing techniques, the integration of advanced manufacturing technologies, including automation, robotics, and increasingly, artificial intelligence (AI) and machine learning (ML), is transforming the production of magnetics powder cores. Automated pressing and handling systems enhance precision and throughput, while AI-driven quality control systems can detect microscopic defects and predict equipment failures, leading to higher product consistency and reduced downtime. Simulation and modeling software also play a significant role, allowing engineers to virtually prototype and optimize core designs, material compositions, and manufacturing parameters before physical production, thereby accelerating the product development cycle and reducing R&D costs. The synergy of these technological advancements across materials, processes, and intelligent manufacturing is pivotal in meeting the ever-growing demands for high-performance, miniaturized, and highly reliable magnetics powder cores in an increasingly electrified and interconnected world.

Regional Highlights

- Asia Pacific: The Asia Pacific region stands as the undisputed leader in the Magnetics Powder Core Market, largely due to its robust manufacturing ecosystem for electronics, automotive, and renewable energy sectors. Countries like China, Japan, South Korea, and Taiwan are at the forefront of producing and consuming these cores. China, in particular, benefits from its vast electronics manufacturing base and significant investments in electric vehicle production and renewable energy projects. Japan and South Korea contribute through their advanced material science research and high-quality core manufacturing capabilities, serving both domestic and international markets with innovative products. The region's rapid industrialization, growing disposable income, and increasing adoption of advanced electronic devices further fuel the demand for magnetics powder cores, making it a critical hub for market growth and technological development.

- North America: North America represents a significant and growing market for magnetics powder cores, characterized by high demand for advanced power electronics, electric vehicles, and data center infrastructure. The United States is a key contributor, with strong innovation in aerospace and defense, medical devices, and high-performance computing, all of which require reliable and efficient magnetic components. The push towards electrification in the automotive sector, coupled with substantial investments in renewable energy technologies and the expansion of 5G networks, drives the adoption of sophisticated powder cores. Manufacturers in this region often focus on high-end, custom solutions and specialize in materials that offer superior performance for demanding applications, capitalizing on the robust R&D capabilities present in the region.

- Europe: Europe is another prominent region in the Magnetics Powder Core Market, distinguished by its strong emphasis on industrial automation, automotive (especially electric vehicles), and renewable energy initiatives. Countries like Germany, France, and the UK are major contributors, driven by stringent energy efficiency regulations and a proactive approach to sustainable technologies. The automotive industry in Europe, with its rapid transition to EVs and HEVs, creates substantial demand for high-performance power inductors and chokes. Furthermore, significant investments in wind and solar energy projects across the continent require reliable and efficient magnetic components for power conversion and grid integration. European manufacturers are known for their precision engineering, material innovation, and adherence to high quality standards, serving both regional and global markets.

- Latin America: The Latin American market for magnetics powder cores is an emerging region with considerable growth potential. This growth is primarily spurred by increasing industrialization, infrastructure development, and growing foreign investments in manufacturing and energy sectors. Countries such as Brazil and Mexico are witnessing expanding automotive production (including a nascent EV market), growth in consumer electronics assembly, and increasing deployment of renewable energy projects. While the market size is currently smaller compared to established regions, the ongoing economic development and technological adoption are expected to drive a steady increase in demand for power management components, including magnetics powder cores, over the forecast period, attracting more global players to establish a presence.

- Middle East and Africa (MEA): The Middle East and Africa region is also an emerging market for magnetics powder cores, driven by ongoing economic diversification efforts, significant infrastructure development projects, and growing investments in renewable energy, particularly solar power. Countries in the Gulf Cooperation Council (GCC) are investing heavily in smart city initiatives and industrial expansion, which require advanced electronic components. The increasing electrification efforts and growing adoption of consumer electronics in various African nations also contribute to market demand. While the manufacturing base for electronic components is still developing, the rising need for robust power management solutions in telecom, automotive, and energy sectors presents long-term growth opportunities for magnetics powder core suppliers in the MEA region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Magnetics Powder Core Market.- TDK Corporation

- Murata Manufacturing Co., Ltd.

- VACUUMSCHMELZE GmbH & Co. KG

- Magnetics (A Division of Spang & Company)

- Delta Electronics, Inc.

- Hitachi Metals, Ltd.

- Sumida Corporation

- EPCOS AG (TDK Group)

- Würth Elektronik eiSos GmbH & Co. KG

- Bourns, Inc.

- Chilisin Electronics Corp.

- Micrometals, Inc.

- Cosmo Ferrites Limited

- Changsung Corporation

- CSC Group (Cosmo Core Technology)

- POCO Magnetic

- Acme Electric Corporation (A Standex Company)

- Arnold Magnetic Technologies

- Dongbu HiTek Co., Ltd.

- Shenzhen Sunlord Electronics Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Magnetics Powder Core market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are magnetics powder cores?

Magnetics powder cores are composite magnetic materials made from fine metallic or alloy particles, insulated from each other and compacted into a solid form. Their unique structure creates a distributed air gap, providing stable magnetic properties such as high saturation flux density, low core losses, and consistent permeability across various frequencies and temperatures, making them ideal for efficient power conversion and filtering in electronic circuits.

Why are magnetics powder cores important in modern electronics?

They are crucial for enhancing the efficiency, reliability, and miniaturization of modern electronic devices. By enabling high-efficiency power conversion, reducing heat generation, and providing effective EMI filtering, powder cores facilitate the development of compact, powerful, and energy-efficient electronics essential for applications ranging from electric vehicles and renewable energy systems to consumer electronics and 5G infrastructure.

What are the primary applications of magnetics powder cores?

Magnetics powder cores are primarily used in power inductors, chokes (common mode and differential mode), transformers, and EMI/RFI filters. Their applications span across diverse industries including automotive electronics (EV/HEV), consumer electronics (smartphones, laptops), renewable energy (solar inverters), industrial power supplies, telecommunications (5G base stations), and medical devices, where stable and efficient magnetic components are vital.

What key factors are driving the growth of the Magnetics Powder Core Market?

The market's growth is predominantly driven by the escalating global demand for energy-efficient power electronics, the rapid expansion of the electric vehicle market, increasing investments in renewable energy infrastructure, the widespread rollout of 5G technology and IoT devices, and the continuous trend towards miniaturization and higher performance in electronic systems. Stringent energy efficiency regulations also play a significant role in promoting their adoption.

How is AI impacting the Magnetics Powder Core Market?

AI is significantly impacting the market by enabling advanced material discovery and optimization, enhancing manufacturing process control for higher quality and efficiency, accelerating core design and simulation, improving supply chain management through predictive analytics, and creating new demand for specialized cores in AI-specific hardware like data centers and edge computing devices. AI helps in achieving superior performance, faster development cycles, and cost efficiencies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- High Flux Magnetics Powder Core Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- High Flux Magnetics Powder Core Market Statistics 2025 Analysis By Application (New Energy, Automobile Industry, Consumer Electronic, Telecommunication), By Type (26 High Flux, 60 High Flux, 125 High Flux, 147 High Flux, 160 High Flux), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager