Mini Excavator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432137 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Mini Excavator Market Size

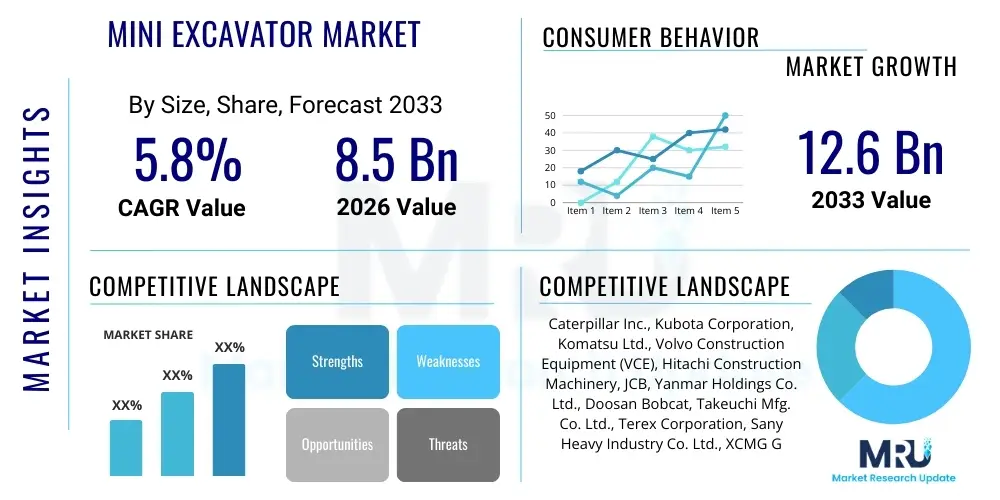

The Mini Excavator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 8.5 Billion in 2026 and is projected to reach USD 12.6 Billion by the end of the forecast period in 2033. This consistent expansion is fundamentally driven by accelerated urbanization trends in developing economies, coupled with increased focus on infrastructure renewal and maintenance projects across established markets in North America and Europe. The compact size and versatility of these machines—typically defined as weighing less than six metric tons—make them indispensable for tasks constrained by space, contributing significantly to their steady market penetration across diverse end-user segments.

Mini Excavator Market introduction

The Mini Excavator Market encompasses specialized construction equipment designed for high maneuverability and operational efficiency in confined spaces, characterized primarily by operating weights ranging from 0.8 to 6 metric tons. These robust machines are integral to modern construction methodologies, offering superior digging, trenching, demolition, and material handling capabilities compared to manual labor or larger, less agile equipment. Key applications span residential and commercial construction, utility installation (water, gas, fiber optics), landscaping, demolition work, and agricultural projects requiring soil preparation or drainage solutions. The inherent benefits include reduced operating costs, enhanced productivity on small-to-mid-sized job sites, lower transportation logistics, and compliance with increasingly stringent urban noise and emission regulations, particularly favoring electric and hybrid models in sensitive areas.

The core driving factors fueling sustained market expansion include significant governmental investments in national infrastructure development, particularly road networks, public housing, and smart city initiatives that require precision excavation. Furthermore, the global trend towards equipment rental, offering construction firms flexible access to capital-intensive machinery without long-term investment commitments, lowers the barrier to entry for smaller contractors, thereby boosting overall demand. Technological advancements, such as advanced telematics systems for remote diagnostics and predictive maintenance, coupled with the integration of ergonomic operator cabins and safety features like proximity sensors, continue to enhance machine appeal and operational lifespan, cementing the mini excavator’s role as a primary tool for modern site preparation and utility work.

Mini excavators provide a critical balance between power and footprint, making them essential in densely populated urban areas where traditional heavy machinery is impractical. Their design often incorporates zero or reduced tail swing characteristics, drastically minimizing the risk of damage in tight operational envelopes, which is a major benefit for utility contractors working adjacent to existing infrastructure. The versatility offered through quick coupler systems allows operators to rapidly interchange attachments—such as hydraulic hammers, augers, buckets, and graders—transforming the machine for multi-purpose roles on a single job site. This adaptability not only increases asset utilization rates but also significantly improves project timelines and resource allocation, reinforcing the market’s reliance on these compact powerhouses for intricate civil engineering and landscaping projects worldwide.

Mini Excavator Market Executive Summary

The global Mini Excavator Market Executive Summary indicates a strong trajectory characterized by pivotal shifts towards sustainability and digital integration, primarily reflected in the increased adoption of electric powertrains and sophisticated telematics platforms. Business trends show consolidation among major Original Equipment Manufacturers (OEMs) focused on expanding their rental fleet presence and developing specialized, high-efficiency models targeting specific niche applications, such as heavy-duty demolition or highly sensitive infrastructure repairs. Competitive strategies emphasize total cost of ownership (TCO) improvements through superior fuel efficiency, extended service intervals, and enhanced predictive maintenance capabilities derived from onboard diagnostic systems. Furthermore, market participants are heavily investing in expanding distribution networks and localized service support to address the diverse needs of regional contractors, who increasingly prioritize immediate parts availability and minimal downtime.

Regionally, the Asia Pacific (APAC) stands out as the primary engine of growth, underpinned by rapid, large-scale urbanization projects, particularly in China and India, necessitating vast quantities of compact equipment for residential and commercial construction. North America and Europe, while mature markets, demonstrate robust demand driven by the replacement cycle of aging fleets, coupled with stringent environmental regulations (like the EU's Stage V emissions standards) that necessitate the procurement of newer, cleaner equipment. Specific regional trends include a stronger uptake of electric mini excavators in European city centers due to zero-emission mandates, whereas North America sees higher demand for models in the 3.5 to 6 metric ton segment, often tailored for residential construction and utility burial projects demanding greater hydraulic power and reach.

Segmentation analysis reveals that the 3.0 to 4.0 Metric Ton segment dominates the market due to its optimal balance of power, transportability, and job site flexibility, appealing to a wide array of general contractors. However, the sub-1.0 Metric Ton segment is experiencing the fastest growth rate, fueled by specialized interior demolition projects and extremely limited access job sites where even standard mini excavators cannot operate. In terms of technology, the integration of advanced hydraulic systems allowing for smoother, more precise operation is a key segment trend, alongside the growing prominence of attachment-based revenue streams. The shift from basic machines to highly sophisticated, interconnected job site assets underscores a fundamental transformation in how construction firms approach productivity and site management, making technological features paramount in purchasing decisions.

AI Impact Analysis on Mini Excavator Market

Analysis of common user questions regarding AI's impact on the Mini Excavator Market reveals significant interest centered around three key themes: autonomous operation capabilities, predictive maintenance accuracy, and optimization of fleet management logistics. Users frequently ask: "When will fully autonomous mini excavators be commonplace?", "How accurate is AI-driven diagnostics in predicting component failure?", and "Can AI systems truly improve job site efficiency and material movement planning?" The prevailing expectation is that AI will rapidly transition mini excavators from manual tools to intelligent, integrated robotic assets. Key concerns revolve around the initial cost of adopting these systems, the security of transmitted operational data, and the requisite upskilling of maintenance personnel and operators to effectively utilize these sophisticated technologies.

The summary indicates that stakeholders view AI integration not merely as an incremental upgrade but as a fundamental disruptor set to enhance safety, efficiency, and sustainability. The ability of AI to process vast amounts of telematics data—including engine load, fuel consumption, hydraulic pressure cycles, and operational location—allows for unprecedented levels of predictive analytics. This moves maintenance from reactive or time-based scheduling to precise, condition-based interventions, significantly reducing unplanned downtime and optimizing component lifecycles. Furthermore, AI algorithms are being deployed to analyze job site requirements in real-time, providing operators with optimal digging patterns and cycle times, thereby maximizing material moved per hour and reducing overall fuel consumption, which addresses both productivity and environmental targets.

Looking ahead, the influence of AI will extend deeply into safety protocols and operator assistance systems. Machine Learning (ML) models trained on historical operational data can detect patterns indicative of operator fatigue or unsafe practices, triggering alerts or temporarily limiting high-risk movements. This enhancement in operational safety is crucial, particularly on dynamic and crowded construction sites. Ultimately, the successful implementation of AI hinges on standardized data protocols and collaborative efforts between equipment manufacturers and technology providers to ensure seamless integration and user-friendly interfaces, driving confidence in the reliability of automated assistance and future autonomous features.

- AI-driven Predictive Maintenance: Enhances uptime by accurately forecasting component failure based on real-time operational data analysis.

- Optimized Operational Efficiency: Algorithms suggest ideal digging depths, boom angles, and cycle times, reducing fuel burn and accelerating project completion.

- Semi-Autonomous Functions: Enables precision grading, trenching, and complex repetitive tasks with minimal operator intervention, improving consistency.

- Enhanced Site Safety: Uses computer vision and AI processing to detect obstacles, personnel, and potential collision zones, increasing situational awareness.

- Fleet Utilization Optimization: AI models analyze historical usage patterns across entire fleets to recommend optimal machine allocation and scheduling for profitability.

DRO & Impact Forces Of Mini Excavator Market

The Mini Excavator Market is heavily influenced by a dynamic interplay of Drivers, Restraints, and Opportunities, collectively forming the key impact forces shaping its trajectory. Primary drivers center around the global acceleration of infrastructure investment and the persistent demand for compact, versatile equipment for urban renewal and utility work. Restraints include the volatility of raw material prices, particularly steel and specialized alloys, which impact manufacturing costs, alongside the scarcity of skilled labor required to operate and maintain sophisticated modern machinery. Opportunities are significantly clustered around technological innovation, including the rapid commercialization of electric and hybrid excavators, alongside expansion into specialized application markets like highly localized site preparation for modular construction. These forces create a complex operational environment where successful market penetration requires strategic cost management combined with aggressive technological leadership and compliance with increasingly stringent environmental and safety regulations globally.

A major driving force is the rapid pace of residential and commercial construction, particularly post-pandemic recoveries and housing shortages in developed nations, requiring compact equipment capable of working within existing dense structures and restricted garden spaces. Furthermore, regulatory support and incentives for emissions reduction actively propel the demand for new equipment, forcing obsolescence in older, less compliant fleets. The sheer versatility provided by the mini excavator’s extensive range of hydraulically powered attachments significantly expands its utility beyond simple digging, encompassing everything from concrete breaking to material sorting, thereby guaranteeing consistent utility across various phases of a construction project and justifying the capital expenditure for contractors.

Conversely, significant restraints manifest in the economic volatility affecting consumer confidence and construction financing, especially in emerging markets where capital availability is often sensitive to geopolitical events. The specialized nature of the components required for advanced systems, such as precise hydraulic valves and complex electronic control units (ECUs), subjects manufacturers to global supply chain disruptions, impacting production timelines and increasing final product cost. Despite these constraints, the overarching opportunities presented by digital transformation, specifically through telematics, remote diagnostics, and the integration of Building Information Modeling (BIM) data directly into machine operation, offer pathways for differentiation and improved customer value proposition. The transition towards sustainable construction practices further opens avenues for manufacturers who prioritize low-carbon equipment solutions, effectively turning regulatory pressure into a market advantage.

Segmentation Analysis

The Mini Excavator Market is primarily segmented based on Operating Weight, which directly correlates with machine power and typical application, and by End-User, defining the primary industries utilizing the equipment. Secondary segmentation includes Technology (Traditional Diesel, Electric/Hybrid) and Sales Channel (Direct Sales, Dealers, Rental Fleets). Analyzing these segments provides strategic insights into demand distribution, key growth areas, and required technological investment. The operating weight segmentation is crucial for understanding specific job site needs, with lighter models targeting indoor and landscaping tasks, while heavier models in the 4-6 metric ton range serve light demolition and large utility installations requiring deeper trenching and higher breakout force. The increasing preference for rental solutions across all weight categories highlights the market's shift towards operational expenditure models over outright capital investment for many smaller and mid-sized contractors globally.

- By Operating Weight:

- Below 1 Metric Ton (Micro Excavators)

- 1 to 2 Metric Tons

- 2 to 3 Metric Tons

- 3 to 4 Metric Tons (Dominant Segment)

- 4 to 5 Metric Tons

- 5 to 6 Metric Tons

- By Application:

- Construction (Residential, Commercial, Infrastructure)

- Utility and Road Works

- Landscaping and Agriculture

- Mining and Quarrying (Limited Use)

- Others (e.g., Waste Management, Forestry)

- By Technology:

- Traditional Diesel Engine

- Electric and Hybrid Power Trains

- By End-User:

- Contractors (General and Specialized)

- Rental Companies (High Growth Segment)

- Government and Municipalities

Value Chain Analysis For Mini Excavator Market

The Value Chain for the Mini Excavator Market is characterized by highly specialized upstream component sourcing, complex assembly processes, and a multi-tiered distribution system focused on localized support. Upstream analysis highlights critical dependencies on suppliers of high-pressure hydraulic components (pumps, valves, cylinders), specialized engine manufacturers (meeting global emission standards like Tier 4 Final/Stage V), and advanced electronics providers for telematics and control systems. The quality and reliability of these core components directly influence the final machine's performance and longevity. Manufacturers often engage in deep, long-term partnerships with select component suppliers to ensure quality control, streamline inventory management, and facilitate the rapid incorporation of technological upgrades, such as new sensor technologies for semi-autonomous functions, which is vital for maintaining a competitive edge.

The mid-stream stage involves the core manufacturing process, where OEMs focus on lean manufacturing principles, stringent quality assurance testing, and efficient final assembly. Critical strategic decisions at this stage involve optimizing production footprint—balancing highly automated facilities with localized assembly points closer to major demand centers (e.g., manufacturing specific models within APAC to meet regional standards and demand). Downstream activities are dominated by sales, distribution, and critical after-sales support. The distribution channel is bifurcated into direct sales to large fleet operators (e.g., global rental corporations) and reliance on an expansive network of authorized independent dealers. Dealers are responsible for localized marketing, financing solutions, spare parts stocking, maintenance, and technical training, serving as the primary touchpoint for the majority of small and medium-sized contractors.

The distinction between direct and indirect distribution is crucial. Large rental corporations often procure fleets directly from OEMs due to volume discounts and customized specifications, allowing manufacturers high volume predictability. Conversely, the vast majority of individual contractor purchases rely on the indirect dealer network, which provides essential value-added services such as equipment demonstrations, trade-in programs, and critical financing options. The efficiency of the parts supply chain—the ability to deliver replacement components within 24-48 hours—is a non-negotiable factor influencing customer loyalty and total cost of ownership (TCO), making robust logistical infrastructure a strategic imperative across the entire value chain for long-term market success.

Mini Excavator Market Potential Customers

The primary potential customers and end-users of mini excavators span a diverse range of industries, but are centrally clustered around the construction and infrastructure sectors. The most significant buying segment consists of general building contractors and specialized trade contractors, such as plumbing, electrical, and landscaping firms, who require compact machines for site preparation, utility trenching, foundation work, and final grading within constrained urban footprints. These customers prioritize machine reliability, hydraulic precision for complex tasks, ease of transport between multiple job sites, and, increasingly, adherence to low-emission standards necessary for municipal contracts. Their purchasing decisions are heavily influenced by the equipment’s utilization rate potential and favorable financing terms offered by dealer networks, often opting for flexible leasing or rental arrangements to manage capital expenditure effectively.

A rapidly growing customer segment is the equipment rental fleet industry, which serves as an intermediary, purchasing large volumes of standardized machines and renting them out to contractors who prefer flexibility over ownership. Rental companies demand machines engineered for maximum durability, ease of serviceability, and advanced telematics for remote asset tracking and predictive maintenance, ensuring high residual value and minimal operational costs. The demand from the rental sector is driven by macroeconomic uncertainty and the increasing trend among contractors to minimize owning costs, making rental companies crucial market drivers, particularly for the high-volume, mid-weight segments (2-4 metric tons) where standardized components are preferred for efficient inventory management.

Additionally, governmental entities and municipal departments represent a stable customer base, procuring mini excavators for road maintenance, drainage projects, park infrastructure development, and emergency utility repairs. These organizations often have long-term procurement cycles and strict regulatory requirements regarding emissions (e.g., requiring electric or hybrid models) and mandatory safety features. Smaller but significant end-user groups include agricultural businesses utilizing the equipment for trenching, irrigation setup, and greenhouse construction, and specialized demolition firms needing micro-excavators for interior structural removal. All potential customers share a common need for high-quality, dependable equipment supported by robust local service and parts availability to minimize costly project delays.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 8.5 Billion |

| Market Forecast in 2033 | USD 12.6 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Caterpillar Inc., Kubota Corporation, Komatsu Ltd., Volvo Construction Equipment (VCE), Hitachi Construction Machinery, JCB, Yanmar Holdings Co. Ltd., Doosan Bobcat, Takeuchi Mfg. Co. Ltd., Terex Corporation, Sany Heavy Industry Co. Ltd., XCMG Group, Wacker Neuson SE, Mecalac, Hyundai Construction Equipment, LiuGong Machinery Co., Zoomlion Heavy Industry Science and Technology Co., Kobelco Construction Machinery Co., ASV Holdings, Case Construction Equipment. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Mini Excavator Market Key Technology Landscape

The technological landscape of the Mini Excavator Market is rapidly evolving, driven primarily by the need for increased operational efficiency, enhanced safety, and strict emissions compliance. A central technological focus involves advanced hydraulic systems, specifically load-sensing hydraulics and electronically controlled pumps, which optimize power distribution based on the immediate demand of the attachment or function. This results in significantly improved fuel efficiency and smoother, more responsive operation, critical for precision tasks like fine grading. Furthermore, manufacturers are integrating sophisticated Human-Machine Interfaces (HMIs) featuring color digital displays that provide real-time performance data, diagnostics, and customized operating modes, moving the operator experience closer to that found in high-end automotive applications and facilitating easier machine control for varied skill levels.

The most transformative technology currently reshaping the market is electrification. Zero-emission battery-electric mini excavators are gaining traction, especially in urban European markets and specialized interior demolition sites where air quality and noise constraints are paramount. These electric models, typically powered by high-capacity lithium-ion battery packs, offer comparable performance to their diesel counterparts but with dramatically reduced maintenance needs due to the elimination of traditional combustion engine complexity. This transition is not only environmentally beneficial but also offers long-term operational cost savings, although the high initial capital investment remains a challenge that OEMs are addressing through improved battery lifespan and charging infrastructure solutions compatible with standard construction site power supplies.

Moreover, digital technology integration, notably Telematics and GPS/GNSS systems, is now standard across most medium to high-end mini excavators. These systems provide fleet managers with essential data on machine location, operational hours, utilization rates, and detailed fuel/power consumption metrics. This data is critical for theft prevention, optimizing scheduling, and implementing highly accurate predictive maintenance schedules, significantly improving asset management effectiveness. Further advancements include the incorporation of semi-autonomous technologies, such as grade control and depth limit systems, which use sensor arrays and sophisticated algorithms to assist the operator in achieving precise specifications faster and with less rework, enhancing productivity on complex earthmoving projects.

Regional Highlights

The global Mini Excavator Market exhibits distinct growth drivers and technological adoption patterns across major geographical regions. Asia Pacific (APAC) dominates the market share due to unparalleled growth in infrastructure investment, particularly in residential construction and public works across India, China, and Southeast Asian nations. The region benefits from lower labor costs, but the sheer volume of construction activities necessitates mechanized solutions like mini excavators for high-density site work. Furthermore, regional OEMs are highly competitive, focusing on providing reliable, cost-effective equipment that caters specifically to the requirements of developing market contractors, leading to intense price competition and rapid volume growth.

Europe represents a highly mature but technologically forward-leaning market. Demand here is overwhelmingly driven by the replacement cycle, modernization of existing infrastructure, and exceptionally stringent environmental regulations, specifically the EU’s Stage V emissions standards which have accelerated the adoption of electric and hybrid mini excavators. Northern and Western European countries are early adopters of advanced digital technology, including telematics and semi-autonomous features, often fueled by generous government subsidies aimed at promoting sustainable construction practices. The preference for zero tail swing models is pronounced due to the narrow streets and confined job sites typical of European city centers.

North America maintains robust demand, primarily centered in the United States, fueled by substantial private residential construction and governmental infrastructure initiatives (e.g., road repair and utility upgrades). The North American market typically favors larger mini excavators (3.5 to 6 metric tons) compared to Europe, reflecting the scale of typical suburban job sites and the demand for increased hydraulic power. Key dynamics include a strong reliance on the rental channel, making durable and easily maintained machines a priority for fleet owners, and the increasing incorporation of advanced safety technologies mandated by insurance requirements and site safety protocols across the industry.

- Asia Pacific (APAC): Highest volume growth driven by urbanization; focuses on cost-effectiveness and high utilization rates; major markets include China, India, and Australia.

- Europe: Leading region for electric/hybrid adoption and zero-emission zones; highly regulated market necessitating Stage V compliant machinery; strong demand for micro and compact models for urban renewal.

- North America: Stable demand driven by housing starts and aging infrastructure repair; large rental market presence; favors larger segments (3.5T+); focus on telematics and safety integration.

- Latin America (LATAM): Growth tied to commodity cycles and resource extraction infrastructure; market penetration challenges due to economic volatility and reliance on imported equipment; demand localized to Brazil and Mexico.

- Middle East and Africa (MEA): Investments concentrated in large-scale strategic projects (e.g., Saudi Arabia’s Vision 2030, UAE development); demand sensitive to oil prices and geopolitical stability; focus on durable equipment capable of handling extreme heat conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Mini Excavator Market.- Caterpillar Inc.

- Kubota Corporation

- Komatsu Ltd.

- Volvo Construction Equipment (VCE)

- Hitachi Construction Machinery

- JCB

- Yanmar Holdings Co. Ltd.

- Doosan Bobcat

- Takeuchi Mfg. Co. Ltd.

- Terex Corporation

- Sany Heavy Industry Co. Ltd.

- XCMG Group

- Wacker Neuson SE

- Mecalac

- Hyundai Construction Equipment

- LiuGong Machinery Co.

- Zoomlion Heavy Industry Science and Technology Co.

- Kobelco Construction Machinery Co.

- ASV Holdings

- Case Construction Equipment

Frequently Asked Questions

Analyze common user questions about the Mini Excavator market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the current growth of the Mini Excavator Market?

The primary factor driving market growth is the global surge in infrastructure development and urban renewal projects, requiring compact, highly maneuverable equipment for trenching, utility installation, and restricted-access construction sites, particularly in dense urban environments and for residential repairs.

How significant are electric mini excavators compared to traditional diesel models?

While traditional diesel models still dominate market volume, electric mini excavators are the fastest-growing technology segment. Their significance is paramount in regions with strict emissions regulations (like Europe) and specific applications requiring zero-emission and low-noise operation, offering comparable power output with reduced maintenance requirements.

What operating weight segment holds the largest market share globally?

The 3.0 to 4.0 Metric Ton operating weight segment typically holds the largest market share. This category offers the best combination of hydraulic power, depth reach, and ease of transportability on standard trailers, making it the preferred choice for a majority of general contractors and specialized utility work globally.

How does telematics technology benefit owners of mini excavator fleets?

Telematics technology provides critical benefits by offering real-time machine location tracking, operational hour logging, and remote diagnostic data. This data is essential for optimizing fleet utilization, preventing unauthorized use, implementing accurate predictive maintenance schedules, and significantly reducing overall total cost of ownership (TCO) through improved efficiency and reduced downtime.

What is the long-term impact of AI and automation on the Mini Excavator operator job role?

The long-term impact of AI is not expected to eliminate operators entirely, but rather to transform the role. AI integration will shift the focus from manual control to supervisory and highly technical intervention, enabling semi-autonomous precision functions (like automated grading) which enhance productivity and require operators skilled in interpreting and managing complex digital interfaces.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Mini Excavator Attachment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Backhoe Excavator Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Mini Excavator Backhoe, Small Excavator Backhoe, Medium Excavator Backhoe), By Application (Road Construction, Bridge Construction, Building), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager