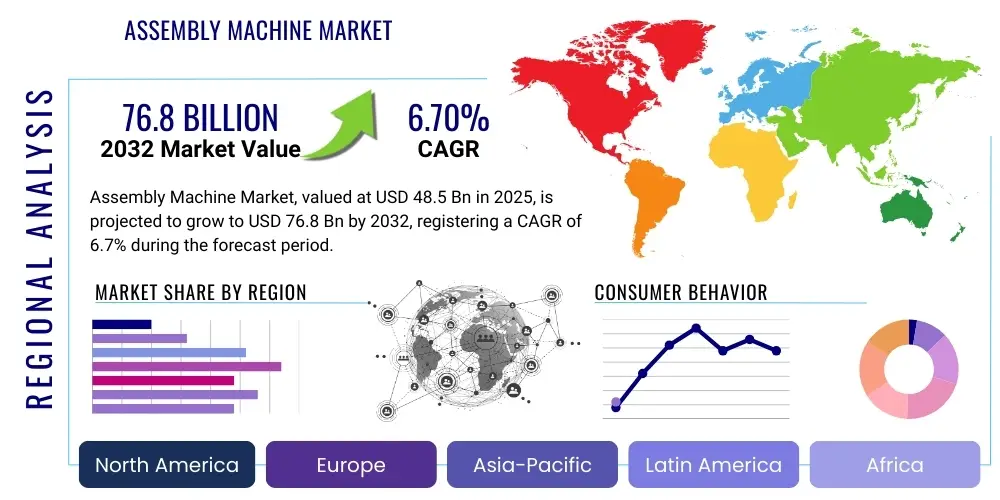

Assembly Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427314 | Date : Oct, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Assembly Machine Market Size

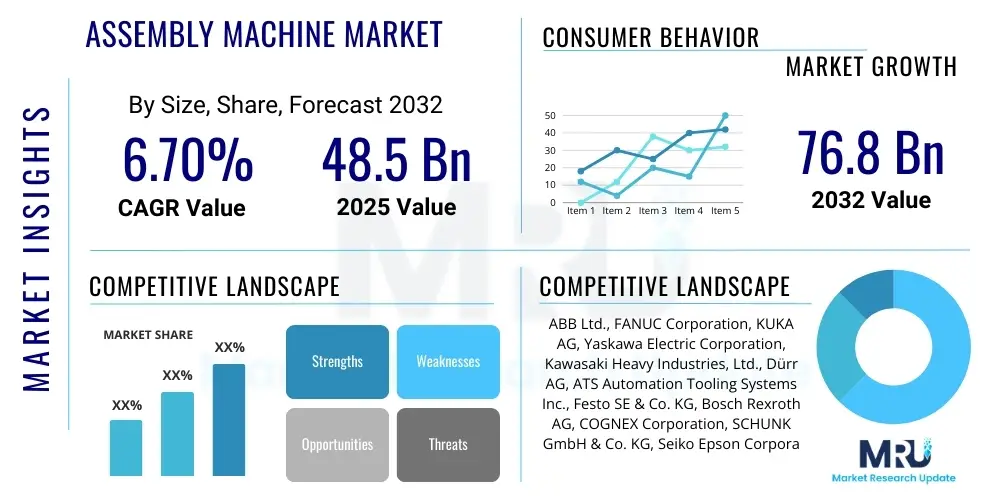

The Assembly Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2025 and 2032. The market is estimated at USD 48.5 billion in 2025 and is projected to reach USD 76.8 billion by the end of the forecast period in 2032. This growth is primarily fueled by the escalating demand for industrial automation across diverse manufacturing sectors, driven by the pursuit of enhanced production efficiency, precision, and cost reduction. The integration of advanced robotics, artificial intelligence, and machine vision technologies is further accelerating market expansion, enabling more complex and flexible assembly processes.

Assembly Machine Market introduction

Assembly machines are sophisticated automated or semi-automated systems designed to combine individual components into a complete product or sub-assembly. These machines are integral to modern manufacturing, replacing manual labor in repetitive, high-precision, or hazardous tasks. Their primary function is to execute a sequence of operations suchifying, orienting, transferring, joining, fastening, and inspecting components, ensuring consistency and accuracy in the final product. The core benefit of employing assembly machines lies in their ability to significantly increase production speed, maintain high levels of quality control, reduce operational costs associated with labor, and enable mass customization through flexible manufacturing approaches.

The product encompasses a wide range of systems, from simple pick-and-place robots to complex multi-station assembly lines integrated with advanced vision systems and artificial intelligence. Major applications span critical industrial sectors including automotive, where they assemble engines, transmissions, and vehicle bodies; electronics and semiconductors, for intricate circuit board and device assembly; medical devices, requiring sterile and high-precision assembly; and consumer goods, for rapid production of household items. Key driving factors propelling the market include the global push towards Industry 4.0 initiatives, persistent labor shortages in manufacturing, the increasing complexity of product designs, and the necessity for superior product quality and faster time-to-market. These elements collectively underscore the indispensable role of assembly machines in global industrial competitiveness.

Assembly Machine Market Executive Summary

The Assembly Machine Market is experiencing robust expansion, propelled by significant business trends such as escalating investments in industrial automation and smart factories, alongside a growing emphasis on lean manufacturing principles. Enterprises are increasingly adopting these technologies to mitigate rising labor costs, enhance production throughput, and improve overall product quality and consistency. The integration of advanced technologies like artificial intelligence, machine learning, and collaborative robotics is reshaping the competitive landscape, fostering innovation in flexible and adaptive assembly solutions. Regional trends indicate a strong market dominance in the Asia-Pacific region, particularly in countries like China, Japan, and South Korea, owing to their vast manufacturing bases and proactive adoption of automation technologies, while North America and Europe continue to invest heavily in advanced manufacturing capabilities, driven by the automotive, aerospace, and medical device sectors. Within segmentation trends, automatic and robotic assembly systems are witnessing the highest growth, spurred by demand for high-volume, high-precision manufacturing, especially in the electronics and automotive industries, underscoring a broader shift towards fully integrated and intelligent production lines.

AI Impact Analysis on Assembly Machine Market

User inquiries concerning AIs impact on the Assembly Machine Market frequently revolve around how artificial intelligence can enhance operational efficiency, precision, and adaptability, while also addressing concerns related to implementation costs, complexity, and potential job displacement. Common questions explore AIs role in predictive maintenance, advanced quality control, real-time optimization of assembly processes, and enabling greater flexibility in production lines for mass customization. There is a strong expectation that AI will unlock new levels of automation, making assembly systems more autonomous and intelligent, capable of handling variations and making data-driven decisions on the factory floor, thereby mitigating human error and improving throughput. Conversely, users also inquire about the practical challenges of integrating AI, including the need for specialized skills, data privacy issues, and the significant capital expenditure required for sophisticated AI-powered systems. The desire for tangible return on investment and clear pathways for upskilling the existing workforce are prominent themes.

The integration of artificial intelligence is fundamentally transforming the capabilities and future trajectory of assembly machine technology, moving beyond mere automation to truly intelligent and adaptive manufacturing systems. AI algorithms can analyze vast datasets from sensors and machine vision systems to detect minute defects, predict potential equipment failures before they occur, and dynamically adjust assembly parameters for optimal performance, ensuring unparalleled precision and minimal downtime. This shift empowers manufacturers to achieve higher levels of product quality and consistency, while also significantly extending the operational lifespan of machinery through proactive maintenance. Furthermore, AI facilitates enhanced human-robot collaboration, allowing cobots to perform complex tasks safely alongside human operators, and enables assembly lines to reconfigure themselves swiftly to accommodate varying product specifications, crucial for industries demanding high-mix, low-volume production. This intelligent evolution positions AI as a pivotal catalyst for the next generation of advanced manufacturing and flexible automation.

- AI enhances real-time quality inspection and defect detection, improving product consistency.

- Predictive maintenance driven by AI minimizes downtime and extends equipment lifespan.

- Optimized process parameters and adaptive control for higher precision and efficiency.

- Enables flexible manufacturing and mass customization through dynamic system reconfiguration.

- Facilitates advanced human-robot collaboration, improving safety and productivity.

- Data-driven decision making for improved throughput and operational intelligence.

- Automated anomaly detection in assembly sequences, reducing errors and waste.

DRO & Impact Forces Of Assembly Machine Market

The Assembly Machine Market is primarily driven by the imperative for enhanced manufacturing efficiency, precision, and cost reduction, alongside the global shift towards Industry 4.0. Key drivers include the escalating demand for industrial automation, fueled by rising labor costs and a scarcity of skilled workers, particularly in developed economies. The increasing complexity of product designs across sectors like automotive, electronics, and medical devices necessitates highly precise and repeatable assembly processes that only automated systems can reliably provide. Furthermore, the burgeoning electric vehicle market and the expansion of consumer electronics production act as significant accelerators. However, the market faces notable restraints such as the substantial initial capital investment required for advanced assembly machines, which can be a barrier for small and medium-sized enterprises (SMEs). Technical complexities in integrating diverse systems and the need for a highly skilled workforce for maintenance and programming also pose challenges. Economic uncertainties and geopolitical tensions can further dampen investment decisions, impacting market growth.

Despite these restraints, significant opportunities abound for the Assembly Machine Market. The growing adoption of collaborative robots (cobots) offers a pathway for automation in less structured environments and for tasks requiring human-robot interaction, expanding the markets reach into new applications. The integration of advanced vision systems, artificial intelligence, and machine learning is creating intelligent assembly solutions capable of self-optimization and predictive maintenance, enhancing system reliability and performance. Emerging markets in Southeast Asia, Latin America, and Africa present untapped potential for industrialization and automation adoption, offering new avenues for growth. Impact forces shaping the market include rapid technological advancements, especially in robotics and AI, which continually push the boundaries of what automated assembly can achieve. Regulatory pressures concerning worker safety and environmental sustainability influence machine design and operational standards, promoting the development of safer and more energy-efficient systems. Global supply chain dynamics, including reshoring initiatives and diversification strategies, also impact investment in domestic assembly capabilities, favoring localized production. These forces collectively steer the market towards more adaptive, intelligent, and sustainable manufacturing solutions.

Segmentation Analysis

The Assembly Machine Market is broadly segmented based on various critical attributes, providing a granular understanding of its dynamics and growth trajectories. These segments reflect the diverse applications, technological complexities, and operational requirements across numerous industrial sectors. Analyzing the market through these segmentations helps identify key growth areas, competitive landscapes, and the varying demands of end-users, enabling market players to tailor their strategies effectively. The primary segmentation categories encompass the type of machine, the level of automation, and the end-use industry, each characterized by distinct technological trends and market demands. Understanding these divisions is crucial for strategic planning and resource allocation within the dynamic industrial automation sector.

Each segment demonstrates unique characteristics and growth drivers. For instance, automatic assembly machines, especially those incorporating advanced robotics, are witnessing rapid adoption due to their ability to deliver high throughput and precision, particularly in high-volume manufacturing environments. Conversely, semi-automatic and manual systems continue to find relevance in smaller-batch production or operations where human flexibility and intervention remain critical. The end-use industry segmentation highlights the varying degrees of automation maturity and investment capacity across sectors like automotive, electronics, and medical devices, each with specific regulatory and quality requirements that influence machine design and deployment. This multifaceted segmentation offers a comprehensive view of the markets structure and the underlying forces driving its evolution.

- By Type

- Robotic Assembly Machines

- Fixed Automation Assembly Machines

- Flexible Assembly Systems

- Semi-Automatic Assembly Machines

- Manual Assembly Workstations

- By Operation Mode

- Automatic

- Semi-Automatic

- Manual

- By End-Use Industry

- Automotive

- Electronics and Semiconductors

- Medical Devices

- Aerospace and Defense

- Consumer Goods

- Industrial Manufacturing and Machinery

- Packaging

- Telecommunications

- By Component

- Hardware (Robots, Vision Systems, Sensors, PLCs, Conveyors)

- Software (AI/ML, SCADA, HMI, Simulation Software)

- Services (Installation, Maintenance, Training, System Integration)

Assembly Machine Market Value Chain Analysis

The value chain for the Assembly Machine Market is a complex ecosystem involving multiple stages, from raw material sourcing to post-sales services, each adding incremental value to the final product and its deployment. At the upstream end, the chain begins with suppliers of critical raw materials such as metals, plastics, and electronic components, which are essential for manufacturing machine structures, robotic arms, and control systems. Following this, component manufacturers specialize in producing sophisticated parts like servo motors, sensors, machine vision cameras, programmable logic controllers (PLCs), human-machine interfaces (HMIs), and precision tooling. These highly specialized components form the technological backbone of modern assembly machines, dictating their performance and capabilities. The quality and availability of these components directly impact the overall efficiency and reliability of the end-assembly system.

Moving downstream, the value chain progresses to the core assembly machine manufacturers who design, integrate, and produce the complete automated systems. These manufacturers often work closely with specialized system integrators who customize and install these machines according to specific end-user requirements, ensuring seamless integration into existing production lines. Distribution channels are crucial for market reach, involving both direct sales forces that handle large, complex projects and indirect channels through distributors, resellers, and value-added partners who serve a broader customer base, including SMEs. Post-sales services, including installation, maintenance, repair, software updates, and training, constitute a significant portion of the value chain, ensuring the long-term operational efficiency and customer satisfaction. Direct channels offer a personalized approach and in-depth technical support for complex systems, while indirect channels leverage extensive networks to provide localized support and access to a wider array of customers. This intricate network of interdependencies ensures the continuous innovation and efficient delivery of assembly machine solutions to global manufacturing industries.

Assembly Machine Market Potential Customers

The potential customers for the Assembly Machine Market are diverse, spanning a wide array of manufacturing industries that require high-precision, repeatable, and efficient production processes. These end-users are primarily driven by the need to enhance productivity, reduce operational costs, ensure consistent product quality, and accelerate time-to-market. The most prominent customer segments include large-scale manufacturers with high-volume production needs, as well as specialized producers requiring intricate assembly for complex products. These buyers are increasingly seeking advanced automation solutions to address challenges such as labor shortages, the demand for mass customization, and the increasing complexity of modern product designs, which necessitate superior accuracy and flexibility.

Specifically, the automotive industry represents a significant customer base, with OEMs and component suppliers investing heavily in assembly machines for vehicle bodies, engines, transmissions, and battery packs for electric vehicles. The electronics and semiconductor industry also constitutes a critical segment, requiring ultra-precision assembly for circuit boards, microchips, and various electronic devices. Medical device manufacturers are increasingly adopting automated assembly to meet stringent regulatory standards, ensure sterile environments, and produce high-quality, life-critical products. Other key customers include aerospace and defense for intricate component assembly, consumer goods manufacturers for high-speed packaging and assembly, and general industrial manufacturers looking to automate various production processes. These diverse sectors collectively drive the demand for a broad spectrum of assembly machine technologies, from robotic systems to highly specialized custom-built solutions.

Assembly Machine Market Key Technology Landscape

The Assembly Machine Market is characterized by a rapidly evolving technological landscape, driven by the continuous pursuit of greater precision, speed, flexibility, and intelligence in manufacturing processes. At its core, the technology revolves around advanced robotics, encompassing a range of robot types such as articulated, SCARA, delta, and Cartesian robots, each suited for specific tasks based on their dexterity, reach, and payload capabilities. These robots are often augmented with sophisticated end-effectors and grippers, custom-designed for handling diverse components. Machine vision systems are indispensable, providing critical capabilities for component recognition, precise positioning, quality inspection, and defect detection, ensuring accuracy and consistency that human eyes cannot match. These vision systems are integral for guiding robots and verifying assembly steps, acting as the eyes of the automated process.

Further augmenting these systems are advanced sensors, including force sensors, proximity sensors, and laser scanners, which provide real-time feedback and enable precise control and adaptive responses during assembly. Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) form the backbone of control and operational management, allowing for seamless programming, monitoring, and interaction with the assembly lines. The integration of Artificial Intelligence (AI) and Machine Learning (ML) is transforming assembly machines from mere automated tools into intelligent, self-optimizing systems capable of predictive maintenance, adaptive process control, and real-time anomaly detection. The Industrial Internet of Things (IIoT) connects these machines, enabling data collection, analysis, and remote monitoring for enhanced operational insights. Additionally, technologies like Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) facilitate the design and simulation of assembly processes, while digital twin technology creates virtual replicas of physical systems for testing and optimization, collectively propelling the market towards highly intelligent and interconnected smart factories.

Regional Highlights

The global Assembly Machine Market exhibits distinct regional dynamics, influenced by varying levels of industrialization, technological adoption rates, and economic development. Each region contributes uniquely to the markets growth, driven by specific industrial sectors and investment trends. Understanding these regional highlights is crucial for market participants to tailor their strategies and capitalize on localized opportunities, addressing the unique demands and regulatory environments prevalent in different parts of the world. The distribution of manufacturing hubs and the pace of technological advancement play significant roles in shaping regional market landscapes. For instance, regions with established automotive and electronics industries often lead in automation adoption, while emerging economies show immense potential for future growth as they industrialize.

Asia-Pacific remains the dominant and fastest-growing region in the Assembly Machine Market, primarily driven by its robust manufacturing sector, particularly in countries like China, Japan, South Korea, and India. Chinas unparalleled manufacturing output, coupled with aggressive government initiatives for industrial automation and smart manufacturing (e.g., "Made in China 2025"), fuels significant demand. Japan and South Korea, with their advanced technological capabilities and established automotive and electronics industries, continue to be key innovators and adopters. North America, led by the United States, represents a mature market with substantial investments in advanced manufacturing across the automotive, aerospace, and medical device sectors, characterized by a focus on high-value, high-precision assembly and a growing emphasis on reshoring manufacturing operations. Europe, particularly Germany, is a hub for high-quality engineering and advanced automation, with strong demand from the automotive, machinery, and pharmaceutical industries, driven by Industry 4.0 initiatives. While smaller in market share, regions like Latin America and the Middle East & Africa are showing increasing potential as they embark on industrial diversification and modernization programs, gradually adopting automated assembly solutions to improve competitiveness and production capabilities. This global spread of demand underscores the universal imperative for manufacturing efficiency and precision.

- Asia-Pacific: Dominant market, driven by extensive manufacturing bases in China, Japan, South Korea, and India. High adoption in automotive, electronics, and consumer goods due to government support for automation and large-scale production.

- North America: Significant market share with strong demand from automotive, aerospace, medical devices, and general industrial sectors. Focus on advanced robotics, AI integration, and precision manufacturing.

- Europe: Key market with high adoption in Germany, Italy, and France. Driven by Industry 4.0 initiatives, sophisticated manufacturing, and strong automotive, machinery, and pharmaceutical industries.

- South America: Emerging market with growing industrialization in Brazil, Mexico, and Argentina. Increasing investments in automotive and consumer goods sectors, gradually adopting automation.

- Middle East & Africa: Nascent but growing market, particularly in countries diversifying their economies away from oil. Investments in infrastructure and manufacturing sectors are slowly driving automation adoption.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Assembly Machine Market.- ABB Ltd.

- FANUC Corporation

- KUKA AG (Midea Group)

- Yaskawa Electric Corporation

- Kawasaki Heavy Industries, Ltd.

- Dürr AG

- ATS Automation Tooling Systems Inc.

- Festo SE & Co. KG

- Bosch Rexroth AG

- COGNEX Corporation

- SCHUNK GmbH & Co. KG

- Seiko Epson Corporation

- Comau S.p.A.

- Stäubli International AG

- Midea Group Co., Ltd. (KUKA AG)

Frequently Asked Questions

What is an assembly machine and its primary purpose?

An assembly machine is an automated or semi-automated system designed to combine individual components into a complete product or sub-assembly. Its primary purpose is to enhance manufacturing efficiency, precision, consistency, and speed while reducing labor costs and errors in the production process.

Which industries are the largest adopters of assembly machines?

The largest adopters of assembly machines include the automotive industry for vehicle and component assembly, electronics and semiconductors for intricate device manufacturing, medical devices for precision and sterile assembly, and consumer goods for high-volume production.

How does AI impact the future of assembly machines?

AI significantly impacts assembly machines by enabling predictive maintenance, advanced quality control, real-time process optimization, adaptive manufacturing for flexibility, and enhanced human-robot collaboration, leading to more intelligent and efficient production systems.

What are the main drivers for the growth of the Assembly Machine Market?

Key drivers include the escalating demand for industrial automation, rising labor costs and shortages, the global push towards Industry 4.0, increasing product complexity, and the imperative for higher precision and quality in manufacturing processes.

What are the major challenges in adopting assembly machine technology?

Major challenges include the substantial initial capital investment, the technical complexity of system integration, the need for a highly skilled workforce for operation and maintenance, and economic uncertainties that can impact investment decisions for manufacturers.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Lithium Battery Cell Assembly Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Global Lithium Battery Assembly Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Lithium Battery Cell Assembly Machine Market Statistics 2025 Analysis By Application (Consumer Electronics, Power Industry, Others), By Type (Die Cutting machine, Laminator, Others), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Assembly Machine Market Statistics 2025 Analysis By Application (Electronics Industry, Equipment Manufacturing Industry), By Type (Fully Automatic Assembly Machine, Semi-Automatic Assembly Machine), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager