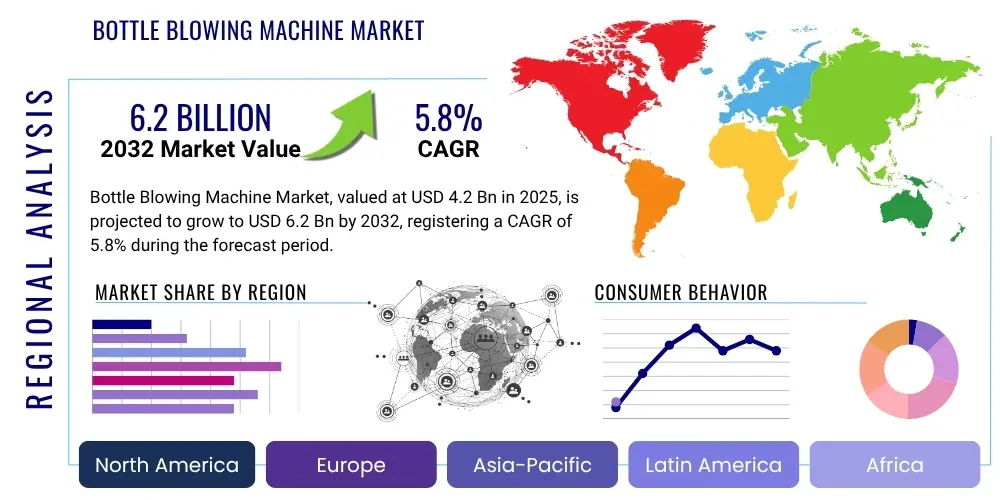

Bottle Blowing Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429423 | Date : Nov, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Bottle Blowing Machine Market Size

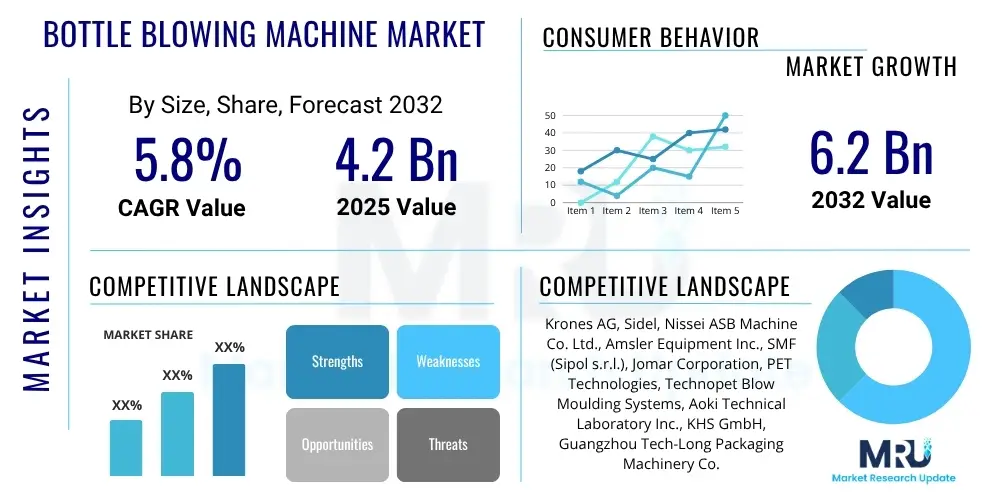

The Bottle Blowing Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at $4.2 Billion USD in 2025 and is projected to reach $6.2 Billion USD by the end of the forecast period in 2032.

Bottle Blowing Machine Market introduction

The bottle blowing machine market forms the backbone of the global plastic packaging industry, enabling the high-volume production of diverse plastic containers essential for a vast array of consumer and industrial goods. These specialized machines convert plastic preforms or granules into finished bottles through various processes, primarily including extrusion blow molding, injection blow molding, and stretch blow molding. Stretch blow molding, particularly for PET materials, dominates segments requiring lightweight, clear, and durable bottles for beverages and food products, while extrusion blow molding is widely used for HDPE and PP containers common in household chemicals and personal care items. The continuous innovation in machine design focuses on enhancing production speed, reducing energy consumption, and improving overall operational efficiency.

Major applications for bottle blowing machines span critical sectors such as beverages, encompassing bottled water, carbonated soft drinks, juices, and dairy products, where high output and consistent quality are paramount. In the food industry, they produce containers for edible oils, sauces, and condiments, ensuring product safety and shelf life. The pharmaceutical sector relies on these machines for sterile and precise packaging of medicines and syrups, often demanding specialized cleanroom capabilities. Cosmetics and personal care brands utilize these machines for aesthetically appealing and ergonomically designed bottles for shampoos, lotions, and sprays, reflecting brand identity. Chemical industries also extensively employ blow molding for robust containers designed to hold lubricants, detergents, and industrial chemicals safely. The inherent benefits of these machines, such as their capability for high-speed production, cost-effectiveness due to automation, versatility in manufacturing various shapes and sizes, and their contribution to lightweight packaging, significantly drive their adoption across these diverse applications.

The market's growth is fundamentally driven by the ever-increasing global demand for packaged goods, fueled by urbanization, rising disposable incomes, and the expansion of e-commerce platforms requiring efficient and secure packaging. Furthermore, technological advancements in machine automation and digitalization, coupled with a growing emphasis on sustainable packaging solutions like lightweighting and the use of recycled or bio-based plastics, are key catalysts. Manufacturers are continuously investing in research and development to offer machines that are more energy-efficient, offer higher precision, and integrate seamlessly into smart factory environments, addressing the evolving needs of packaging producers worldwide and fostering a dynamic and competitive market landscape.

Bottle Blowing Machine Market Executive Summary

The Bottle Blowing Machine Market is characterized by robust business trends centered on technological innovation and operational efficiency. Industry players are heavily investing in research and development to introduce advanced machinery featuring enhanced automation, predictive maintenance capabilities through IoT integration, and improved energy efficiency to reduce operational costs and environmental impact. There is a discernible trend towards modular designs and customization options, allowing manufacturers to cater to specific production requirements and varying bottle designs. Furthermore, the competitive landscape is witnessing strategic collaborations, mergers, and acquisitions aimed at expanding product portfolios, enhancing technological expertise, and strengthening market presence across key regions, indicating a dynamic environment focused on competitive advantage and market share consolidation.

Regional trends indicate Asia Pacific as the dominant market, propelled by rapid industrialization, burgeoning population growth, and escalating demand for packaged food and beverages in countries like China, India, and Southeast Asian nations. This region benefits from lower manufacturing costs and a large consumer base, attracting significant investments. North America and Europe, while mature markets, exhibit steady growth driven by the adoption of advanced, high-performance machinery, stringent regulatory frameworks pushing for sustainable packaging solutions, and a strong focus on automation to optimize labor costs and productivity. Latin America and the Middle East and Africa regions are emerging as high-potential markets, experiencing increasing urbanization, rising disposable incomes, and developing industrial infrastructures, leading to a growing demand for packaged goods and, consequently, bottle blowing machines.

Segment trends within the market underscore the continued supremacy of PET as the primary material for beverage and food packaging due to its clarity, barrier properties, and recyclability, driving demand for stretch blow molding machines. However, there is an increasing demand for machines capable of processing specialty plastics for applications requiring enhanced chemical resistance, temperature stability, or barrier characteristics, such as for pharmaceuticals and industrial chemicals. The market is also witnessing a shift towards fully automatic machines equipped with sophisticated control systems, significantly improving throughput, reducing labor dependency, and ensuring consistent product quality. The integration of aseptic blowing technologies is gaining traction, particularly in the food and beverage sectors, to meet stringent hygiene standards and extend product shelf life, reflecting the industry's response to evolving consumer expectations and regulatory mandates.

AI Impact Analysis on Bottle Blowing Machine Market

Common user questions related to the impact of AI on the Bottle Blowing Machine Market frequently revolve around how AI can enhance manufacturing processes, reduce waste, and improve overall product quality. Users are particularly keen to understand AI's capabilities in enabling predictive maintenance for machines, optimizing operational parameters for energy efficiency and material usage, and implementing advanced quality control systems to detect defects early. There is also significant interest in how AI can contribute to more flexible production schedules and customized manufacturing runs. Concerns often include the initial investment costs associated with AI integration, the complexity of implementing new AI-driven systems into existing infrastructure, data security issues, and the need for a skilled workforce capable of managing and troubleshooting AI-powered machinery. Despite these challenges, there is a clear expectation that AI will be a transformative force, driving the next wave of automation, intelligence, and sustainability in the plastic packaging industry.

- AI enables highly accurate predictive maintenance by analyzing machine sensor data, foreseeing potential failures before they occur and minimizing costly downtime.

- Advanced AI algorithms optimize process parameters such as heating temperatures, blowing pressures, and cycle times, leading to significant improvements in energy efficiency and material yield.

- AI-powered vision systems provide real-time, precise quality control, identifying minuscule defects in bottles that human inspection might miss, ensuring consistent product standards.

- Machine learning models analyze historical production data to optimize scheduling and resource allocation, enhancing overall plant productivity and responsiveness to demand fluctuations.

- AI assists in the design phase by simulating bottle performance and mold designs, reducing prototyping costs and accelerating time-to-market for new packaging solutions.

- Through deep learning, AI can facilitate self-correction mechanisms in machines, automatically adjusting settings to compensate for minor deviations in production and maintain optimal performance.

DRO & Impact Forces Of Bottle Blowing Machine Market

The Bottle Blowing Machine Market is primarily driven by the escalating global demand for packaged consumer goods, including food, beverages, pharmaceuticals, and cosmetics, which directly translates into a continuous need for efficient bottle manufacturing solutions. Rapid urbanization, increasing disposable incomes, and the expansion of organized retail and e-commerce channels worldwide further amplify this demand. Technological advancements, particularly in automation, robotics, and energy-efficient designs, play a crucial role in boosting machine capabilities, reducing operational costs, and attracting investments. Additionally, the growing focus on sustainable and lightweight packaging solutions motivates manufacturers to adopt modern bottle blowing machines capable of processing recycled materials and optimizing material usage, thereby aligning with environmental regulations and consumer preferences.

Despite robust growth drivers, the market faces several significant restraints. The high initial capital investment required for acquiring advanced bottle blowing machines, coupled with the costs associated with installation, training, and maintenance, can be prohibitive for small and medium-sized enterprises (SMEs). Volatility in the prices of raw plastic materials, such as PET, HDPE, and PP, directly impacts production costs and profit margins for bottle manufacturers, creating market uncertainties. Moreover, increasingly stringent environmental regulations concerning plastic waste and pollution in various regions compel industries to seek alternative packaging materials or implement costly recycling initiatives, which can indirectly dampen the demand for new plastic bottle blowing equipment. The shortage of skilled labor required to operate and maintain sophisticated, automated machinery also presents an operational challenge for many companies.

Opportunities within the market abound in the development and adoption of bioplastics and increased incorporation of post-consumer recycled (PCR) content, driven by sustainability mandates and consumer demand for eco-friendly packaging. The integration of Industry 4.0 technologies, including the Internet of Things (IoT), artificial intelligence (AI), and data analytics, offers substantial potential for optimizing production processes, enabling predictive maintenance, and enhancing operational efficiency. Furthermore, emerging economies in Asia Pacific, Latin America, and the Middle East and Africa represent untapped growth potential due to their developing industrial infrastructures and rising consumer bases. The market is influenced by intense competitive rivalry, where differentiation through technological innovation and comprehensive after-sales service is key. The bargaining power of large buyers can be significant, demanding customized and cost-effective solutions, while the threat of new entrants is moderate due to high capital requirements and specialized technical expertise needed. Substitutes, primarily packaging made from glass, metal, or paper, pose a moderate threat, particularly as sustainability concerns drive material diversification efforts across industries.

Segmentation Analysis

The Bottle Blowing Machine Market is extensively segmented to provide a detailed understanding of its complex dynamics and varied applications. This segmentation allows for precise market analysis based on the specific type of technology employed, the raw materials processed, the diverse range of end-use applications across different industries, and the level of automation integrated into the machinery. Each segment plays a crucial role in shaping market demand, technological advancements, and competitive strategies, offering invaluable insights for manufacturers, suppliers, and investors to identify lucrative niches and tailor their offerings effectively to meet specific industry requirements and consumer preferences, thereby fostering targeted growth and innovation within the global packaging sector.

- By Type: This segment categorizes machines based on their operational mechanism.

- Extrusion Blow Molding: Utilized for producing hollow parts from thermoplastic materials, common for HDPE and PP bottles like those for detergents and motor oils.

- Injection Blow Molding: Combines injection molding of a preform with blow molding, suitable for small to medium-sized bottles with high precision, often for pharmaceuticals and cosmetics.

- Stretch Blow Molding: Involves stretching a preform, then blowing it into a mold, predominantly used for PET bottles due to its ability to enhance material strength and clarity.

- Reheat Stretch Blow Molding (RSBM): The most common method for PET bottles, where preforms are made separately and then reheated and blown.

- Injection Stretch Blow Molding (ISBM): Integrates preform injection and blowing into a single machine, ideal for high-volume, integrated production.

- Other Types: Includes specialized processes like co-extrusion blow molding for multi-layer bottles and accumulators for larger container sizes.

- By Material: This segment differentiates machines by the type of plastic resin they are designed to process.

- PET (Polyethylene Terephthalate): Widely used for beverages, food, and personal care due to its clarity, strength, and recyclability.

- PP (Polypropylene): Known for its heat resistance and durability, used for hot-fill products, medical containers, and detergents.

- HDPE (High-Density Polyethylene): Common for milk jugs, detergent bottles, and industrial containers due to its rigidity and chemical resistance.

- PVC (Polyvinyl Chloride): Used for certain chemical and oil bottles, though its usage is declining due to environmental concerns.

- LDPE (Low-Density Polyethylene): Offers flexibility, used for squeeze bottles and some food packaging.

- Others: Includes PC (Polycarbonate) for water cooler bottles, PS (Polystyrene) for certain food applications, and other engineering plastics.

- By Application: This segment focuses on the primary industry or product category for which the bottles are manufactured.

- Beverages: Encompasses bottled water, carbonated soft drinks, juices, dairy products, and alcoholic beverages, demanding high-speed and hygienic production.

- Food: Includes packaging for edible oils, sauces, condiments, jams, dairy products, and other processed foods, requiring specific barrier properties and food safety standards.

- Pharmaceuticals: Involves sterile and precise packaging for medicines, syrups, drops, and pill containers, often requiring specialized cleanroom conditions.

- Cosmetics and Personal Care: Covers bottles for shampoos, lotions, creams, sprays, and other beauty products, emphasizing aesthetic design and material compatibility.

- Chemicals: Used for robust containers for lubricants, cleaning agents, agrochemicals, and industrial solvents, prioritizing chemical resistance and durability.

- Others: Includes automotive fluids, household products, toys, and various industrial components.

- By Automation Level: This segment distinguishes machines based on their degree of automated operation.

- Fully Automatic: Machines that perform all production steps, from preform loading to bottle discharge, without manual intervention, ideal for high-volume, continuous production.

- Semi-Automatic: Machines requiring some manual involvement, such as preform loading, suitable for smaller batches, specialized products, or developing markets with lower labor costs.

Value Chain Analysis For Bottle Blowing Machine Market

The value chain for the bottle blowing machine market is a multi-tiered process beginning with critical upstream activities, where raw material suppliers play a foundational role. These suppliers primarily provide various polymer resins, such as PET, HDPE, and PP, which are essential for manufacturing plastic bottles, along with specialized components like precision molds, heating elements, hydraulic systems, and electrical controls that constitute the core of the blowing machines. Key players in this stage ensure the quality and consistent supply of these vital inputs, directly impacting the final machine's performance and cost-effectiveness. This segment requires strong relationships between resin producers and machine manufacturers to ensure material compatibility and innovation in processing diverse plastics, including recycled and bio-based variants.

Moving through the value chain, machine manufacturers procure these raw materials and components to design, engineer, and assemble the bottle blowing equipment. This stage involves significant research and development to incorporate advanced technologies like servo motors, automation, and intelligent control systems, ensuring high efficiency, precision, and energy savings. Once manufactured, the machines move into the distribution phase. Direct sales channels are frequently utilized for large-scale industrial clients and multinational corporations, offering tailored solutions, comprehensive technical support, and direct after-sales service. This approach fosters strong client relationships and facilitates customization for complex production requirements. In parallel, indirect distribution channels involve a network of regional distributors, agents, and system integrators who serve smaller enterprises, local businesses, and emerging markets, providing localized sales, installation, and maintenance support. These intermediaries often play a crucial role in market penetration and reaching a broader customer base, especially in regions with diverse operational needs.

The downstream segment of the value chain consists of the end-users who integrate these machines into their production lines to manufacture finished plastic bottles and containers. This diverse group includes beverage companies, food processing units, pharmaceutical manufacturers, cosmetic brands, and chemical industries. These end-users, in turn, sell their packaged products to consumers, making the bottle blowing machine an indispensable asset in their overall product delivery strategy. The efficiency, reliability, and versatility of the bottle blowing machines directly influence the speed, cost, and quality of the final packaged goods, thus impacting consumer satisfaction and market competitiveness. The entire value chain is constantly evolving, driven by technological advancements, sustainability goals, and shifts in consumer demand, necessitating continuous innovation and collaboration among all stakeholders to maintain efficiency and responsiveness.

Bottle Blowing Machine Market Potential Customers

Potential customers for bottle blowing machines represent a broad and diverse spectrum of industries, all united by their critical need for efficient and high-quality plastic packaging solutions. At the forefront are large-scale beverage companies, including manufacturers of bottled water, carbonated soft drinks, juices, and dairy products, which require robust, high-speed machines to meet immense production volumes and stringent hygiene standards for their consumer goods. The food processing industry also constitutes a substantial customer base, utilizing these machines to produce containers for edible oils, sauces, condiments, and various food items, often demanding specialized barrier properties to extend shelf life and ensure product integrity.

Pharmaceutical manufacturers are another key segment, investing in bottle blowing machines for the precise and sterile production of containers for medicines, syrups, and tablets. Their requirements frequently involve specialized cleanroom-compatible machinery and materials that ensure product safety and compliance with strict regulatory standards. The cosmetics and personal care sector represents a significant market, where companies require versatile machines capable of producing a wide array of aesthetically diverse and ergonomically designed bottles for shampoos, lotions, fragrances, and other beauty products, often emphasizing design flexibility and brand differentiation. Furthermore, chemical and industrial product manufacturers constitute an important customer group, purchasing bottle blowing machines for robust containers designed to hold lubricants, cleaning agents, agrochemicals, and other specialized liquids, prioritizing durability and chemical resistance to ensure safe storage and transportation.

Beyond these primary industries, contract packaging companies are a vital customer segment. These firms offer outsourced packaging services to various brands, necessitating versatile and adaptable bottle blowing machines capable of handling diverse product types, batch sizes, and quick changeovers to meet the varied demands of their clients. Additionally, companies venturing into new product lines, expanding their production capacities, or seeking to modernize their existing equipment to enhance efficiency and sustainability are consistently potential buyers. Ultimately, any enterprise involved in the manufacturing, distribution, or sale of liquids, powders, or small granular products that require plastic containment is a potential end-user for bottle blowing machine technology, seeking reliable, cost-effective, and technologically advanced solutions to fulfill their packaging needs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $4.2 Billion USD |

| Market Forecast in 2032 | $6.2 Billion USD |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Krones AG, Sidel, Nissei ASB Machine Co. Ltd., Amsler Equipment Inc., SMF (Sipol s.r.l.), Jomar Corporation, PET Technologies, Technopet Blow Moulding Systems, Aoki Technical Laboratory Inc., KHS GmbH, Guangzhou Tech-Long Packaging Machinery Co. Ltd., Chumpower Machinery Corp., Zilli & Bellini Srl, Parker Plastic Machinery Co. Ltd., Graham Engineering Corporation, FONG KE INDUSTRY CO. LTD., Automa S.p.A., Bekum Maschinenfabriken GmbH, Magic MP SpA, Sacmi Imola S.C. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Bottle Blowing Machine Market Key Technology Landscape

The bottle blowing machine market is currently shaped by a dynamic and continuously evolving technological landscape, driven by the persistent demands for enhanced efficiency, precision, sustainability, and intelligent manufacturing capabilities. A pivotal advancement is the widespread adoption of servo motor technology across various machine types. Servo motors offer superior control over machine movements, leading to reduced energy consumption, higher precision in mold clamping and stretching, and significantly quieter operation compared to traditional hydraulic systems. This shift enables faster cycle times and more consistent product quality, directly impacting overall production throughput and operational costs, making them a preferred choice for high-volume, performance-driven applications. The integration of advanced control systems, often featuring sophisticated Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs), provides operators with intuitive command over complex processes and real-time monitoring capabilities.

Furthermore, Industry 4.0 concepts are fundamentally transforming the market, with the increasing integration of the Internet of Things (IoT), artificial intelligence (AI), and data analytics. IoT sensors embedded within machines enable real-time data collection on various parameters such as temperature, pressure, and energy consumption. This data is then analyzed by AI algorithms to facilitate predictive maintenance, allowing potential equipment failures to be identified and addressed before they lead to costly downtime. AI also optimizes production parameters automatically, leading to reduced material waste and improved energy efficiency. Cloud connectivity and remote monitoring capabilities allow manufacturers and service providers to diagnose issues remotely, update software, and provide proactive support, enhancing machine uptime and performance globally. This digitalization trend extends to mold design and simulation software, which significantly accelerates product development cycles, reduces prototyping costs, and allows for virtual testing of complex bottle geometries and material behaviors.

Sustainability concerns are also a major driver of technological innovation, leading to developments in machines capable of processing a wider range of recycled plastics, including post-consumer recycled (PCR) PET, and bio-based polymers. Multi-layer co-extrusion blow molding technology is becoming more prevalent, enabling the production of bottles with enhanced barrier properties for sensitive products like pharmaceuticals and certain food items, by layering different plastics. Aseptic blow molding, which combines sterile bottle production with filling, is gaining traction in the food and beverage sectors to meet stringent hygiene standards and extend product shelf life without preservatives. Moreover, advancements in auxiliary equipment such as efficient air recovery systems and improved cooling technologies further contribute to the overall energy efficiency and reduced environmental footprint of modern bottle blowing operations. Robotic handling systems for preform loading, bottle collection, and quality inspection are becoming standard, reducing manual labor, increasing consistency, and boosting overall production line efficiency.

Regional Highlights

- North America: The North American market is characterized by a strong emphasis on automation and advanced manufacturing technologies, driven by high labor costs and the need for operational efficiency. There is a significant demand for customized packaging solutions, particularly in the food, beverage, and pharmaceutical sectors, pushing innovation in machine flexibility and quick changeover capabilities. Stringent environmental regulations in the region are also accelerating the adoption of machines capable of processing recycled plastics and lightweight designs, aligning with circular economy initiatives and consumer preference for sustainable packaging.

- Europe: Europe stands as a hub for sophisticated bottle blowing machine technology, with a robust focus on sustainability, energy efficiency, and adherence to stringent environmental and health standards. Countries like Germany and Italy are leaders in manufacturing advanced machinery. The market is propelled by the widespread adoption of Industry 4.0 solutions, demand for high-quality and safe packaging in the food and pharmaceutical industries, and proactive regulatory measures promoting recycled content and waste reduction, driving innovation in machine design and material processing.

- Asia Pacific (APAC): Asia Pacific is the largest and fastest-growing market for bottle blowing machines globally, fueled by rapid industrialization, massive population growth, and rising disposable incomes across countries like China, India, and Southeast Asian nations. The region benefits from expanding food and beverage industries, burgeoning e-commerce, and increasing demand for packaged consumer goods. While cost-effectiveness remains a key factor, there is a growing trend towards adopting automated and semi-automatic machines to enhance production capacity and meet escalating consumer demand.

- Latin America: The Latin American market exhibits strong growth potential, primarily driven by increasing urbanization, improving economic conditions, and the expansion of the packaged food and beverage sectors. Countries such as Brazil and Mexico are witnessing significant investments in manufacturing capabilities, leading to a rise in demand for bottle blowing machines. The focus is on acquiring reliable and efficient machinery to cater to a growing consumer base, often balancing initial investment costs with long-term operational benefits and local market demands for various product categories.

- Middle East and Africa (MEA): The MEA region is emerging as a promising market for bottle blowing machines, spurred by ongoing infrastructure development, diversification of economies away from oil, and a rising consumer goods market. Increasing foreign direct investments, coupled with efforts to establish local manufacturing bases, are contributing to market expansion. The demand is particularly notable in the bottled water, juice, and dairy sectors, as well as for personal care products, with a growing need for machines that can handle diverse production scales and product types.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Bottle Blowing Machine Market.- Krones AG

- Sidel

- Nissei ASB Machine Co. Ltd.

- Amsler Equipment Inc.

- SMF (Sipol s.r.l.)

- Jomar Corporation

- PET Technologies

- Technopet Blow Moulding Systems

- Aoki Technical Laboratory Inc.

- KHS GmbH

- Guangzhou Tech-Long Packaging Machinery Co. Ltd.

- Chumpower Machinery Corp.

- Zilli & Bellini Srl

- Parker Plastic Machinery Co. Ltd.

- Graham Engineering Corporation

- FONG KE INDUSTRY CO. LTD.

- Automa S.p.A.

- Bekum Maschinenfabriken GmbH

- Magic MP SpA

- Sacmi Imola S.C.

Frequently Asked Questions

What is a bottle blowing machine and how does it work?

A bottle blowing machine is a specialized industrial equipment used to manufacture plastic bottles and containers by transforming plastic preforms or molten plastic into desired shapes. The fundamental process typically involves heating the plastic to a malleable state, then introducing it into a mold, and subsequently inflating it with compressed air to conform to the mold's cavity. The most common methods include extrusion blow molding, injection blow molding, and stretch blow molding, each suited for different plastic types and bottle characteristics, enabling high-speed and efficient production for various industries.

What are the primary types of bottle blowing machines available in the market?

The primary types of bottle blowing machines are Extrusion Blow Molding (EBM) machines, Injection Blow Molding (IBM) machines, and Stretch Blow Molding (SBM) machines. EBM is used for hollow products like detergent bottles. IBM is ideal for small, precise bottles like those for pharmaceuticals. SBM, particularly Reheat Stretch Blow Molding (RSBM), is predominant for PET bottles (e.g., water, soft drinks) due to its ability to enhance material strength and clarity. Each type caters to specific production needs based on material, volume, and bottle design requirements.

What types of plastic materials can be processed by these machines?

Bottle blowing machines are highly versatile and can process a wide range of thermoplastic materials. The most commonly processed plastics include Polyethylene Terephthalate (PET) for beverages and clear food containers, High-Density Polyethylene (HDPE) for milk jugs and chemical bottles, Polypropylene (PP) for hot-fill products and medical applications, and to a lesser extent, Polyvinyl Chloride (PVC) and Low-Density Polyethylene (LDPE). Specialized machines also handle materials like Polycarbonate (PC) for large water bottles, adapting to the diverse requirements of different end-use industries and product characteristics.

What are the key benefits of investing in modern bottle blowing machine technology?

Investing in modern bottle blowing machine technology offers numerous benefits, including significantly increased production efficiency and speed, resulting in higher output and reduced manufacturing costs per unit. These advanced machines are designed for superior energy efficiency, lowering operational expenses and environmental impact. They provide enhanced precision and control, leading to consistent product quality and reduced material waste. Furthermore, modern machines often feature greater automation, requiring less manual intervention, and offer improved flexibility for quick changeovers between different bottle designs and sizes, catering to diverse market demands and promoting overall operational excellence.

How do sustainability initiatives impact the bottle blowing machine market?

Sustainability initiatives profoundly impact the bottle blowing machine market by driving innovation towards eco-friendlier solutions. Manufacturers are developing machines capable of processing a higher percentage of recycled content, such as post-consumer recycled (PCR) PET, and supporting the use of bio-based plastics. There is a strong focus on lightweighting bottle designs to reduce material usage and transportation costs, while simultaneously investing in energy-efficient machine designs to minimize carbon footprints. These efforts are crucial for meeting stringent environmental regulations, addressing growing consumer demand for sustainable packaging, and contributing to a circular economy, influencing both machine design and material compatibility.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Automatic Bottle Blowing Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Bottle Blowing Machine Market Size Report By Type (Semi-automatic Machine, Automatic Machine), By Application (Food and Beverages, Pharmaceuticals, Cosmetic & Personal Care, Consumer Goods, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Automatic Bottle Blowing Machine Market Statistics 2025 Analysis By Application (Food and Beverages, Pharmaceuticals Cosmetics, Cosmetics), By Type (Semi-Automatic Machine, Fully-Automatic Machine), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager