Chemical Boiler Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431039 | Date : Nov, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Chemical Boiler Market Size

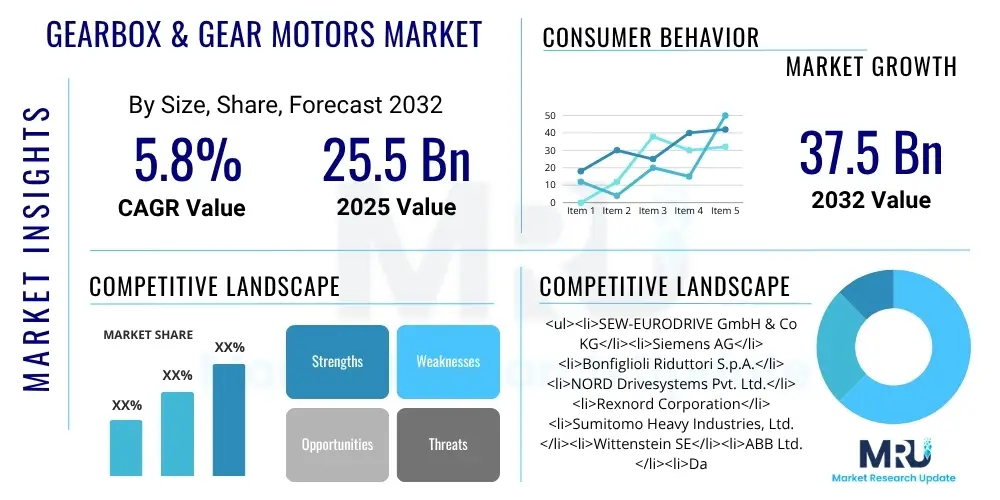

The Chemical Boiler Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 18.5 billion in 2025 and is projected to reach USD 27.3 billion by the end of the forecast period in 2032.

Chemical Boiler Market introduction

The Chemical Boiler Market encompasses the design, manufacturing, installation, and comprehensive servicing of highly specialized heating and steam generation equipment tailored for the demanding environments of the chemical processing industries. These critical industrial assets are engineered to provide precise temperature and pressure control, generating steam or hot thermal fluids essential for a vast array of chemical reactions, material processing, and energy requirements within modern plants. The primary function involves transferring heat from a fuel source to a fluid, usually water to produce steam, under controlled conditions to facilitate processes like distillation, evaporation, crystallization, and polymerization, all while adhering to rigorous safety and environmental protocols.

Product offerings in this market segment are characterized by robust construction, often utilizing advanced materials capable of resisting corrosive chemicals and extreme temperatures, ensuring longevity and operational reliability. Key features include highly efficient heat transfer surfaces, sophisticated burner technologies for optimal combustion, and integrated control systems that allow for precise regulation of operational parameters. Major applications span a wide spectrum of industrial sectors, including but not limited to petrochemical refining, where boilers support crude oil processing and hydrocarbon cracking; pharmaceutical manufacturing, requiring sterile steam for product synthesis and equipment sterilization; and specialty chemical production, where tailored heating solutions are vital for proprietary processes. The pulp and paper industry, food and beverage processing, and textiles also represent significant end-use sectors, leveraging chemical boilers for diverse heating and drying applications.

The core benefits derived from advanced chemical boiler systems include significantly improved energy efficiency, leading to reduced operational costs and a smaller carbon footprint, alongside enhanced process control that ensures consistent product quality and yield. Furthermore, modern boilers are designed with integrated safety features and robust regulatory compliance mechanisms, minimizing operational risks and environmental impact. Key driving factors propelling this market forward include the sustained global growth of the chemical industry, particularly in emerging economies, the imperative for industries to adopt more energy-efficient and sustainable production methods, increasingly stringent environmental regulations mandating lower emissions, and the widespread adoption of automation and digitalization to optimize boiler performance, maintenance schedules, and overall lifecycle management. The ongoing need for infrastructure modernization and replacement of older, less efficient units in developed regions also provides a continuous impetus for market expansion.

Chemical Boiler Market Executive Summary

The Chemical Boiler Market is experiencing a period of significant expansion, fundamentally propelled by the dynamic growth of the global chemical sector and an intensified industry-wide commitment to operational efficiency, sustainability, and stringent regulatory compliance. Business trends within this market are indicative of a pronounced shift towards sophisticated boiler technologies that incorporate advanced features such as enhanced energy recovery systems, significantly reduced emissions profiles, and fully integrated digital control platforms. These digital integrations are not merely for basic automation but extend to predictive maintenance, real-time performance optimization, and comprehensive data analytics, enabling chemical manufacturers to achieve unprecedented levels of operational excellence and reliability. Furthermore, there is a growing demand for highly customized boiler solutions that are precisely engineered to meet the unique and often complex thermal requirements of specific chemical processes, placing a premium on adaptability, durability, and adherence to the highest safety standards.

Analysis of regional trends unequivocally identifies Asia Pacific as the prevailing and most rapidly expanding market for chemical boilers. This dominance is attributable to aggressive industrialization, substantial capital investments in new chemical manufacturing facilities, and the escalating energy demands prevalent across economic powerhouses such as China, India, and other Southeast Asian nations. In stark contrast, North America and Europe represent mature market landscapes, characterized by well-established industrial infrastructures and the proactive implementation of exceptionally stringent environmental regulations. These regulatory frameworks are acting as powerful catalysts, driving the accelerated adoption of high-efficiency, ultra-low emission boiler technologies and necessitating continuous modernization initiatives for existing plant assets. Emerging markets in Latin America, the Middle East, and Africa are concurrently demonstrating considerable growth potential, spurred by new industrial projects, significant infrastructure development, and a concerted push for industrial diversification, particularly within the petrochemical and associated chemical sectors.

Segmentation trends within the chemical boiler market reveal distinct preferences and technological trajectories. Water-tube boilers continue to be the preferred choice for large-scale chemical and petrochemical complexes due to their inherent capabilities for generating high-pressure, high-capacity steam, which is critical for complex industrial processes. Conversely, fire-tube boilers retain strong market penetration in smaller to medium-scale industrial applications, where their robust design and moderate steam output align with less intensive operational requirements. A prominent emerging trend is the increasing market demand for boilers capable of operating efficiently with alternative and renewable fuel sources, including biomass, industrial waste, and advanced biofuels. This shift is deeply intertwined with global decarbonization efforts and corporate sustainability objectives. End-user segments, particularly within the petrochemical and pharmaceutical industries, are consistently allocating significant capital towards investing in state-of-the-art boiler systems, aiming to not only enhance productive capacities and process yields but also to rigorously comply with evolving environmental and safety regulations, thereby securing their long-term operational viability.

AI Impact Analysis on Chemical Boiler Market

Industry stakeholders and end-users frequently pose critical questions regarding the transformative potential of Artificial Intelligence within the chemical boiler market. Their inquiries primarily focus on how AI can fundamentally enhance operational efficiency, revolutionize maintenance strategies through predictive capabilities, and significantly bolster overall plant safety. Specific concerns and expectations often center on AI's ability to precisely optimize fuel consumption, thereby reducing costs and environmental impact; its capacity to predict equipment failures with high accuracy, minimizing costly unplanned downtime; and its role in automating complex control processes, which can drastically reduce the potential for human error and improve system stability. Furthermore, there is considerable interest in leveraging AI to achieve higher levels of operational sustainability and ensure rigorous compliance with continually evolving environmental standards through intelligent energy management and advanced emissions control systems.

- AI-driven predictive maintenance algorithms proactively identify potential equipment failures, significantly reducing unplanned downtime and extending the operational lifespan of critical boiler components.

- Real-time optimization of combustion processes using AI analytics leads to substantial improvements in fuel efficiency, minimizing operational expenditures and enhancing thermal output.

- Enhanced safety protocols are established through AI-powered anomaly detection and intelligent alert systems that can identify deviations from normal operating conditions before they escalate into critical incidents.

- Automated control systems, leveraging AI, adapt to changing process parameters, improving operational stability, reducing the need for constant manual intervention, and ensuring consistent output quality.

- AI assists in sophisticated energy consumption management by forecasting demand and optimizing boiler output, contributing significantly to reduced carbon footprints and compliance with environmental regulations.

- Faster and more accurate fault diagnosis and troubleshooting are enabled by AI, which can process vast amounts of sensor data to pinpoint issues, leading to quicker resolutions and minimized production interruptions.

- Improved regulatory compliance is facilitated through continuous, AI-driven monitoring and comprehensive data analysis, ensuring that boiler operations consistently meet or exceed environmental and safety standards.

DRO & Impact Forces Of Chemical Boiler Market

The Chemical Boiler Market is profoundly shaped by an intricate interplay of driving forces, inherent restraining factors, and burgeoning opportunities that collectively influence its growth trajectory and competitive landscape. A primary driver is the relentless expansion of the global chemical industry, particularly in developing economies, which inherently demands a sustained and reliable supply of process heat and steam. This expansion necessitates new boiler installations and upgrades to existing infrastructure. Concurrently, the escalating imperative for industries to achieve superior energy efficiency across their operations is a powerful catalyst. Modern chemical boilers, designed for optimized fuel consumption and maximum heat recovery, offer a crucial pathway to reduce operational costs and enhance competitiveness. Moreover, increasingly stringent global environmental regulations pertaining to industrial emissions and fuel consumption vigorously compel chemical manufacturers to adopt advanced, cleaner combustion technologies and to continuously modernize their boiler fleets, further stimulating market demand. The ongoing trend towards industrial automation and the integration of digital technologies for process optimization also acts as a significant market impetus, driving demand for smart, connected boiler systems.

Despite these robust drivers, the market navigates several notable restraints. The initial capital expenditure associated with acquiring and installing advanced chemical boiler systems can be exceptionally high, often representing a substantial financial barrier, particularly for small and medium-sized enterprises (SMEs). This high upfront cost can lead to delayed investment cycles or a preference for less efficient, older technologies. Furthermore, the inherent technical complexity involved in the design, installation, operation, and meticulous maintenance of these sophisticated industrial assets, combined with a persistent shortage of adequately skilled labor capable of managing advanced boiler systems, poses considerable operational challenges. Volatility in the prices of critical raw materials, such as high-grade steel, specialized alloys, and control components, can significantly impact manufacturing costs and, consequently, the final pricing of boiler units. Additionally, the paramount importance of safety within chemical processing environments necessitates extraordinarily rigorous design, manufacturing, and operational standards for boilers, which inevitably adds to development costs and project timelines, acting as a constraining factor.

However, the Chemical Boiler Market is also replete with compelling opportunities that promise future growth and innovation. A significant avenue lies in providing highly customized boiler solutions that can be precisely engineered to meet the unique and diverse thermal processing specifications of various chemical reactions and production lines, offering a competitive edge. The accelerating integration of digitalization, the Internet of Things (IoT), and Artificial Intelligence (AI) presents substantial opportunities for enhancing boiler performance through predictive maintenance, real-time operational optimization, and advanced fault diagnostics. Furthermore, the global push towards decarbonization and sustainable manufacturing creates immense potential for developing boilers that are fully compatible with and optimized for renewable energy sources, including biomass, industrial waste heat recovery systems, and electric heating solutions, aligning with global environmental objectives. Lastly, strategic expansion into rapidly industrializing emerging economies, characterized by growing industrial bases and increasing energy demands, offers lucrative growth prospects for manufacturers capable of delivering cost-effective and reliable boiler technologies.

Segmentation Analysis

The Chemical Boiler Market undergoes comprehensive segmentation across several pivotal parameters, providing an intricate and granular perspective on its underlying structure, demand drivers, and competitive dynamics. This segmentation is instrumental in deciphering the varied technological preferences, application-specific requirements, and distinct growth trajectories prevalent within the diverse landscape of the global chemical processing industry. By categorizing the market based on boiler type, operational capacity, primary fuel source, and specific end-use industry, a detailed understanding of market niches and evolving customer needs emerges. Each segment and its corresponding subsegments are influenced by unique sets of technical specifications, regulatory pressures, and economic considerations, collectively shaping product innovation and strategic investment decisions by market participants.

The segmentation by boiler type delineates the fundamental design and operating principles of the heating systems. Water-tube boilers, known for their high pressure and capacity capabilities, are distinct from fire-tube boilers, which are favored for their robustness and suitability for lower-capacity applications. Electric boilers offer clean operation and flexibility in energy sourcing, while thermal fluid heaters provide high-temperature heat without pressure. Hybrid boilers represent innovative solutions combining features for optimized performance. Capacity-based segmentation addresses the scale of industrial operations, ranging from small units for pilot plants or auxiliary processes to large units capable of supporting entire chemical complexes. Fuel type segmentation is crucial as it reflects energy cost considerations, environmental mandates, and the availability of resources, moving towards greater reliance on natural gas and sustainable alternatives.

- By Type

- Water-tube Boilers: Characterized by water flowing inside tubes, heated externally by combustion gases, offering high pressure and large steam generation capacities, ideal for large chemical complexes.

- Fire-tube Boilers: Feature hot gases flowing through tubes surrounded by water, known for robust construction, ease of maintenance, and suitability for moderate steam demands.

- Electric Boilers: Utilize electric resistance to heat water, offering zero direct emissions, rapid response, and compact size, often used where electricity is abundant or emissions are strictly controlled.

- Thermal Fluid Heaters: Employ thermal oil or other synthetic fluids instead of water, providing high process temperatures at low pressures, critical for specific chemical reactions.

- Hybrid Boilers: Combine different heating methods or fuel sources, such as gas and electric, to optimize efficiency, flexibility, and reliability based on operational needs.

- By Capacity

- Small (Up to 10 TPH - Tons Per Hour): Typically used for smaller plants, specific process units, or auxiliary heating requirements, emphasizing compactness and quick startup.

- Medium (10 TPH - 50 TPH): Caters to a broad range of industrial applications, balancing capacity with efficiency and footprint, common in mid-sized chemical facilities.

- Large (Above 50 TPH): Designed for extensive chemical and petrochemical complexes requiring substantial and continuous steam or heat supply, often custom-engineered for specific high-volume processes.

- By Fuel Type

- Natural Gas: Dominant due to its clean burning properties, abundant supply, and cost-effectiveness, widely preferred in regions with established gas infrastructure.

- Oil (Heavy Fuel Oil, Light Fuel Oil): Continues to be used, especially in areas where gas infrastructure is limited, offering high energy density but facing scrutiny for emissions.

- Coal: While declining in favor of cleaner fuels, still utilized in some regions due to its low cost and abundance, often with advanced emissions control technologies.

- Biomass and Waste: Growing segment driven by sustainability goals, utilizing agricultural waste, wood chips, or industrial waste for energy generation, reducing reliance on fossil fuels.

- Electric: Increasingly adopted for its zero-emission profile at the point of use, particularly where renewable electricity sources are available, and for small to medium capacities.

- Other Alternative Fuels: Includes hydrogen, biogas, and other emerging fuels, representing future growth avenues for ultra-low emission boiler systems.

- By End-Use Industry

- Chemical and Petrochemical: Largest segment, demanding high-capacity and robust boilers for refining, cracking, synthesis, and various downstream processes.

- Pharmaceuticals: Requires clean steam for sterilization, distillation, and precise temperature control in drug manufacturing, emphasizing purity and compliance.

- Food and Beverage: Utilizes boilers for cooking, sterilization, drying, and cleaning processes, with a focus on hygiene and energy efficiency.

- Pulp and Paper: Depends on boilers for generating steam for wood pulping, drying, and energy recovery from biomass byproducts.

- Textiles: Employs boilers for dyeing, finishing, and drying processes, with a need for consistent steam quality and temperature.

- Power Generation (Industrial Co-generation): Integral for combined heat and power (CHP) plants in industrial settings, optimizing energy utilization.

- Other Manufacturing Industries: Includes metals, automotive, and various industrial facilities requiring process heat or steam.

Value Chain Analysis For Chemical Boiler Market

The value chain for the Chemical Boiler Market commences with an exhaustive upstream analysis, focusing on the intricate procurement of essential raw materials, specialized components, and sophisticated sub-systems that form the bedrock of boiler construction. This foundational stage involves sourcing high-grade steel plates and tubes, corrosion-resistant alloys, refractory linings, insulation materials, precision-engineered pumps, control valves, high-efficiency burners, and advanced instrumentation for pressure, temperature, and flow monitoring. Furthermore, critical elements like digital control systems (DCS/SCADA), safety interlocks, and emission control technologies are acquired from specialized suppliers. Establishing and maintaining robust, long-term relationships with a diverse network of reputable and quality-focused suppliers is paramount to ensure the consistent availability of materials that meet stringent industrial standards, specific chemical resistance requirements, and certifications for structural integrity and thermal performance.

Progressing through the midstream, the focus shifts to the manufacturing, assembly, and rigorous quality assurance processes. This phase includes precision cutting, welding, bending, and heat treatment of materials, followed by the meticulous assembly of boiler components. Manufacturers leverage advanced engineering capabilities, specialized fabrication techniques, and stringent quality control protocols to ensure each boiler unit adheres to international codes (e.g., ASME, EN) and client specifications. Testing, commissioning, and factory acceptance tests are integral to this stage, verifying performance, safety, and reliability before shipment. Strategic decisions regarding modular construction, customization capabilities, and production scalability are made here, significantly impacting efficiency and responsiveness to market demands.

The downstream segment of the value chain is centered on the deployment, operationalization, and sustained support of chemical boilers within end-user facilities. This critical stage encompasses site preparation, complex logistical coordination for transportation, professional installation, and comprehensive commissioning services to integrate the boiler seamlessly into existing plant infrastructure. Beyond initial setup, the downstream value chain is characterized by the provision of extensive after-sales services, including scheduled maintenance, emergency repairs, spare parts supply, performance optimization upgrades, and operator training. These ongoing support services are vital for ensuring the long-term operational efficiency, safety, and longevity of the boiler system, directly impacting the end-user's productivity and return on investment. The feedback loop from downstream operations to upstream design and manufacturing is crucial for continuous product improvement and innovation.

Distribution channels within the Chemical Boiler Market are diverse, employing both direct and indirect sales strategies to reach a broad customer base. Direct sales are typically favored for large-scale, complex projects involving major chemical and petrochemical corporations. Here, manufacturers deploy dedicated sales teams, highly specialized engineering consultants, and project managers who work closely with clients to provide bespoke boiler solutions, technical expertise, and comprehensive project management from concept to completion. Indirect channels involve strategic partnerships with Engineering Procurement and Construction (EPC) firms, who integrate boiler packages into larger turnkey plant projects, and a network of authorized distributors, local agents, and value-added resellers. These indirect partners often provide regional market access, localized support, and smaller-scale project management, catering to a wider array of industrial buyers, including small and medium-sized chemical enterprises. The selection of the most appropriate distribution channel is often dictated by the project's size, geographical location, the complexity of technical requirements, and the specific service needs of the end-user, ensuring optimal market penetration and efficient service delivery across global markets.

Chemical Boiler Market Potential Customers

Potential customers for the Chemical Boiler Market primarily encompass a broad spectrum of industrial enterprises deeply entrenched in various chemical processing, manufacturing, and energy-intensive operations that necessitate a consistent and precisely controlled supply of heat or steam. These end-users are intrinsically defined by their need for exceptionally reliable, highly efficient, and frequently customized boiler systems designed to withstand and support complex, often hazardous, and continuous production cycles. The inherent nature of their industrial operations, which often involves the handling of corrosive, flammable, or toxic materials, mandates that boilers adhere to the most rigorous safety standards, environmental compliance frameworks, and operational longevity requirements, thereby making technologically advanced and robust solutions an absolute imperative for their procurement decisions.

Key segments within this extensive customer base include, but are not limited to, colossal petrochemical complexes that leverage boilers for a myriad of processes such as crude oil refining, hydrocarbon cracking, and the synthesis of foundational chemicals like ethylene and propylene. Pharmaceutical manufacturing facilities also represent a significant customer segment, where ultra-pure steam is indispensable for sterilization of equipment, precise temperature control in chemical reactions, distillation processes, and the synthesis of active pharmaceutical ingredients (APIs), all under strict regulatory scrutiny. Furthermore, the specialty chemical sector, agrochemical producers, manufacturers of plastics and polymers, and the fertilizer industry are substantial buyers, utilizing boilers for a diverse range of thermal applications, from heating reaction vessels and industrial dryers to generating power for plant utilities, highlighting the versatility required in boiler design.

Beyond the direct chemical processing industries, industrial power generation facilities, particularly those implementing advanced co-generation (CHP – Combined Heat and Power) or trigeneration systems, constitute a substantial and growing customer segment. These entities seek sophisticated boiler solutions capable of efficiently producing both electricity and process steam or hot water simultaneously, thereby maximizing energy utilization, reducing overall operating costs, and enhancing energy independence. The procurement processes within these diverse sectors are typically governed by an array of critical factors, including demonstrated boiler efficiency and fuel flexibility, meticulous compliance with evolving emissions standards and safety regulations, comprehensive consideration of long-term maintenance costs and total cost of ownership (TCO), and crucially, the seamless capability of the boiler system to integrate flawlessly with existing plant infrastructure and advanced automation systems. These multifaceted considerations underscore the strategic importance of boiler selection in sustaining competitive advantage and ensuring operational continuity for industrial clients.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 18.5 billion |

| Market Forecast in 2032 | USD 27.3 billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Babcock & Wilcox Enterprises Inc., Siemens Energy AG, General Electric Company, Mitsubishi Heavy Industries Ltd., Thermax Limited, Cleaver-Brooks, Inc., Bosch Industriekessel GmbH, Fulton Boiler Works, Inc., Miura Co. Ltd., John Cockerill, Sofinter S.p.A. (Macchi), Kawasaki Heavy Industries Ltd., IHI Corporation, Hurst Boiler & Welding Co., Inc., Viessmann Group, Aalborg CSP A/S, Clayton Industries, Foster Wheeler AG, Byworth Boilers, York-Shipley Global |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Chemical Boiler Market Key Technology Landscape

The Chemical Boiler Market is characterized by a rapidly evolving and sophisticated technology landscape, primarily driven by the overarching industry goals of enhancing operational efficiency, drastically reducing environmental emissions, and improving overall operational intelligence and safety. A paramount trend involves the widespread integration of highly advanced digital control systems, such as Distributed Control Systems (DCS) and Supervisory Control and Data Acquisition (SCADA) platforms. These sophisticated systems enable exceptionally precise and real-time management of critical operational parameters, including combustion ratios, fuel-air mixtures, steam pressure, and fluid temperatures. Such granular control directly translates into optimized fuel consumption, sustained process stability, and ultimately, superior product quality and yield. This technological evolution is invariably coupled with the deployment of smart sensors and interconnected Internet of Things (IoT) devices, which continuously gather vast amounts of operational data for comprehensive performance monitoring, predictive analytics, and proactive maintenance strategies, signaling a significant shift from reactive to preventive asset management.

Further significant advancements are being realized in innovative combustion technologies, which are meticulously engineered for the cleaner and more efficient burning of an increasingly diverse range of fuel types. This includes not only conventional natural gas and various grades of oil but also extends to biomass, industrial waste products, and advanced biofuels. These next-generation combustion systems are specifically designed to significantly reduce the emission of harmful pollutants such as nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter, thereby ensuring stricter compliance with global environmental regulations and enhancing corporate social responsibility. Concurrently, the adoption of modular boiler designs is gaining considerable traction across the industry. This design philosophy offers compelling benefits, including dramatically faster installation times, simplified scalability to meet fluctuating production demands, and a reduced physical footprint, which is particularly advantageous in space-constrained industrial environments common in chemical plants. Furthermore, relentless innovation in material science plays an absolutely crucial role, with ongoing research and development focused on discovering and implementing new high-performance alloys and refractory materials that offer superior corrosion resistance, enhanced thermal stability, and extended durability, particularly under the highly aggressive chemical processing conditions prevalent in the sector.

Emerging and cutting-edge technologies within the chemical boiler market are also intensely focused on maximizing energy recovery and fostering overall plant sustainability. This includes the strategic implementation of advanced waste heat recovery units (WHRU), which are meticulously designed to capture and effectively reuse exhaust heat that would otherwise be wasted. This recovered heat can be repurposed to preheat boiler feedwater, generate additional process steam, or even contribute to auxiliary power generation, thereby significantly boosting overall thermal efficiency and reducing primary fuel consumption. Another area gaining substantial prominence is the application of digital twin technology. This innovative approach allows for the creation of virtual replicas of physical boiler systems, enabling comprehensive virtual modeling and simulation of complex boiler operations. These digital twins are invaluable for optimizing performance under various scenarios, developing robust operator training programs, and rigorously testing maintenance strategies or system upgrades without any risk or disruption to live production. Collectively, these multifaceted technological developments are converging to provide chemical manufacturers with safer, exponentially more efficient, environmentally compliant, and economically viable boiler solutions, positioning the industry for a sustainable and technologically advanced future.

Regional Highlights

- North America: This region constitutes a mature yet dynamic market, predominantly influenced by rigorous environmental regulations, an urgent imperative for industrial infrastructure modernization, and a pervasive emphasis on achieving superior energy efficiency. The United States and Canada stand out as pivotal contributors, characterized by substantial investments in the retrofitting and upgrading of existing chemical plants and the enthusiastic adoption of advanced automation and digital technologies across their operational spectrum. The availability of cost-effective natural gas, bolstered by the domestic shale gas boom, has significantly favored the installation of highly efficient gas-fired boiler systems, supporting a cleaner energy transition.

- Europe: Europe is uniquely defined by its unwavering commitment to sustainability, ambitious decarbonization targets, and strict adherence to some of the world's most demanding emissions standards. Countries such as Germany, the United Kingdom, and France are at the forefront, channeling considerable investments into the deployment of ultra-high efficiency boilers, pioneering waste-to-energy solutions, and actively integrating technologies that harness renewable energy sources for process heat. The market here is additionally spurred by the critical need to replace an aging industrial infrastructure and by the overarching policy push towards circular economy principles throughout the chemical manufacturing value chain, driving continuous innovation.

- Asia Pacific (APAC): APAC solidifies its position as the largest and most rapidly expanding market for chemical boilers globally. This explosive growth is primarily attributable to sweeping industrialization initiatives, massive capital injections into new chemical and petrochemical manufacturing capacities, and the relentlessly escalating energy demands across rapidly developing economies. Major economic powerhouses like China, India, Japan, and South Korea are experiencing robust growth across a diverse array of end-use industries, including pharmaceuticals and specialty chemicals. Proactive government policies and supportive initiatives aimed at fostering industrial manufacturing and infrastructure development further accelerate market expansion and technology adoption in this vibrant region.

- Latin America: The market for chemical boilers in Latin America is demonstrating consistent and robust growth, underpinned by significant industrial expansion across key nations such as Brazil, Mexico, and Argentina. Escalating investments in the petrochemical, fertilizer, and pharmaceutical sectors are acting as strong drivers for the demand for both new boiler installations and substantial upgrades to existing systems. Increasing economic stability, coupled with growing foreign direct investments (FDI) into the region's burgeoning industrial sectors, are crucial determinants shaping and driving the dynamic market landscape.

- Middle East and Africa (MEA): The MEA region presents substantial and compelling growth opportunities, particularly within the Gulf Cooperation Council (GCC) countries. This is largely due to their immense oil and gas reserves and aggressive economic diversification strategies that involve significant expansion into downstream chemical production, petrochemicals, and other manufacturing industries. Countries like Saudi Arabia, the UAE, and Qatar are embarking on colossal projects to establish new, integrated petrochemical complexes, leading to an exponential demand for high-capacity, technologically advanced, and highly reliable chemical boiler systems. Concurrently, Africa’s burgeoning industrial landscape, driven by urbanization and nascent manufacturing growth, also significantly contributes to the expanding market for industrial heating solutions in the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Chemical Boiler Market.- Babcock & Wilcox Enterprises Inc.

- Siemens Energy AG

- General Electric Company

- Mitsubishi Heavy Industries Ltd.

- Thermax Limited

- Cleaver-Brooks, Inc.

- Bosch Industriekessel GmbH

- Fulton Boiler Works, Inc.

- Miura Co. Ltd.

- John Cockerill

- Sofinter S.p.A. (Macchi)

- Kawasaki Heavy Industries Ltd.

- IHI Corporation

- Hurst Boiler & Welding Co., Inc.

- Viessmann Group

- Aalborg CSP A/S

- Clayton Industries

- Foster Wheeler AG

- Byworth Boilers

- York-Shipley Global

Frequently Asked Questions

What is a chemical boiler used for?

A chemical boiler is an industrial heat exchanger system specifically designed to generate high-pressure steam or hot thermal fluid. It is indispensable for various processes within chemical manufacturing plants, including precisely heating reactants for chemical synthesis, driving distillation columns for product separation, and providing motive power or sterilization for auxiliary equipment and processes.

How do chemical boilers contribute to sustainability?

Modern chemical boilers significantly contribute to sustainability through several mechanisms: they achieve enhanced energy efficiency, leading to substantially reduced fossil fuel consumption; they incorporate advanced combustion technologies that drastically lower greenhouse gas emissions; and many are designed with the flexibility to utilize alternative or waste fuels, actively minimizing overall environmental impact and promoting responsible resource management.

What are the main types of chemical boilers?

The main types of chemical boilers include water-tube boilers, highly favored for their ability to generate high-pressure steam in large volumes for extensive industrial applications; fire-tube boilers, which are robust and typically chosen for moderate steam demands in smaller industrial settings; electric boilers, valued for their zero direct emissions at the point of use and rapid response capabilities; and thermal fluid heaters, which deliver extremely high temperatures at lower pressures for specialized chemical reactions.

What factors drive the chemical boiler market growth?

The chemical boiler market growth is primarily propelled by the continuous expansion and modernization of the global chemical industry, the increasing and critical demand for highly energy-efficient process heating solutions, the imperative to comply with increasingly stringent environmental regulations concerning emissions, and the accelerating adoption of industrial automation and digitalization technologies to optimize plant operations and boiler performance.

How does AI enhance chemical boiler operations?

Artificial Intelligence (AI) revolutionizes chemical boiler operations by enabling sophisticated predictive maintenance, which proactively identifies potential failures and reduces costly downtime. It optimizes combustion processes in real-time for superior fuel efficiency, automates complex control systems to ensure stable performance, and detects subtle anomalies, thereby significantly boosting overall safety and operational reliability while reducing human intervention.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Fire Tube Chemical Boiler Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Condensing Chemical Boiler Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Condensing Fire Tube Chemical Boiler Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Gas Fueled Fire Tube Chemical Boiler Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Water Tube Chemical Boiler Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager