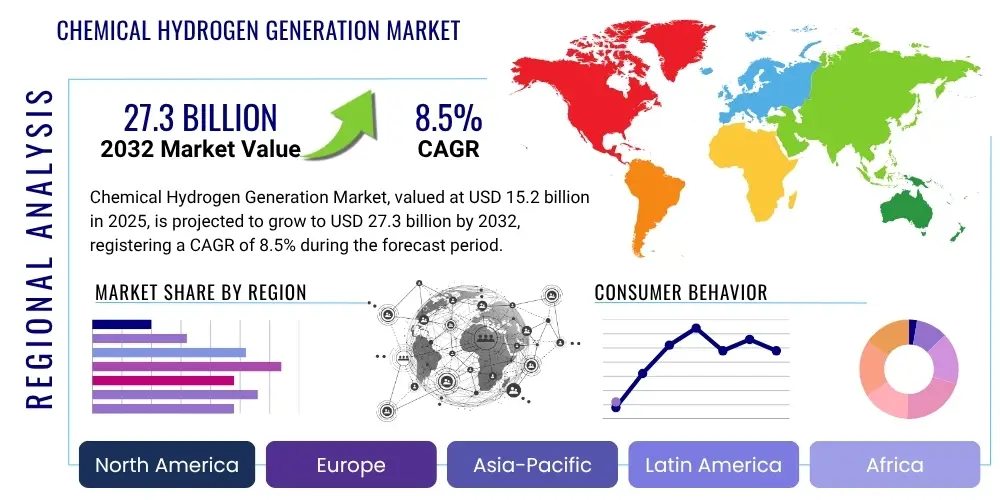

Chemical Hydrogen Generation Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428762 | Date : Oct, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Chemical Hydrogen Generation Market Size

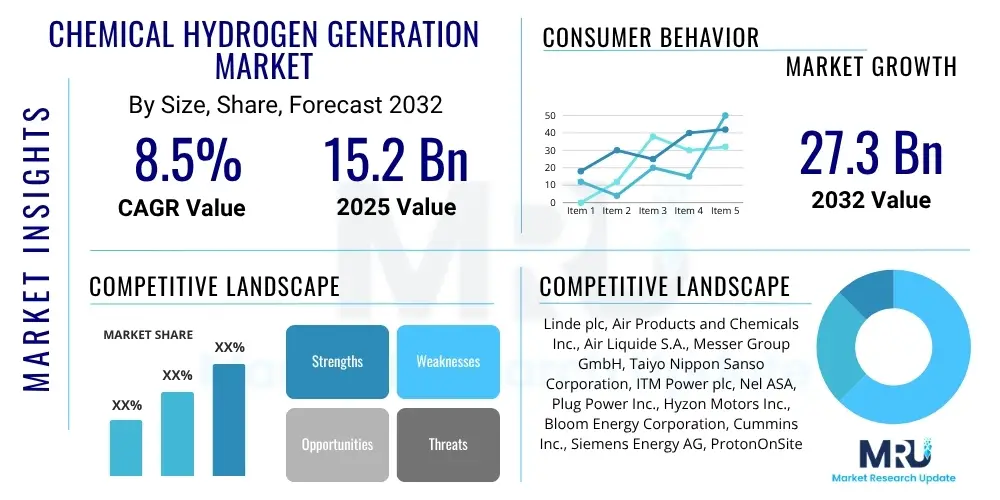

The Chemical Hydrogen Generation Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2025 and 2032. The market is estimated at USD 15.2 billion in 2025 and is projected to reach USD 27.3 billion by the end of the forecast period in 2032.

Chemical Hydrogen Generation Market introduction

The Chemical Hydrogen Generation Market encompasses various technologies and processes focused on producing hydrogen through chemical reactions, as opposed to physical separation or direct extraction. This sector is critical for the evolving energy landscape, providing on-demand and decentralized hydrogen supply solutions. Products in this market range from highly efficient catalysts and chemical hydrides to complete modular hydrogen generation systems, each designed for specific applications and operational scales.

Major applications for chemically generated hydrogen span across diverse industries including fuel cell vehicles, industrial feedstock for ammonia and methanol production, power generation, and energy storage. The unique benefits of chemical hydrogen generation include enhanced safety through lower storage pressures, reduced transportation costs, and the potential for greater energy independence. This flexibility makes it particularly appealing for niche applications requiring portable or remote hydrogen supplies, where traditional bulk storage or centralized production is impractical.

Key driving factors for the expansion of this market include the global push for decarbonization and the urgent need for clean energy alternatives. Governments worldwide are implementing stringent environmental regulations and offering substantial incentives for green hydrogen production and adoption. Furthermore, rapid advancements in fuel cell technology across automotive, marine, and stationary power sectors are fueling demand for reliable and efficient hydrogen supply, positioning chemical generation as a viable and attractive option for future energy ecosystems.

Chemical Hydrogen Generation Market Executive Summary

The Chemical Hydrogen Generation Market is experiencing robust growth driven by an accelerating global energy transition and a burgeoning demand for clean hydrogen. Business trends indicate a strong focus on strategic partnerships and collaborations between technology developers, chemical producers, and energy companies, aiming to scale up production capacities and optimize cost structures. There is also a significant surge in research and development investment towards novel, more efficient, and sustainable chemical routes for hydrogen generation, including advanced catalyst development and innovative hydride technologies.

Regional trends reveal Asia Pacific as a dominant and rapidly expanding market, primarily due to ambitious industrial growth, increasing investments in renewable energy infrastructure, and strong governmental support for hydrogen-based economies in countries like China, Japan, and South Korea. Europe is also a key player, propelled by the European Green Deal and extensive initiatives to establish a continent-wide hydrogen economy, emphasizing green hydrogen production and utilization. North America shows steady progress, driven by decarbonization targets, increasing adoption of fuel cell technology, and investments in hydrogen hubs, particularly in the United States.

Segmentation trends highlight a growing emphasis on specific generation methods and end-use applications. Electrolysis, particularly PEM (Proton Exchange Membrane) and Solid Oxide Electrolysis (SOEC), powered by renewable electricity, is gaining significant traction due to its "green" credentials. Chemical hydride-based generation, offering compact and portable solutions, is also seeing increased interest for niche applications. Application-wise, industrial feedstock remains a foundational segment, while power generation, fuel cell electric vehicles (FCEVs), and energy storage are emerging as high-growth areas, promising substantial market expansion over the forecast period.

AI Impact Analysis on Chemical Hydrogen Generation Market

User inquiries concerning AI's influence on the Chemical Hydrogen Generation Market frequently revolve around optimizing complex chemical processes, enhancing safety protocols, and improving the overall efficiency of hydrogen production. There is a keen interest in how artificial intelligence can minimize operational costs, predict equipment failures, and enable smarter integration with renewable energy sources. Key themes include the potential for AI to accelerate material discovery for catalysts and hydrides, refine process parameters in real-time, and manage the intricate supply chains associated with hydrogen distribution. Stakeholders anticipate AI playing a pivotal role in making chemical hydrogen generation more economically viable and environmentally sustainable by overcoming current technological and operational hurdles.

- AI-driven optimization of reaction conditions and catalyst performance in chemical hydrogen generation processes.

- Predictive maintenance and fault detection for hydrogen generation equipment, enhancing operational uptime and safety.

- Automated control systems improving energy efficiency and reducing raw material consumption in hydrogen production.

- AI-assisted design and discovery of novel chemical hydrides and catalysts with superior hydrogen storage and release properties.

- Intelligent supply chain management for hydrogen distribution, optimizing logistics and reducing transportation costs.

- Real-time monitoring and data analysis for improved process stability and compliance with environmental regulations.

- Integration of chemical hydrogen generation units with smart grids, enabling dynamic response to renewable energy fluctuations.

- Robotics and AI in automated assembly and maintenance of chemical hydrogen generation modules.

DRO & Impact Forces Of Chemical Hydrogen Generation Market

The Chemical Hydrogen Generation Market is significantly influenced by a confluence of driving factors, pervasive restraints, substantial opportunities, and impactful external forces. The escalating global demand for clean energy and the imperative to reduce carbon emissions stand as primary drivers, pushing industries and governments towards hydrogen as a viable alternative fuel. Advancements in fuel cell technology, making hydrogen more accessible and efficient for various applications, further bolster this demand. Concurrently, supportive government policies, including subsidies, tax incentives, and regulatory frameworks promoting hydrogen infrastructure, are instrumental in fostering market growth.

Despite these drivers, the market faces several restraining factors. The high capital expenditure associated with establishing hydrogen generation plants and distribution infrastructure remains a significant barrier for new entrants and scaling existing operations. Safety concerns related to hydrogen storage, handling, and transportation, although being addressed through continuous innovation, still pose a challenge to public acceptance and widespread adoption. Additionally, the reliance on specific raw materials, such as natural gas for steam methane reforming or specialized chemicals for hydrides, can lead to supply chain vulnerabilities and price volatility.

Nevertheless, the market is rich with opportunities. The emergence of new and cost-effective hydrogen generation technologies, particularly those leveraging renewable feedstocks, offers immense potential for sustainable expansion. The expanding application base, including long-duration energy storage, industrial decarbonization, and heavy-duty transportation, presents new avenues for market penetration. Furthermore, international collaborations and investments in cross-border hydrogen projects are poised to accelerate technological transfer and market development, creating a truly global hydrogen economy.

Segmentation Analysis

The Chemical Hydrogen Generation Market is broadly segmented based on several key criteria, allowing for a detailed understanding of its dynamics and growth trajectories. These segments include the method of generation, the application areas, the end-use industries, and the types of raw materials utilized. Each segment possesses distinct characteristics, market drivers, and technological landscapes, contributing uniquely to the overall market structure and competitive environment. Analyzing these segments helps stakeholders identify lucrative opportunities and tailor strategies to specific market needs.

Understanding the interplay between these segments is crucial for market participants. For instance, while traditional methods like steam methane reforming currently dominate due to cost-effectiveness, the increasing emphasis on decarbonization is rapidly shifting investment towards greener methods like electrolysis and chemical looping. Similarly, while industrial feedstock remains a foundational application, the high-growth potential lies in emerging sectors such as fuel cell electric vehicles and grid-scale energy storage, which demand different specifications and supply chain considerations for hydrogen generation.

- By Method

- Steam Methane Reforming (SMR)

- Autothermal Reforming (ATR)

- Partial Oxidation (POX)

- Electrolysis (Alkaline, PEM, SOEC)

- Chemical Hydride Hydrolysis (e.g., Borohydrides, Ammoniaborane)

- Biomass Gasification

- Chemical Looping Reforming

- Photoelectrochemical (PEC) Water Splitting

- By Application

- Industrial Feedstock (Ammonia Production, Methanol Production, Refinery Hydrotreating)

- Power Generation (Fuel Cells, Turbines)

- Transportation (Fuel Cell Electric Vehicles, Maritime, Aviation, Rail)

- Energy Storage

- Electronics

- Metallurgy

- Glass Manufacturing

- By End-Use Industry

- Chemicals and Petrochemicals

- Refining

- Metals

- Automotive

- Power Sector

- Pharmaceuticals

- Food and Beverage

- By Raw Material

- Natural Gas

- Water

- Biomass

- Chemical Hydrides (e.g., Sodium Borohydride, Magnesium Hydride)

- Methanol

- Naphtha

Value Chain Analysis For Chemical Hydrogen Generation Market

The value chain for the Chemical Hydrogen Generation Market is intricate, beginning with the sourcing of diverse raw materials and extending to the ultimate consumption of hydrogen in various end-use applications. Upstream activities primarily involve the procurement and processing of feedstocks such as natural gas, water, biomass, or chemical hydrides. This stage includes exploration and extraction for fossil fuels, water purification for electrolysis, and the synthesis of specialized chemical hydrides. Efficiency and cost-effectiveness at this initial stage are crucial, as they significantly impact the overall production cost of hydrogen.

Midstream operations focus on the actual hydrogen generation processes, encompassing a wide array of technologies from large-scale industrial reformers to modular electrolyzers and chemical hydride reactors. This segment also includes the purification and compression of hydrogen to meet specific quality standards required by different applications. Downstream activities involve the storage, transportation, and distribution of hydrogen to various end-users. This can range from high-pressure gas storage and cryogenic liquefaction to pipeline networks and specialized delivery vehicles, each chosen based on volume, distance, and application needs.

Distribution channels for chemically generated hydrogen are bifurcated into direct and indirect methods. Direct channels involve producers supplying hydrogen directly to large industrial consumers such as refineries, chemical plants, and steel manufacturers through dedicated pipelines or bulk deliveries. Indirect channels involve a network of distributors, retailers, and refueling stations that serve smaller industrial users, fuel cell vehicle operators, and other commercial applications. The optimization of these channels is vital for reducing costs and enhancing accessibility, thereby supporting the broader adoption of hydrogen as an energy carrier.

Chemical Hydrogen Generation Market Potential Customers

The Chemical Hydrogen Generation Market caters to a diverse range of end-users and buyers, each with unique requirements for hydrogen quality, volume, and delivery. Industrial sectors form the bedrock of demand, particularly the chemical and petrochemical industries which utilize hydrogen extensively as a feedstock for producing ammonia, methanol, and for various refining processes like hydrotreating and hydrocracking. These entities seek reliable, large-volume, and often onsite generation solutions to ensure continuous operations and cost efficiency, often prioritizing established, mature generation technologies.

Beyond traditional industrial applications, the burgeoning clean energy sector represents a significant growth area for chemically generated hydrogen. This includes manufacturers of fuel cell electric vehicles (FCEVs) and operators of hydrogen refueling stations, who require high-purity hydrogen for transportation. Power generation companies are also emerging as key customers, employing hydrogen for fuel cells in stationary power applications, grid balancing, and as a clean fuel in gas turbines. These customers prioritize solutions that offer high efficiency, rapid response times, and scalability to integrate with renewable energy sources.

Furthermore, industries involved in metallurgy, such as steel production, are increasingly exploring hydrogen as a reducing agent to decarbonize their processes, moving away from coal-based methods. The electronics industry uses ultra-high purity hydrogen in semiconductor manufacturing, while the food and beverage sector employs it for hydrogenation processes. The diversity of these end-users underscores the broad applicability and growing strategic importance of the Chemical Hydrogen Generation Market across various economic sectors, driving continuous innovation in generation and delivery methods.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 15.2 billion |

| Market Forecast in 2032 | USD 27.3 billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Linde plc, Air Products and Chemicals Inc., Air Liquide S.A., Messer Group GmbH, Taiyo Nippon Sanso Corporation, ITM Power plc, Nel ASA, Plug Power Inc., Hyzon Motors Inc., Bloom Energy Corporation, Cummins Inc., Siemens Energy AG, ProtonOnSite (Nel Hydrogen), H2E Power Systems Pvt Ltd, GKN Hydrogen, Kawasaki Heavy Industries Ltd., Toshiba Energy Systems & Solutions Corporation, McPhy Energy S.A., Sunfire GmbH, C.A.T. Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Chemical Hydrogen Generation Market Key Technology Landscape

The Chemical Hydrogen Generation Market is characterized by a dynamic and evolving technology landscape, encompassing a range of established and emerging methods aimed at efficient and sustainable hydrogen production. Steam Methane Reforming (SMR) remains the most prevalent technology globally due to its cost-effectiveness and maturity, utilizing natural gas to produce hydrogen, often with carbon capture capabilities being integrated to reduce emissions. Autothermal Reforming (ATR) and Partial Oxidation (POX) offer variations for natural gas and other hydrocarbon feedstocks, providing different levels of efficiency and hydrogen purity.

Electrolysis of water is gaining significant traction, particularly for green hydrogen production when powered by renewable electricity. Proton Exchange Membrane (PEM) electrolyzers are favored for their dynamic operation and compact size, suitable for fluctuating renewable energy sources. Alkaline electrolyzers offer robust and well-established solutions for large-scale production, while Solid Oxide Electrolysis Cells (SOEC) operate at high temperatures, offering higher efficiency and potential for co-production with industrial heat. These electrolytic methods are central to decarbonization efforts.

Beyond these, innovative chemical hydrogen generation technologies include the hydrolysis of chemical hydrides, such as sodium borohydride or magnesium hydride, which offer compact, on-demand hydrogen release for portable and niche applications. Biomass gasification provides a pathway for producing hydrogen from renewable organic matter, while chemical looping reforming offers a promising approach for inherent carbon capture. Photoelectrochemical (PEC) water splitting, although still largely in research and development, holds potential for direct solar-to-hydrogen conversion, representing a future frontier in sustainable hydrogen generation. The continuous advancement and commercialization of these diverse technologies are pivotal for the market's growth and diversification.

Regional Highlights

- North America: The United States and Canada are driving forces, with substantial investments in hydrogen hubs, tax credits, and supportive policies aimed at decarbonizing heavy industry and transportation. Growth is fueled by a robust natural gas infrastructure and increasing deployment of fuel cell technology in commercial fleets.

- Europe: Leading the charge with the European Green Deal and national hydrogen strategies, particularly in Germany, France, and the UK. Focus on green hydrogen production via electrolysis, development of cross-border hydrogen pipelines, and widespread adoption in industrial and mobility sectors.

- Asia Pacific (APAC): The largest and fastest-growing market, led by China, Japan, South Korea, and India. Driven by rapid industrial expansion, ambitious national hydrogen strategies, significant government funding for R&D, and large-scale renewable energy projects supporting green hydrogen.

- Latin America: Emerging market with high potential, especially in countries like Chile and Brazil, leveraging abundant renewable energy resources (solar, wind) for green hydrogen production aimed at export and domestic industrial use.

- Middle East and Africa (MEA): Region focusing on diversifying energy economies, with significant investments in large-scale green hydrogen projects, particularly in Saudi Arabia and the UAE, capitalizing on vast solar resources and strategic geographic locations for export.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Chemical Hydrogen Generation Market.- Linde plc

- Air Products and Chemicals Inc.

- Air Liquide S.A.

- Messer Group GmbH

- Taiyo Nippon Sanso Corporation

- ITM Power plc

- Nel ASA

- Plug Power Inc.

- Hyzon Motors Inc.

- Bloom Energy Corporation

- Cummins Inc.

- Siemens Energy AG

- ProtonOnSite (Nel Hydrogen)

- H2E Power Systems Pvt Ltd

- GKN Hydrogen

- Kawasaki Heavy Industries Ltd.

- Toshiba Energy Systems & Solutions Corporation

- McPhy Energy S.A.

- Sunfire GmbH

- C.A.T. Group

Frequently Asked Questions

What is chemical hydrogen generation?

Chemical hydrogen generation refers to the production of hydrogen through various chemical reactions, distinct from physical separation. This includes processes like steam methane reforming, water electrolysis, and the hydrolysis of chemical hydrides.

What are the primary applications of chemically generated hydrogen?

Primary applications include industrial feedstock for ammonia and methanol production, fuel for fuel cell electric vehicles, power generation in stationary fuel cells, and energy storage solutions.

Which region currently leads the Chemical Hydrogen Generation Market?

Asia Pacific currently leads the Chemical Hydrogen Generation Market, driven by robust industrial growth, significant investments in renewable energy, and strong governmental support for hydrogen initiatives.

What are the main drivers for market growth?

Key drivers include global decarbonization targets, increasing demand for clean energy, advancements in fuel cell technology, and supportive government policies and incentives for hydrogen production.

How does AI impact the Chemical Hydrogen Generation Market?

AI impacts the market by optimizing reaction conditions, enabling predictive maintenance for equipment, improving energy efficiency, accelerating material discovery for catalysts, and enhancing supply chain management for hydrogen distribution.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager