Cold Plasma Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428190 | Date : Oct, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Cold Plasma Market Size

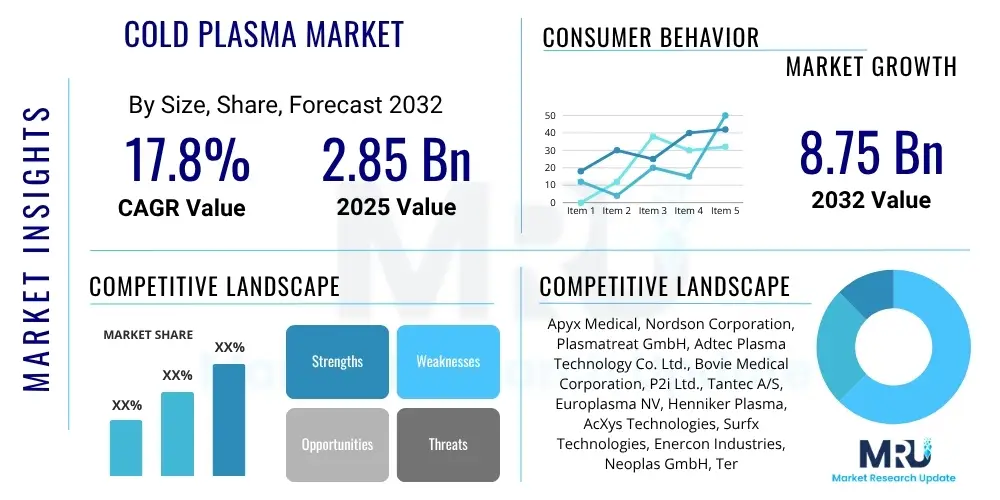

The Cold Plasma Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 17.8% between 2025 and 2032. The market is estimated at USD 2.85 billion in 2025 and is projected to reach USD 8.75 billion by the end of the forecast period in 2032.

Cold Plasma Market Introduction

Cold plasma technology represents a revolutionary advancement across a multitude of industrial, medical, and environmental sectors, leveraging ionized gases at near-ambient temperatures. This unique state of matter, distinct from conventional hot plasma, is characterized by its ability to generate highly reactive species—including electrons, ions, free radicals, and UV photons—without exposing treated materials to damaging heat. This non-thermal characteristic is fundamental to its expanding utility, enabling precise surface modification, sterilization, and decontamination on heat-sensitive substrates that would otherwise be compromised by traditional thermal or chemical processes. The intricate interplay of these reactive species at a molecular level allows for targeted interventions, making cold plasma an indispensable tool for advanced material science and biological applications.

The product description of cold plasma systems encompasses a range of devices from small, handheld plasma jets used in dermatology to large-scale atmospheric pressure plasma systems integrated into industrial production lines. These systems typically consist of a power supply, a gas inlet for carrier gases (such as air, argon, helium, or nitrogen), and electrodes that generate an electrical discharge, transforming the gas into plasma. The ability to customize the gas mixture and electrical parameters allows for fine-tuning the plasma’s properties and reactive species composition, thereby tailoring the treatment effect to specific applications. This adaptability and precision are key factors driving the technology's widespread adoption and continuous innovation, allowing it to address diverse and complex challenges in various industries effectively.

Major applications of cold plasma are remarkably diverse. In healthcare, it is revolutionizing wound care, surgical instrument sterilization, and dermatology, offering potent antimicrobial action and stimulating tissue regeneration without systemic side effects. Industrially, cold plasma enhances surface properties of polymers, metals, and textiles, improving adhesion for coatings, increasing wettability for printing, and enhancing biocompatibility for medical devices. Furthermore, its efficacy extends to food processing for decontamination and shelf-life extension, water purification for pollutant degradation, and air treatment for volatile organic compound (VOC) removal. The multifaceted benefits of cold plasma, including its energy efficiency, reduced environmental impact compared to chemical alternatives, and ability to operate at atmospheric pressure, are significant driving factors. It offers a sustainable, versatile, and highly effective solution for critical challenges across numerous global sectors, promising further growth and technological advancements in the coming years as research yields even more novel uses and efficiencies.

Cold Plasma Market Executive Summary

The global Cold Plasma Market is undergoing a period of dynamic expansion, fueled by increasing awareness of its broad applicability and the compelling advantages it offers over conventional methods. Current business trends highlight a surge in strategic collaborations between academic research institutions and industrial manufacturers, aimed at accelerating the commercialization of novel cold plasma applications and refining existing technologies. There is a discernible market shift towards the development of more compact, energy-efficient, and user-friendly cold plasma devices, which are broadening the market's reach beyond specialized industrial settings into mainstream healthcare facilities and even consumer-level applications. Furthermore, significant investments in R&D are driving the miniaturization of systems and the exploration of new plasma chemistries, which promise enhanced efficacy and reduced operational costs, making the technology more accessible to a wider array of end-users globally.

From a regional perspective, North America and Europe currently lead the market, largely attributable to robust healthcare infrastructures, substantial governmental funding for advanced technological research, and stringent regulatory environments that favor sterile and safe manufacturing practices. These regions benefit from a high concentration of key market players and early adoption of innovative medical and industrial solutions. However, the Asia Pacific region is poised to emerge as the fastest-growing market, propelled by rapid industrialization, burgeoning populations demanding improved healthcare and food safety standards, and increasing governmental and private sector investments in technological advancements across countries like China, India, and Japan. Latin America, the Middle East, and Africa are also expected to witness considerable growth as economic development progresses and the need for advanced sanitation and surface treatment solutions becomes more pressing, facilitating infrastructure improvements and technology adoption.

Segment-wise, the market demonstrates distinct growth patterns. The atmospheric cold plasma (ACP) segment is gaining significant traction due to its ability to operate without expensive vacuum systems, making it highly suitable for large-scale industrial applications such as textile treatment and surface activation. The medical and healthcare application segment continues to be a primary revenue generator, driven by continuous innovations in wound management, sterilization of medical devices, and dermatological treatments. Simultaneously, the food processing and packaging segment is rapidly expanding as cold plasma provides an effective, non-thermal solution for pathogen reduction, extending the shelf-life of perishable goods and addressing critical food safety concerns. These trends collectively underscore the versatile utility of cold plasma technology and its potential to profoundly impact multiple industries, promising sustained growth and diverse opportunities across its various applications and end-user segments.

AI Impact Analysis on Cold Plasma Market

Common user questions related to the impact of AI on the Cold Plasma Market frequently inquire about the potential for artificial intelligence to revolutionize the control, optimization, and application of plasma technologies. Users are particularly interested in how AI can facilitate more precise and adaptive plasma generation, leading to enhanced treatment efficacy and reproducibility across diverse applications. There's also considerable curiosity regarding AI's role in advancing material science through predictive modeling of plasma-surface interactions, and its capacity to accelerate the discovery of novel cold plasma formulations for specific industrial or medical needs. Concerns often touch upon the initial investment required for AI integration, the complexity of data management, and the need for specialized expertise, but these are largely overshadowed by expectations for significant operational efficiencies, improved product quality, and the unlocking of previously unattainable application capabilities.

The integration of artificial intelligence is poised to fundamentally transform the cold plasma landscape by enabling levels of precision and autonomy previously unachievable. AI algorithms can analyze real-time data from plasma systems to dynamically adjust parameters such as gas flow rates, power levels, and treatment durations, ensuring optimal plasma properties for specific applications and materials. This adaptive control not only enhances treatment effectiveness but also significantly improves energy efficiency and reduces material waste, addressing key operational challenges faced by manufacturers and end-users. Furthermore, AI's ability to process vast datasets of experimental results can rapidly identify correlations between plasma parameters and treatment outcomes, dramatically accelerating research and development cycles for new applications and innovative device designs.

- AI can precisely optimize cold plasma device parameters, such as gas mixtures, power input, and treatment duration, in real-time to achieve superior performance and consistent results for specific applications like delicate medical sterilization or complex surface modifications.

- Predictive analytics powered by AI can forecast equipment wear and potential malfunctions in cold plasma systems, enabling proactive maintenance scheduling and significantly reducing unexpected downtime and costly repairs in high-throughput industrial environments.

- AI-driven image recognition and advanced data analysis algorithms can enhance diagnostic capabilities in medical cold plasma treatments, allowing for more accurate assessment of wound healing progression and leading to highly personalized and adaptive therapeutic protocols for patients.

- Machine learning algorithms can analyze vast experimental datasets to identify optimal cold plasma compositions and operating conditions for novel applications, significantly accelerating the discovery of new plasma-based solutions in fields like environmental remediation or advanced material synthesis.

- AI integration facilitates the development of automated control systems for cold plasma processes, minimizing human error and ensuring highly reproducible treatments, which is critical for compliance with stringent regulatory standards in pharmaceutical and medical device manufacturing.

- Enhanced data processing and pattern recognition capabilities by AI can lead to a deeper, more nuanced understanding of complex plasma-material interactions at a molecular level, fostering groundbreaking innovation in surface engineering, biocompatibility enhancement, and adhesion technologies.

- AI enables sophisticated remote monitoring and control of cold plasma devices, enhancing operational flexibility for geographically dispersed facilities and allowing expert technicians to manage and troubleshoot systems from any location, improving global accessibility and support efficiency.

- The development of "smart" cold plasma systems with adaptive capabilities, driven by embedded AI, allows devices to autonomously adjust to real-time variations in environmental conditions, material properties, or biological responses, thereby maximizing efficacy and safety across diverse and dynamic application scenarios.

DRO & Impact Forces Of Cold Plasma Market

The Cold Plasma Market is profoundly shaped by an intricate interplay of drivers, restraints, opportunities, and pervasive impact forces that collectively dictate its growth trajectory and competitive landscape. A primary driver is the burgeoning global demand for advanced, non-thermal sterilization and decontamination solutions, particularly in the healthcare sector where concerns over hospital-acquired infections (HAIs) and antibiotic-resistant microbes are escalating. Cold plasma offers an effective, residue-free alternative to traditional chemical sterilants and high-temperature methods, making it invaluable for heat-sensitive medical devices and delicate biological tissues. Beyond healthcare, the increasing emphasis on food safety and pathogen reduction in the food processing industry further fuels market expansion, as cold plasma provides a gentle yet powerful means of decontaminating produce and packaging materials without compromising quality.

Another significant driver stems from the versatility of cold plasma in advanced material science and surface engineering. Industries such as automotive, aerospace, electronics, and textiles are increasingly adopting cold plasma technology for surface activation, functionalization, and coating adhesion enhancement. This enables manufacturers to improve material properties like wettability, biocompatibility, and wear resistance without altering the bulk characteristics of the treated materials. The growing global focus on sustainable manufacturing practices and environmental protection also serves as a strong impetus, as cold plasma processes are often energy-efficient and reduce the reliance on hazardous chemicals, aligning with green technology initiatives and regulatory pressures for cleaner industrial operations across developed and developing economies.

Despite these powerful drivers, the Cold Plasma Market faces several notable restraints. The high initial capital investment required for purchasing and installing cold plasma equipment, coupled with the specialized expertise needed for operation and maintenance, can pose significant barriers to entry for smaller businesses and limit adoption in budget-constrained regions. Furthermore, the nascent stage of regulatory standardization for cold plasma applications, especially in the medical and food contact sectors, creates uncertainty for manufacturers regarding product approval and market access. This lack of comprehensive, globally harmonized guidelines can slow down market expansion and create inconsistencies in product development and commercialization. Limited awareness among potential end-users about the full spectrum of cold plasma's capabilities and its long-term benefits also acts as a significant impediment, requiring substantial market education efforts.

However, the market is brimming with promising opportunities. The expansion of cold plasma applications into novel and emerging fields, such as environmental remediation for water and air purification, agricultural seed treatment for enhanced germination and disease resistance, and personalized medicine for targeted therapies, represents vast untapped potential. Continuous technological advancements, including the development of more compact, energy-efficient, and cost-effective cold plasma systems, are expected to overcome some of the existing restraints, making the technology more accessible and attractive to a broader range of users. The increasing global shift towards sustainable industrial practices and the rising demand for advanced wound care solutions globally also present fertile grounds for market expansion, driving ongoing research and development into novel cold plasma-based devices and therapeutic protocols, thereby fostering innovation and new market entries.

The pervasive impact forces influencing the Cold Plasma Market are multifaceted and include dynamic regulatory landscapes that are gradually evolving to accommodate this innovative technology. Stringent public health concerns, particularly in the wake of global pandemics, are accelerating the demand for advanced disinfection solutions, creating a strong pull for cold plasma. Continuous advancements in plasma generation technologies and materials science are pushing the boundaries of what cold plasma can achieve, leading to more robust and versatile systems. Furthermore, economic factors such as government funding for R&D in green technologies and healthcare innovation, alongside societal trends favoring non-toxic and sustainable solutions, play a crucial role. The competitive landscape, characterized by intellectual property development, strategic alliances, and intense innovation, continually shapes market dynamics, compelling companies to invest heavily in differentiation and advanced product offerings to maintain or secure their market position against both established players and agile startups.

Segmentation Analysis

The Cold Plasma Market is meticulously segmented across various dimensions to provide a granular and comprehensive understanding of its complex structure, diverse applications, and wide-ranging end-user base. This detailed segmentation is crucial for market participants, researchers, and investors to accurately identify specific growth drivers, competitive landscapes, and emerging opportunities within distinct niches of the market. By categorizing the market based on technology type, specific application areas, and the distinct end-user industries, the analysis reveals nuanced trends and demand patterns, reflecting the broad utility and varying stages of maturity for cold plasma technology in different sectors. Such a granular view allows for highly targeted strategic planning and resource allocation, ensuring that market offerings are aligned with specific industry needs and regulatory requirements.

The segmentation by type primarily differentiates between atmospheric and low-pressure cold plasma systems, each with unique operational characteristics and suitability for various applications. Application-based segmentation provides insight into the diverse problems cold plasma addresses, from critical medical interventions to industrial process enhancements and environmental solutions. This classification helps in understanding where the most significant demand lies and which application areas are experiencing rapid innovation or adoption. Finally, segmenting by end-user highlights the key industries and institutional settings that benefit from cold plasma technology, allowing for a focused analysis of their specific requirements, purchasing behaviors, and market penetration strategies. Each segment, therefore, contributes uniquely to the overall market dynamics, with its own set of growth stimulants and potential barriers.

- By Type:

- Atmospheric Cold Plasma (ACP): This segment includes systems that operate at ambient atmospheric pressure, eliminating the need for expensive vacuum chambers. ACP is highly versatile, cost-effective for large-area treatments, and increasingly preferred for applications such as textile processing, surface cleaning, disinfection, and certain medical procedures like wound healing, due to its ease of integration into existing production lines and portability options.

- Low-Pressure Cold Plasma (LPP): Operating in a vacuum environment, LPP systems offer superior control over plasma parameters and can achieve highly uniform and precise treatments. They are typically employed for more demanding applications such as advanced surface modification of delicate materials, thin film deposition, sterilization of complex medical devices, and high-precision etching in semiconductor manufacturing, where absolute purity and meticulous control are paramount despite the higher operational costs.

- By Application:

- Wound Healing: Utilizing cold plasma's antimicrobial and tissue regeneration properties for chronic wounds, diabetic foot ulcers, and burns, promoting faster, infection-free recovery.

- Disinfection and Sterilization: Critical for sterilizing heat-sensitive medical devices, instruments, and surfaces in healthcare settings, as well as for general decontamination in public spaces and industrial environments.

- Surface Treatment (Adhesion, Coating, Activation): Enhancing surface energy for improved adhesion of paints, glues, and coatings; functionalizing surfaces for desired chemical properties; and activating materials like polymers, metals, and ceramics in automotive, aerospace, and electronics industries.

- Food Decontamination and Shelf-Life Extension: Reducing microbial load on fruits, vegetables, meat, and seafood; sterilizing packaging materials; and extending the freshness and safety of perishable goods.

- Textile Processing: Improving dyeing, printing, and coating adhesion on fabrics; enhancing water repellency, flame resistance, and antimicrobial properties of textiles for sportswear, medical textiles, and technical fabrics.

- Medical Device Sterilization: A non-thermal method crucial for sterilizing complex and heat-sensitive medical instruments and implants without compromising their structural integrity or material properties.

- Air and Water Purification: Degrading pollutants, volatile organic compounds (VOCs), odors, and microorganisms in air filtration systems and treating wastewater for disinfection and removal of pharmaceutical residues.

- Others (e.g., Agriculture, Cosmetics, Dentistry): Includes applications in agricultural seed treatment, plant growth stimulation, cosmetic skin rejuvenation, dental disinfection, and environmental soil decontamination.

- By End-User:

- Hospitals and Clinics: Major users for wound care, surgical site disinfection, and sterilization of medical equipment, driven by patient safety and infection control needs.

- Academic and Research Institutes: Engaged in fundamental research, new application development, and material science studies, serving as innovation hubs for cold plasma technology.

- Pharmaceutical & Biotechnology Companies: Utilizing cold plasma for aseptic packaging, surface sterilization in cleanrooms, and potential drug delivery system enhancements, ensuring product integrity.

- Food Processing and Packaging Industries: Implementing cold plasma for microbial decontamination of food products, extending shelf-life, and ensuring hygienic food contact surfaces.

- Textile Industry: Adopting cold plasma for environmentally friendly surface modification of fabrics, improving functional properties and reducing reliance on wet chemical processes.

- Automotive Industry: Employing cold plasma for improving paint adhesion, surface preparation for bonding, and enhancing the durability of components and interior materials.

- Electronics and Semiconductor Industry: Utilizing LPP for precise etching, surface cleaning, and modification of sensitive components and wafers in microfabrication processes.

- Others (e.g., Chemical Industry, Environmental Services): Includes the chemical industry for catalyst preparation, environmental services for pollution control, and emerging applications in dentistry and agriculture.

Value Chain Analysis For Cold Plasma Market

The value chain for the Cold Plasma Market is an intricate and multi-faceted network that spans from fundamental scientific research and the procurement of specialized raw materials to the final integration and post-sales support of cold plasma systems across diverse end-user industries. This comprehensive chain illuminates the sequential activities and interconnected relationships among various stakeholders, each adding significant value at different stages of product development and delivery. A thorough understanding of this value chain is paramount for market participants to identify critical junctures for innovation, optimize operational efficiencies, mitigate risks, and establish sustainable competitive advantages in a rapidly evolving technological landscape. It also highlights areas where strategic partnerships and collaborations can enhance market reach and foster technological advancement.

Upstream analysis in the cold plasma value chain primarily focuses on the sourcing and supply of essential components and foundational technologies that form the core of cold plasma systems. This stage involves the procurement of high-purity process gases, such as argon, helium, nitrogen, and oxygen, from specialized gas suppliers, as these gases are crucial for generating the plasma. Additionally, it includes the supply of critical electronic components like high-voltage power supplies, frequency generators, electrodes, and sophisticated control units from electronic manufacturers. Furthermore, research and development institutions play a pivotal upstream role, continuously advancing plasma physics, developing novel plasma sources, and exploring new application methodologies. These foundational activities are crucial for pushing the technological boundaries and ensuring the availability of high-quality, reliable, and innovative components that are integral to the performance and efficacy of cold plasma devices, enabling the midstream manufacturing processes to create cutting-edge systems.

Midstream activities encompass the core processes of designing, manufacturing, assembling, and testing the actual cold plasma devices and integrated systems. This stage demands significant technical expertise in plasma engineering, materials science, and electronics. Manufacturers leverage the upstream components to construct devices ranging from handheld plasma torches to large industrial atmospheric plasma treatment units. Key activities include precision engineering of plasma sources (e.g., dielectric barrier discharges, plasma jets), integration of gas delivery and vacuum systems (for LPP), and the development of user-friendly interfaces and robust control software. Quality assurance and rigorous testing are vital at this stage to ensure the reliability, safety, and regulatory compliance of the cold plasma systems, particularly for applications in highly regulated sectors like healthcare and food processing. Innovation in device design, aiming for miniaturization, energy efficiency, and enhanced application-specific performance, is a constant focus for midstream players to differentiate their offerings and capture market share.

Downstream analysis covers the critical functions of market access, distribution, sales, installation, and comprehensive post-sales support for cold plasma products. Distribution channels can be bifurcated into direct and indirect routes. Direct distribution involves manufacturers selling directly to large industrial clients, hospitals, or research institutions, often providing tailored solutions, on-site training, and extensive technical support. This approach allows for deep customer relationships and customized integration. Indirect distribution utilizes a network of specialized distributors, agents, and system integrators who possess regional market knowledge and provide localized sales and support services, particularly effective for reaching smaller enterprises or niche markets. These intermediaries are crucial for expanding market reach, offering technical consultation, and facilitating the integration of cold plasma systems into diverse operational environments. Effective downstream management, including responsive customer service, maintenance contracts, and spare parts supply, is essential for ensuring long-term customer satisfaction, building brand loyalty, and fostering sustained market growth by ensuring optimal performance and maximum uptime of cold plasma installations in various demanding application scenarios.

Cold Plasma Market Potential Customers

The potential customer base for the Cold Plasma Market is remarkably broad and diverse, reflecting the technology's versatile capabilities in addressing a wide array of challenges across numerous industries. Fundamentally, any organization or institution that requires advanced, non-thermal solutions for sterilization, decontamination, surface modification, or material processing represents a potential buyer. This extensive applicability is a core strength of cold plasma, enabling its adoption by entities seeking to enhance product quality, ensure safety, improve operational efficiency, or develop innovative materials. As the benefits of cold plasma become more widely recognized and integrated, this customer base is continuously expanding, driving significant market growth across global economies.

In the highly regulated healthcare sector, potential customers are extensive and critical for market growth. This includes a vast network of hospitals, clinics, dental practices, and outpatient surgical centers that are increasingly seeking advanced solutions for wound care, surgical site disinfection, and the sterilization of heat-sensitive medical instruments and implants. Pharmaceutical and biotechnology companies also represent a significant segment, utilizing cold plasma for aseptic packaging, surface decontamination in sterile environments, and exploring its potential in drug delivery systems and personalized medicine. Academic and research institutes worldwide are vital customers, investing in cold plasma systems for fundamental plasma physics research, material science studies, and the development of novel applications, serving as crucial innovation hubs that continuously expand the technology's potential and practical uses across various scientific and engineering disciplines.

Beyond healthcare, industrial end-users form a substantial and rapidly growing segment of the customer base. Manufacturers in the automotive, aerospace, electronics, and textile industries are key clients, leveraging cold plasma for critical processes such as enhancing paint adhesion, preparing surfaces for bonding, improving the durability of composite materials, and functionalizing fabrics for specific performance characteristics like water repellency or flame resistance. The food processing and packaging industry constitutes another crucial customer segment, where cold plasma is employed for reducing microbial loads on perishable foods, extending shelf-life, and ensuring the hygienic integrity of food contact surfaces and packaging materials. Furthermore, environmental service companies are emerging as significant buyers, deploying cold plasma solutions for industrial wastewater treatment, air purification to remove pollutants and volatile organic compounds (VOCs), and even for soil remediation, underscoring the technology's potential in sustainable development and public health, demonstrating a broad and impactful reach across diverse economic sectors.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 2.85 billion |

| Market Forecast in 2032 | USD 8.75 billion |

| Growth Rate | 17.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Apyx Medical, Nordson Corporation, Plasmatreat GmbH, Adtec Plasma Technology Co. Ltd., Bovie Medical Corporation, P2i Ltd., Tantec A/S, Europlasma NV, Henniker Plasma, AcXys Technologies, Surfx Technologies, Enercon Industries, Neoplas GmbH, Terraplasma GmbH, Relyon Plasma, Cinogy GmbH, Cold Plasma Medical AG, Kawai Industrial Co., Ltd., KSA-AT Plasmatronic GmbH, Plasma Etch Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cold Plasma Market Key Technology Landscape

The Cold Plasma Market is underpinned by a rapidly evolving and technologically sophisticated landscape, characterized by continuous innovation in plasma generation techniques, device engineering, and integrated control systems. At the core of this landscape are diverse plasma sources, each meticulously designed to optimize parameters such as electron density, gas temperature, and reactive species composition, thereby enabling highly specific and efficient treatments for a broad spectrum of applications. These advancements are driven by ongoing research in plasma physics and engineering, focused on enhancing efficiency, scalability, and ease of use, which collectively contribute to the expanding utility and accessibility of cold plasma technology across various industrial and scientific domains.

Prominent technologies include Dielectric Barrier Discharges (DBD), which are widely utilized for generating cold plasma at atmospheric pressure. DBD systems are favored for their ability to produce uniform plasma over large surface areas, making them ideal for high-throughput applications such as surface activation of polymer films, treatment of textiles, and broad-area disinfection. The design typically involves two electrodes separated by a dielectric barrier, with the discharge occurring in the gas gap. Another significant technology is Atmospheric Pressure Plasma Jets (APPJ), which deliver a focused stream of reactive plasma species directly to a target area without the need for a vacuum chamber. APPJs are particularly valued in medical applications like wound healing, dermatology, and localized sterilization due to their precision, portability, and minimal thermal impact on biological tissues. Advancements in both DBD and APPJ technologies are focused on improving plasma uniformity, increasing reactive species yield, and enhancing operational stability and longevity for demanding industrial and clinical environments.

Beyond atmospheric pressure systems, low-pressure cold plasma (LPP) technologies, often employing microwave or radiofrequency (RF) plasma sources, remain critical for applications requiring extremely precise and uniform surface modification under vacuum conditions. These systems offer unparalleled control over plasma chemistry and are indispensable for advanced coating, etching, and cleaning processes in the semiconductor, aerospace, and medical device manufacturing industries, where even minor variations can lead to significant product defects. Furthermore, a key trend in the technological landscape is the increasing integration of sophisticated control systems, often leveraging sensor arrays and artificial intelligence (AI). These smart systems enable real-time monitoring and dynamic adjustment of plasma parameters, ensuring optimal treatment conditions, enhancing process reproducibility, and simplifying operation. Miniaturization techniques are also profoundly impacting the market, leading to the development of compact, handheld cold plasma devices that offer greater flexibility and ease of integration into existing workflows, thus democratizing access to this transformative technology for a wider range of professional and potentially even consumer applications.

Regional Highlights

- North America: This region stands as a dominant force in the Cold Plasma Market, primarily driven by substantial investments in healthcare infrastructure, vigorous research and development activities in plasma technology, and stringent regulatory frameworks that mandate high standards for sterilization and hygiene. The United States, in particular, leads in the adoption of advanced medical devices and sophisticated industrial surface treatment technologies. The presence of numerous key market players, coupled with a high adoption rate of innovative solutions across pharmaceutical and biomedical sectors, contributes significantly to its market share. Continuous government funding for scientific research and a strong focus on public health further solidify North America's leading position, particularly in medical and food safety applications.

- Europe: Europe represents another significant market for cold plasma technology, characterized by strong governmental support for sustainable technological innovation and a robust medical device manufacturing sector. Countries like Germany, the United Kingdom, France, and Switzerland are at the forefront of cold plasma research and commercialization. The region benefits from a proactive approach to environmental protection, leading to increased adoption in water and air purification, as well as textile processing industries seeking greener alternatives. The aging population and rising healthcare expenditure also drive the demand for advanced wound care and sterilization solutions, further contributing to market growth and technological advancements, with a strong emphasis on regulatory compliance and high-quality standards.

- Asia Pacific (APAC): The Asia Pacific region is projected to register the highest growth rate in the Cold Plasma Market during the forecast period. This accelerated growth is primarily attributed to rapid industrialization, expanding healthcare infrastructure, and increasing awareness of the multifaceted benefits of cold plasma technology across populous nations like China, Japan, India, and South Korea. Significant investments in R&D, coupled with a booming manufacturing sector and a growing focus on food safety and agricultural productivity, are key catalysts. The region's large consumer base and government initiatives promoting advanced technologies and sustainable practices are creating a fertile ground for market expansion, particularly in food processing, textile industries, and medical device manufacturing.

- Latin America: Latin America is emerging as a promising market for cold plasma technology, showing steady growth driven by increasing investments in healthcare infrastructure and ongoing industrial modernization efforts. Countries such as Brazil, Mexico, and Argentina are leading the regional adoption, particularly in medical applications like wound care and disinfection, as well as in the food processing sector for enhancing food safety and extending shelf-life. The rising awareness of advanced technological solutions and a growing emphasis on improving public health standards are fostering market expansion. Economic development and increasing foreign direct investment in manufacturing capabilities further contribute to the gradual but consistent uptake of cold plasma systems in various local industries.

- Middle East and Africa (MEA): The Middle East and Africa region is experiencing gradual but consistent growth in the Cold Plasma Market, spurred by increasing investments in healthcare facilities, diversification of industrial sectors away from oil dependence, and rising awareness of advanced technological solutions. Countries like the UAE, Saudi Arabia, and South Africa are focusing on adopting innovative technologies to address local challenges in sanitation, food security, and advanced medical treatments. The establishment of new research centers and a growing commitment to modernizing industrial processes are key factors contributing to the market's development. While currently a smaller market share, the region holds significant potential for future expansion as infrastructure improves and technological adoption barriers are overcome, especially in areas like water treatment and medical disinfection.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cold Plasma Market.- Apyx Medical

- Nordson Corporation

- Plasmatreat GmbH

- Adtec Plasma Technology Co. Ltd.

- Bovie Medical Corporation

- P2i Ltd.

- Tantec A/S

- Europlasma NV

- Henniker Plasma

- AcXys Technologies

- Surfx Technologies

- Enercon Industries

- Neoplas GmbH

- Terraplasma GmbH

- Relyon Plasma

- Cinogy GmbH

- Cold Plasma Medical AG

- Kawai Industrial Co., Ltd.

- KSA-AT Plasmatronic GmbH

- Plasma Etch Inc.

Frequently Asked Questions

Analyze common user questions about the Cold Plasma market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is cold plasma technology and how does it fundamentally differ from traditional plasma?

Cold plasma technology, also known as non-thermal plasma, involves generating ionized gases at temperatures close to ambient, typically below 50°C. This differentiates it from traditional "hot" plasma, which operates at extremely high temperatures, unsuitable for sensitive materials. Cold plasma works by creating a reactive mixture of electrons, ions, neutral atoms, free radicals, and UV photons that interact with surfaces to achieve various effects like sterilization, decontamination, or surface modification. The crucial advantage lies in its ability to deliver powerful chemical and physical effects without thermal damage, making it ideal for treating delicate biological tissues, heat-sensitive polymers, and complex electronic components, which would otherwise be compromised by heat or harsh chemicals. Its non-thermal nature is central to its expanding applications across numerous industries, offering a versatile and gentle yet highly effective treatment solution.

What are the primary applications of cold plasma in the medical and healthcare sectors?

In the medical and healthcare sectors, cold plasma technology is rapidly gaining prominence for its diverse and critical applications. Primarily, it is revolutionizing wound healing, particularly for chronic, non-healing, and infected wounds, by effectively killing bacteria, including antibiotic-resistant strains, reducing inflammation, and stimulating tissue regeneration without discomfort to the patient. It is also extensively used for the high-level disinfection and sterilization of heat-sensitive surgical instruments, endoscopes, and medical implants, preventing hospital-acquired infections (HAIs) and ensuring patient safety. Emerging applications include dermatology (for acne treatment, skin rejuvenation), dentistry (for tooth disinfection and surface preparation), and even in oncology research for selective cancer cell targeting. Its ability to achieve powerful antimicrobial action and promote biological responses without thermal damage or toxic residues makes it an indispensable tool for modern healthcare.

How does cold plasma contribute to food safety, quality, and extended shelf-life in the food industry?

Cold plasma plays a transformative role in enhancing food safety and extending the shelf-life of various food products. By generating reactive species, it effectively inactivates a wide range of foodborne pathogens, including bacteria like E. coli and Salmonella, viruses, and fungi on the surfaces of fresh produce, meat, seafood, and even packaged goods. This non-thermal decontamination method reduces microbial load without altering the nutritional composition, taste, or texture of the food, preserving its quality. Additionally, cold plasma can sterilize food packaging materials, further preventing contamination and extending the freshness of perishable items. Its ability to provide a residue-free and environmentally friendly alternative to traditional chemical treatments makes it a highly attractive and sustainable solution for the food processing and packaging industries, addressing critical consumer demands for safer and fresher food products with a longer market presence.

What are the key environmental benefits and sustainability aspects of implementing cold plasma technology?

Cold plasma technology offers substantial environmental benefits and aligns strongly with global sustainability goals. One of its primary advantages is the significant reduction in the reliance on hazardous chemicals and harsh solvents commonly used in traditional sterilization and surface treatment processes. This leads to a substantial decrease in the generation of toxic waste and wastewater, thereby minimizing environmental pollution. Furthermore, cold plasma systems are often energy-efficient, particularly atmospheric pressure systems, as they operate at ambient temperatures and require less energy compared to high-temperature thermal processes. Its applications extend to environmental remediation, such as the efficient degradation of pollutants, volatile organic compounds (VOCs), and odors in air and water purification systems, offering an eco-friendly approach to tackling industrial and municipal waste. By providing a cleaner, safer, and more energy-efficient alternative, cold plasma contributes significantly to promoting green manufacturing practices and fostering a more sustainable industrial future.

What are the major future trends and emerging opportunities expected in the Cold Plasma Market?

The Cold Plasma Market is poised for dynamic growth, driven by several key future trends and emerging opportunities. A major trend is the increasing integration of artificial intelligence (AI) and machine learning for optimizing plasma parameters, enhancing diagnostic capabilities, and developing personalized treatment protocols, particularly in medical applications. Miniaturization and increased portability of cold plasma devices are also prominent, expanding their utility to point-of-care settings and localized industrial treatments. Opportunities are vast, including the expansion into novel applications such as advanced environmental remediation (e.g., microplastic degradation, soil decontamination), agricultural enhancements (e.g., seed treatment for improved germination and disease resistance), and further penetration into personalized medicine for highly targeted therapies. Additionally, market growth will be fueled by efforts to standardize regulatory frameworks globally, increasing awareness among potential end-users, and continuous R&D leading to more cost-effective, energy-efficient, and versatile cold plasma systems that can cater to an even broader spectrum of industrial and societal challenges.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Medical Cold Plasma Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Cold Plasma Solution Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Atmospheric, Low-Pressure), By Application (Textile, Polymer and Plastic, Electronics and Semiconductor, Food and Agriculture, Medical applications), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

- Cold Plasma Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Atmospheric Cold Plasma, Low-Pressure Cold Plasma), By Application (Wound Healing, Blood Coagulation, Dentistry, Cancer Treatment, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager