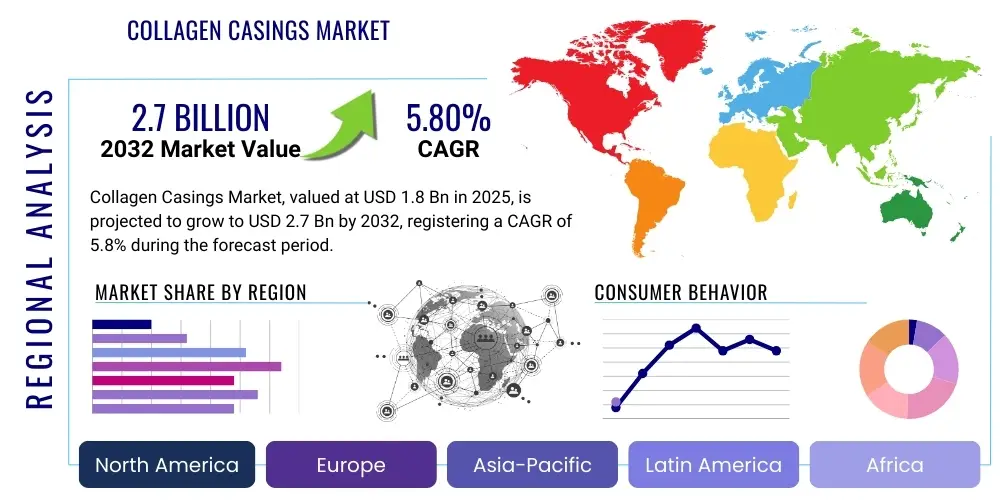

Collagen Casings Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427409 | Date : Oct, 2025 | Pages : 254 | Region : Global | Publisher : MRU

Collagen Casings Market Size

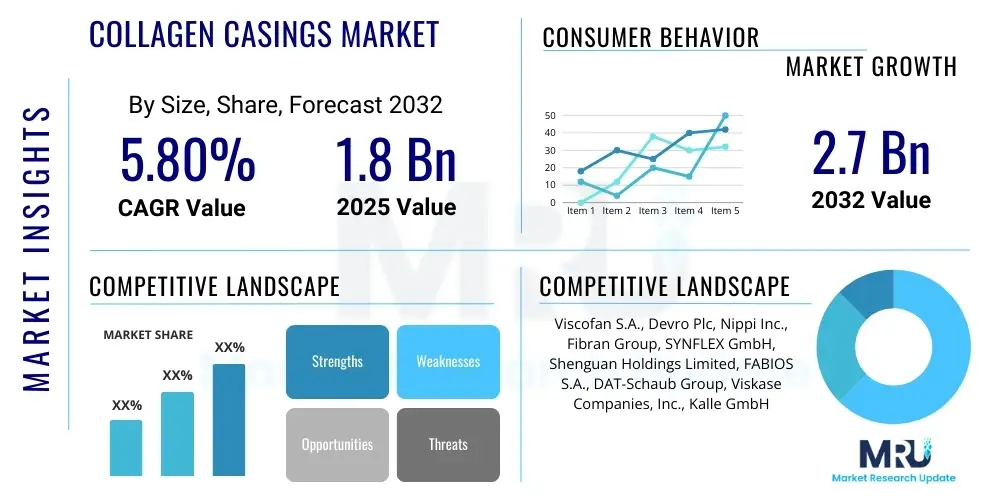

The Collagen Casings Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 1.8 Billion in 2025 and is projected to reach USD 2.7 Billion by the end of the forecast period in 2032. This growth is primarily fueled by the increasing global demand for processed meat products, the operational efficiencies collagen casings offer, and their versatility across various food applications. The markets expansion is further supported by technological advancements in manufacturing processes and a growing consumer preference for consistent, high-quality, and safe food products.

The consistent rise in disposable incomes, particularly in emerging economies, has led to a greater consumption of convenience foods, including sausages and processed meats, where collagen casings are predominantly used. Manufacturers benefit from the standardized caliber and length that collagen casings provide, which enhances automation in production lines, reducing labor costs and improving overall output. Furthermore, the inherent edibility and biodegradability of these casings align with evolving consumer preferences for natural and sustainable food ingredients, despite their industrial origin.

Collagen Casings Market introduction

The Collagen Casings Market is a significant segment within the food processing industry, driven by the global demand for sausages and other processed meat products. Collagen casings are manufactured from collagen, primarily derived from bovine or porcine hides, which are by-products of the meat industry. These casings offer a superior alternative to natural casings due to their uniformity, strength, and consistent performance during the stuffing, cooking, and smoking processes. They are widely used in the production of frankfurters, hot dogs, fresh sausages, dry sausages, and various other processed meat items, offering excellent bite, appearance, and shelf-life characteristics for the end product.

Product description highlights their distinct properties, including permeability to smoke and moisture, which is crucial for flavor development and preservation, alongside their inherent edibility. The major applications span across high-volume industrial food production, artisanal butcher shops, and even specialized food manufacturers creating plant-based sausage alternatives, leveraging collagens structural integrity. Benefits extend beyond manufacturing efficiency to include enhanced food safety, as they are produced under controlled hygienic conditions, significantly reducing the risk of contamination compared to traditional natural casings. Moreover, their consistent dimensions facilitate automated processing, leading to higher throughput and reduced operational costs for food manufacturers.

Key driving factors for market growth include the burgeoning global population and the subsequent increase in meat consumption, particularly in developing regions. The expansion of the organized retail sector and the rising popularity of convenience foods further bolster demand. Additionally, stringent food safety regulations globally encourage the adoption of standardized and hygienically produced casings, positioning collagen casings as a preferred choice. The market also benefits from ongoing innovation in collagen extraction and processing technologies, which lead to improved product attributes and broader application possibilities.

Collagen Casings Market Executive Summary

The Collagen Casings Market is experiencing robust growth, propelled by the increasing demand for processed meat products and the operational advantages these casings offer to food manufacturers. Key business trends indicate a strong focus on product innovation, with manufacturers exploring new collagen sources and developing specialized casings for different applications, including plant-based alternatives. There is a discernible shift towards sustainable sourcing and production practices, driven by both regulatory pressures and growing consumer environmental consciousness. Furthermore, strategic expansions into emerging markets through mergers, acquisitions, and partnerships are common, as companies seek to capitalize on rapidly expanding meat consumption in regions such as Asia-Pacific and Latin America.

Regionally, the market exhibits diverse dynamics. Asia-Pacific is projected to demonstrate the highest growth rate, fueled by a burgeoning middle class, increasing urbanization, and evolving dietary preferences that favor processed convenience foods. Europe, a historically mature market for processed meats, continues to show stable demand, characterized by a preference for premium and artisanal sausage products, alongside stringent food safety and quality standards. North America also presents significant growth, driven by product innovation, the adoption of advanced processing technologies, and a strong consumer base for hot dogs and frankfurters. These regional trends underscore the global nature of the market, with each geography contributing uniquely to its overall expansion.

Segmentation trends reveal that edible collagen casings continue to dominate the market due to their convenience and consumer acceptance, especially for small-caliber sausages like frankfurters and breakfast links. The application segment sees processed sausages, including hot dogs and fresh sausages, as the primary drivers of demand. There is also a growing interest in using collagen casings for vegetarian and vegan sausage alternatives, expanding the market beyond traditional meat applications. From a source perspective, bovine collagen remains the predominant raw material, though research into alternative and more sustainable sources is ongoing. These segmentation insights highlight the versatile nature of collagen casings and their adaptability to diverse market needs and consumer preferences.

AI Impact Analysis on Collagen Casings Market

The integration of Artificial Intelligence (AI) within the Collagen Casings Market is poised to significantly transform various operational facets, from raw material sourcing and manufacturing efficiency to quality control and supply chain optimization. Common user questions related to AI’s impact often revolve around how AI can enhance predictive analytics for demand forecasting, thereby minimizing waste and optimizing inventory levels. Users also frequently inquire about AIs potential in improving the precision and consistency of collagen casing production, identifying potential defects early in the process, and personalizing product offerings. The overarching theme of these inquiries is centered on leveraging AI to drive greater efficiency, ensure higher product quality, and build a more resilient and responsive supply chain within the industry.

AIs influence is anticipated to extend across the entire value chain, introducing capabilities that were previously unattainable through traditional methods. By analyzing vast datasets related to raw material quality, processing parameters, and market demand, AI algorithms can identify subtle patterns and correlations, leading to optimized production recipes and operating conditions. This not only enhances the uniformity and strength of the casings but also contributes to significant cost reductions through improved resource utilization and reduced rework. Furthermore, AI-powered systems can provide real-time insights, enabling manufacturers to react swiftly to market changes and operational challenges, maintaining a competitive edge in a dynamic industry landscape.

- Predictive analytics for precise demand forecasting, optimizing production schedules and inventory management.

- Enhanced quality control through AI-powered visual inspection systems, identifying microscopic defects and ensuring consistent caliber.

- Optimization of manufacturing processes, including extrusion and drying, to improve yield, reduce energy consumption, and increase production speed.

- Supply chain management improvements, enabling real-time tracking, risk assessment, and efficient logistics for raw materials and finished products.

- Facilitation of research and development for new collagen sources, formulations, and processing techniques through data-driven simulations.

- Waste reduction and sustainability initiatives by optimizing material usage and identifying opportunities for byproduct valorization.

- Personalized product development and market analysis by understanding consumer preferences and tailoring casing characteristics accordingly.

DRO & Impact Forces Of Collagen Casings Market

The Collagen Casings Market is influenced by a complex interplay of drivers, restraints, and opportunities, alongside significant impact forces that shape its competitive landscape. Key drivers include the ever-increasing global consumption of processed meat products, especially convenience items such as sausages and hot dogs, which rely heavily on efficient and uniform casings. The cost-effectiveness, consistency in quality and caliber, and improved shelf-life offered by collagen casings further propel their adoption over traditional alternatives. Moreover, the expanding food processing industry, coupled with advancements in automation technologies, favors collagen casings due to their compatibility with high-speed production lines, leading to greater operational efficiency and reduced labor costs for manufacturers.

However, the market also faces several notable restraints. The primary raw materials, bovine and porcine hides, are subject to supply chain volatilities influenced by livestock farming practices, disease outbreaks, and trade policies, which can lead to price fluctuations and supply shortages. Competition from natural casings, which are often preferred in niche and premium markets for their authentic texture and appearance, and from alternative synthetic casings (e.g., cellulose) also poses a challenge. Furthermore, cultural preferences in certain regions and growing ethical concerns regarding animal-derived products among a segment of consumers could impede market growth, alongside the need for specialized processing expertise and equipment.

Opportunities for growth are abundant, particularly in product innovation, such as the development of specialized casings for organic, Halal, or Kosher products, as well as casings with enhanced barrier properties or flavor release characteristics. The expansion into emerging markets, where meat consumption and food processing industries are rapidly growing, presents significant untapped potential. Furthermore, continuous investment in sustainable sourcing of collagen and developing environmentally friendly manufacturing processes can enhance market appeal and address consumer concerns. The impact forces, as analyzed through Porters Five Forces model, indicate a moderately competitive market. The bargaining power of buyers is significant due due to the presence of large food processing companies, while the bargaining power of suppliers is moderate, dependent on the availability and processing of hides. The threat of new entrants is moderate, given the capital intensity and technological expertise required. The threat of substitutes from natural and other synthetic casings is ever-present, demanding continuous innovation. Finally, competitive rivalry among existing players remains high, driven by product differentiation, pricing strategies, and market expansion efforts.

Segmentation Analysis

The Collagen Casings Market is comprehensively segmented to provide a detailed understanding of its diverse applications, product types, and end-user demands. This segmentation allows for targeted market strategies, identifying specific growth opportunities within distinct categories. The primary segmentation approaches typically include product type (edible and non-edible), caliber (small and large), application (fresh sausages, processed sausages, dried sausages, cooked sausages, and others), and raw material source (bovine, porcine, and others). Each segment exhibits unique growth drivers and competitive landscapes, reflecting the varied requirements of the global food processing industry and consumer preferences.

Edible collagen casings, for instance, dominate the market due to their convenience and suitability for high-speed automated production, particularly for products like hot dogs and frankfurters where the casing is consumed as part of the product. Non-edible casings, while a smaller segment, are crucial for larger-diameter products that require strength during the curing or smoking process, where the casing is removed before consumption. The caliber of the casing directly correlates with the type of sausage product, with small calibers being prevalent for breakfast sausages and large calibers for salami or pepperoni. The source of collagen is also a key differentiator, influencing regional acceptance based on religious or cultural dietary restrictions. Understanding these segmentations is critical for market players to tailor their product offerings, marketing efforts, and distribution strategies effectively across different geographic regions and consumer demographics.

- Product Type:

- Edible Collagen Casings

- Non-Edible Collagen Casings

- Caliber:

- Small Caliber (e.g., for frankfurters, breakfast sausages)

- Large Caliber (e.g., for salamis, pepperoni, cooked ham)

- Application:

- Fresh Sausages

- Processed Sausages (Hot Dogs, Frankfurters)

- Dried Sausages (Salami, Pepperoni)

- Cooked Sausages (Bologna, Liverwurst)

- Other Meat Products (e.g., poultry products, vegetarian/vegan alternatives)

- Source:

- Bovine Collagen

- Porcine Collagen

- Other Sources (e.g., marine collagen, synthetic collagen, plant-based collagen)

Collagen Casings Market Value Chain Analysis

A comprehensive value chain analysis of the Collagen Casings Market reveals a multi-stage process, beginning with the acquisition and processing of raw materials and extending to the final distribution to end-users. The upstream segment of the value chain is critical, involving the sourcing of bovine and porcine hides, which are by-products from slaughterhouses. These hides undergo extensive processing, including cleaning, dehairing, and liming, before the collagen is extracted through chemical or enzymatic hydrolysis. Key upstream activities also involve the manufacturing of various additives and chemicals essential for the collagen casing production process, such as plasticizers, cross-linking agents, and preservatives. The efficiency and quality of these initial stages directly impact the properties and cost of the final collagen casing product, necessitating strong relationships with raw material suppliers and stringent quality control measures.

The core manufacturing stage involves the extrusion of the processed collagen paste into tubular forms, followed by drying, cross-linking, and shirring to achieve the desired caliber, strength, and elasticity. This stage is highly capital-intensive and requires advanced technology and specialized expertise. Downstream activities focus on the distribution and sale of the finished collagen casings to a diverse range of customers. These customers primarily include large-scale industrial meat processors, who utilize the casings for high-volume production of sausages, hot dogs, and other processed meats. Additionally, the downstream segment caters to smaller artisanal butchers, food service providers, and in some cases, direct retail for home use or specialized food production.

Distribution channels in the Collagen Casings Market are multifaceted, encompassing both direct and indirect routes. Direct distribution involves manufacturers selling directly to major food processing companies, fostering close relationships and often offering customized solutions. This channel allows for greater control over sales and customer service. Indirect distribution, on the other hand, relies on a network of distributors, wholesalers, and agents who facilitate market penetration to smaller and geographically dispersed customers, including local butchers and regional food manufacturers. These intermediaries play a crucial role in logistics, inventory management, and providing local market insights, ensuring broad market reach. The effectiveness of these distribution strategies is paramount for market players to maximize sales and maintain a competitive presence across various customer segments and geographic regions.

Collagen Casings Market Potential Customers

The Collagen Casings Market serves a broad and diverse range of potential customers, primarily concentrated within the food processing and preparation sectors. The largest segment of end-users consists of large-scale industrial meat processing companies that produce a high volume of sausages, frankfurters, hot dogs, and other processed meat products. These manufacturers seek collagen casings for their consistency, uniformity, and compatibility with automated, high-speed production lines, which are crucial for maintaining efficiency and meeting consumer demand for standardized products. For these industrial clients, the cost-effectiveness and reliability of supply are paramount considerations when selecting a casing supplier.

Beyond the industrial giants, small and medium-sized butcher shops and artisanal meat producers represent another significant customer segment. These businesses often prioritize the quality, appearance, and texture that collagen casings can impart to their specialty sausages and cured meats, balancing traditional craftsmanship with modern efficiency. While they may not require the same volume as large processors, their demand for diverse calibers and specific casing properties makes them valuable customers. The expanding food service industry, including restaurants, catering companies, and institutional food providers, also constitutes a growing base of buyers, as they increasingly rely on pre-packaged or semi-processed meat products that often utilize collagen casings.

Moreover, the market for collagen casings is evolving to include emerging customer segments, such as manufacturers of vegetarian and vegan food products. As plant-based alternatives to traditional sausages gain popularity, these companies are exploring the use of specially formulated collagen or plant-derived collagen-like casings to provide a familiar texture and appearance to their non-meat offerings. This diversification highlights the adaptability of collagen casings beyond conventional meat applications, expanding the potential customer base to include innovators in the alternative protein sector. Retailers, through their own private label processed meat production, also act as indirect buyers, influencing demand through their purchasing decisions from collagen casing manufacturers and meat processors.

Collagen Casings Market Key Technology Landscape

The Collagen Casings Market is underpinned by a sophisticated array of technologies that drive the efficiency, quality, and versatility of casing production. At the core of the manufacturing process is extrusion technology, where a precisely formulated collagen paste is extruded through a die to form a continuous tube. This process requires advanced rheological understanding and precision engineering to ensure consistent wall thickness, caliber, and structural integrity of the casing. Innovations in extrusion are continuously focused on increasing speed, reducing material waste, and improving the uniformity of the final product, which is crucial for high-speed sausage stuffing machines.

Beyond extrusion, various chemical and enzymatic technologies play a vital role in processing raw collagen and enhancing casing properties. Enzymatic hydrolysis is employed to break down collagen fibers to the desired molecular weight, while chemical cross-linking agents are used to strengthen the casing and impart specific characteristics such such as smoke permeability and bite. Membrane filtration and purification techniques are also critical in the upstream process for extracting high-purity collagen from animal hides, minimizing impurities and ensuring food safety compliance. Furthermore, drying technologies, including controlled air drying and vacuum drying, are essential for achieving the optimal moisture content and shelf stability of the casings without compromising their physical properties.

The technology landscape also extends to advancements in coating and co-extrusion techniques. Co-extrusion allows for the creation of multi-layered casings that can offer enhanced barrier properties, incorporate flavors, or even integrate functional ingredients, expanding the application scope of collagen casings. Novel coating technologies can provide improved smoke adherence, color development, or even antimicrobial properties, further differentiating products. Digitalization and automation are increasingly integrated into the production lines, leveraging sensors, data analytics, and robotic systems to monitor and control every stage of the manufacturing process, from raw material preparation to final shirring and packaging, thereby ensuring consistent quality and maximizing operational output.

Regional Highlights

- North America: Characterized by high consumption of processed meats, particularly hot dogs and frankfurters, driving consistent demand for collagen casings. The region emphasizes innovation in processing technologies and product development, including casings for plant-based meat alternatives. Strict food safety regulations also favor standardized collagen casings.

- Europe: A mature market with a strong tradition of sausage making, Europe exhibits stable demand across both industrial and artisanal segments. Germany, France, and Poland are significant consumers, driven by diverse sausage cultures. The region focuses on quality, sustainability, and adherence to stringent food standards.

- Asia-Pacific: Projected to be the fastest-growing region, fueled by rising disposable incomes, urbanization, and changing dietary preferences leading to increased consumption of processed foods. Countries like China, India, and Japan are experiencing rapid expansion in their meat processing industries, creating substantial opportunities for collagen casing manufacturers.

- South America: This region shows promising growth, especially in countries like Brazil and Argentina, which have strong traditions of meat consumption and a developing food processing sector. Local production and increasing exports of processed meats contribute to the demand for collagen casings.

- Middle East and Africa: An emerging market with increasing demand for processed meat products, driven by population growth and changing lifestyles. Cultural and religious dietary requirements (Halal) often influence product specifications, leading to demand for specific types of collagen casings or alternative sources.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Collagen Casings Market.- Viscofan S.A.

- Devro Plc

- Nippi Inc.

- Fibran Group

- SYNFLEX GmbH

- Shenguan Holdings (Group) Limited

- FABIOS S.A.

- DAT-Schaub Group

- Viskase Companies, Inc.

- Kalle GmbH

Frequently Asked Questions

What are collagen casings made from and how are they produced?

Collagen casings are primarily made from the collagen protein extracted from the hides of bovine (cattle) or porcine (pigs) animals, which are by-products of the meat industry. The production process involves cleaning, treating, and grinding the hides, followed by collagen extraction. This collagen is then formed into a paste, extruded through a die to create a continuous tube, and subsequently dried, cross-linked, and shirred into a usable form. This manufacturing process ensures uniformity, strength, and consistency in the final casing product.

What are the primary advantages of collagen casings over natural casings?

Collagen casings offer several key advantages over natural casings, including superior uniformity in caliber and length, which facilitates high-speed, automated production processes and reduces operational costs. They provide consistent performance during stuffing, cooking, and smoking, leading to a standardized final product. Additionally, collagen casings boast excellent strength, edibility, and a reduced risk of food safety issues as they are manufactured under controlled, hygienic conditions, making them a more reliable and efficient choice for industrial meat processors.

Are collagen casings edible and what are their main applications?

Yes, the vast majority of collagen casings are fully edible and easily digestible, contributing to the overall eating experience of the product. Their primary applications are in the production of a wide range of sausages and processed meat products, including frankfurters, hot dogs, fresh sausages, breakfast sausages, and some types of cooked and dried sausages like pepperoni. Their edibility and consistent bite make them ideal for products where the casing is intended to be consumed along with the filling.

How does the Collagen Casings Market address sustainability concerns?

The Collagen Casings Market addresses sustainability by primarily utilizing by-products from the meat industry (animal hides), which minimizes waste and contributes to a circular economy. Manufacturers are increasingly investing in sustainable sourcing practices for raw materials, optimizing production processes to reduce water and energy consumption, and implementing waste reduction strategies within their facilities. Research into alternative and plant-based collagen sources is also underway, further enhancing the industrys commitment to environmental responsibility and resource efficiency.

What role does technology play in the advancement of collagen casings?

Technology plays a crucial role in the advancement of collagen casings, driving innovation from raw material processing to final product characteristics. Modern extrusion technologies ensure precise caliber control and high-speed production. Advanced chemical and enzymatic treatments enhance casing strength, elasticity, and smoke permeability. Furthermore, digitalization, automation, and AI-powered analytics are increasingly integrated into manufacturing lines for improved quality control, process optimization, and demand forecasting, leading to more efficient and higher-quality collagen casing products.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager