Commercial Vehicle Urea Tank Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429717 | Date : Nov, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Commercial Vehicle Urea Tank Market Size

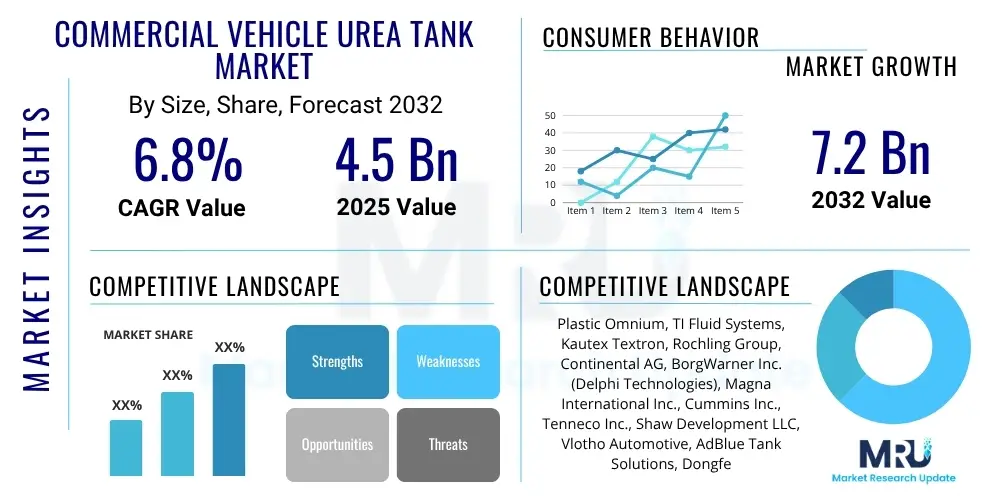

The Commercial Vehicle Urea Tank Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at $4.5 billion in 2025 and is projected to reach $7.2 billion by the end of the forecast period in 2032.

Commercial Vehicle Urea Tank Market introduction

The Commercial Vehicle Urea Tank Market is integral to modern diesel engine systems, specifically supporting Selective Catalytic Reduction (SCR) technology. These tanks are designed to store Diesel Exhaust Fluid (DEF), a non-toxic solution comprising urea and deionized water, which is injected into the exhaust stream of diesel engines. This process chemically converts harmful nitrogen oxides (NOx) into harmless nitrogen and water vapor, significantly reducing atmospheric pollution.

The product, a specialized storage unit for DEF, is predominantly made from high-density polyethylene (HDPE) due to its chemical resistance, durability, and lightweight properties. These tanks come in various capacities and configurations to suit different commercial vehicle types, from light-duty vans to heavy-duty trucks and buses. Their primary function is to ensure a continuous and reliable supply of DEF to the SCR system, enabling vehicles to comply with increasingly stringent global emission standards such as Euro VI, EPA 2010, and Bharat Stage VI.

Major applications of commercial vehicle urea tanks span across the entire commercial transportation sector, including long-haul trucking, construction vehicles, public transport buses, agricultural machinery, and municipal service vehicles. The benefits derived from these tanks and the associated SCR systems are substantial, encompassing compliance with environmental regulations, improved fuel efficiency for many modern diesel engines, and a positive contribution to corporate social responsibility by reducing the carbon footprint. Key driving factors for market growth include the global mandate for lower vehicle emissions, the expansion of commercial vehicle fleets in developing economies, and continuous technological advancements in SCR systems.

Commercial Vehicle Urea Tank Market Executive Summary

The Commercial Vehicle Urea Tank Market is experiencing robust growth driven by escalating global environmental regulations and the increasing adoption of Selective Catalytic Reduction (SCR) technology across the commercial vehicle sector. Business trends indicate a strong focus on lightweighting materials, modular designs, and integration capabilities to meet the diverse needs of Original Equipment Manufacturers (OEMs) and the aftermarket. Manufacturers are investing in advanced manufacturing processes to produce tanks that are more durable, offer better thermal management, and can withstand harsh operating conditions, reflecting a shift towards higher performance and reliability.

Regional trends highlight significant growth in Asia Pacific, particularly in countries like China and India, due to rapid industrialization, expanding logistics sectors, and the implementation of stricter emission norms. Europe continues to be a mature market with high adoption rates, driven by stringent Euro VI standards, while North America also shows steady growth fueled by EPA regulations and a large commercial vehicle fleet. Latin America and the Middle East & Africa are emerging markets, gradually adopting SCR technology as their regulatory frameworks evolve, creating new avenues for market expansion.

Segment trends reveal a dominance of high-density polyethylene (HDPE) tanks due to their cost-effectiveness and material properties, though advancements in composite materials are gaining traction. Tanks with capacities between 30-50 liters and 50-80 liters are particularly popular for medium and heavy commercial vehicles. The OEM segment accounts for the largest share, benefiting from new vehicle production, while the aftermarket segment is projected to grow steadily as older vehicles are retrofitted or require replacement parts. Overall, the market is characterized by innovation aimed at optimizing DEF storage and delivery systems to enhance vehicle performance and environmental compliance.

AI Impact Analysis on Commercial Vehicle Urea Tank Market

User inquiries concerning AI's influence on the Commercial Vehicle Urea Tank Market primarily revolve around how artificial intelligence could optimize design, manufacturing processes, and predictive maintenance for these components. Users frequently question whether AI can lead to more efficient tank geometries, reduce production costs, or enhance the longevity and reliability of urea tanks through smart monitoring. There is a general expectation that AI might enable more sophisticated integration of urea tanks into broader vehicle management systems, potentially informing drivers or fleet managers about DEF levels and system health with greater precision, thereby preventing downtime and ensuring emission compliance. Concerns also touch upon the data security implications of such interconnected systems and the potential for increased complexity in maintenance and diagnostics.

- AI could optimize urea tank designs for lighter weight and greater capacity through generative design algorithms.

- Predictive maintenance analytics, powered by AI, can monitor DEF consumption patterns and tank sensor data, forecasting potential issues before failure.

- AI-driven automation in manufacturing can improve precision, reduce waste, and lower production costs for urea tanks.

- Enhanced integration of urea tank data with vehicle telematics systems using AI for real-time emission compliance monitoring.

- AI could enable dynamic DEF injection strategies based on driving conditions, optimizing SCR system performance and DEF consumption.

- Improved supply chain logistics for DEF replenishment through AI-powered demand forecasting and routing optimization for fleets.

- Advanced quality control systems utilizing AI for automated inspection of tank manufacturing to detect defects with higher accuracy.

DRO & Impact Forces Of Commercial Vehicle Urea Tank Market

The Commercial Vehicle Urea Tank Market is significantly influenced by a confluence of drivers, restraints, and opportunities, all shaped by various impact forces. The primary driver is the global escalation of stringent emission regulations, such as Euro VI, EPA 2010, and equivalent standards in other regions, which mandate the reduction of nitrogen oxide (NOx) emissions from diesel vehicles. This regulatory pressure directly fuels the demand for Selective Catalytic Reduction (SCR) systems and, consequently, urea tanks. Additionally, the continuous growth in global commercial vehicle production, driven by increasing freight transportation and logistics activities, further expands the market. The inherent benefits of SCR technology, including potential fuel economy improvements for modern diesel engines, also contribute to its widespread adoption, indirectly boosting urea tank sales.

However, the market faces several restraints that could impede its growth. The relatively high initial cost of integrating SCR systems, including the urea tank and associated components, can be a barrier for some fleet operators, particularly in price-sensitive markets. Fluctuations in raw material prices, specifically for high-density polyethylene (HDPE) and other plastics, can impact manufacturing costs and profit margins. Furthermore, the need for a robust DEF distribution infrastructure, along with the consistent availability and quality of DEF, remains a logistical challenge in certain regions. The technical complexity involved in designing durable, chemically resistant, and thermally stable tanks that integrate seamlessly into diverse vehicle architectures also poses a design and engineering hurdle.

Opportunities for market players lie in several areas. There is a growing demand for lightweight and compact urea tanks that optimize vehicle payload and space utilization, leading to innovation in material science and design. The development and adoption of advanced materials, such as composites, could offer improved performance characteristics and durability. Furthermore, the expansion into emerging markets, where emission standards are progressively tightening and commercial vehicle fleets are rapidly modernizing, presents significant untapped potential. Strategic partnerships with OEMs and the development of integrated DEF management solutions also represent key avenues for market growth. Impact forces such as governmental policies, technological advancements in automotive components, economic growth indicators influencing commercial vehicle sales, and prevailing environmental concerns continue to steer the market's trajectory.

Segmentation Analysis

The Commercial Vehicle Urea Tank Market is segmented to provide a granular understanding of its dynamics, distinguishing trends based on various attributes such as material, capacity, vehicle type, and sales channel. This segmentation allows for a detailed analysis of demand patterns, technological preferences, and regional market behaviors, offering critical insights for manufacturers, suppliers, and investors. Understanding these segments is crucial for strategic planning, product development, and market penetration efforts, ensuring offerings align with specific industry needs and regulatory requirements across the diverse commercial vehicle landscape.

- By Material:

- High-Density Polyethylene (HDPE)

- Metal (e.g., Stainless Steel)

- Composites

- By Capacity:

- 10-30 Liters

- 30-50 Liters

- 50-80 Liters

- Above 80 Liters

- By Vehicle Type:

- Light Commercial Vehicles (LCV)

- Medium Commercial Vehicles (MCV)

- Heavy Commercial Vehicles (HCV)

- Buses and Coaches

- Off-Highway Vehicles (e.g., Construction, Agricultural)

- By Sales Channel:

- Original Equipment Manufacturer (OEM)

- Aftermarket

Value Chain Analysis For Commercial Vehicle Urea Tank Market

The value chain for the Commercial Vehicle Urea Tank Market encompasses a series of interconnected activities, beginning with the sourcing of raw materials and culminating in the delivery of the finished product to end-users. The upstream segment involves suppliers of primary raw materials such as high-density polyethylene (HDPE) granules, stainless steel, and various additives used for tank construction. Key component manufacturers, including those producing sensors, heaters, caps, and mounting brackets, also form a crucial part of the upstream activities. Quality and cost-effectiveness at this stage are paramount, as they directly influence the final product's performance and market competitiveness.

Midstream activities primarily involve the manufacturing and assembly of the urea tanks. This includes processes like blow molding for HDPE tanks, welding for metal tanks, and the integration of internal components such as baffles, level sensors, and heating elements. Manufacturers focus on advanced production techniques to ensure durability, leak-proof designs, and compliance with automotive safety standards. Research and development plays a significant role here, driving innovation in tank design, material science, and manufacturing efficiency to meet evolving emission regulations and OEM specifications. This stage also includes quality control and testing to ensure product reliability and longevity in harsh operating conditions.

The downstream segment of the value chain focuses on distribution and sales. Urea tanks are primarily sold through two main channels: direct to Original Equipment Manufacturers (OEMs) for integration into new commercial vehicles, and through indirect channels to the aftermarket. The OEM channel involves direct supply contracts with major commercial vehicle manufacturers, requiring robust logistics and just-in-time delivery capabilities. The aftermarket channel, conversely, involves a network of distributors, wholesalers, and authorized service centers that provide replacement tanks and parts for existing vehicles. Effective distribution networks, whether direct or indirect, are critical for ensuring market reach and customer satisfaction, encompassing logistics, inventory management, and technical support services for end-users like fleet operators and individual vehicle owners.

Commercial Vehicle Urea Tank Market Potential Customers

The primary potential customers and end-users of commercial vehicle urea tanks are diverse, spanning various sectors that operate diesel-powered commercial fleets. These include, but are not limited to, global and regional Original Equipment Manufacturers (OEMs) of heavy-duty trucks, medium-duty trucks, light commercial vehicles, and buses, who integrate these tanks into their new vehicle production lines. For OEMs, the key considerations are design integration, reliability, cost-effectiveness, and compliance with specific vehicle architectures and emission standards. They seek suppliers capable of producing high-volume, quality-assured components that meet their stringent specifications and supply chain demands, often fostering long-term partnerships with leading tank manufacturers.

Beyond new vehicle manufacturing, a significant customer segment exists within the aftermarket. This includes large commercial fleet operators in logistics, transportation, construction, mining, and agriculture sectors who require replacement urea tanks due to damage, wear, or upgrades. For these end-users, factors like product availability, durability, ease of installation, and cost-efficiency are paramount to minimize vehicle downtime and maintain operational efficiency. Independent repair shops, service centers, and spare parts distributors also act as intermediaries, procuring urea tanks to serve the replacement market, emphasizing the need for a robust and accessible supply chain.

Furthermore, government agencies and municipal corporations operating their own fleets of public transport buses, waste management vehicles, and emergency services also represent a substantial customer base. Their purchasing decisions are often influenced by long-term durability, environmental compliance, and total cost of ownership. The burgeoning market for off-highway vehicles, including construction equipment, agricultural machinery, and industrial vehicles, also constitutes a growing segment of potential customers, all driven by the necessity to comply with regional emission regulations and optimize the performance of their diesel engines through SCR technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $4.5 billion |

| Market Forecast in 2032 | $7.2 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Plastic Omnium, TI Fluid Systems, Kautex Textron, Rochling Group, Continental AG, BorgWarner Inc. (Delphi Technologies), Magna International Inc., Cummins Inc., Tenneco Inc., Shaw Development LLC, Vlotho Automotive, AdBlue Tank Solutions, Dongfeng Motor Parts and Components Group Co., Ltd., Ningbo Meishan Bonded Port Area Huitai Plastic Co., Ltd., Shandong Guotai Engineering Plastics Co., Ltd., Hwashin Co., Ltd., Foton Motor Group, Daimler Truck AG, Volvo Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Commercial Vehicle Urea Tank Market Key Technology Landscape

The Commercial Vehicle Urea Tank Market is characterized by a dynamic technology landscape focused on optimizing performance, durability, and integration within modern vehicle architectures. A cornerstone technology is advanced blow molding for High-Density Polyethylene (HDPE) tanks, enabling the creation of complex geometries that maximize capacity while fitting into confined vehicle spaces. These processes emphasize precision engineering to ensure consistent wall thickness, minimizing weight without compromising structural integrity or chemical resistance. Research into multi-layer HDPE constructions is ongoing, aimed at enhancing barrier properties and preventing DEF degradation over time, which is critical for maintaining SCR system efficiency and compliance.

Another pivotal area involves the integration of sophisticated sensor technologies within the urea tanks. These include highly accurate level sensors that provide real-time information to the vehicle's engine control unit (ECU) regarding DEF fluid volume, crucial for timely replenishment warnings and avoiding vehicle derate scenarios. Heating elements, often electric or engine coolant-based, are also essential technologies, preventing DEF from freezing in cold climates and ensuring its availability for injection. The development of robust thermal management systems within the tank is paramount, as DEF's optimal performance is temperature-dependent. These systems often utilize advanced materials for insulation and efficient heat transfer mechanisms.

Furthermore, the market benefits from advancements in materials science, exploring composites and novel plastics that offer improved strength-to-weight ratios, enhanced chemical resistance, and better thermal stability than traditional HDPE. Smart tank technology, incorporating embedded electronics and connectivity features, is also emerging. These innovations facilitate predictive maintenance by monitoring DEF quality, consumption rates, and system health in real-time, communicating data to fleet management systems. Such technological progress ensures that urea tanks are not merely storage units but intelligent components contributing to the overall efficiency, reliability, and environmental compliance of commercial vehicles, aligning with the broader trends of vehicle electrification and autonomy.

Regional Highlights

- North America: This region is a mature market driven by the robust enforcement of EPA 2010 and subsequent emission standards. The presence of major commercial vehicle manufacturers and a large freight industry ensures a steady demand for urea tanks. Innovations focus on larger capacities for long-haul trucking and robust designs for diverse climate conditions.

- Europe: Dominated by stringent Euro VI emission standards, Europe exhibits high adoption rates of SCR technology across all commercial vehicle segments. The market is characterized by a strong emphasis on efficiency, lightweight design, and advanced material usage. Germany, France, and the UK are key contributors, with a focus on sustainable transportation solutions.

- Asia Pacific (APAC): APAC is the fastest-growing region, fueled by rapid industrialization, increasing commercial vehicle production, and the implementation of stricter emission norms (e.g., Bharat Stage VI in India, China VI). Countries like China, India, and Japan are significant markets. The focus is on balancing cost-effectiveness with regulatory compliance and adapting to diverse local operating conditions.

- Latin America: This region is an emerging market, with increasing adoption of emission regulations pushing the demand for SCR systems. Brazil and Mexico are leading the transition, driven by expanding logistics and construction sectors. The market is characterized by a gradual shift towards modern emission technologies.

- Middle East and Africa (MEA): MEA is another developing market for commercial vehicle urea tanks. The adoption is slower but steadily increasing as countries in the GCC region and South Africa begin to implement or upgrade their emission standards. Growth is driven by infrastructure development projects and expanding transportation networks.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Commercial Vehicle Urea Tank Market.- Plastic Omnium

- TI Fluid Systems

- Kautex Textron

- Rochling Group

- Continental AG

- BorgWarner Inc.

- Magna International Inc.

- Cummins Inc.

- Tenneco Inc.

- Shaw Development LLC

- Vlotho Automotive

- AdBlue Tank Solutions

- Dongfeng Motor Parts and Components Group Co., Ltd.

- Ningbo Meishan Bonded Port Area Huitai Plastic Co., Ltd.

- Shandong Guotai Engineering Plastics Co., Ltd.

- Hwashin Co., Ltd.

- Foton Motor Group

- Daimler Truck AG

- Volvo Group

- Scania AB

Frequently Asked Questions

What is a commercial vehicle urea tank and why is it used?

A commercial vehicle urea tank stores Diesel Exhaust Fluid (DEF), a liquid used in Selective Catalytic Reduction (SCR) systems to reduce harmful nitrogen oxide (NOx) emissions from diesel engines, converting them into harmless nitrogen and water vapor to meet environmental regulations.

What are the primary materials used for manufacturing urea tanks?

The most common material for commercial vehicle urea tanks is High-Density Polyethylene (HDPE) due to its chemical resistance, durability, and lightweight properties. Some specialized applications may use metal or composite materials for enhanced performance.

How do emission regulations impact the Commercial Vehicle Urea Tank Market?

Stringent global emission regulations, such as Euro VI and EPA 2010, are the primary drivers of the Commercial Vehicle Urea Tank Market. These regulations mandate the use of SCR systems, directly increasing the demand for urea tanks as an essential component for compliance.

What capacity ranges are common for commercial vehicle urea tanks?

Commercial vehicle urea tanks come in various capacities, typically ranging from 10-30 liters for light commercial vehicles to over 80 liters for heavy-duty trucks and buses, with intermediate sizes like 30-50 liters and 50-80 liters also being common.

What role does the aftermarket play in the Commercial Vehicle Urea Tank Market?

The aftermarket is crucial for providing replacement urea tanks due to damage, wear, or system upgrades in existing commercial vehicles. This segment supports vehicle longevity and continued emission compliance for the installed base of vehicles, complementing OEM sales.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Commercial Vehicle Urea Tank Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Commercial Vehicle Urea Tank Market Size Report By Type (19 liters, 38 liters, 57 liters, 114 liters, Other size), By Application (HD Off Road, HD On Road), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager