Conductive Ink Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430113 | Date : Nov, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Conductive Ink Market Size

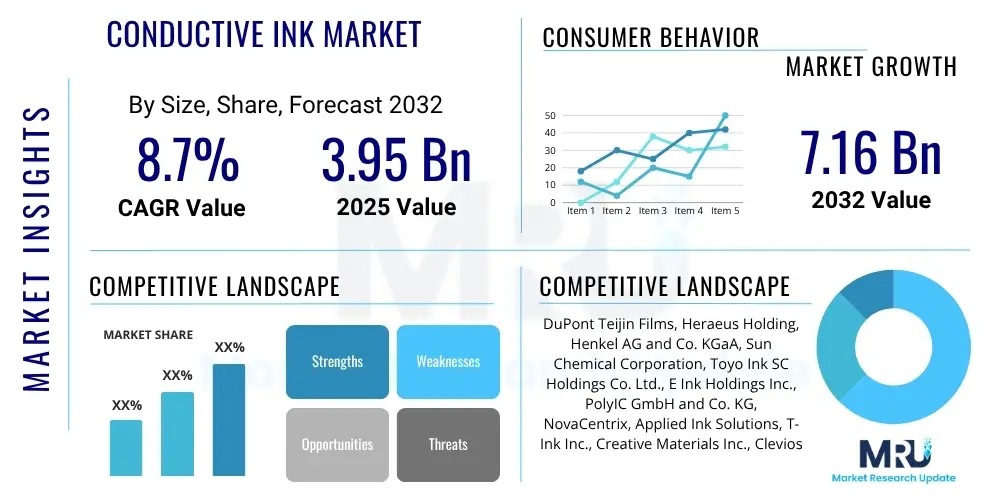

The Conductive Ink Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.7% between 2025 and 2032. The market is estimated at USD 3.95 Billion in 2025 and is projected to reach USD 7.16 Billion by the end of the forecast period in 2032.

Conductive Ink Market introduction

The Conductive Ink Market encompasses a diverse range of materials that exhibit electrical conductivity when applied to various substrates. These inks are formulated by dispersing conductive particles, such as silver, copper, carbon, or conductive polymers, within a binder system, enabling them to form electrical pathways. This innovation allows for the printing of circuits, sensors, and other electronic components using conventional printing techniques like screen printing, inkjet printing, and gravure printing, offering a flexible and cost-effective alternative to traditional manufacturing processes. The versatility of conductive inks extends their utility across numerous industries, from consumer electronics to advanced medical devices.

Products within this market are characterized by their ability to provide reliable electrical connections, often on flexible or unconventional substrates, opening avenues for miniaturization and novel product designs. Major applications include flexible circuits for displays and touchscreens, RFID tags for logistics and inventory management, solar cells for renewable energy, medical sensors for diagnostics and monitoring, and automotive components for lightweight electronics. These applications leverage the unique advantages of conductive inks, such as their low processing temperatures, excellent adhesion, and environmental stability, which are critical for high-performance and durable electronic devices.

The primary benefits of conductive inks stem from their ability to facilitate cost-effective, high-throughput manufacturing of electronic devices with enhanced flexibility and reduced form factors. They are crucial for the ongoing trend of miniaturization in electronics and the widespread adoption of smart, connected devices. Key driving factors propelling market growth include the escalating demand for flexible and printed electronics in various consumer and industrial applications, the rapid expansion of the Internet of Things (IoT) ecosystem, advancements in 5G technology requiring more sophisticated antenna designs, and increasing investment in renewable energy technologies like photovoltaics.

Conductive Ink Market Executive Summary

The Conductive Ink Market is experiencing significant momentum driven by continuous technological advancements and burgeoning demand across several high-growth sectors. Business trends indicate a strong focus on research and development to enhance ink performance, reduce material costs, and develop sustainable formulations. Companies are actively pursuing strategic collaborations and partnerships to expand their product portfolios and geographical reach, particularly in emerging markets. There is a discernible shift towards specialized inks tailored for specific applications, such as high-temperature resistant inks for automotive electronics or stretchable inks for wearable devices, reflecting the diverse and evolving needs of end-users. Consolidation activities and increasing competitive intensity characterize the market landscape as key players vie for technological leadership and market share.

Regional trends highlight Asia Pacific as the leading and fastest-growing market, primarily due to its robust manufacturing infrastructure for consumer electronics, automotive components, and solar cells, coupled with a large consumer base and government support for technological innovation. North America and Europe are also significant contributors, driven by strong R&D capabilities, early adoption of advanced technologies, and a growing emphasis on smart healthcare, industrial automation, and electric vehicles. Latin America and the Middle East and Africa represent emerging opportunities, propelled by increasing industrialization, infrastructure development, and growing disposable incomes, leading to higher adoption rates of electronic devices.

Segment trends reveal that silver conductive inks continue to dominate due to their superior conductivity and established performance, although there is a growing interest and investment in copper and carbon-based inks as cost-effective alternatives. Polymer conductive inks are gaining traction in flexible and stretchable electronics. Application-wise, the market is heavily influenced by the consumer electronics, automotive, and medical sectors, which demand high-performance and miniaturized solutions. Within end-use industries, flexible electronics and advanced packaging are anticipated to exhibit the highest growth rates, driven by the proliferation of IoT devices and the ongoing evolution of display technologies. The market is characterized by innovation in both material science and printing technologies to meet the evolving requirements of these diverse segments.

AI Impact Analysis on Conductive Ink Market

Users frequently inquire about how artificial intelligence (AI) can revolutionize the conductive ink market, particularly regarding material discovery, manufacturing efficiency, and product customization. Common questions revolve around AI's capability to predict optimal ink formulations for specific applications, enhance the precision and speed of printing processes, and identify novel conductive materials with improved properties or lower costs. There is a strong expectation that AI will streamline research and development cycles, accelerate the commercialization of new ink technologies, and enable smarter, more adaptive production lines. Users are also keen to understand AI's role in quality control, predictive maintenance of printing equipment, and managing complex supply chains for raw materials, aiming to reduce waste and improve overall operational effectiveness in conductive ink manufacturing.

The key themes emerging from this analysis include the potential for AI-driven material informatics to discover and design advanced conductive composites, reducing the trial-and-error often associated with traditional R&D. Concerns often touch upon the initial investment required for AI integration, data privacy issues, and the need for a skilled workforce capable of operating and interpreting AI-powered systems. However, the overarching expectation is that AI will be a transformative force, enabling unprecedented levels of efficiency, innovation, and customization within the conductive ink industry, making it more responsive to dynamic market demands and pushing the boundaries of what is technically feasible in printed electronics. AI's ability to analyze vast datasets related to material properties, processing parameters, and performance metrics is seen as a critical enabler for the next generation of conductive ink solutions.

The integration of AI is expected to lead to significant advancements across the conductive ink value chain, from raw material sourcing and formulation to application and quality assurance. AI algorithms can optimize parameters for printing processes, leading to higher yields and reduced manufacturing defects. Furthermore, AI could facilitate predictive modeling of ink performance under various environmental conditions, allowing for the development of more robust and reliable products. The proactive identification of market needs and the rapid development of tailored solutions through AI-powered design tools will provide a significant competitive advantage to companies that embrace this technology, ultimately shaping the future trajectory of the conductive ink market. The analytical capabilities of AI will assist in understanding complex material interactions, leading to more stable and higher-performing ink formulations.

- AI-driven material discovery accelerates the identification of new conductive compounds and optimal formulations.

- Enhanced process optimization through AI improves printing precision, speed, and efficiency, reducing manufacturing costs.

- Predictive analytics enables proactive maintenance of printing equipment, minimizing downtime and increasing productivity.

- Advanced quality control systems powered by AI detect defects more accurately and rapidly during production.

- Personalized ink development capabilities allow for rapid customization of conductive inks for specific client applications.

- Supply chain optimization using AI ensures efficient sourcing of raw materials and better inventory management.

- Simulation and modeling with AI tools predict ink performance and reliability under diverse operational conditions.

- Reduced R&D cycles through AI-assisted experimentation and data analysis.

- Facilitates intelligent manufacturing processes, moving towards Industry 4.0 standards.

- Enables creation of novel functionalities in printed electronics through optimized material combinations.

DRO & Impact Forces Of Conductive Ink Market

The Conductive Ink Market is significantly propelled by several robust drivers that underscore its integral role in modern electronics. A primary driver is the accelerating trend of miniaturization and the growing demand for flexible and lightweight electronic components across consumer electronics, automotive, and medical industries. The proliferation of the Internet of Things (IoT) devices, which require compact, cost-effective, and often flexible circuitry, further fuels this demand. Additionally, the rapid advancements in 5G technology necessitate sophisticated antenna designs and high-frequency capabilities, where conductive inks offer versatile solutions. The increasing adoption of advanced packaging technologies and the expansion of wearable electronics also contribute substantially to market growth, as conductive inks are crucial for creating these innovative products.

Despite the strong growth drivers, the market faces notable restraints. The high cost of noble metal-based conductive inks, particularly those utilizing silver, remains a significant challenge, limiting their adoption in cost-sensitive applications. Furthermore, achieving consistent reliability and long-term stability for certain conductive ink formulations, especially on flexible substrates, requires continuous research and development, which can be resource-intensive. Competition from established traditional wiring and etching processes, though less versatile, presents a barrier in certain industrial applications where conventional methods are deeply entrenched. The complex interplay of material properties, printing techniques, and substrate compatibility also poses technical hurdles that must be overcome to broaden application areas.

Opportunities within the conductive ink market are extensive and diverse, promising future expansion. The emergence of smart textiles, where electronic functionalities are seamlessly integrated into fabrics, presents a burgeoning application area for stretchable and wash-resistant conductive inks. The continued growth of the medical device sector, particularly in point-of-care diagnostics and wearable health monitors, offers significant potential for high-performance bio-compatible conductive inks. Furthermore, advancements in sustainable and environmentally friendly conductive ink formulations, including those based on copper, graphene, and carbon nanotubes, are opening new markets by addressing environmental concerns and reducing production costs. The development of advanced manufacturing techniques like 3D printing for electronics also provides novel avenues for conductive ink innovation and application. These opportunities, coupled with ongoing technological breakthroughs, are expected to redefine the market landscape.

Impact forces on the conductive ink market are multifaceted. Technological advancements in material science, particularly nanotechnology, are continuously improving ink performance, stability, and conductivity. This includes the development of highly dispersed nanoparticles and the exploration of novel composite materials. The regulatory landscape, including restrictions on certain chemicals and increasing emphasis on sustainability, significantly influences product development towards greener alternatives. Economic fluctuations can impact raw material prices, particularly for precious metals, affecting production costs and market pricing strategies. Lastly, the stability and efficiency of global supply chains for specialized raw materials and manufacturing equipment are critical impact forces, determining the availability and cost-effectiveness of conductive ink products.

Segmentation Analysis

The Conductive Ink Market is broadly segmented based on several key parameters, including the type of conductive material used, the specific application areas, and the end-use industries that integrate these innovative materials. This comprehensive segmentation allows for a detailed analysis of market dynamics, growth trajectories, and competitive landscapes within each distinct category. Understanding these segments is crucial for identifying targeted opportunities, developing specialized products, and formulating effective market entry strategies. The versatility of conductive inks enables their application across a wide array of technological fields, leading to a rich and complex market structure. The market’s segmentation is a reflection of the diverse requirements and performance criteria demanded by various industrial and consumer applications. Furthermore, regional segmentation provides insights into geographical adoption patterns and growth pockets, highlighting the disparities in technological maturity and industrial concentration worldwide.

- By Type

- Silver Conductive Inks

- Silver Flake Inks

- Silver Nanoparticle Inks

- Silver-Coated Copper Inks

- Copper Conductive Inks

- Copper Flake Inks

- Copper Nanoparticle Inks

- Carbon Conductive Inks

- Graphite Inks

- Carbon Nanotube (CNT) Inks

- Graphene Inks

- Conductive Polymer Inks

- PEDOTPSS Inks

- Polyaniline (PANI) Inks

- Hybrid/Other Conductive Inks

- Nickel Inks

- Gold Inks

- Platinum Inks

- Mixed Metal Inks

- Silver Conductive Inks

- By Application

- Printed Circuit Boards (PCBs)

- Flexible Displays & Touchscreens

- RFID Tags & Smart Labels

- Photovoltaics (Solar Cells)

- Sensors (Medical, Environmental, Automotive)

- Wearable Electronics

- EMI/RFI Shielding

- Heating Elements

- Automotive Electronics (Heated Windows, Antennas)

- Medical Electrodes

- Smart Packaging

- Membrane Switches

- LED/OLED Lighting

- Stretchable Electronics

- By End-Use Industry

- Consumer Electronics

- Smartphones

- Tablets

- Laptops

- Wearables

- Gaming Devices

- Automotive

- Interior Electronics

- Sensors

- Heating Systems

- Lighting

- Medical & Healthcare

- Diagnostic Devices

- Wearable Medical Devices

- Electrodes

- Biosensors

- Aerospace & Defense

- Avionics

- Smart Skins

- Heaters

- Telecommunications

- Antennas

- Networking Devices

- Energy (Solar & Batteries)

- Photovoltaic Cells

- Battery Electrodes

- Industrial

- Sensors

- Controls

- Automation Equipment

- Smart Packaging & Logistics

- Textiles & Wearables

- Building & Construction

- Consumer Electronics

- By Printing Technology

- Screen Printing

- Inkjet Printing

- Flexographic Printing

- Gravure Printing

- Dispensing

- Aerosol Jet Printing

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Conductive Ink Market

The value chain for the conductive ink market begins with an intricate upstream analysis involving the sourcing and refinement of foundational raw materials. This critical stage includes suppliers of highly pure conductive particles, such as silver flakes, silver nanoparticles, copper powders, carbon black, graphite, graphene, and carbon nanotubes. Additionally, it encompasses manufacturers of specialized polymer resins, organic solvents, and various additives like binders, dispersants, and rheology modifiers that are essential for formulating stable and printable ink systems. The quality and cost-effectiveness of these raw materials directly impact the final performance and market viability of the conductive inks. Innovations at this upstream level, such as more efficient nanoparticle synthesis or development of novel conductive polymers, are vital for continuous product improvement and cost reduction within the industry.

Moving downstream, the value chain progresses through the manufacturing of conductive inks, where raw materials are precisely blended and processed to create finished ink products with specific electrical, rheological, and printing properties. These inks are then supplied to various electronic component manufacturers, original equipment manufacturers (OEMs), and specialized printed electronics companies. These downstream players utilize the conductive inks in their production processes for applications ranging from flexible circuits, RFID tags, and sensors to solar cells and automotive components. The efficiency and precision of application technologies, such as screen printing, inkjet printing, and gravure printing, at this stage, are paramount for producing high-quality and functional electronic devices, showcasing the interconnectedness of ink formulation and application methods.

The distribution channel for conductive inks typically involves a combination of direct sales and indirect channels. Direct sales are often utilized for large-volume customers, key strategic accounts, or those requiring highly customized ink formulations and technical support, allowing for close collaboration between the ink manufacturer and the end-user. Indirect channels primarily involve a network of specialized distributors and agents who cater to smaller businesses, provide local inventory, and offer technical services. These distributors often possess expertise in specific regional markets or application areas, facilitating broader market penetration. The choice of distribution strategy depends on factors such as market maturity, customer size, and the technical complexity of the ink products, ensuring efficient delivery and support throughout the global supply chain.

In addition to direct and indirect sales, the distribution channel also involves collaborations with equipment manufacturers who develop printing systems compatible with specific conductive ink formulations. This symbiotic relationship ensures that ink innovations are matched with suitable application technologies, driving market adoption. Furthermore, online platforms and e-commerce are increasingly playing a role, particularly for standard ink products or for reaching smaller enterprises globally, streamlining the purchasing process. The robustness of the entire value chain, from raw material sourcing through manufacturing, distribution, and end-use application, is crucial for the sustainable growth and continued innovation within the conductive ink market, addressing both global reach and localized support needs.

Conductive Ink Market Potential Customers

The Conductive Ink Market serves a diverse and expanding base of potential customers across a multitude of industries, all seeking innovative solutions for creating electronic functionalities. These customers are primarily end-users or buyers of the conductive ink products, integrating them into their manufacturing processes to produce a vast array of electronic components and devices. A significant segment of potential customers includes manufacturers in the consumer electronics sector, such as those producing smartphones, tablets, laptops, and a growing range of wearable devices. These companies leverage conductive inks for touchscreens, flexible displays, printed antennas, and internal circuitry to enable smaller, lighter, and more aesthetically pleasing products, driving demand for high-performance and reliable ink formulations.

Another crucial customer segment is the automotive industry, where conductive inks are increasingly adopted for various applications. This includes printed heating elements for defogging windows, sophisticated sensors for advanced driver-assistance systems (ADAS), in-cabin electronics, and flexible circuitry for infotainment systems. The demand for lightweight, space-efficient, and durable electronic solutions in modern vehicles makes conductive inks an attractive option for automotive OEMs and their tier-1 suppliers. Similarly, the medical and healthcare sectors represent a high-growth customer base, utilizing conductive inks for disposable diagnostic sensors, wearable health monitors, smart bandages, and flexible electrodes for various therapeutic and monitoring devices, where biocompatibility and precision are paramount.

Beyond these major sectors, potential customers also include manufacturers in the renewable energy industry, particularly for photovoltaic cells, where conductive inks are used to create front and rear electrodes for solar panels, improving efficiency and reducing manufacturing costs. The aerospace and defense industries utilize conductive inks for EMI/RFI shielding, lightweight antennas, and specialized sensors in demanding environments. Furthermore, companies involved in smart packaging, RFID tags for logistics, industrial sensors, and smart textiles are rapidly emerging as significant buyers, seeking to embed electronic functionalities into everyday objects and materials. This broad spectrum of end-users underscores the pervasive influence and growing importance of conductive ink technology in shaping the future of interconnected and intelligent products.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 3.95 Billion |

| Market Forecast in 2032 | USD 7.16 Billion |

| Growth Rate | 8.7% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | DuPont Teijin Films, Heraeus Holding, Henkel AG and Co. KGaA, Sun Chemical Corporation, Toyo Ink SC Holdings Co. Ltd., E Ink Holdings Inc., PolyIC GmbH and Co. KG, NovaCentrix, Applied Ink Solutions, T-Ink Inc., Creative Materials Inc., Clevios GmbH (Heraeus Group), Intrinsiq Materials Ltd., VARTA Microbattery GmbH, Inkron (Nagase ChemteX), Methode Electronics Inc., Jujo Chemical Co. Ltd., Mitsubishi Chemical Corporation, Lord Corporation, Fujikura Kasei Co. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Conductive Ink Market Key Technology Landscape

The Conductive Ink Market is characterized by a dynamic and continuously evolving technology landscape, where innovations in material science and printing methodologies are driving significant advancements. A core aspect of this landscape involves the development of novel conductive materials, moving beyond traditional silver to include cost-effective alternatives like copper, carbon nanotubes (CNTs), graphene, and conductive polymers. Nanotechnology plays a crucial role in enhancing ink performance, as nanoparticles of metals and carbon offer superior conductivity, smaller feature sizes, and improved dispersion stability. Research is focused on optimizing particle size, morphology, and surface functionalization to achieve desired electrical properties and printability across various substrates, including flexible and stretchable ones.

Another pivotal area of technological focus is the advancement of printing techniques used for applying conductive inks. Screen printing remains a dominant method due to its versatility and cost-effectiveness for a wide range of applications, but significant strides are being made in developing finer mesh screens and more precise paste formulations. Inkjet printing technology is gaining increasing importance for its ability to produce high-resolution patterns, enable digital fabrication, and facilitate rapid prototyping, requiring inks with finely tuned viscosity and surface tension. Other emerging printing methods like gravure printing, flexographic printing, and aerosol jet printing are expanding the capabilities of printed electronics by offering higher throughput, greater deposition control, and compatibility with diverse substrates, opening up new application avenues.

Furthermore, the key technology landscape includes innovations in curing methods and ink formulation chemistry to optimize performance and manufacturing efficiency. Traditional thermal curing is being complemented by rapid curing techniques such as UV curing, photonic sintering, and microwave curing, which allow for faster processing and are compatible with heat-sensitive substrates. Advances in binder systems and additives are critical for improving ink adhesion, flexibility, stretchability, and environmental stability. The integration of these material and process innovations aims to reduce manufacturing costs, improve product reliability, and enable the creation of highly integrated, miniaturized, and flexible electronic devices. These continuous technological enhancements are fundamental to meeting the increasingly stringent performance demands of modern electronics and expanding the overall market for conductive inks.

Regional Highlights

- North America: This region stands as a significant market for conductive inks, characterized by robust research and development activities and a strong presence of key technology companies. The demand is largely driven by the automotive sector for advanced driver-assistance systems and in-cabin electronics, as well as the medical industry for wearable sensors and diagnostic devices. The region also benefits from early adoption of cutting-edge technologies and substantial investments in IoT and flexible electronics.

- Strong R&D infrastructure supports innovation in new materials and printing techniques.

- High demand from automotive, medical, and aerospace and defense industries.

- Significant market for specialized high-performance conductive inks.

- Government initiatives promoting advanced manufacturing and smart technologies.

- Europe: Europe represents a mature but growing market for conductive inks, with a strong emphasis on industrial electronics, automotive applications, and sustainability. Countries like Germany, France, and the UK are at the forefront of adopting printed electronics in smart homes, industrial automation, and electric vehicle components. The region is also focusing on developing eco-friendly conductive ink formulations and optimizing production processes to meet stringent environmental regulations.

- Focus on sustainable and eco-friendly conductive ink solutions.

- High adoption in industrial electronics and automotive sectors.

- Strong regulatory framework driving innovation in safe and efficient materials.

- Collaborative efforts between industry and academia for technological advancements.

- Asia Pacific (APAC): APAC is the largest and fastest-growing market for conductive inks globally, primarily fueled by its dominant position in consumer electronics manufacturing, rapid industrialization, and a vast population with increasing disposable income. Countries such as China, South Korea, Japan, and Taiwan are major production hubs for smartphones, displays, and other electronic devices, driving immense demand for high-volume, cost-effective conductive ink solutions. Furthermore, the region is witnessing significant investments in solar energy and smart packaging, further boosting market expansion.

- Dominant position in consumer electronics manufacturing and export.

- Rapid growth in IoT, flexible displays, and smart packaging applications.

- Significant investments in solar energy and automotive electronics production.

- Large consumer base and increasing disposable income contributing to electronics demand.

- Latin America: This region is an emerging market for conductive inks, showing steady growth driven by increasing industrialization, infrastructure development, and growing adoption of consumer electronics. Countries like Brazil and Mexico are leading the way, with expanding automotive manufacturing sectors and rising demand for smart home devices. While smaller in scale compared to APAC, the potential for growth is considerable as local industries mature and integrate more advanced electronic components.

- Increasing industrialization and manufacturing activities.

- Growing demand for consumer electronics and automotive components.

- Developing infrastructure supports greater adoption of printed electronics.

- Emerging opportunities in local market segments for customized solutions.

- Middle East and Africa (MEA): The MEA region is at an nascent stage in the conductive ink market but holds promising growth potential due to ongoing urbanization, increasing government investments in technology and smart city initiatives, and diversification of economies away from oil. The demand is slowly picking up in electronics assembly, telecommunications, and infrastructure projects, creating new opportunities for conductive ink manufacturers and suppliers.

- Growing investment in smart city projects and technological infrastructure.

- Increasing adoption of electronics in various sectors due to urbanization.

- Emerging demand from telecommunications and automotive assembly.

- Potential for localized production and customization of ink solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Conductive Ink Market.- DuPont Teijin Films

- Heraeus Holding

- Henkel AG and Co. KGaA

- Sun Chemical Corporation

- Toyo Ink SC Holdings Co. Ltd.

- E Ink Holdings Inc.

- PolyIC GmbH and Co. KG

- NovaCentrix

- Applied Ink Solutions

- T-Ink Inc.

- Creative Materials Inc.

- Clevios GmbH (Heraeus Group)

- Intrinsiq Materials Ltd.

- VARTA Microbattery GmbH

- Inkron (Nagase ChemteX)

- Methode Electronics Inc.

- Jujo Chemical Co. Ltd.

- Mitsubishi Chemical Corporation

- Lord Corporation

- Fujikura Kasei Co. Ltd.

Frequently Asked Questions

What is the projected growth rate of the Conductive Ink Market?

The Conductive Ink Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.7% between 2025 and 2032, driven by increasing demand for flexible and printed electronics.

What are the primary applications of conductive inks?

Conductive inks are primarily used in applications such as flexible displays, RFID tags, solar cells, medical sensors, wearable electronics, automotive components, and printed circuit boards, facilitating miniaturization and cost-effective manufacturing.

Which type of conductive ink holds the largest market share?

Silver conductive inks currently hold the largest market share due to their superior electrical conductivity and established performance, although copper and carbon-based inks are gaining traction as cost-effective alternatives.

What are the main challenges facing the Conductive Ink Market?

Key challenges include the high cost of noble metal-based inks, achieving consistent long-term reliability on various substrates, intense R&D requirements, and competition from traditional electronic manufacturing methods.

How does AI impact the future of conductive inks?

AI is expected to transform the conductive ink market by accelerating material discovery, optimizing ink formulations, enhancing printing process efficiency, and enabling advanced quality control, leading to more innovative and customized products.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Conductive Ink Pen Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- In-mold electronics (IME) Market Statistics 2025 Analysis By Application (Consumer Electronics, Car, Home Appliance, Industry, Other), By Type (Silver Conductive ink Material, Carbon Conductive ink Material, Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Non-Conductive Ink Market Statistics 2025 Analysis By Application (PCB Panels, PV Panels, Led Packaging), By Type (Glass Substrate, Ceramic Substrate, Acrylic Substrate), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- In-mold electronics (IME) Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Silver Conductive ink Material, Carbon Conductive ink Material, Other), By Application (Consumer Electronics, Car, Home Appliance, Industry, Other), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager