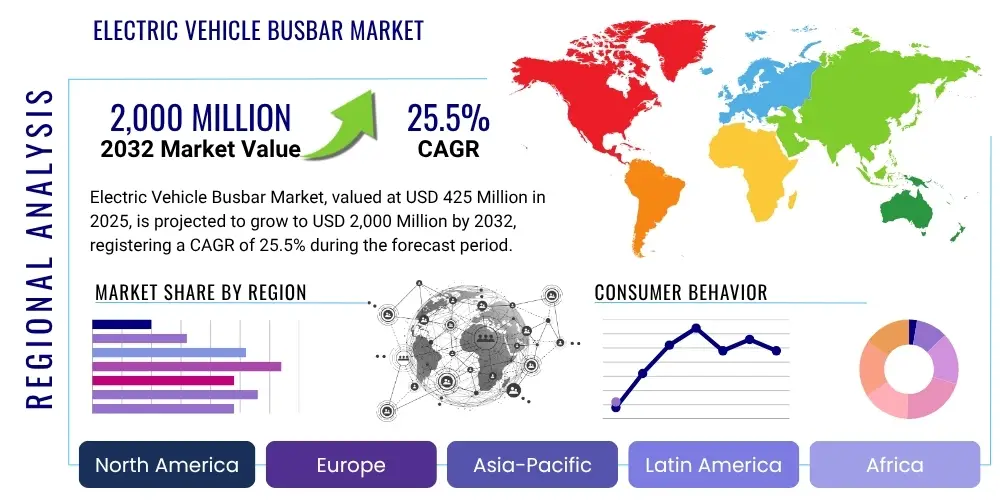

Electric Vehicle Busbar Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429024 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Electric Vehicle Busbar Market Size

The Electric Vehicle Busbar Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 25.5% between 2025 and 2032. The market is estimated at USD 425 Million in 2025 and is projected to reach USD 2,000 Million by the end of the forecast period in 2032.

Electric Vehicle Busbar Market introduction

The Electric Vehicle Busbar Market encompasses components critical for efficient power distribution within electric vehicles, including passenger cars, commercial vehicles, and two-wheelers. Busbars, essentially metallic strips or bars, are designed to carry significant electrical current and distribute power from the battery pack to various high-voltage components such as inverters, motors, and charging units. These specialized conductors offer superior current carrying capacity, excellent thermal management properties, and a compact design compared to traditional wiring harnesses, which are often heavier and more prone to electromagnetic interference. The fundamental role of EV busbars is to ensure reliable and safe electrical connectivity, minimizing energy losses and enhancing the overall performance and efficiency of the electric powertrain.

The product description of EV busbars highlights their construction, typically involving copper or aluminum conductors encased in insulating materials like plastics, epoxy, or powder coatings, which provide dielectric strength and protection against environmental factors. Key applications span the entire high-voltage architecture of an EV, from connecting individual battery cells and modules within the battery pack to enabling power flow between the battery, inverter, motor, and onboard charger. Benefits of integrating busbars include enhanced thermal management due to their large surface area, reduced assembly time, improved reliability through fewer connection points, and significant space and weight savings, which are crucial for extending vehicle range and performance. Their rigid and precise form factor also aids in vibration resistance and structural integrity within the vehicle's electrical system, contributing to greater safety and longevity.

Driving factors for the substantial growth of the Electric Vehicle Busbar Market are deeply intertwined with the global acceleration in electric vehicle adoption, supported by stringent emission regulations and increasing consumer demand for sustainable transportation. Government incentives, subsidies, and favorable policies in numerous countries are actively promoting EV sales and the development of associated infrastructure, thereby directly fueling the demand for EV busbars. Furthermore, continuous advancements in battery technology, leading to higher energy densities and faster charging capabilities, necessitate more robust and efficient power distribution solutions that busbars intrinsically provide. The expanding network of charging infrastructure and the increasing complexity of EV electrical systems further underscore the indispensable role of busbars in facilitating high-power transfer and ensuring system reliability.

Electric Vehicle Busbar Market Executive Summary

The Electric Vehicle Busbar Market is experiencing robust expansion, driven by the escalating global demand for electric vehicles and significant advancements in battery technology. Business trends indicate a strong focus on material innovation, particularly in copper and aluminum alternatives, as manufacturers strive for lighter, more cost-effective, and higher-performing solutions. There is also a growing emphasis on modular and standardized busbar designs to streamline manufacturing processes and enhance scalability for EV original equipment manufacturers (OEMs). Strategic collaborations between busbar suppliers and EV component manufacturers are becoming more prevalent, aimed at co-developing customized solutions that meet specific vehicle architecture requirements, ensuring optimal integration and performance within diverse EV platforms. Furthermore, the market is witnessing increased investment in automation and advanced manufacturing techniques to improve production efficiency and meet the rapidly rising volume demands of the EV sector.

Regional trends reveal Asia Pacific as the dominant market, primarily due to the high concentration of EV manufacturing hubs, substantial government support for electric mobility, and a large consumer base in countries like China, Japan, and South Korea. Europe and North America are also demonstrating significant growth, propelled by ambitious decarbonization targets, increasing EV adoption rates, and a strong push for domestic battery and EV component production. These regions are investing heavily in establishing resilient supply chains and fostering innovation in EV technologies, thereby contributing substantially to the busbar market's expansion. The Middle East and Africa, alongside Latin America, represent emerging markets with nascent but rapidly developing EV ecosystems, indicating future growth potential as their respective governments and industries ramp up efforts to transition towards electric transportation.

Segment trends within the Electric Vehicle Busbar Market highlight a shift towards high-power applications, particularly in commercial EVs and fast-charging infrastructure, where busbars must handle extremely high current densities and dissipate heat effectively. Copper busbars continue to hold a significant share due to their superior conductivity and thermal properties, while aluminum busbars are gaining traction for their lighter weight and cost-effectiveness, especially in applications where weight reduction is a critical design parameter. The integration of busbars directly into battery modules, power distribution units (PDUs), and inverter systems is becoming standard, underscoring their critical role in optimizing space utilization and enhancing the safety and efficiency of the entire electrical system. Furthermore, there is an increasing demand for flexible busbars, which offer greater design versatility and ease of assembly, particularly in complex battery pack configurations. The focus on robust insulation materials and advanced joining technologies is also a key trend, ensuring durability and performance under harsh operating conditions.

AI Impact Analysis on Electric Vehicle Busbar Market

Users are increasingly curious about how Artificial Intelligence will revolutionize the Electric Vehicle Busbar market, particularly in areas like design optimization, manufacturing efficiency, and predictive maintenance. Common questions revolve around AI's ability to simulate complex electrical and thermal scenarios for busbar performance, thereby reducing prototyping costs and accelerating development cycles. There is significant interest in AI-driven quality control during the manufacturing process to ensure defect-free production at high volumes, and how AI can optimize supply chain logistics for raw materials like copper and aluminum amidst fluctuating prices. Furthermore, users often inquire about the potential for AI to integrate smart features into busbars, enabling real-time diagnostics and condition monitoring within the EV's electrical system, which could significantly enhance reliability and safety throughout the vehicle's lifespan.

- AI-driven generative design for optimal busbar geometries, enhancing thermal and electrical performance while minimizing material usage.

- Predictive analytics for manufacturing defects, improving quality control and reducing scrap rates in busbar production lines.

- Supply chain optimization using AI algorithms to manage raw material procurement, anticipating price fluctuations and ensuring timely delivery.

- Integration of AI in thermal management systems, allowing busbars to intelligently adjust power distribution based on real-time temperature data.

- Enhanced simulation and modeling capabilities for busbar performance under various operating conditions, accelerating R&D and reducing physical testing.

- AI-powered inspection systems for automated visual defect detection on busbar surfaces and connections.

- Development of smart busbars with integrated sensors and AI for real-time diagnostics and predictive maintenance within EV battery packs.

DRO & Impact Forces Of Electric Vehicle Busbar Market

The Electric Vehicle Busbar Market is significantly influenced by a confluence of driving factors, critical restraints, and substantial opportunities, all of which constitute various impact forces shaping its trajectory. The primary driver is the exponential growth in electric vehicle sales worldwide, spurred by increasing environmental consciousness, stringent emission regulations, and government incentives promoting EV adoption. Coupled with this, advancements in battery technology, leading to higher voltage systems and faster charging capabilities, directly elevate the demand for high-performance and robust busbar solutions capable of efficiently handling increased power. Furthermore, the expansion of global EV charging infrastructure necessitates reliable and efficient power transfer components, positioning busbars as indispensable elements in the entire EV ecosystem. These factors collectively create a positive feedback loop, continuously propelling market growth and technological innovation within the busbar sector.

Despite the favorable market conditions, several restraints pose challenges to the sustained growth of the EV busbar market. The volatility in raw material prices, particularly for copper and aluminum, introduces significant cost uncertainties for manufacturers, potentially impacting profit margins and product pricing. Moreover, the lack of universally accepted standardization in busbar designs across different EV manufacturers can lead to customization requirements, increasing complexity and production costs. The initial capital investment required for establishing advanced manufacturing facilities capable of producing high-precision, insulated busbars also acts as a barrier for new entrants. Furthermore, technical challenges related to thermal management in extremely high-power applications and the need for durable insulation materials that can withstand harsh operating environments present ongoing R&D hurdles that must be addressed to ensure long-term market viability and innovation.

Opportunities for growth within the Electric Vehicle Busbar Market are abundant, particularly with the advent of next-generation electric vehicles, including autonomous and heavy-duty commercial EVs, which require more sophisticated and high-power electrical distribution systems. The ongoing research and development into advanced materials, such as composites and specialized alloys, alongside innovative manufacturing processes like additive manufacturing, offer pathways for developing lighter, more efficient, and potentially more cost-effective busbars. The growing trend of vehicle-to-grid (V2G) technology and bidirectional charging also presents new avenues for busbar applications, requiring components capable of handling power flow in multiple directions. Additionally, emerging markets in Southeast Asia, Africa, and Latin America, with their nascent but rapidly developing EV industries, represent untapped potential for market expansion. The strategic focus on modularity and smart busbar integration, offering real-time diagnostics and enhanced safety features, also presents significant avenues for product differentiation and market leadership.

Segmentation Analysis

The Electric Vehicle Busbar Market is comprehensively segmented based on various attributes to provide a detailed understanding of its dynamics and growth prospects. These segmentations allow for a granular analysis of market trends, consumer preferences, technological advancements, and competitive landscapes across different product types, materials, applications, and regional footprints. Understanding these segments is crucial for stakeholders to identify key growth areas, tailor product development strategies, and penetrate specific market niches effectively. The market's complexity and rapid evolution necessitate a multi-faceted approach to segmentation, reflecting the diverse requirements and technological demands within the electric vehicle industry, from power generation and distribution within the battery pack to the final power delivery to the motor and other ancillary systems. This detailed breakdown ensures that market participants can accurately assess opportunities and challenges, fostering informed decision-making and strategic planning in a highly competitive environment.

- By Material Type:

- Copper Busbar: Valued for high conductivity, thermal efficiency, and mechanical strength.

- Aluminum Busbar: Preferred for lightweight applications and cost-effectiveness.

- Other Materials (e.g., Composite, Coated Alloys): Emerging for specialized requirements.

- By Voltage Type:

- Low Voltage Busbar (<= 60V): Primarily for auxiliary systems and lower power applications.

- High Voltage Busbar (> 60V): Dominant for powertrain, battery, and fast-charging systems.

- By Application:

- Battery Modules: Connecting cells and modules within the battery pack.

- Power Distribution Unit (PDU): Centralized power management and distribution.

- On-Board Charger (OBC): Power transfer during AC charging.

- Inverter: Connecting battery to motor for power conversion.

- Motor: Direct power supply to the electric motor.

- Other Applications (e.g., DC-DC Converter, Air Conditioning): Specialized power routing.

- By Vehicle Type:

- Passenger Electric Vehicles: Including Battery Electric Vehicles (BEV), Plug-in Hybrid Electric Vehicles (PHEV), Fuel Cell Electric Vehicles (FCEV).

- Commercial Electric Vehicles: Electric buses, trucks, vans, and light commercial vehicles.

- Electric Two-Wheelers and Three-Wheelers: E-bikes, scooters, rickshaws.

- By End-Use:

- Original Equipment Manufacturers (OEMs): Direct supply to EV manufacturers for new vehicle production.

- Aftermarket: Replacement and upgrade components.

- By Type of Busbar:

- Rigid Busbars: Traditional solid conductors, often laminated.

- Flexible Busbars: Multi-layered flexible conductors offering design versatility.

Value Chain Analysis For Electric Vehicle Busbar Market

The value chain of the Electric Vehicle Busbar Market commences with the upstream segment, which involves the sourcing and processing of essential raw materials. This stage is dominated by suppliers of high-purity copper and aluminum, which are the primary conductive materials, alongside manufacturers of insulation materials such as specialized plastics, epoxy resins, and powder coatings. Companies in this segment focus on ensuring consistent quality, managing supply chain resilience against geopolitical and economic fluctuations, and optimizing extraction and refining processes to meet the stringent specifications required for EV applications. Innovation in raw material processing, including recycling initiatives and the development of alternative lightweight conductive materials, is crucial here to address sustainability goals and cost pressures, ultimately impacting the final product's performance and environmental footprint.

Moving downstream, the value chain encompasses the manufacturing and assembly of busbars, followed by their integration into electric vehicle components. This segment includes specialized busbar manufacturers who design, fabricate, and test these critical components, often working closely with Tier 1 suppliers and EV OEMs to meet specific design and performance criteria. The busbars are then supplied to manufacturers of battery packs, inverters, power distribution units, and electric motors, where they are integrated into the higher-level assemblies of electric vehicles. This integration requires precision engineering, robust connection technologies, and advanced thermal management solutions to ensure optimal performance, reliability, and safety of the entire EV electrical system. The quality and efficiency of these downstream integration processes are paramount, as they directly influence the overall performance, range, and longevity of electric vehicles.

Distribution channels for EV busbars are primarily direct, particularly for OEM partnerships, where busbar manufacturers supply directly to electric vehicle producers and their Tier 1 suppliers. This direct distribution model facilitates close collaboration on design, specification, and delivery schedules, which is vital given the customized nature and critical function of busbars within EV architectures. For smaller volume orders, aftermarket needs, or for non-critical applications, indirect distribution through specialized industrial component distributors may also exist, providing a broader reach and logistical support. The emphasis on direct engagement underscores the technical complexity and strategic importance of busbars, requiring strong relationships and integrated supply chain management between manufacturers and their key customers to ensure efficient delivery, technical support, and responsive problem-solving throughout the product lifecycle. This intricate network ensures that high-quality busbar solutions are delivered promptly to meet the escalating demands of the rapidly evolving electric vehicle industry.

Electric Vehicle Busbar Market Potential Customers

The primary potential customers and end-users of Electric Vehicle Busbars are unequivocally the Original Equipment Manufacturers (OEMs) within the automotive industry, specifically those specializing in the production of electric vehicles. This includes global automotive giants actively transitioning their portfolios to electric powertrains, as well as emerging EV startups seeking innovative and efficient component solutions. These OEMs directly procure busbars for integration into their new vehicle designs across various categories, including passenger cars, electric buses, heavy-duty electric trucks, and electric two-wheelers. Their purchasing decisions are driven by stringent requirements for performance, reliability, thermal management, weight reduction, and cost-effectiveness, alongside compliance with international safety and environmental standards. Establishing robust relationships with these OEMs through customized product offerings, technical support, and efficient supply chain management is paramount for busbar manufacturers to secure long-term contracts and market share in this rapidly expanding sector.

Beyond the direct OEM market, a significant segment of potential customers includes Tier 1 and Tier 2 automotive suppliers that specialize in critical EV components. This comprises manufacturers of complete battery packs, inverter systems, power distribution units (PDUs), and electric motors. These suppliers integrate busbars into their sub-assemblies before delivering them to the final EV manufacturers. For instance, a battery pack manufacturer would require busbars for connecting individual battery cells and modules, ensuring efficient current collection and distribution within the pack. Similarly, inverter manufacturers utilize busbars for high-current connections between power semiconductors. These customers prioritize busbars that offer high thermal stability, excellent electrical conductivity, and robust mechanical integrity, ensuring the overall reliability and performance of their advanced power electronics. Their demand is highly technical, often requiring busbar designs that are optimized for specific component architectures and cooling strategies, making collaborative development crucial.

Additionally, the burgeoning market for specialized electric vehicle conversion companies and aftermarket service providers represents a growing niche for busbar suppliers. These entities cater to the retrofitting of conventional vehicles with electric powertrains or provide maintenance and upgrade services for existing EVs. While smaller in scale compared to OEM demand, this segment often requires flexible, modular, and readily available busbar solutions that can be adapted to various vehicle platforms and repair scenarios. Research and development institutions, as well as academic bodies focused on electric mobility and power electronics, also constitute potential customers for specialized or prototyping busbar solutions, driving innovation in new materials and designs. The expansion of charging infrastructure developers, who require robust busbar solutions for high-power DC fast chargers, also represents a growing customer base, demanding durable and efficient components for extreme current applications and outdoor environments. This diverse customer landscape necessitates a flexible and adaptive approach from busbar manufacturers, offering both highly customized and standardized solutions to meet the varied needs of the entire EV ecosystem.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 425 Million |

| Market Forecast in 2032 | USD 2,000 Million |

| Growth Rate | 25.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Mersen, Rogers Corporation, Amphenol Corporation, TE Connectivity, Schneider Electric, ABB Ltd, Eaton Corporation, LAPP Group, Samhwa Busbar Co Ltd, Methode Electronics, ERICO (Pentair), Sumitomo Electric Industries, Huber+Suhner, Storm Power Components, Suzhou Smart Busbar Technology Co Ltd, EMS Group, Jiaxing Minfeng Busbar Co Ltd, Suzhou Huawei Busbar Co Ltd, Shanghai Huayuan Electronic Co Ltd, Guizhou Space Appliance Co Ltd |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electric Vehicle Busbar Market Key Technology Landscape

The Electric Vehicle Busbar Market is continually evolving, driven by advancements aimed at enhancing efficiency, reducing size and weight, and improving thermal management capabilities. A key technological focus is on laminated busbars, which involve multiple layers of conductive material separated by thin dielectric insulation, compressed into a rigid, compact structure. This design significantly reduces inductance and capacitance, minimizing electromagnetic interference and improving power quality, which is crucial for high-frequency switching in inverters. Furthermore, laminated busbars offer excellent thermal dissipation due to their flat surface area, allowing for efficient heat transfer and more robust operation in demanding EV environments. The adoption of these sophisticated designs is paramount for meeting the increasing power density requirements of modern electric powertrains and fast-charging systems, enabling greater compactness and reliability compared to conventional wiring harnesses.

Another significant area of technological advancement is in flexible busbars, which are gaining traction for their ability to accommodate complex and irregular geometries within EV battery packs and power electronics. These busbars consist of multiple thin layers of conductive material, typically copper, bonded together with flexible insulation, allowing them to bend and twist without compromising electrical integrity. This flexibility offers considerable advantages in terms of assembly ease, vibration absorption, and optimizing space utilization, especially in modular battery designs where space is at a premium and custom shapes are often required. The development of advanced insulation materials, including high-performance polymer films and epoxy-based coatings, is also critical. These materials must provide superior dielectric strength, thermal resistance, and chemical compatibility to ensure long-term reliability and safety of busbars under the challenging operating conditions of electric vehicles, including wide temperature fluctuations and exposure to various fluids.

The integration of smart features into busbars represents an emerging technological frontier, moving towards "smart busbars" equipped with integrated sensors. These sensors can monitor real-time parameters such as temperature, current, and even voltage drops along the busbar, providing crucial data for predictive maintenance, system diagnostics, and optimizing power management strategies within the EV. This capability enables earlier detection of potential issues, enhances safety, and contributes to the overall longevity and performance of the vehicle's electrical system. Additionally, advancements in joining technologies, such as laser welding and ultrasonic welding, are being deployed to create highly reliable and low-resistance connections between busbar segments and other electrical components. These precise manufacturing techniques minimize contact resistance and improve the overall efficiency of power transfer, thereby reducing energy losses and enhancing the performance of the entire electric vehicle powertrain. The continuous pursuit of these technological innovations is central to addressing the evolving demands for higher power, greater efficiency, and enhanced safety in the rapidly expanding EV market.

Regional Highlights

- Asia Pacific: This region stands as the undisputed leader in the Electric Vehicle Busbar Market, primarily driven by robust government support, favorable policies, and a high concentration of major EV manufacturers and battery production facilities, particularly in China, Japan, and South Korea. China leads in both EV production and adoption, creating immense demand for busbar solutions, while significant investments in EV infrastructure and technological advancements further solidify the region's dominance. The presence of a vast supply chain ecosystem for electronic components further enables cost-effective production and rapid innovation.

- Europe: Europe represents a rapidly growing market for EV busbars, propelled by ambitious decarbonization targets, stringent emission regulations, and substantial government incentives for electric vehicle purchases. Countries like Germany, Norway, France, and the UK are witnessing significant investments in local EV manufacturing and battery gigafactories, fostering increased demand for high-quality busbar components. The region's focus on sustainable mobility and advanced engineering drives demand for innovative and efficient busbar solutions.

- North America: The North American market is experiencing substantial growth in the EV busbar sector, largely due to significant investments by major automotive players in electric vehicle production facilities and battery manufacturing plants across the United States and Canada. Government initiatives, such as tax credits and infrastructure development programs, are accelerating EV adoption. The region emphasizes robust and reliable busbar solutions to support powerful electric truck and SUV segments, alongside advanced passenger EVs, driving innovation in material science and power electronics integration.

- Latin America: This region is an emerging market for EV busbars, characterized by nascent but growing EV adoption rates and increasing awareness of sustainable transportation. While currently a smaller market, go

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager