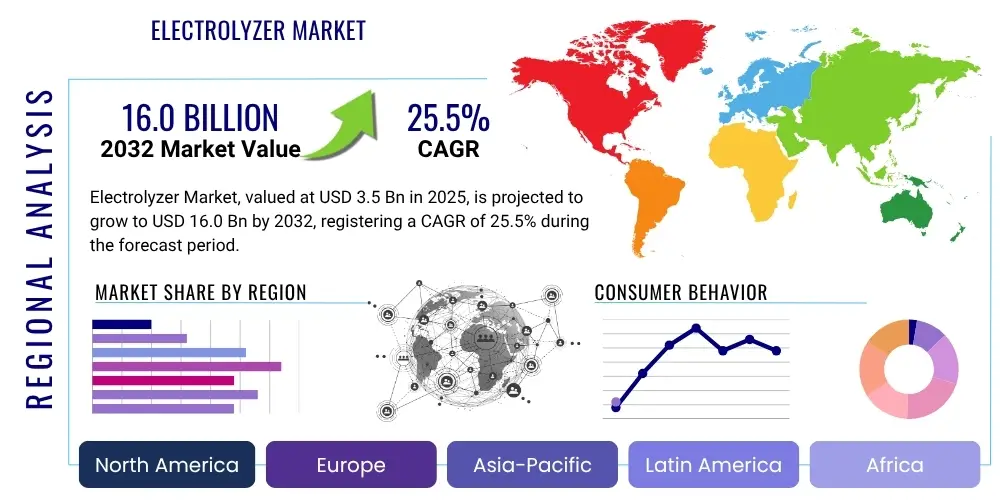

Electrolyzer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431274 | Date : Nov, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Electrolyzer Market Size

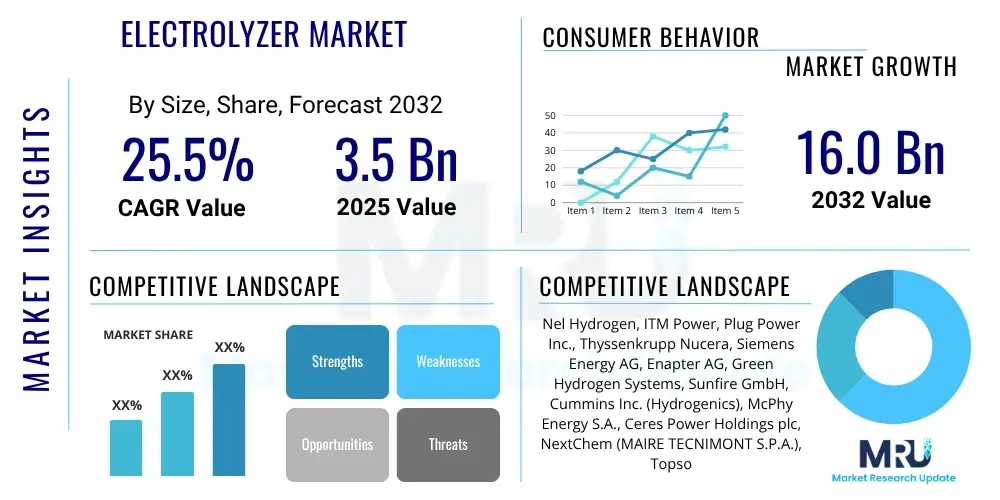

The Electrolyzer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 25.5% between 2025 and 2032. The market is estimated at $3.5 Billion in 2025 and is projected to reach $16.0 Billion by the end of the forecast period in 2032.

Electrolyzer Market introduction

The global electrolyzer market is a pivotal segment within the burgeoning green hydrogen economy, dedicated to the production of hydrogen through electrolysis of water. Electrolyzers are sophisticated systems that use electricity to split water (H2O) into hydrogen (H2) and oxygen (O2), primarily aiming for hydrogen production without greenhouse gas emissions when powered by renewable energy sources. This technology is foundational for decarbonizing hard-to-abate sectors such as heavy industry, long-haul transportation, and energy storage, offering a pathway to sustainable energy systems.

Product descriptions typically encompass various types of electrolyzers, including Alkaline Electrolyzers, Proton Exchange Membrane (PEM) Electrolyzers, Solid Oxide Electrolyzers (SOEC), and emerging Anion Exchange Membrane (AEM) Electrolyzers, each possessing distinct operational characteristics, efficiencies, and material requirements. Major applications of green hydrogen derived from electrolyzers span industrial feedstock for ammonia and methanol production, steelmaking, refining, as well as fuel for transportation (fuel cells in vehicles, shipping, aviation), and grid balancing or energy storage solutions (power-to-gas). The inherent benefits of electrolyzer technology are profound, contributing significantly to reducing carbon footprints, enhancing energy independence by utilizing diverse renewable resources, and providing a versatile energy carrier for various applications.

The market's robust growth is primarily driven by escalating global climate change mitigation efforts, stringent decarbonization mandates from governments and industries, and the continuous decline in renewable energy costs, making green hydrogen increasingly economically viable. Furthermore, substantial governmental incentives, supportive policies, and strategic investments in hydrogen infrastructure development across major economies are accelerating the adoption and deployment of electrolyzer technologies on a grand scale. This collective momentum is positioning electrolyzers as a cornerstone technology for achieving net-zero emission targets worldwide.

Electrolyzer Market Executive Summary

The Electrolyzer Market is experiencing unprecedented growth, propelled by global decarbonization initiatives and robust policy support. Business trends indicate a surge in strategic partnerships and joint ventures aimed at scaling manufacturing capacities and developing more efficient, cost-effective electrolyzer technologies. Major players are investing heavily in research and development to enhance system longevity, reduce capital expenditure, and integrate electrolyzers seamlessly with renewable energy sources. The competitive landscape is characterized by innovation, with companies focusing on advanced materials and automated production processes to meet the escalating demand for green hydrogen.

Regional trends highlight Europe and North America as frontrunners in market development, largely due to ambitious hydrogen strategies, generous subsidies, and carbon pricing mechanisms. The European Union's Green Deal and the Inflation Reduction Act (IRA) in the United States are providing significant financial incentives for green hydrogen projects, fostering rapid deployment of electrolyzer installations. Asia Pacific, particularly China, India, and Japan, is emerging as a critical growth region, driven by strong industrial demand for hydrogen and increasing investments in renewable energy infrastructure. The Middle East also shows considerable promise, leveraging abundant solar resources for large-scale green hydrogen production projects aimed at export markets.

Segmentation trends reveal a dynamic shift towards Proton Exchange Membrane (PEM) electrolyzers for applications requiring rapid response times and compact footprints, although Alkaline Electrolyzers continue to dominate in terms of installed capacity due to their proven reliability and lower capital costs for large-scale, steady-state operations. Solid Oxide Electrolyzers (SOEC) are gaining traction for their high efficiency when integrated with industrial heat sources, especially for next-generation hydrogen production. The market is also seeing increased demand for electrolyzers across various end-use applications, including industrial feedstock, power-to-gas solutions for grid balancing, and the burgeoning clean transportation sector, indicating a diversified growth trajectory across all major segments.

AI Impact Analysis on Electrolyzer Market

Common user questions regarding AI's impact on the Electrolyzer Market often revolve around how artificial intelligence can enhance operational efficiency, reduce costs, improve system reliability, and accelerate the development of next-generation technologies. Users are keen to understand AI's role in optimizing the complex interplay between renewable energy variability and electrolyzer performance, as well as its potential to streamline manufacturing processes and facilitate predictive maintenance. The prevailing themes indicate an expectation that AI will be a transformative force, enabling smarter, more autonomous, and economically viable green hydrogen production at scale, addressing current challenges related to energy intermittency, operational stability, and total cost of ownership.

- AI optimizes real-time energy management, matching intermittent renewable energy supply with electrolyzer demand for maximum efficiency.

- Predictive maintenance analytics, powered by AI, reduce downtime and extend the operational lifespan of electrolyzer components.

- AI-driven process control enhances hydrogen production rates and purity while minimizing energy consumption.

- Machine learning algorithms accelerate the discovery and testing of new materials for electrodes and membranes, leading to more efficient electrolyzer designs.

- Automated quality control and anomaly detection in manufacturing processes improve production yield and reduce defect rates for electrolyzer stacks.

DRO & Impact Forces Of Electrolyzer Market

The Electrolyzer Market is primarily driven by an aggressive global pursuit of decarbonization and the urgent need to transition to sustainable energy sources. Government initiatives and substantial subsidies, such as the US Inflation Reduction Act and Europe's Hydrogen Strategy, are providing significant financial incentives, making green hydrogen projects economically attractive. Concurrently, the continuous decrease in the cost of renewable energy, particularly solar and wind power, directly lowers the operational expenses of electrolyzers, making green hydrogen competitive with fossil fuel-derived hydrogen. Moreover, the increasing industrial demand for green hydrogen as a feedstock in sectors like ammonia production, steel manufacturing, and chemical processing further fuels market expansion, positioning electrolyzers as a critical technology for industrial decarbonization.

However, the market faces several restraints that could impede its rapid acceleration. High capital expenditure (CapEx) for initial electrolyzer plant setup remains a significant barrier, particularly for large-scale projects, despite ongoing cost reduction efforts. The energy intensity of electrolysis, even when powered by renewables, means substantial electricity consumption, which can impact overall economic viability and grid stability if not managed effectively. Infrastructure limitations, including the nascent state of hydrogen storage, transportation, and distribution networks, pose challenges for widespread adoption and delivery to end-users. Furthermore, supply chain bottlenecks for critical materials like iridium and platinum, essential for PEM electrolyzers, can lead to price volatility and production delays.

Opportunities within the electrolyzer market are vast and diverse. The development of advanced materials and novel electrolyzer technologies, such as Anion Exchange Membrane (AEM) electrolyzers, promises to reduce costs and improve performance, expanding market accessibility. The integration of electrolyzers with offshore wind power projects offers a pathway to produce green hydrogen at scale in regions with strong wind resources, mitigating intermittency challenges. Emerging markets in developing economies present significant untapped potential for green hydrogen adoption as they industrialize and seek sustainable energy solutions. Additionally, the synergy between electrolyzers and carbon capture technologies, as well as direct air capture, could open new avenues for carbon-negative hydrogen production.

The impact forces shaping the electrolyzer market are multifaceted. Regulatory frameworks and evolving policy landscapes globally exert considerable influence, with strong government support acting as a primary catalyst for growth. Technological advancements, particularly in efficiency, durability, and manufacturing scalability, are critical for overcoming current limitations and driving down costs. Geopolitical shifts and energy security concerns are prompting nations to invest in domestic green hydrogen production, reducing reliance on imported fossil fuels. Public perception and acceptance of hydrogen as a clean energy vector, alongside the development of safety standards, will also play a crucial role in shaping market dynamics and accelerating widespread adoption.

Segmentation Analysis

The Electrolyzer Market is segmented to provide a granular view of its diverse landscape, reflecting variations in technology, capacity, application, and end-use sectors. This segmentation helps in understanding the specific drivers, challenges, and opportunities present across different market niches. The primary segmentation distinguishes between the various types of electrolyzer technologies, each with unique performance characteristics and cost profiles, influencing their suitability for different applications. Furthermore, market analysis considers the scale of deployment, ranging from small-scale modular units to large industrial installations, impacting investment requirements and integration complexities. The end-use application segments highlight the wide array of industries and sectors that are increasingly adopting green hydrogen, underscoring the technology's versatile utility in the global energy transition.

- By Technology

- Alkaline Electrolyzer

- Proton Exchange Membrane (PEM) Electrolyzer

- Solid Oxide Electrolyzer (SOEC)

- Anion Exchange Membrane (AEM) Electrolyzer

- Others (e.g., Proton Ceramic Electrolyzer)

- By Capacity

- Small Scale (Less than 1 MW)

- Medium Scale (1 MW to 10 MW)

- Large Scale (More than 10 MW)

- By Application

- Industrial Feedstock

- Fueling Stations

- Power Generation

- Grid Injection (Power-to-Gas)

- Energy Storage

- Others (e.g., Residential, Transportation)

- By End-Use Industry

- Chemicals (Ammonia, Methanol)

- Power (Utilities, IPPs)

- Transportation (Heavy Duty, Maritime, Aviation)

- Manufacturing (Steel, Cement)

- Refining

- Residential & Commercial

- Others

Value Chain Analysis For Electrolyzer Market

The value chain for the Electrolyzer Market begins with upstream activities focused on the sourcing and manufacturing of critical components and raw materials. This includes the extraction and processing of rare earth metals like platinum and iridium for PEM electrolyzers, nickel for alkaline systems, and specialized ceramics for SOECs. Component manufacturing involves the production of electrodes, membranes, bipolar plates, power electronics, and balance of plant (BOP) equipment. Key players in this segment are material suppliers, component manufacturers, and specialized engineering firms that develop proprietary designs for electrolyzer stacks, ensuring high purity and performance of materials, which are critical for the efficiency and durability of the final product.

Midstream activities primarily encompass the assembly and manufacturing of complete electrolyzer systems, from individual stacks to large-scale modular units. This stage involves the integration of various components, sophisticated engineering design, and rigorous testing to ensure system integrity and optimal performance. After manufacturing, the value chain progresses to the downstream segment, which involves the installation, operation, and maintenance of electrolyzer plants, often integrated with renewable energy sources. This also includes the crucial steps of hydrogen compression, storage, and distribution to various end-use applications, which can range from pipelines and tube trailers to liquid hydrogen tankers. Companies specializing in project development, EPC (Engineering, Procurement, and Construction) services, and energy infrastructure play a vital role here.

Distribution channels for electrolyzers and the green hydrogen they produce are multifaceted. Direct sales typically occur for large industrial clients or energy utilities that procure electrolyzer systems directly from manufacturers for integration into their own facilities or projects. Indirect channels involve partnerships with EPC contractors, system integrators, and project developers who design, build, and commission entire green hydrogen ecosystems, including the electrolyzer component. These channels facilitate the broader market reach and deployment of complex green hydrogen solutions, often involving long-term supply agreements. The strategic selection of distribution partners and the establishment of robust logistics networks are essential for market penetration and efficient delivery of both the technology and the resultant hydrogen to a diverse customer base globally.

Electrolyzer Market Potential Customers

The potential customers for electrolyzer technology are diverse, spanning multiple industrial, energy, and transportation sectors, all unified by a growing imperative for decarbonization and sustainable energy solutions. Industrial end-users represent a significant segment, particularly those in hard-to-abate sectors that rely heavily on hydrogen as a feedstock or process gas. This includes manufacturers of ammonia for fertilizers, methanol for various chemical products, and steel producers seeking to replace carbon-intensive blast furnaces with direct reduced iron (DRI) processes utilizing green hydrogen. Oil refineries also present a substantial customer base, as they currently use significant amounts of grey hydrogen and are under increasing pressure to reduce their carbon footprint by switching to green alternatives.

Beyond traditional industrial applications, the energy sector is a burgeoning customer segment. This includes utilities and independent power producers (IPPs) exploring power-to-gas solutions for grid balancing, energy storage, and converting excess renewable electricity into storable hydrogen. Hydrogen can then be re-electrified, injected into natural gas grids (up to certain blend limits), or used as fuel for hydrogen-fired power plants. Furthermore, the transportation sector is emerging as a critical end-user, with demand stemming from heavy-duty vehicles (trucks, buses), maritime shipping, and potentially aviation, all transitioning to fuel cell electric vehicles or hydrogen-powered propulsion systems to achieve emission reduction targets. Companies developing hydrogen fueling station infrastructure are also key customers.

Other significant buyers and end-users include entities involved in the production of synthetic fuels, which combine green hydrogen with captured carbon dioxide to create sustainable aviation fuel (SAF) or e-methanol. Residential and commercial establishments might also emerge as niche markets for smaller-scale electrolyzers, especially in remote or off-grid locations seeking energy independence through hydrogen-based solutions. Research institutions and government agencies also act as key customers for pilot projects, technological advancement, and demonstration purposes, helping to mature the technology and establish best practices. The broad applicability of green hydrogen makes the customer base for electrolyzers exceptionally wide and continuously expanding as the global energy transition accelerates.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $3.5 Billion |

| Market Forecast in 2032 | $16.0 Billion |

| Growth Rate | 25.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Nel Hydrogen, ITM Power, Plug Power Inc., Thyssenkrupp Nucera, Siemens Energy AG, Enapter AG, Green Hydrogen Systems, Sunfire GmbH, Cummins Inc. (Hydrogenics), McPhy Energy S.A., Ceres Power Holdings plc, NextChem (MAIRE TECNIMONT S.P.A.), Topsoe A/S, Proton Exchange Membrane Electrolyser, Giner Inc., Ionomr Innovations Inc., Accelera by Cummins, Verdagy, Bloom Energy. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electrolyzer Market Key Technology Landscape

The Electrolyzer Market is characterized by a dynamic and rapidly evolving technology landscape, with several core technologies competing and innovating to achieve greater efficiency, lower costs, and enhanced durability. Alkaline Electrolyzers (AEL) represent the most mature and widely deployed technology, known for their robust design, relatively low capital cost, and long operational lifespan. While they operate at lower current densities and are less flexible to fluctuating power inputs compared to newer technologies, ongoing advancements in electrode materials and cell designs are improving their overall performance and responsiveness for large-scale, steady-state green hydrogen production.

Proton Exchange Membrane (PEM) Electrolyzers are gaining significant traction due to their ability to operate at high current densities, rapid response times to dynamic renewable energy inputs, and compact footprint. These characteristics make PEM electrolyzers ideal for integration with intermittent renewable sources like wind and solar. However, their reliance on expensive platinum group metals (PGMs) like platinum and iridium for catalysts presents a cost challenge, prompting intensive research into developing alternative, PGM-free catalysts and improving membrane longevity. Advances in membrane materials and stack design are continuously enhancing their efficiency and reducing overall system costs, positioning PEM as a key technology for the future green hydrogen economy.

Solid Oxide Electrolyzers (SOEC) offer the highest electrical efficiency among current technologies, particularly when integrated with high-temperature industrial waste heat or nuclear power, significantly reducing the electrical energy required for electrolysis. Their ability to co-electrolyze water and carbon dioxide also opens pathways for producing syngas. While SOECs operate at high temperatures (typically 500-850°C), which requires specialized materials and engineering, ongoing research is focused on improving material stability, reducing degradation rates, and developing more robust sealants to extend their operational life and expand their application in high-efficiency industrial settings. Furthermore, Anion Exchange Membrane (AEM) Electrolyzers are an emerging technology aiming to combine the cost advantages of alkaline electrolyzers (using non-precious metal catalysts) with the dynamic operation benefits of PEM systems, representing a promising area of innovation for future market disruption.

Regional Highlights

- North America: The region is experiencing substantial growth driven by the U.S. Inflation Reduction Act (IRA), which offers significant tax credits for green hydrogen production, making projects highly competitive. Canada also has a strong focus on hydrogen strategies and investments.

- Europe: A global leader in green hydrogen initiatives, propelled by the European Green Deal and national hydrogen strategies (Germany, Netherlands, Spain). Europe is focused on large-scale renewable hydrogen production, imports, and cross-border infrastructure development.

- Asia Pacific (APAC): Emerging as a major growth engine, led by China's extensive renewable energy capacity and industrial demand, Japan's commitment to a hydrogen-based society, and India's National Green Hydrogen Mission. Significant investments in manufacturing and large-scale project deployments are observed.

- Middle East and Africa (MEA): This region is positioned to become a significant exporter of green hydrogen, leveraging abundant solar and wind resources for large-scale production, particularly in countries like Saudi Arabia, UAE, and Oman.

- Latin America: Countries like Chile and Brazil are developing ambitious green hydrogen strategies, capitalizing on excellent renewable energy resources to establish themselves as future green hydrogen producers and exporters.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electrolyzer Market.- Nel Hydrogen

- ITM Power

- Plug Power Inc.

- Thyssenkrupp Nucera

- Siemens Energy AG

- Enapter AG

- Green Hydrogen Systems

- Sunfire GmbH

- Cummins Inc. (Hydrogenics)

- McPhy Energy S.A.

- Ceres Power Holdings plc

- NextChem (MAIRE TECNIMONT S.P.A.)

- Topsoe A/S

- Proton Exchange Membrane Electrolyser

- Giner Inc.

- Ionomr Innovations Inc.

- Accelera by Cummins

- Verdagy

- Bloom Energy

Frequently Asked Questions

What is an electrolyzer and how does it contribute to green hydrogen production?

An electrolyzer is a device that splits water (H2O) into hydrogen (H2) and oxygen (O2) using electricity, a process known as electrolysis. When the electricity used is generated from renewable sources like solar or wind power, the produced hydrogen is classified as green hydrogen, making electrolyzers fundamental to decarbonizing various industries and enabling sustainable energy systems without greenhouse gas emissions.

What are the main types of electrolyzers and their key differences?

The main types are Alkaline Electrolyzers (AEL), Proton Exchange Membrane (PEM) Electrolyzers, and Solid Oxide Electrolyzers (SOEC). AELs are mature and cost-effective for large-scale, steady operations. PEMs offer faster response times, higher current densities, and a compact footprint, ideal for intermittent renewable integration, but use expensive noble metals. SOECs provide the highest electrical efficiency, especially with waste heat integration, but operate at high temperatures, suitable for industrial co-electrolysis.

What are the primary applications of green hydrogen produced by electrolyzers?

Green hydrogen from electrolyzers has diverse applications, including industrial feedstock for ammonia and methanol production, steel manufacturing, and refining. It is also used in the energy sector for power-to-gas solutions, grid balancing, and energy storage. Furthermore, it serves as a clean fuel for transportation, powering fuel cell electric vehicles in heavy-duty, maritime, and potentially aviation segments, supporting a broad energy transition.

What are the key drivers for the growth of the electrolyzer market?

The market's growth is primarily driven by global decarbonization targets, substantial government policies and incentives (e.g., carbon pricing, subsidies), the rapidly decreasing cost of renewable energy, and increasing industrial demand for green hydrogen as a sustainable alternative to fossil fuels. These factors collectively make green hydrogen projects more economically viable and strategically important.

What challenges does the electrolyzer market currently face?

Key challenges include the high upfront capital expenditure for electrolyzer installations, the significant energy intensity of the electrolysis process, and the nascent stage of hydrogen infrastructure for storage, transport, and distribution. Additionally, supply chain bottlenecks for critical materials like platinum and iridium, essential for certain electrolyzer types, can impact production costs and scalability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Small Capacity Electrolyzer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Electrolyzer Market Size Report By Type (Traditional Alkaline Electroliser, PEM Electroliser), By Application (Power Plants, Steel Plant, Electronics and Photovoltaics, Industrial Gases, Energy Storage or Fueling for FCEV's, Power to Gas, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Asbestos Cloth Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (SB-24, SB-19, SB-16), By Application (Filtering material, Electrolyzer diaphragm, Heat preservation material), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager