Floor Saw Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430161 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Floor Saw Market Size

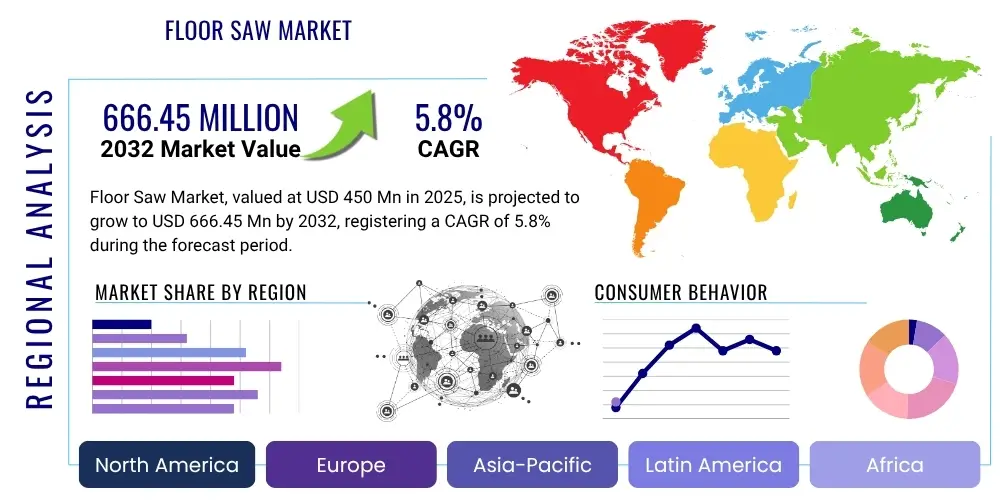

The Floor Saw Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 450 million in 2025 and is projected to reach USD 666.45 million by the end of the forecast period in 2032.

Floor Saw Market introduction

Floor saws, often referred to as concrete saws or road saws, represent a critical category of robust power tools specifically engineered for cutting horizontal surfaces with precision and efficiency. These indispensable machines are designed to cut through a variety of hard materials including concrete, asphalt, stone, masonry, and even reinforced concrete. Their primary function involves creating clean, straight, and deep cuts in diverse environments ranging from massive infrastructure projects to detailed renovation work, making them a cornerstone in the construction, demolition, and maintenance industries. The robust construction and powerful engines of modern floor saws ensure high performance and durability under demanding operational conditions, providing a superior alternative to less efficient or more hazardous manual cutting methods.

The product portfolio within the floor saw market is diverse, encompassing various types tailored to specific operational scales and requirements. Walk-behind floor saws are popular for medium-sized projects, offering a balance of maneuverability and cutting power, while ride-on floor saws are employed for large-scale applications such as extensive road construction or airport runway maintenance, providing enhanced operator comfort and higher productivity. Hand-held floor saws, on the other hand, offer versatility for smaller, more intricate cutting tasks. These machines can be powered by a range of sources including gasoline, diesel, electric, or hydraulic systems, each offering distinct advantages in terms of power, emissions, and suitability for indoor or outdoor use. The cutting mechanism typically involves high-performance diamond blades, specifically designed for abrasive materials, ensuring optimal cutting speed and blade longevity.

Major applications for floor saws span across vital sectors, including the creation of expansion joints, trench cutting for utility installations like plumbing and electrical conduits, slab removal during demolition, and precise cuts for road and bridge repair. The inherent benefits of using floor saws are significant, encompassing superior cutting accuracy, substantial time savings due to high operational speeds, and improved worker safety through reduced physical exertion and advanced dust suppression technologies. Key driving factors propelling the growth of this market include pervasive global infrastructure development initiatives, rapid urbanization leading to an increasing demand for new construction and renovation projects, and a continuous industry push for more efficient, precise, and safer cutting solutions that meet contemporary environmental and safety standards across various geographies.

Floor Saw Market Executive Summary

The Floor Saw Market is currently undergoing a transformative period, characterized by several key business trends shaping its trajectory. A significant shift towards automation and the integration of smart technologies is evident, aiming to enhance operational efficiency, precision, and safety across construction sites. Manufacturers are increasingly investing in research and development to introduce advanced features such as GPS-guided cutting systems, remote control capabilities, and ergonomic designs that reduce operator fatigue. Furthermore, there is a growing demand for environmentally friendly solutions, leading to the proliferation of electric and hybrid-powered floor saws that meet stringent emission and noise regulations, especially in urban and enclosed environments. The expansion of the equipment rental market also plays a crucial role, making high-cost, specialized floor saws accessible to a broader range of contractors and project sizes, thereby stimulating market demand.

Regional dynamics play a pivotal role in the Floor Saw Market's growth and distribution. Asia Pacific stands out as a primary growth engine, fueled by extensive government investments in infrastructure development, rapid urbanization, and a burgeoning construction sector in countries like China, India, and Southeast Asian nations. This region demonstrates a high demand for both traditional heavy-duty diesel saws and increasingly, more efficient electric alternatives. In contrast, North America and Europe represent mature markets where demand is largely driven by the replacement of aging equipment, a focus on technological innovation, and strict adherence to environmental and safety standards. These regions are keen adopters of advanced, high-productivity machines, including those with automation features and reduced environmental impact, reflecting a sophisticated market that prioritizes long-term operational cost savings and compliance.

Segment-wise, the market exhibits robust trends across various categories. Walk-behind and ride-on floor saws continue to dominate due to their versatility and efficiency in diverse applications, with ride-on variants gaining traction for large-scale projects requiring extended operation. The power source segmentation highlights a growing preference for electric and hydraulic floor saws for indoor, low-emission, and noise-sensitive operations, while gasoline and diesel models maintain their strong position for heavy-duty outdoor applications where power and mobility are paramount. The application segment sees sustained demand from road and bridge construction, demolition, and utility installation, driven by ongoing infrastructure maintenance and expansion. Overall, the market's executive summary points to a landscape of continuous innovation, regional market diversification, and a strong emphasis on sustainability and operational excellence, all contributing to a steady and positive growth outlook for the floor saw industry over the forecast period.

AI Impact Analysis on Floor Saw Market

User inquiries and industry discussions concerning the integration of Artificial Intelligence (AI) into the Floor Saw Market consistently highlight several key themes: the potential for unprecedented gains in operational precision, the realization of autonomous or semi-autonomous cutting operations, and the transformative impact of predictive maintenance driven by AI algorithms. Stakeholders are particularly interested in how AI can optimize cutting paths, dynamically adjust cutting parameters based on real-time material analysis, and significantly reduce human error and material waste. Concurrently, there are concerns regarding the initial capital investment required for AI-enabled machinery, the complexity of integrating these advanced systems into existing workflows, and the necessity for specialized training to upskill the workforce. Despite these challenges, the prevailing sentiment is that AI holds the promise to fundamentally reshape efficiency, enhance safety protocols, and elevate sustainability standards within the floor sawing domain, ushering in an era of smarter, more responsive, and increasingly automated construction processes.

- Autonomous operation capabilities, allowing floor saws to execute pre-programmed cutting patterns with minimal human intervention, thereby increasing throughput and reducing labor costs in repetitive tasks.

- Predictive maintenance systems, leveraging AI algorithms to analyze sensor data from machinery, forecast potential component failures, and schedule maintenance proactively, significantly extending equipment lifespan and minimizing costly downtime.

- Enhanced cutting precision and optimization, where AI-powered vision systems and sensors can detect variations in material composition and hardness, adjusting blade speed and pressure in real-time to achieve optimal cut quality and reduce blade wear.

- Real-time safety monitoring and risk mitigation, as AI can process data from proximity sensors and cameras to identify potential hazards, alert operators, or automatically halt operations to prevent accidents on busy construction sites.

- Optimized resource allocation and project management, with AI analyzing historical data to recommend the most efficient cutting strategies, predict material consumption, and manage energy usage, leading to reduced operational costs and a smaller environmental footprint.

- Integration with Building Information Modeling (BIM) systems, allowing floor saws to precisely interpret digital blueprints and execute cuts according to detailed 3D models, ensuring greater accuracy and reducing rework.

- Remote diagnostics and troubleshooting, where AI systems can assist technicians in diagnosing issues from a remote location, streamlining repair processes and improving service response times for complex machinery.

DRO & Impact Forces Of Floor Saw Market

The Floor Saw Market is experiencing robust growth propelled by several significant drivers. Chief among these is the escalating global investment in infrastructure development, including expansive road networks, bridge construction, and commercial building projects, particularly in rapidly urbanizing regions. This infrastructure boom inherently increases the demand for efficient and precise concrete cutting equipment. Furthermore, the growing global population and subsequent urbanization trends necessitate constant expansion and renovation of existing urban landscapes, driving a consistent need for floor saws in new construction, demolition, and utility installation activities. Technological advancements in floor saw design, such as more powerful engines, durable diamond blades, and enhanced automation features, also act as a strong driver, offering superior performance and operational efficiency that attract contractors.

Despite these growth drivers, the market faces several notable restraints. The substantial initial capital outlay required for purchasing high-quality, advanced floor sawing equipment can be a barrier for smaller contractors or those in developing economies, limiting market penetration. Additionally, the industry is grappling with a persistent shortage of skilled labor capable of operating and maintaining sophisticated floor saws, which can hinder productivity and lead to operational inefficiencies. Stringent environmental regulations, particularly concerning noise emissions, dust control, and exhaust fumes, impose significant compliance costs on manufacturers and operators, sometimes necessitating more expensive, specialized equipment like electric or hybrid models, which can impact overall market growth in certain segments.

Opportunities within the Floor Saw Market are emerging from various avenues. The expansion of equipment rental markets presents a compelling opportunity, allowing a wider range of businesses to access high-cost floor saws without the burden of outright purchase, thereby boosting utilization rates and market reach. The increasing demand for automated and remote-controlled cutting solutions, driven by safety concerns and efficiency requirements, offers avenues for technological innovation and market differentiation. Moreover, a growing global focus on sustainable construction practices and green building initiatives is creating demand for environmentally friendly floor saws, including battery-electric and hybrid models, paving the way for new product development and market segments. The broader impact forces shaping this market include global economic cycles influencing construction spending, evolving governmental policies and regulations regarding infrastructure and environmental protection, fluctuations in raw material prices affecting manufacturing costs, and the relentless pace of technological innovation that continually reshapes product capabilities and market expectations. These forces collectively dictate the market’s trajectory and competitive landscape.

Segmentation Analysis

The Floor Saw Market is meticulously segmented across various crucial dimensions, offering a comprehensive and granular understanding of its structure, operational dynamics, and underlying demand drivers. This detailed segmentation is instrumental for market participants to identify niche opportunities, tailor product offerings, and formulate targeted marketing strategies. By dissecting the market based on distinct characteristics, stakeholders can gain profound insights into customer preferences, regional disparities, technological adoption rates, and the competitive landscape, thereby facilitating informed decision-making and strategic planning. The primary segmentation criteria typically include the type of floor saw, its power source, the specific application areas, and the diverse end-user profiles, each contributing uniquely to the market's overall ecosystem.

The segmentation by type differentiates between walk-behind, ride-on, and hand-held floor saws, reflecting varying scales of operation, maneuverability requirements, and operational capacities. This distinction helps in understanding the demand for equipment based on project size and site accessibility. Power source segmentation is equally vital, classifying saws into electric, gasoline, diesel, and hydraulic categories. This provides insights into market preferences driven by environmental concerns, power availability, operational cost considerations, and performance demands for indoor versus outdoor applications. The electric segment, for instance, is seeing increased adoption due to stringent emission regulations and a push for sustainable construction practices, particularly in urban and enclosed environments.

Furthermore, segmenting by application elucidates the specific industries and tasks where floor saws are predominantly utilized, such as road and bridge construction, demolition, utility installation, airport runway maintenance, and industrial flooring projects. This highlights the versatility and indispensable nature of these tools across diverse construction activities. Finally, the end-user segmentation categorizes purchasers into construction companies, rental companies, municipalities, and industrial facilities, among others. This allows for an understanding of the purchasing power, specific requirements, and procurement processes of different customer groups, which is crucial for sales and distribution strategies. Together, these segmentation approaches provide a robust framework for analyzing the multifaceted Floor Saw Market and forecasting its future growth trajectories with greater accuracy and strategic depth.

- By Type:

- Walk-Behind Floor Saws: Designed for mid-sized projects, offering a balance of maneuverability and cutting power for trenches, slab cutting, and joint creation.

- Ride-On Floor Saws: Employed for large-scale, extensive projects like highway construction or runway refurbishment, providing higher productivity and operator comfort over long durations.

- Hand-Held Floor Saws: Versatile and compact, ideal for smaller, intricate cuts, detailed demolition, or working in confined spaces where larger machines cannot operate.

- By Power Source:

- Electric: Preferred for indoor use, sensitive environments, or where emissions are a concern, offering quieter operation and zero exhaust fumes.

- Gasoline: Widely used for outdoor, general-purpose cutting tasks, providing good power-to-weight ratio and mobility without electrical constraints.

- Diesel: Suited for heavy-duty, large-scale outdoor applications requiring maximum power and continuous operation, typically found in major infrastructure projects.

- Hydraulic: Known for high torque and consistent power delivery, often integrated into larger machinery or specialized systems for demanding cutting tasks.

- By Application:

- Road and Bridge Construction: Essential for cutting expansion joints, repairing damaged sections, and preparing surfaces for new layers of asphalt or concrete.

- Demolition: Used for precise removal of concrete slabs, walls, and structural elements, minimizing damage to surrounding structures.

- Utility Installation (Water, Sewer, Electrical): Critical for creating trenches and channels for laying pipes, cables, and conduits with minimal disruption.

- Airport Runways: Employed for precise joint cutting, crack repair, and surface refurbishment on high-stress concrete and asphalt runways.

- Industrial Flooring: For cutting control joints, floor repairs, and preparing surfaces in warehouses, factories, and other large industrial complexes.

- Building Renovation and Expansion: Facilitates structural modifications, opening creation, and precise material removal in existing buildings.

- By End-User:

- Construction Companies: Primary buyers for a wide range of new construction, renovation, and demolition projects.

- Rental Companies: Key providers of equipment for short-term projects, making specialized saws accessible to various contractors.

- Municipalities and Public Works: Utilize floor saws for maintaining public infrastructure, including roads, sidewalks, and utility networks.

- Industrial Facilities: For in-house maintenance, modifications, and specialized cutting requirements within manufacturing plants and warehouses.

- Contractors and Service Providers: Specialized firms focusing solely on concrete cutting, demolition, or utility installation services.

Value Chain Analysis For Floor Saw Market

The value chain for the Floor Saw Market is a complex ecosystem that commences with the upstream sourcing of specialized raw materials and sophisticated components, extends through advanced manufacturing processes, and culminates in a diversified network for distribution and comprehensive aftermarket services. At the upstream stage, critical inputs such as high-strength steel for chassis and blade guards, specialized diamond segments for cutting blades, powerful internal combustion engines or electric motors, hydraulic systems, and advanced electronic controls are procured from a global network of suppliers. The quality and availability of these components significantly influence the final product's performance, durability, and cost-effectiveness. Strategic partnerships with key component manufacturers are crucial for ensuring a steady supply chain and integrating the latest technological advancements into floor saw designs, maintaining a competitive edge in a demanding market.

The midstream segment of the value chain is dominated by manufacturing and assembly operations, where raw materials and components are transformed into finished floor saws. This phase involves precision engineering, advanced fabrication techniques, and rigorous quality control measures to ensure that the equipment meets industry standards for performance, safety, and reliability. Manufacturers invest heavily in research and development to innovate new models, improve existing designs, and integrate features such as enhanced dust suppression, ergonomic controls, and smart diagnostic systems. The manufacturing process often involves a blend of automated production lines for standardized components and skilled manual assembly for specialized or high-end models, reflecting the varying complexity and customization required across the product range.

Downstream activities focus on the effective distribution of floor saws to end-users and the provision of essential aftermarket support. Distribution channels are varied, encompassing direct sales to large construction enterprises or government agencies, extensive networks of independent dealers and distributors, and a burgeoning equipment rental sector. Direct channels allow for customized sales solutions and stronger client relationships, particularly for major infrastructure projects. Indirect channels, through dealers and rental companies, provide broader market reach, catering to small and medium-sized contractors who prefer renting over purchasing due to cost considerations. Aftermarket services, including maintenance, repairs, spare parts supply, and operator training, are integral to customer satisfaction and equipment longevity, representing a significant revenue stream and a critical factor in brand loyalty. The efficiency and reliability of these distribution and service networks are paramount for sustained market success and widespread product adoption.

Floor Saw Market Potential Customers

The potential customer base for the Floor Saw Market is broad and diverse, primarily comprising entities engaged in various facets of construction, infrastructure development, renovation, and property maintenance. These end-users are perpetually seeking robust, efficient, and precise cutting solutions to manage a wide array of tasks on horizontal surfaces, which include concrete slabs, asphalt pavements, stone, and other dense construction materials. The demand for floor saws is intrinsically linked to the lifecycle of buildings and infrastructure, from initial construction and utility installation to renovation, repair, and eventual demolition. Understanding the specific needs and operational environments of these varied customers is crucial for manufacturers and distributors to effectively segment the market and develop targeted product and service offerings that truly resonate.

Key buyers include large-scale construction companies involved in major civil engineering projects such as highway construction, bridge building, and commercial facility development, where high-capacity, ride-on floor saws are indispensable for achieving extensive, deep cuts rapidly. Demolition contractors represent another significant customer segment, relying on floor saws for controlled and precise removal of concrete sections, minimizing collateral damage to adjacent structures. Public works departments and municipalities are consistent purchasers, utilizing floor saws for ongoing maintenance of urban infrastructure, including road repair, sidewalk renovation, and utility trenching. These governmental bodies often prioritize equipment longevity, ease of maintenance, and compliance with local environmental regulations, influencing their procurement decisions.

Beyond these large-scale users, the market also caters to a substantial number of rental equipment companies who purchase floor saws to lease out to smaller contractors, independent tradespersons, and even homeowners undertaking DIY projects. This segment provides accessibility to expensive machinery for those who do not require it for continuous operation, thereby broadening the market's reach. Industrial facilities, such as manufacturing plants and warehouses, also constitute potential customers for in-house maintenance, modifications to concrete floors, and specialized cutting requirements. Ultimately, the purchasing decisions of these diverse customers are influenced by factors such as machine power, cutting depth capabilities, operational efficiency, advanced safety features, overall durability, brand reputation, and compliance with evolving environmental and occupational safety standards, all of which underscore the dynamic nature of the floor saw customer landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 450 Million |

| Market Forecast in 2032 | USD 666.45 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Husqvarna AB, Hilti Corporation, Tyrolit Group, Wacker Neuson SE, Atlas Copco, Cedima GmbH, Lissmac Maschinenbau GmbH, Norton Clipper (Saint-Gobain), Makita Corporation, DeWalt (Stanley Black and Decker), Bosch Power Tools, Stihl AG, Dynapac (Fayat Group), Multiquip Inc., ICS Blount Inc., Sawtec, Diamond Products, Faccin, CIMA S.p.A., Dr. Bender GmbH. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Floor Saw Market Key Technology Landscape

The Floor Saw Market is continuously evolving, driven by significant advancements in technology aimed at enhancing performance, improving operator safety, and ensuring environmental compliance. A core area of innovation lies in diamond blade technology, where new bonding materials and diamond segment configurations are leading to significantly faster cutting speeds, extended blade life, and greater versatility across diverse material types, including reinforced concrete and high-strength asphalt. These advanced blades reduce operational downtime and consumable costs, making projects more efficient. Furthermore, the development of more efficient and powerful cutting engines, including sophisticated diesel engines with advanced exhaust after-treatment systems and high-torque electric motors, is crucial for meeting stringent environmental regulations while delivering uncompromising power output.

Beyond cutting capabilities, modern floor saws are integrating a suite of smart technologies to elevate operational intelligence and user experience. Ergonomic designs are paramount, focusing on features that reduce operator fatigue, such as adjustable handles, anti-vibration systems, and intuitive control panels, thereby improving productivity and reducing the risk of work-related injuries. Integrated dust suppression systems, often incorporating advanced vacuum attachments and water-misting technologies, are becoming standard to comply with health and safety regulations by minimizing airborne silica dust particles on job sites. These systems not only protect operators but also contribute to a cleaner work environment, which is increasingly important in urban and indoor settings.

The future of floor saw technology is also being shaped by the integration of digital and autonomous capabilities. GPS guidance systems are enabling highly accurate, pre-programmed cutting paths, which is particularly beneficial for large-scale infrastructure projects requiring precise linear cuts over long distances. Remote control capabilities are gaining traction, allowing operators to manage the machine from a safe distance, especially in hazardous or confined environments, significantly enhancing safety. Moreover, the emergence of telematics and Internet of Things (IoT) connectivity is providing real-time operational data, facilitating predictive maintenance, fleet management, and performance optimization. These digital innovations are not only boosting efficiency but also transforming the floor saw from a simple cutting tool into a sophisticated, data-driven piece of construction equipment, capable of higher levels of automation and remote management.

Regional Highlights

-

North America:

The North American floor saw market is characterized by its maturity and a strong focus on high-performance and technologically advanced equipment. This region, encompassing the United States and Canada, benefits from substantial governmental and private investments in upgrading aging infrastructure, including extensive road networks, bridges, and commercial buildings. Demand is predominantly driven by the need for durable, reliable, and highly efficient floor saws capable of handling large-scale repair, maintenance, and new construction projects with precision. The market here places a significant emphasis on adhering to stringent worker safety standards and environmental regulations, leading to a higher adoption rate of floor saws equipped with advanced dust suppression systems, ergonomic designs, and increasingly, low-emission or electric power sources. Furthermore, the well-developed and robust equipment rental market in North America plays a pivotal role, providing easy access to specialized and high-cost floor saws for a wide spectrum of contractors, from large construction firms to smaller, independent operators, thereby ensuring consistent demand and market stability.

Innovation is a key differentiator in the North American market, with manufacturers actively developing and introducing models that offer enhanced automation features, such as GPS-guided cutting and remote control capabilities, aiming to boost productivity and reduce labor costs. The demand for ride-on floor saws for extensive highway and runway projects remains strong, while walk-behind models are consistently sought after for urban renovation and utility work. The aftermarket segment, including spare parts and maintenance services, is also highly significant, supported by a vast network of distributors and service centers. Economic stability and ongoing urbanization projects further contribute to the steady growth and continuous evolution of the floor saw market across this region, as both public and private sectors continue to invest in modernizing their infrastructure and facilities.

-

Europe:

The European floor saw market is a dynamic and highly regulated environment, strongly influenced by a robust commitment to environmental protection and occupational safety. Countries across Western and Northern Europe, in particular, exhibit a strong preference for advanced, eco-friendly floor saws, with a discernible shift towards electric, battery-powered, and hybrid models. This trend is a direct response to stringent emission standards (e.g., Euro V) and noise pollution regulations, especially prevalent in densely populated urban areas and enclosed construction sites. The market is stable, underpinned by continuous investment in urban renewal projects, renovation of historical buildings, maintenance of existing infrastructure such as road networks, and modernization of industrial facilities. European customers prioritize equipment reliability, operational efficiency, and low environmental impact, making them early adopters of cutting-edge technologies.

The European market is also characterized by a strong emphasis on ergonomic design and digital integration, aiming to enhance operator comfort, reduce fatigue, and improve overall job site productivity. Manufacturers active in this region often highlight features like intuitive digital controls, advanced vibration dampening systems, and smart diagnostics. The rental sector in Europe is well-established and plays a critical role in equipment dissemination, providing flexibility for contractors and ensuring high utilization rates for specialized machinery. Germany, the UK, France, and the Nordic countries represent key markets within Europe, driving innovation and demand for high-quality, sustainable floor sawing solutions. The ongoing need for infrastructure upgrades, coupled with a progressive regulatory landscape, ensures consistent growth and technological advancement within the European floor saw market, fostering a competitive environment focused on sustainability and efficiency.

-

Asia Pacific (APAC):

The Asia Pacific region stands out as the fastest-growing market for floor saws globally, propelled by unparalleled levels of urbanization, massive government-led infrastructure development initiatives, and a burgeoning construction sector. Countries like China, India, and the rapidly developing nations of Southeast Asia are experiencing an unprecedented boom in residential, commercial, and industrial construction, alongside significant investments in transportation networks, including new roads, railways, and airports. This extensive development directly translates into a high and escalating demand for efficient and powerful concrete cutting equipment, with both new equipment sales and a burgeoning rental market contributing to this growth. The sheer scale of projects in APAC often necessitates a large volume of heavy-duty, high-capacity floor saws, including both diesel-powered and increasingly, electric models as environmental awareness grows.

While cost-effectiveness remains a significant purchasing factor in many parts of the APAC market, there is a growing recognition and adoption of advanced technologies, especially in more developed economies within the region like Japan, South Korea, and Australia. These countries are seeing a greater integration of automation, improved safety features, and environmentally friendly solutions into their floor saw fleets. Local manufacturing capabilities are also expanding, leading to a competitive landscape with a mix of international and regional players. The demand for walk-behind floor saws is strong for urban development and smaller projects, while ride-on variants are crucial for large-scale infrastructure projects. The robust economic growth, coupled with sustained investment in urban and rural infrastructure, positions the Asia Pacific region as the leading contributor to the global floor saw market's expansion over the forecast period, driving both volume and technological innovation.

-

Latin America:

Latin America represents an emerging yet increasingly significant market for floor saws, driven by a renewed focus on infrastructure investment and a growing construction sector across several key economies. Countries such as Brazil, Mexico, and Chile are witnessing increased governmental spending on public works projects, including road construction, utility upgrades, and the development of new residential and commercial complexes. This uptick in construction activity is directly translating into a rising demand for robust and reliable concrete cutting equipment. While the market may still be somewhat price-sensitive compared to more developed regions, there is a growing appreciation for equipment that offers enhanced efficiency, durability, and operational safety, as contractors seek to improve project timelines and reduce labor costs.

The floor saw market in Latin America is characterized by a mix of direct imports from global manufacturers and local distribution networks. The rental market is also gaining traction, providing essential access to high-cost machinery for a diverse range of contractors, thereby lowering entry barriers for smaller firms. Environmental regulations are becoming more prominent, albeit at varying paces across different countries, slowly influencing the demand towards more eco-friendly and fuel-efficient models. As economies in the region continue to stabilize and grow, sustained investment in both urban and industrial infrastructure is expected to further fuel the demand for floor saws, making Latin America a region with considerable untapped potential and a growing opportunity for both established and new market players.

-

Middle East and Africa (MEA):

The Middle East and Africa (MEA) region is experiencing a substantial boom in its construction sector, positioning it as a rapidly expanding market for floor saws. This growth is predominantly driven by ambitious mega-projects in the Gulf Cooperation Council (GCC) countries, focusing on urban development, tourism infrastructure, and diversification from oil-dependent economies. These include new cities, airports, ports, and extensive road networks, all requiring vast quantities of concrete cutting and demolition work. Africa, on the other hand, is witnessing increasing investment in infrastructure development, including roads, energy projects, and commercial buildings, albeit at varying paces across its diverse nations. The demand in MEA is largely for heavy-duty, high-performance floor saws capable of operating efficiently in challenging environmental conditions, such as extreme temperatures and dusty environments.

The market in the MEA region often prioritizes equipment robustness, reliability, and powerful cutting capabilities, given the scale and intensity of construction projects. While electric and more environmentally conscious models are emerging, diesel-powered floor saws remain highly dominant due to their power and operational flexibility in remote or large-scale outdoor settings where electrical infrastructure might be limited. International manufacturers hold a strong presence in this market, supported by robust distribution networks and a growing emphasis on aftermarket services to ensure equipment uptime. As governments continue to diversify their economies and invest in modern infrastructure, the MEA region is expected to maintain its upward trajectory, presenting significant opportunities for floor saw manufacturers and service providers to cater to the burgeoning demand for advanced cutting solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Floor Saw Market.- Husqvarna AB

- Hilti Corporation

- Tyrolit Group

- Wacker Neuson SE

- Atlas Copco

- Cedima GmbH

- Lissmac Maschinenbau GmbH

- Norton Clipper (Saint-Gobain)

- Makita Corporation

- DeWalt (Stanley Black and Decker)

- Bosch Power Tools

- Stihl AG

- Dynapac (Fayat Group)

- Multiquip Inc.

- ICS Blount Inc.

- Sawtec

- Diamond Products

- Faccin

- CIMA S.p.A.

- Dr. Bender GmbH

Frequently Asked Questions

What are the primary applications of floor saws in construction?

Floor saws are indispensable for precision cutting of concrete, asphalt, and other hard surfaces. Their primary applications include creating control joints in new slabs, cutting trenches for utility installations like plumbing and electrical conduits, controlled demolition of concrete structures, repairing roads and bridges, and cutting expansion joints in airport runways or industrial flooring. These tools ensure clean, straight, and deep cuts essential for maintaining structural integrity and facilitating subsequent construction phases.

How do modern floor saws improve job site safety and environmental impact?

Modern floor saws significantly enhance job site safety through integrated dust suppression systems, often combining water and vacuum technologies to minimize airborne silica dust, thereby protecting operator respiratory health. Ergonomic designs reduce physical strain and fatigue, while remote control options enable operation from a safe distance in hazardous areas. Environmentally, advancements include the development of lower-emission diesel engines and a growing adoption of electric or hybrid models that produce zero emissions and reduced noise levels, particularly crucial for indoor or urban projects.

What are the key factors to consider when selecting a floor saw for a project?

Key factors include the type of material to be cut (concrete, asphalt, stone), required cutting depth, power source availability (electric for indoors, gasoline/diesel for outdoors), project scale (walk-behind for smaller, ride-on for larger), and budget. Additionally, consider features like blade size, engine power, water tank capacity for dust suppression, ease of maneuverability, and integrated safety mechanisms to ensure optimal performance and compliance with site-specific requirements.

What is the role of technology, such as AI and IoT, in the future of floor saws?

AI and IoT are poised to revolutionize floor saws by enabling greater automation, precision, and efficiency. AI can facilitate autonomous cutting paths, optimize blade performance through real-time material analysis, and enhance safety by detecting hazards. IoT connectivity allows for telematics, providing real-time data on machine performance, usage, and location, which is crucial for predictive maintenance, fleet management, and improving overall operational uptime. These technologies will lead to smarter, more sustainable, and safer cutting operations.

How does the rental market influence the Floor Saw industry?

The rental market plays a crucial role by making high-cost, specialized floor saws accessible to a broader range of contractors, particularly smaller firms or those with intermittent needs, without the necessity of significant capital investment. This boosts overall market demand and product utilization. Rental companies often invest in the latest equipment, driving innovation and providing flexibility to end-users to select the most appropriate saw for specific project requirements, thus supporting market growth and equipment adoption across various segments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Floor Saw Cutting Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Building and Construction Light Equipment Market Size Report By Type (Masonry Saw Cutting Equipment, Floor Saw Cutting Equipment, Tile Cutting Equipment), By Application (Building, Bridge, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Floor Saw Market Size Report By Type (Diesel Floor Saw, Petrol Floor Saw, Hydraulic Floor Saw, Others (Electric Floor Saws, etc.)), By Application (Highways, Construction Sites, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Floor Saw Market Statistics 2025 Analysis By Application (Highways, Construction Sites), By Type (Diesel Floor Saw, Petrol Floor Saw, Hydraulic Floor Saw), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager