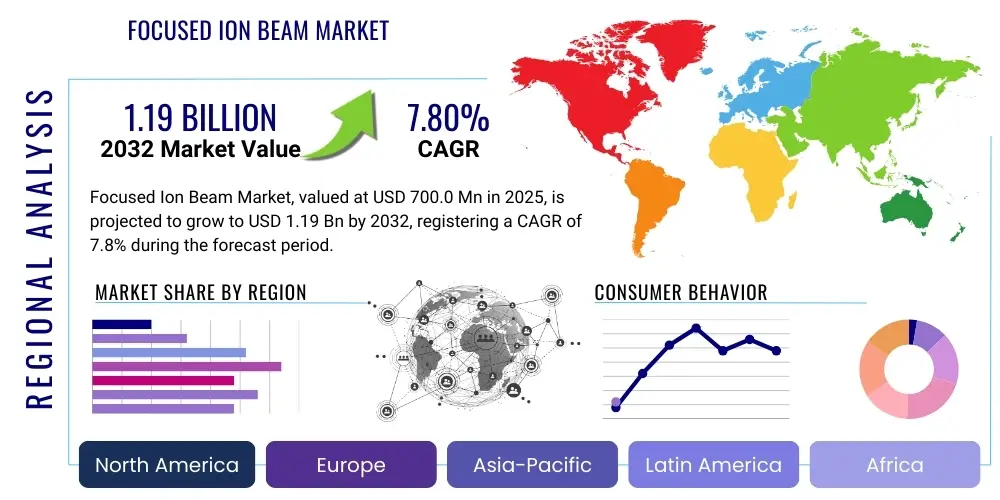

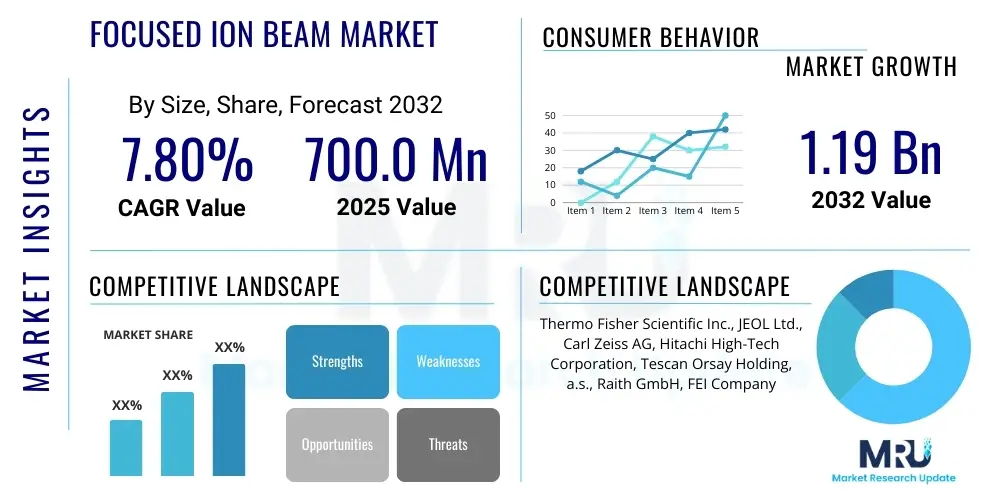

Focused Ion Beam Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427646 | Date : Oct, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Focused Ion Beam Market Size

The Focused Ion Beam Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at USD 700.0 million in 2025 and is projected to reach USD 1.19 billion by the end of the forecast period in 2032. This growth trajectory is underpinned by escalating demand for advanced material characterization and nanofabrication across critical industrial sectors.

Focused Ion Beam Market introduction

The Focused Ion Beam (FIB) market encompasses advanced scientific instruments that utilize a precisely controlled beam of ions, typically gallium, to mill, deposit, and image materials at the nanoscale. These systems are indispensable tools for a diverse range of applications, including semiconductor device analysis, material science research, and biological sample preparation. FIB technology offers unparalleled capabilities in creating ultra-fine structures, performing precise cross-sectional imaging, and enabling site-specific sample preparation for further analysis by other instruments like transmission electron microscopes (TEM). The inherent benefits of FIB technology, such as its high spatial resolution, versatility in material modification, and ability to perform both subtractive and additive processes, position it as a critical asset in modern scientific and industrial R&D.

Major applications of Focused Ion Beam systems include defect analysis and failure analysis in microelectronics, thin film characterization, and the creation of prototypes for micro-electromechanical systems (MEMS). Furthermore, FIB plays a crucial role in preparing delicate biological specimens for advanced microscopy, ensuring their structural integrity and optimal visualization. The driving factors behind the markets expansion are primarily the continuous miniaturization of electronic components, the increasing complexity of new materials requiring detailed characterization, and the escalating demand for quality control and process monitoring in advanced manufacturing.

Focused Ion Beam Market Executive Summary

The Focused Ion Beam market is experiencing robust expansion, driven by significant business trends such as the relentless innovation in semiconductor technology and the burgeoning field of nanotechnology. Manufacturers are increasingly integrating FIB systems into their R&D and quality control workflows to meet stringent performance requirements and accelerate product development cycles. This strategic adoption is fostering a competitive landscape where technological superiority and application-specific solutions dictate market share. Key business trends also include strategic collaborations between FIB manufacturers and academic institutions to push the boundaries of research, alongside an increased focus on developing automated and user-friendly systems to broaden the adoption base beyond specialized research facilities.

Regionally, the Asia Pacific market is poised for significant growth, fueled by massive investments in electronics manufacturing and advanced materials research, particularly in countries like China, Japan, South Korea, and Taiwan. North America and Europe also maintain strong market positions due to established semiconductor industries, robust academic research ecosystems, and significant government funding for scientific initiatives. Segment-wise, the market is primarily categorized by ion source type, application, and end-user. The semiconductor industry remains the dominant application segment, with a substantial portion of demand originating from failure analysis, device modification, and process development. Material science and biological sciences also represent critical and expanding segments, benefiting from FIBs unique capabilities in sample preparation and nanoscale manipulation. The increasing demand for advanced analytics tools in these diverse sectors underscores the markets inherent resilience and growth potential.

AI Impact Analysis on Focused Ion Beam Market

The integration of Artificial Intelligence (AI) is set to revolutionize the Focused Ion Beam market, addressing user questions centered around enhancing automation, improving data analysis, and streamlining complex workflows. Users are keen to understand how AI can reduce the need for highly specialized operators, accelerate sample preparation times, and provide more insightful interpretations of FIB-generated data. Concerns often revolve around the reliability of AI algorithms in critical applications, the cost-effectiveness of AI integration, and the potential for AI to introduce new complexities or biases into sensitive analytical processes. Expectations are high for AI to unlock new capabilities, such as predictive maintenance for FIB systems, advanced image recognition for defect detection, and intelligent optimization of milling parameters, thereby driving greater efficiency and accuracy across diverse applications, from semiconductor failure analysis to advanced material characterization.

- AI-driven automation of FIB system operations, reducing manual intervention and operator variability.

- Enhanced image processing and analysis for faster, more accurate defect detection and material characterization.

- Intelligent parameter optimization for milling and deposition, leading to improved precision and throughput.

- Predictive maintenance capabilities for FIB equipment, minimizing downtime and extending system lifespan.

- Accelerated data interpretation and correlation with other analytical techniques through machine learning algorithms.

- Development of autonomous sample preparation protocols for high-throughput applications.

- Improved classification and identification of nanoscale features and anomalies.

DRO & Impact Forces Of Focused Ion Beam Market

The Focused Ion Beam market is propelled by a confluence of robust drivers, notably the relentless demand for advanced material characterization and precise nanofabrication in industries such as semiconductors, automotive, and aerospace. The continuous miniaturization of electronic devices necessitates ultra-high resolution imaging and manipulation tools, directly bolstering the adoption of FIB systems for failure analysis, quality control, and device modification. Furthermore, the burgeoning field of nanotechnology and the development of novel materials with complex structures are creating a sustained need for FIB technology’s unique capabilities in creating and analyzing nanoscale features. Increased R&D investments globally, particularly in academic and industrial research institutions, further fuel market expansion, pushing the boundaries of material science and engineering. These drivers collectively create a strong impetus for market growth, establishing FIB as an indispensable tool in modern scientific and industrial endeavors.

However, the market faces significant restraints, primarily the high initial capital investment required for FIB systems, which can be prohibitive for smaller research facilities or emerging companies. The complexity of operating and maintaining these sophisticated instruments also demands highly skilled personnel, leading to additional operational costs and a limited pool of qualified users. Opportunities within the FIB market are emerging through the development of hybrid systems that combine FIB with other analytical techniques like Scanning Electron Microscopy (SEM) or Energy Dispersive X-ray Spectroscopy (EDS), offering enhanced analytical capabilities and streamlined workflows. Furthermore, the expanding applications in life sciences, particularly for 3D cellular imaging and biological sample preparation, present new avenues for growth. The impact forces driving the market include technological advancements leading to improved resolution and throughput, while restraining forces involve economic slowdowns and geopolitical uncertainties that can affect R&D budgets and capital expenditures. The ongoing innovation in ion source technology, such as plasma FIB, is also a significant positive impact force, offering faster milling rates and broader material applicability.

Segmentation Analysis

The Focused Ion Beam market is comprehensively segmented to address the diverse needs of its extensive application base. Key segmentation criteria include the type of ion source employed, the specific applications for which the systems are utilized, and the end-user industries that leverage this advanced technology. This multi-faceted segmentation allows for a detailed understanding of market dynamics, revealing specific growth pockets and demand trends within distinct categories. The primary ion source types delineate the performance characteristics and operational costs of FIB systems, while application-based segmentation highlights the functional utility across various scientific and industrial processes. End-user classification provides insight into the primary consumers and their evolving requirements, reflecting the breadth of industries benefiting from FIB technology.

- By Ion Source Type:

- Gallium Liquid Metal Ion Source (LMIS) FIB

- Plasma FIB (Xe, Ar, O, N)

- Gas Field Ion Source (GFIS) FIB (He, Ne)

- By Application:

- Semiconductor Failure Analysis

- Device Modification and Prototyping

- Material Science and Nanofabrication

- Life Sciences (3D Imaging, Sample Preparation)

- Quality Control and Process Monitoring

- By End User:

- Semiconductor Industry

- Academic & Research Institutions

- Material Science Laboratories

- Biotechnology & Pharmaceutical Companies

- Automotive & Aerospace Industry

Focused Ion Beam Market Value Chain Analysis

The value chain for the Focused Ion Beam market commences with upstream activities focused on the research, development, and manufacturing of critical components. This includes the production of ion sources (such as gallium LMIS, plasma sources, and gas field ion sources), high-precision optics, vacuum systems, detection systems, and advanced software for instrument control and data analysis. Suppliers of these specialized components form the foundational layer, providing the technological building blocks essential for FIB system assembly. These upstream activities are highly specialized, requiring significant R&D investment and expertise in precision engineering and materials science. Innovation in ion source technology, for example, directly impacts the performance, speed, and versatility of the final FIB product, making these suppliers crucial to the overall value proposition.

Midstream, the value chain involves the assembly, integration, and testing of complete Focused Ion Beam systems by leading manufacturers. This stage includes sophisticated calibration, quality assurance, and system optimization to ensure peak performance. Downstream activities focus on the distribution channels, which can be direct or indirect. Direct sales involve manufacturers selling directly to end-users, providing personalized service, installation, training, and ongoing technical support. This approach is often favored for high-value, complex systems requiring specialized client relationships. Indirect channels involve distributors, agents, and value-added resellers who market and sell FIB systems, particularly in regions where manufacturers may not have a direct presence. These intermediaries often provide localized support and act as a bridge between manufacturers and a broader customer base. The efficiency of both direct and indirect distribution channels significantly influences market reach and customer satisfaction.

Focused Ion Beam Market Potential Customers

The primary potential customers for Focused Ion Beam technology are diverse, spanning various high-tech and research-intensive industries that require precise material manipulation, advanced imaging, and failure analysis capabilities. End-users in the semiconductor sector represent a significant portion of this customer base, leveraging FIB systems for critical applications such as defect localization, circuit modification, and cross-sectional analysis of microelectronic devices. As semiconductor devices continue to shrink and become more complex, the demand for FIB technology in quality control, process development, and research remains consistently high. These customers seek tools that can identify and rectify nanometer-scale faults, ensuring product reliability and accelerating time-to-market for new designs.

Beyond semiconductors, academic and industrial research institutions constitute another major segment of potential customers. Researchers in material science utilize FIB for exploring novel materials, creating nanostructures, and preparing specimens for transmission electron microscopy (TEM) and other advanced analytical techniques. In the life sciences, a growing number of biotechnology and pharmaceutical companies, as well as biological research labs, are adopting FIB for 3D imaging of cells and tissues, precise biological sample preparation, and understanding complex cellular structures at ultrastructural levels. Automotive and aerospace industries also represent emerging customer segments, using FIB for material characterization, failure analysis of components, and development of advanced composites and coatings, underscoring the broad applicability and value proposition of Focused Ion Beam technology across the scientific and industrial landscape.

Focused Ion Beam Market Key Technology Landscape

The technological landscape of the Focused Ion Beam market is characterized by continuous innovation aimed at enhancing resolution, increasing throughput, improving elemental analysis capabilities, and expanding application versatility. A foundational technology involves the various ion source types, with Gallium Liquid Metal Ion Sources (LMIS) being the traditional standard, offering high brightness and excellent spatial resolution. However, the market is rapidly evolving with the adoption of Plasma FIB (P-FIB) systems, which utilize sources like Xenon, Argon, or Oxygen. P-FIB offers significantly higher current and faster milling rates, making them ideal for high-volume material removal and large-area cross-sectioning, especially beneficial in semiconductor failure analysis and material science for bulk sample preparation. This advancement addresses the growing need for speed without compromising precision in many applications.

Another critical area of technological development is the emergence of Gas Field Ion Sources (GFIS), typically using Helium or Neon ions. These sources provide exceptionally high resolution and minimal sample damage, making them indispensable for ultra-fine nanopatterning and imaging of highly sensitive materials. Hybrid systems, which combine FIB with Scanning Electron Microscopy (SEM) into a single instrument (FIB-SEM), represent a dominant technological trend, enabling simultaneous imaging and milling, thereby streamlining workflow and enhancing analytical capabilities. Integrated detectors, advanced software for automation, 3D reconstruction, and elemental analysis (such as Energy Dispersive X-ray Spectroscopy (EDS) and Electron Backscatter Diffraction (EBSD) attachments) further enrich the technological offerings, providing comprehensive multi-modal analytical solutions. The ongoing focus on automation, AI integration, and user-friendly interfaces is also shaping the key technology landscape, making FIB systems more accessible and efficient for a broader range of users.

Regional Highlights

- North America: A mature market driven by significant R&D investments in semiconductors, materials science, and academic research. Strong presence of key players and early adoption of advanced FIB technologies.

- Europe: Characterized by robust academic and governmental research funding, with a focus on nanotechnology, automotive, and aerospace applications. Germany, UK, and France are key contributors.

- Asia Pacific: The fastest-growing region due to massive investments in electronics manufacturing, semiconductor foundries, and advanced materials research, particularly in China, Japan, South Korea, and Taiwan. Increasing demand for quality control and failure analysis.

- Latin America: An emerging market with growing investments in research and industrial development, gradually increasing adoption of FIB systems in academic institutions and select manufacturing sectors.

- Middle East & Africa: Nascent market with potential growth, driven by diversification efforts in industrial sectors and increasing investment in scientific research infrastructure, especially in countries like Saudi Arabia and UAE.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Focused Ion Beam Market.- Thermo Fisher Scientific Inc.

- JEOL Ltd.

- Carl Zeiss AG

- Hitachi High-Tech Corporation

- Tescan Orsay Holding, a.s.

- Raith GmbH

- FEI Company (now part of Thermo Fisher Scientific)

Frequently Asked Questions

What is a Focused Ion Beam (FIB) system primarily used for?

Focused Ion Beam (FIB) systems are primarily utilized for precise material removal (milling), material deposition, and high-resolution imaging at the nanoscale. Key applications include semiconductor failure analysis, defect characterization, advanced sample preparation for transmission electron microscopy (TEM), and nanofabrication in material science and life sciences.

How does Plasma FIB (P-FIB) differ from traditional Gallium FIB?

Plasma FIB (P-FIB) systems use ion sources like Xenon or Argon, offering significantly higher beam currents and faster milling rates compared to traditional Gallium FIBs. This makes P-FIB ideal for rapid, large-area material removal and cross-sectioning, especially in semiconductor and material science applications, while Gallium FIB excels in ultra-high resolution imaging and fine-scale patterning.

What are the key drivers for the growth of the Focused Ion Beam market?

The primary drivers for the FIB market growth include the increasing demand for advanced material characterization, the continuous miniaturization and complexity of electronic devices requiring precise failure analysis, growing investments in nanotechnology research, and the expanding need for high-resolution imaging and sample preparation across diverse scientific and industrial applications.

Which industries are the major end-users of Focused Ion Beam technology?

The major end-users of Focused Ion Beam technology are predominantly the semiconductor industry for quality control and defect analysis, academic and industrial research institutions for material science and nanotechnology studies, and increasingly, biotechnology and pharmaceutical companies for advanced biological imaging and sample preparation. The automotive and aerospace sectors are also emerging as significant users.

What impact is AI expected to have on the Focused Ion Beam market?

AI is expected to significantly impact the FIB market by enhancing automation, improving image processing and data analysis, and optimizing milling parameters. This will lead to reduced operator dependency, faster throughput, more accurate defect detection, and intelligent system maintenance, ultimately boosting efficiency and expanding the capabilities of FIB technology across various applications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager