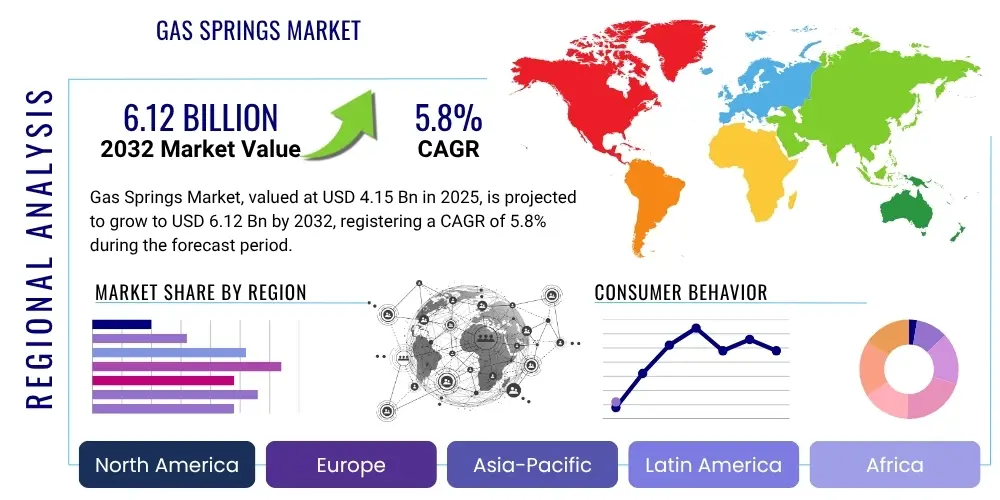

Gas Springs Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430915 | Date : Nov, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Gas Springs Market Size

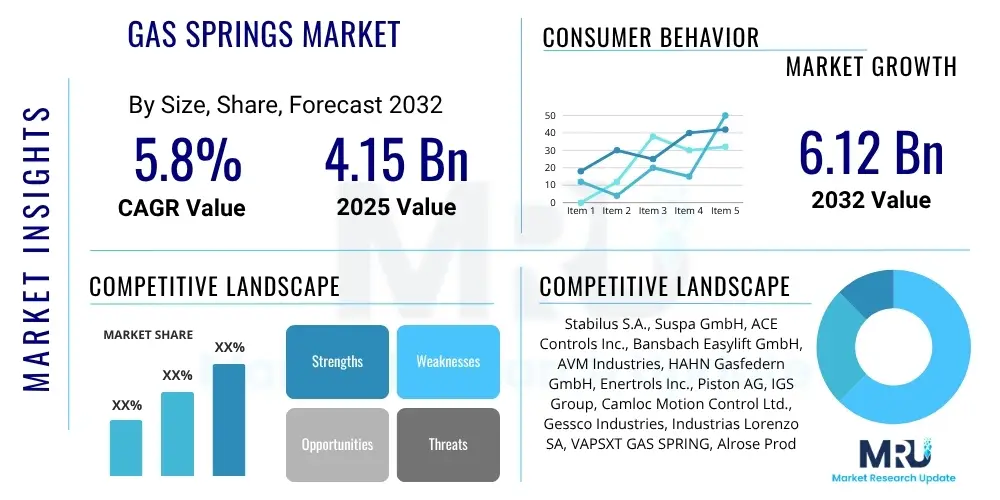

The Gas Springs Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 4.15 Billion in 2025 and is projected to reach USD 6.12 Billion by the end of the forecast period in 2032.

Gas Springs Market introduction

The Gas Springs Market encompasses the global production and consumption of mechanical devices that fundamentally rely on the principle of compressed gas, most commonly inert nitrogen, contained within a meticulously sealed cylinder. This gas interacts with a precisely engineered piston rod, which moves in and out of the cylinder, thereby providing controlled and consistent force for lifting, lowering, balancing, supporting, and dampening functions. These versatile components are ingeniously designed to deliver smooth, reliable, and often effortless motion control across an extensive array of applications. They significantly distinguish themselves from traditional mechanical coil springs by offering inherently progressive damping characteristics and maintaining a remarkably consistent force output throughout their entire stroke, a critical advantage in many dynamic systems. Their inherent capability to precisely manage motion, effectively absorb mechanical shocks, and securely maintain desired positions without the need for continuous external power sources makes them an indispensable element in sophisticated modern engineering and industrial designs, enhancing both functionality and safety.

The core product definition of a gas spring involves several critical components: a robustly sealed cylinder, typically fabricated from high-strength steel or corrosion-resistant stainless steel, filled with an inert gas such as nitrogen under high pressure. A precisely machined piston rod, often surface-treated for durability and low friction, moves axially within this cylinder. The movement of this piston rod compresses or expands the contained gas, generating a predictable and consistent force that facilitates the controlled operation of various mechanisms and components. Major applications of gas springs are extraordinarily broad, spanning crucial and diverse industries. These include the automotive sector, where they are vital for smooth operation of bonnets, tailgates, glove compartments, and even steering column adjustments; medical equipment, enhancing the ergonomics and safety of hospital beds, operating tables, diagnostic machinery, and mobility aids; the furniture industry, where they enable soft-closing cabinet doors, height-adjustable office chairs, and adaptable desks; heavy industrial machinery, functioning in machine guards, access panels, heavy-duty lifting mechanisms, and conveyor systems; and niche applications such as aerospace for compartment doors, luggage bins, and specialized seating adjustments. The primary benefits derived from incorporating gas springs are manifold, including significantly enhanced user safety through strictly controlled motion, vastly improved ergonomics by considerably reducing manual effort, an extended product lifespan attributed to reduced wear and tear on mating components, and their inherently compact and adaptable design which allows for seamless integration into complex systems.

The sustained and projected growth of the gas springs market is underpinned by a confluence of powerful driving factors. A primary impetus is the rapid and expansive growth within global automotive production, particularly the increasing integration of sophisticated gas spring systems in both conventional luxury vehicles for premium comfort and functionality, and more notably in electric vehicles (EVs) where lightweighting and precise component access (e.g., battery compartments) are paramount. This trend is accompanied by the global surge in industrial automation, where gas springs are crucial for facilitating the smooth, precise, and safe operation of advanced machinery, robotic arms, assembly lines, and access gates, thereby boosting productivity and safety. Furthermore, the intensifying focus on ergonomic designs in contemporary office and home furniture, aimed at enhancing user comfort and long-term health, coupled with the escalating demand for highly advanced medical devices that necessitate ultra-precise, reliable, and sterile motion control solutions, are significant contributors to market expansion. Beyond these, continuous technological advancements leading to the development of even more durable, exceptionally compact, highly customizable, and cost-effective gas spring solutions also play a pivotal role in continually widening their applicability and accelerating their adoption across an ever-broader spectrum of diverse industrial and consumer sectors.

Gas Springs Market Executive Summary

The Gas Springs Market is currently demonstrating a period of robust and dynamic growth, intricately shaped by a complex interplay of evolving global business trends, distinct regional market dynamics, and specific segment-level developments. Modern business trends are characterized by a pronounced global shift towards enhanced automation, increased demand for customization, and a strong imperative for sustainability, all of which directly and profoundly influence the demand landscape for advanced gas spring solutions. In response, leading manufacturers are progressively dedicating their research and development efforts towards engineering application-specific gas springs that not only offer superior performance and extended lifecycles but also boast lighter designs and incorporate specialized materials, meticulously catering to the highly bespoke and demanding requirements of a myriad of industrial sectors. Concurrently, the integration of smart manufacturing processes, including predictive maintenance capabilities, is steadily gaining significant traction within the production ecosystem, aiming to optimize operational efficiency, minimize unforeseen downtime, and substantially reduce overall operational costs for both gas spring producers and their diverse range of end-users. Furthermore, the strategic imperative for robust supply chain resilience and geographical diversification is becoming increasingly critical, enabling companies to effectively mitigate geopolitical risks, overcome logistical challenges, and ensure a consistent and reliable availability of essential raw materials and components.

Analyzing regional trends reveals that the Asia Pacific (APAC) region stands out as the unequivocal growth leader, poised to maintain its position as the fastest-expanding market segment globally. This impressive growth is fundamentally fueled by widespread and rapid industrialization, the proliferation of burgeoning automotive manufacturing hubs particularly in economic powerhouses like China and India, and substantial, sustained investments in infrastructure development across major Southeast Asian economies. While North America and Europe represent highly mature and established markets, they continue to exhibit a steady and resilient demand, primarily propelled by the enforcement of stringent safety regulations, a pronounced societal and industrial focus on ergonomic designs in workplace equipment, and continuous, incremental innovation in advanced medical device technology. Latin America and the Middle East & Africa are rapidly solidifying their status as burgeoning emerging markets, demonstrating promising growth trajectories attributed to their expanding manufacturing sectors, accelerating urbanization rates, and rising healthcare expenditures, all of which cumulatively lead to a heightened adoption of gas springs in diverse applications such as construction equipment, essential infrastructure projects, and consumer goods. These regions are also concurrently witnessing an influx of increased foreign direct investment in local manufacturing capabilities, further bolstering their market expansion potential and fostering a more localized production ecosystem.

Segment-specific trends within the Gas Springs Market highlight a persistent and widespread demand for standard gas springs, which continue to find extensive utility across a broad spectrum of industrial and furniture applications owing to their inherent cost-effectiveness and versatile utility. Nevertheless, the lockable gas springs segment is specifically projected to experience a markedly accelerated growth rate, particularly within the highly sensitive medical and ergonomic furniture sectors. This surge is primarily attributable to their critical ability to provide precise positioning, offer enhanced safety mechanisms, and facilitate user-friendly adjustments. The automotive segment rigorously maintains its position as a dominant application area, with significant ongoing advancements focused on developing lightweight materials and innovative compact designs, specifically tailored to meet the evolving demands and space constraints of the rapidly expanding electric vehicle (EV) market. Moreover, there is a discernible and growing trend in the demand for stainless steel gas springs, especially in environments characterized by harsh corrosive conditions and hygiene-critical applications such as pharmaceutical manufacturing, food processing facilities, and medical cleanrooms, primarily due to their superior corrosion resistance, exceptional durability, and ease of sterilization. The overall market is concurrently observing a significant shift towards integrated solutions that seamlessly combine gas springs with other advanced motion control components, aiming to achieve highly cohesive system functionality and optimized performance across complex applications.

AI Impact Analysis on Gas Springs Market

Common user inquiries regarding the transformative impact of Artificial Intelligence (AI) on the Gas Springs Market frequently coalesce around several key thematic areas. Foremost among these is the pervasive question of how AI can be leveraged to fundamentally optimize existing manufacturing processes, ranging from raw material inspection to final product assembly, thereby enhancing overall efficiency and reducing waste. Users are particularly interested in understanding how AI can contribute to the enhancement of product design capabilities, potentially enabling predictive modeling for new gas spring configurations, and critically, how AI can facilitate advanced predictive maintenance regimes for complex systems that extensively utilize gas springs, moving beyond reactive repairs to proactive intervention. Another significant area of concern and expectation revolves around the potential integration of genuinely "smart" features directly into the gas springs themselves, transforming them from passive mechanical components into intelligent, data-generating elements within larger connected systems. Users are keenly interested in determining whether AI can lead to demonstrably more efficient and agile production lines, significantly reduce defect rates through automated inspection, and dramatically accelerate the research and development (R&D) cycles for groundbreaking gas spring innovations. Further concerns also extend to the prospects for AI-driven automation to revolutionize the entire assembly and quality control frameworks for gas springs, as well as the potential for AI to be seamlessly integrated into end-user applications. This integration would allow for real-time monitoring of gas spring performance, accurate assessment of their operational lifespan, and the early detection of potential failures, thereby preventing costly downtime and substantially improving overall system reliability and safety. Ultimately, expectations firmly center on AI's ability to drive unprecedented levels of precision, facilitate greater customization capabilities, and spearhead the adoption of more sustainable and environmentally conscious manufacturing practices throughout the gas springs industry value chain.

- AI-powered predictive maintenance systems can monitor gas spring wear and performance in real-time, forecasting failures and optimizing replacement schedules for equipment, thereby significantly extending asset lifespan and reducing unplanned downtime.

- Advanced optimization of gas spring design through AI-driven simulation and generative design tools, enabling the development of superior performance characteristics, customized force curves, and enhanced material efficiency, leading to lighter and more durable products.

- Implementation of enhanced manufacturing quality control processes utilizing AI-driven vision systems and machine learning algorithms to meticulously detect minute defects, anomalies, and inconsistencies during production, ensuring higher product reliability and consistency.

- Increased automation of complex gas spring assembly and calibration procedures through AI-guided robotics, leading to significantly higher production speeds, superior precision, reduced labor costs, and a substantial minimization of human-induced errors.

- Sophisticated supply chain optimization strategies empowered by AI, capable of accurately predicting demand fluctuations, dynamically managing inventory levels for raw materials and finished goods, and identifying potential logistical bottlenecks to ensure seamless production and delivery.

- Development of 'smart' gas springs with seamlessly integrated micro-sensors that collect real-time data on pressure, temperature, stroke velocity, and cycle counts, which can then be analyzed by AI for performance analytics, usage patterns, and condition monitoring.

- Facilitation of personalized and highly customized gas spring solutions based on AI-driven analysis of specific application requirements, environmental conditions, and user preferences, enabling bespoke product offerings tailored to niche markets and individual client needs.

DRO & Impact Forces Of Gas Springs Market

The Gas Springs Market operates within a complex ecosystem profoundly influenced by a dynamic interplay of drivers, inherent restraints, emerging opportunities, and various overarching impact forces that collectively dictate its growth trajectory and competitive dynamics. Among the most significant drivers propelling the market forward is the robust and continuous expansion of the global automotive industry, particularly evident in the escalating production volumes of Sport Utility Vehicles (SUVs), high-end luxury vehicles, and, crucially, the rapidly growing electric vehicle (EV) segment. All these vehicle types increasingly integrate sophisticated gas spring systems for enhanced user experience in applications such as smooth hood operation, effortless tailgate lifting, precise glove compartment opening, and advanced seating adjustments. Furthermore, the accelerating demand for ergonomically designed furniture in both residential and commercial environments, driven by a global focus on improving user comfort, health, and productivity, serves as another substantial market catalyst. This is coupled with the burgeoning industrial automation sector, where robotics and advanced machinery rely heavily on gas springs for precise motion control, safety, and operational efficiency. Lastly, continuous innovation and expanding adoption in the medical equipment sector, which demands exceptionally smooth, reliable, and hygienic movement mechanisms for hospital beds, diagnostic devices, and surgical tables, are primary generators of demand, collectively underscoring the versatile and indispensable nature of gas spring technology across a multitude of high-growth, technically demanding sectors.

Despite these powerful drivers, the market concurrently faces several notable restraints that pose challenges to unhindered growth. One significant hurdle is the inherent volatility in the prices of critical raw materials, such as various grades of steel for cylinders and rods, specialized sealing materials, and inert gases like nitrogen. Such fluctuations can markedly impact manufacturing costs, compress profit margins, and complicate long-term pricing strategies for gas spring manufacturers. Another restraint is the intrinsic design complexity often involved in tailoring gas springs for highly specialized or custom applications, which frequently necessitates extensive research and development (R&D) investments, intricate precision engineering, and specialized manufacturing expertise, potentially posing barriers for smaller or less resource-rich manufacturers. Moreover, the market faces intense competition from a diverse range of alternative motion control solutions, including traditional mechanical springs, hydraulic cylinders, and increasingly sophisticated electric actuators. This competition is particularly acute in cost-sensitive markets or applications where the specific advantages of gas springs may be less critical. Additionally, the ongoing challenge of consistently ensuring uniform quality and long-term durability across immensely diverse operating conditions, coupled with the necessity for highly specialized manufacturing techniques to prevent gas leakage and guarantee sustained performance over the product's lifespan, represents persistent technical hurdles that demand continuous investment in innovation, materials science, and advanced production processes.

Amidst these challenges, substantial opportunities for market expansion are continually emerging. The global paradigm shift towards electric vehicles (EVs) presents a significant growth avenue, potentially necessitating the development of entirely new gas spring designs tailored for unique EV components such as battery compartments, charging port covers, and specialized access panels, all requiring lightweight yet robust solutions. The burgeoning adoption of smart home devices and advanced assistive technologies in elder care or disability support creates novel avenues for integrated, digitally controlled gas spring solutions that enhance user experience and accessibility. Furthermore, the highly specialized aerospace and defense sectors offer particularly high-value opportunities for manufacturers capable of developing bespoke, ultra-lightweight, high-performance, and extremely durable gas springs engineered to operate reliably under the most extreme environmental conditions and stringent safety requirements. Beyond direct market opportunities, several pervasive impact forces are continually shaping the industry. These include rapid technological advancements in both materials science and manufacturing processes, which are leading to the creation of even more compact, energy-efficient, and exceptionally durable gas springs. Evolving regulatory standards, particularly in areas like automotive safety, medical device efficacy, and industrial workplace ergonomics, dictate increasingly stringent requirements that inherently drive continuous innovation and product redesign. Global macroeconomic cycles directly influence capital expenditure in manufacturing, construction, and infrastructure development, thereby affecting overall demand for gas springs. Lastly, intensifying environmental regulations and a growing societal emphasis on sustainability are compelling manufacturers to adopt more eco-friendly production methods, utilize recyclable components, and develop products with reduced environmental footprints, thus driving green innovation across the sector.

Segmentation Analysis

The Gas Springs Market is meticulously segmented across several critical dimensions, including product type, specific application areas, primary end-use sectors, and the materials utilized in their construction. This comprehensive, multi-faceted segmentation framework is instrumental in facilitating a nuanced and detailed understanding of the market's intricate dynamics, enabling stakeholders to engage in more precise and effective strategic planning. Such a granular analysis provides invaluable insights into distinct product demands, highlights industry-specific adoption patterns, and elucidates the varying preferences and technical requirements of diverse end-user groups worldwide. By dissecting the market along these lines, it becomes possible to accurately identify discrete growth pockets, analyze the competitive landscape within specialized niches, and discern emerging technological or commercial trends that significantly influence product development trajectories, market penetration strategies, and overall investment decisions across the globe. Critically, each distinct market segment responds uniquely to broader macroeconomic shifts, breakthroughs in technological innovation, and localized industrial growth trends, underscoring why a granular, segment-specific analytical approach is not merely beneficial but absolutely essential for all stakeholders seeking to make informed decisions and maintain a competitive edge in this dynamic industry.

For instance, segmentation by type reveals market preferences for standard, non-adjustable units in high-volume, cost-sensitive applications, contrasting sharply with the rising demand for lockable or adjustable gas springs in precision-focused sectors like medical devices or ergonomic furniture, where controlled positioning is paramount. Application-based segmentation clearly demarcates the dominant role of the automotive industry as a key consumer, alongside the steadily growing demand from industrial machinery, furniture, and medical equipment manufacturers, each with distinct technical specifications and performance expectations. The distinction between OEM and aftermarket end-users highlights different sales channels and product lifecycle considerations, with OEMs demanding customization and integrated supply chains, while the aftermarket focuses on readily available replacement parts and standardized offerings. Lastly, segmentation by material, particularly between carbon steel and stainless steel, reflects varying requirements for corrosion resistance, strength, and hygienic properties, influencing adoption in harsh environments versus general industrial use. This detailed breakdown ensures that market participants can accurately size opportunities, mitigate risks, and develop highly targeted product and marketing strategies that resonate with the specific needs of each identified segment, driving efficient resource allocation and sustainable growth.

- By Type:

- Lockable Gas Springs: Offer rigid locking in any position, ideal for medical beds, ergonomic workstations, and height-adjustable tables.

- Standard Gas Springs: Most common type, providing controlled extension/compression force, used in automotive bonnets, tailgates, and industrial covers.

- Dampers (Hydraulic Dampers, Friction Dampers): Specifically designed to absorb kinetic energy and control motion speed without providing lift, crucial in machinery and safety applications.

- Traction Gas Springs: Pulling force rather than pushing, used for counterbalancing upward-opening hatches or components that need to be pulled closed.

- Adjustable Gas Springs: Allow for modification of gas pressure/force after installation, providing flexibility for diverse load requirements.

- By Application:

- Automotive (Bonnet, Tailgate, Glove Box, Seating): Crucial for vehicle safety, comfort, and convenience, facilitating smooth operation of various compartments.

- Furniture (Cabinet Doors, Office Chairs, Adjustable Beds/Desks): Enhances ergonomics, ease of use, and soft-closing mechanisms in modern furniture designs.

- Industrial (Machine Guards, Access Panels, Tool Boxes, Production Lines): Improves operational safety, accessibility, and efficiency in manufacturing and heavy industry.

- Medical (Hospital Beds, Operating Tables, Diagnostic Equipment, Wheelchairs): Demands high precision, reliability, and often sterile materials for patient care and equipment functionality.

- Aerospace and Defense (Aircraft Interiors, Storage Compartments, Seating): Requires lightweight, high-performance, and extremely durable solutions for critical applications.

- Building and Construction (Roof Hatches, Window Openers): Used for controlled opening and closing of heavy architectural components, ensuring safety and ease of access.

- Marine (Boat Hatches, Engine Covers): Provides corrosion-resistant motion control for various components in demanding marine environments.

- Other Applications: Includes applications in sports equipment, agricultural machinery, retail displays, and specialized consumer electronics.

- By End-Use:

- Original Equipment Manufacturers (OEM): Major clients who integrate gas springs directly into their manufactured products.

- Aftermarket: Customers requiring replacement or upgrade gas springs for existing equipment and vehicles.

- By Material:

- Stainless Steel: Preferred for corrosive environments, medical applications, food processing, and marine uses due to superior resistance and hygiene.

- Carbon Steel: Widely used for general industrial and automotive applications due to cost-effectiveness and good strength.

- Other Alloys: Niche materials for specific high-performance or lightweight requirements.

Value Chain Analysis For Gas Springs Market

The value chain for the Gas Springs Market is a sophisticated, multi-stage process that meticulously tracks the transformation of raw materials into finished products and their eventual delivery to end-users, with each successive stage adding distinct value. This intricate chain commences with upstream activities, primarily involving the strategic sourcing and procurement of essential raw materials. Key components at this foundational stage include high-grade steel, which is indispensable for fabricating the robust cylinders and precision piston rods, specialized sealing materials such as advanced elastomers and high-performance polymers, which are crucial for preventing gas leakage and ensuring long-term operational integrity, and inert gases, predominantly nitrogen, used for internal pressurization. The major suppliers participating in this initial stage typically comprise large-scale metal processing companies, specialized chemical manufacturers providing advanced polymer compounds, and industrial gas suppliers. The unwavering quality, consistent composition, and reliable supply of these raw materials are absolutely paramount, as they directly dictate the performance, durability, and operational longevity of the final gas spring products. This critical dependency fosters a strong emphasis on establishing robust, long-term supplier relationships and implementing rigorous material inspection and quality assurance protocols. Furthermore, ongoing advancements in materials science, including the development of novel steel alloys and innovative polymer composites, continually influence this upstream segment, driving the pursuit of improved durability, enhanced performance characteristics, and significant weight reduction in gas spring designs.

Moving downstream within the value chain, midstream activities encompass the intricate manufacturing, precise assembly, and meticulous quality control processes of the gas springs themselves. This stage is characterized by highly specialized precision engineering techniques. These include sophisticated tube drawing, advanced surface finishing treatments for piston rods (such as nitriding, hard chrome plating, or specialized ceramic coatings which enhance corrosion resistance and reduce friction), high-precision welding, the careful assembly of internal components (including the piston, seals, valves, and guide bearings), and finally, the critical process of gas filling under controlled conditions, followed by hermetic sealing. Manufacturers in this segment often specialize in particular types of gas springs, for instance, lockable or adjustable variants, or cater exclusively to specific industry standards and application requirements, which necessitates substantial capital investment in state-of-the-art machinery, advanced automation technologies, and a highly skilled labor force proficient in precision manufacturing. Rigorous testing for force consistency, leak integrity, and cycle life is conducted at this stage to ensure product reliability and adherence to performance specifications. The efficiency and technological sophistication of these manufacturing processes are key differentiators in a competitive market.

The final phase, downstream activities, centers on effectively reaching the diverse end-users. This involves a complex and multi-faceted network of distribution channels, broadly categorized into direct and indirect routes. Direct distribution typically involves manufacturers forging strong, long-term relationships with large-scale Original Equipment Manufacturers (OEMs) who integrate gas springs directly into their finished products. This direct engagement often includes collaborative custom design projects, bulk supply agreements, and comprehensive technical support, which are critically important for complex industrial, automotive, and medical applications where bespoke solutions are frequently required. Indirect distribution channels, conversely, involve a broader network of wholesalers, regional distributors, and specialized retailers who supply gas springs to a wider array of smaller OEMs, the crucial aftermarket segment, and various maintenance, repair, and overhaul (MRO) service providers. In recent years, online platforms and e-commerce portals have emerged as an increasingly vital indirect channel, enabling extensive market reach, streamlined order processing, and efficient delivery to a highly diverse customer base, encompassing individual consumers, small businesses, and specialized workshops seeking replacement parts or component upgrades. The overall efficiency, reliability, and responsiveness of these diverse distribution channels are absolutely critical for effective inventory management, ensuring timely delivery, and ultimately achieving high levels of customer satisfaction and loyalty. Furthermore, advanced logistics and strategically located warehousing facilities play a pivotal role in optimizing the entire value chain, significantly minimizing operational costs, and enhancing the market's overall responsiveness to fluctuating demand, thereby contributing substantially to competitive advantage and market share within the gas springs industry.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.15 Billion |

| Market Forecast in 2032 | USD 6.12 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Stabilus S.A., Suspa GmbH, ACE Controls Inc., Bansbach Easylift GmbH, AVM Industries, HAHN Gasfedern GmbH, Enertrols Inc., Piston AG, IGS Group, Camloc Motion Control Ltd., Gessco Industries, Industrias Lorenzo SA, VAPSXT GAS SPRING, Alrose Products Inc., Lift-O-Mat, Weforma Dämpfungstechnik GmbH, Zimmer Group, Lesjöfors AB, Metrol Springs Ltd., WZ Eurotech Sp. z o.o. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Gas Springs Market Key Technology Landscape

The Gas Springs Market is characterized by a relentlessly evolving technological landscape, driven by an imperative to continuously enhance product performance, bolster durability, and expand functional capabilities, all while adeptly addressing the highly specific and often rigorous demands of diverse industrial applications. A cornerstone of these technological advancements lies in the realm of precision engineering and advanced manufacturing techniques. This encompasses cutting-edge piston rod surface treatments, such as complex nitriding processes, hard chrome plating, or innovative ceramic coatings. These treatments are meticulously applied to significantly improve resistance to corrosion, drastically reduce friction between moving parts, and thereby extend the operational lifespan and ensure the flawlessly smooth operation of the gas springs. Concurrently, substantial improvements in sophisticated sealing technologies are paramount. These advancements involve the development and integration of specialized elastomers and intricate seal designs, which are absolutely crucial for preventing minute gas leakage, guaranteeing consistent force output over prolonged periods, and maintaining unwavering reliability even when subjected to the most demanding and harsh environmental conditions. Furthermore, the strategic development of increasingly compact and lightweight designs, frequently achieved through the innovative utilization of high-strength, lightweight alloys or advanced composite materials, represents a key focus area. This trend is particularly critical for applications in the automotive (especially electric vehicles) and aerospace industries, where weight reduction is a primary driver for enhanced fuel efficiency, extended range, and superior overall performance.

Regional Highlights

- North America: This region is characterized by a mature and highly developed market with a pronounced emphasis on pioneering technological innovation and the unwavering demand for premium-quality products. Market demand is robustly driven by a thriving automotive sector, with particular strength observed in the luxury vehicle and SUV segments, alongside substantial and sustained investments within the advanced medical and aerospace industries. Furthermore, the enforcement of stringent safety regulations and a pervasive industrial and societal focus on ergonomics across various industrial and furniture applications significantly contribute to steady and consistent market growth. The prominent presence of leading global market players and a well-established, sophisticated industrial infrastructure collectively foster a highly competitive environment, stimulating continuous product development, localized manufacturing, and the rapid adoption of advanced gas spring solutions across a broad spectrum of end-uses. The region’s economic stability also supports high-value applications.

- Europe: Europe represents another exceptionally well-established and technologically advanced market for gas springs, propelled by its highly sophisticated automotive manufacturing base, stringent quality standards in industrial automation, and a world-renowned, innovative medical device sector. Germany, in particular, stands out as a preeminent hub for gas spring innovation, precision engineering, and high-volume production, hosting several key global manufacturers. The region's unwavering commitment to energy efficiency, environmental sustainability, and circular economy principles also drives a strong demand for optimized, durable, and environmentally conscious gas spring solutions. Robust economic stability, coupled with an intrinsic focus on engineering excellence and adherence to comprehensive regulatory frameworks (like REACH), ensures sustained market expansion and the widespread adoption of high-performance, specialized gas springs across a vast and diverse array of end-uses. Innovation in smart factory concepts further integrates gas springs into automated systems.

- Asia Pacific (APAC): APAC undeniably represents the fastest-growing and most dynamic market for gas springs globally. This remarkable growth is primarily attributable to widespread and rapid industrialization, the exponential expansion of automotive production capacities (especially in economic powerhouses like China, India, Japan, and South Korea), and substantial, ongoing investments in critical infrastructure development projects across the entire region. Concurrently, rising disposable incomes, rapid urbanization trends, and the increasing affluence of a burgeoning middle class further fuel demand for modern furniture, sophisticated consumer goods, and advanced industrial equipment that incorporates gas springs. The region's highly competitive manufacturing landscape, combined with accelerating investments in automation technologies, advanced robotics, and an expanding healthcare sector, collectively positions APAC as the predominant growth engine for the global gas springs market. This vibrant environment continues to attract both established local manufacturers and major international players seeking to capitalize on robust demand and expanding market opportunities.

- Latin America: This region is firmly establishing itself as an emerging market for gas springs, currently experiencing consistent growth driven by ongoing industrialization initiatives, the expansion of automotive manufacturing bases (notably in countries such as Brazil, Mexico, and Argentina), and significant advancements in developing healthcare infrastructure. Demand is additionally influenced by burgeoning growth within the construction and agricultural sectors, where gas springs are extensively utilized in heavy machinery, off-highway vehicles, and essential farm equipment. While the market size remains comparatively smaller than the highly developed regions of North America and Europe, Latin America offers considerable untapped potential for future expansion. The region is poised for steady and sustainable growth as industrial development progresses, urbanization accelerates, and overall living standards and technological adoption rates continue to improve, attracting increased foreign investment in manufacturing capabilities and local distribution networks.

- Middle East and Africa (MEA): The MEA region is also progressively solidifying its position as an emerging market for gas springs, with growth primarily underpinned by ambitious investments in large-scale infrastructure projects, ongoing government efforts towards economic diversification away from traditional oil-based economies, and steadily increasing healthcare expenditures. Rapid urbanization and a booming construction sector, particularly evident in the Gulf Cooperation Council (GCC) countries, are significant drivers for gas spring demand in architectural applications, building access solutions, and modern furniture. Industrial development and the establishment of new automotive assembly plants in key nations like South Africa, Egypt, and Saudi Arabia also contribute significantly to market expansion. While the market is highly dependent on foreign direct investment, technological imports, and global supply chains, the long-term outlook remains positive as these economies continue to industrialize and diversify, creating new opportunities for gas spring adoption across various sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Gas Springs Market.- Stabilus S.A.

- Suspa GmbH

- ACE Controls Inc.

- Bansbach Easylift GmbH

- AVM Industries

- HAHN Gasfedern GmbH

- Enertrols Inc.

- Piston AG

- IGS Group

- Camloc Motion Control Ltd.

- Gessco Industries

- Industrias Lorenzo SA

- VAPSXT GAS SPRING

- Alrose Products Inc.

- Lift-O-Mat

- Weforma Dämpfungstechnik GmbH

- Zimmer Group

- Lesjöfors AB

- Metrol Springs Ltd.

- WZ Eurotech Sp. z o.o.

Frequently Asked Questions

What are the primary applications of gas springs?

Gas springs are widely utilized across a diverse spectrum of industries to provide precise and controlled motion. Their primary applications encompass the automotive sector (for bonnets, tailgates, and glove compartments), the furniture industry (enabling soft-closing cabinet doors and adjustable desks), industrial machinery (facilitating safe access panels and machine guards), and medical equipment (enhancing functionality in hospital beds and operating tables), where they consistently deliver reliable lifting, lowering, balancing, and effective dampening functions.

How do gas springs fundamentally differ from traditional mechanical springs?

Unlike conventional mechanical springs that typically provide a linear or progressive increase in force, gas springs offer a remarkably consistent force output throughout their entire stroke length, coupled with inherent progressive damping characteristics. They achieve this through the use of compressed gas, primarily nitrogen, contained within a sealed cylinder. This design enables smooth, controlled motion, efficient shock absorption, and stable position holding, thereby requiring less manual effort and significantly enhancing overall operational safety and user experience compared to mechanical alternatives.

Which key factors are primarily driving the robust growth of the Gas Springs Market?

The significant growth in the Gas Springs Market is predominantly fueled by several synergistic factors. These include the escalating global automotive production, particularly a surge in demand for electric vehicles (EVs) and SUVs, the increasing adoption of ergonomic designs in both office and residential furniture, the rapid expansion of industrial automation and robotics, and continuous, impactful innovations within the medical device technology sector. These combined drivers collectively stimulate the widespread adoption of gas springs due to their superior motion control capabilities and inherent functional benefits across various industries.

What pivotal role does advanced technology play in shaping the Gas Springs Market?

Advanced technology is a crucial determinant in the Gas Springs Market, profoundly influencing product evolution. It encompasses breakthroughs in precision engineering, innovative material science (e.g., lightweight alloys, specialized polymers), and sophisticated sealing techniques. These advancements collectively lead to the development of more durable, compact, efficient, and application-specific gas springs. Emerging technological trends, such as the integration of smart sensors for real-time predictive maintenance and the application of AI-driven tools for design optimization, are further enhancing product performance, reliability, and enabling smarter, more integrated motion control solutions within the broader Industry 4.0 landscape.

What are the most significant regional growth areas contributing to the gas springs market expansion?

The Asia Pacific (APAC) region currently stands as the most dynamic and fastest-growing market, driven by rapid industrialization, expanding automotive manufacturing, and substantial infrastructure investments. North America and Europe represent mature, yet steadily growing markets, characterized by advanced industrial sectors and strict regulatory frameworks. Latin America and the Middle East & Africa are emerging regions that exhibit promising growth potential, fueled by ongoing industrial development, urbanization, and increasing investments in key sectors like healthcare and construction, indicating a geographically diversified market expansion.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Automotive Gas Springs Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Nitrogen Gas Springs Market Statistics 2025 Analysis By Application (Automotive, Electronics), By Type (Standard, Compact, Super Compact, Micro), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Gas Springs Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Lockable Gas Spring, Lift Gas Spring, Swivel Chair Gas Spring, Non-lockable Gas Spring, Damper, Gas Traction Spring), By Application (Automotive, Aerospace, Marine, Medical, Furniture, Industrial), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager