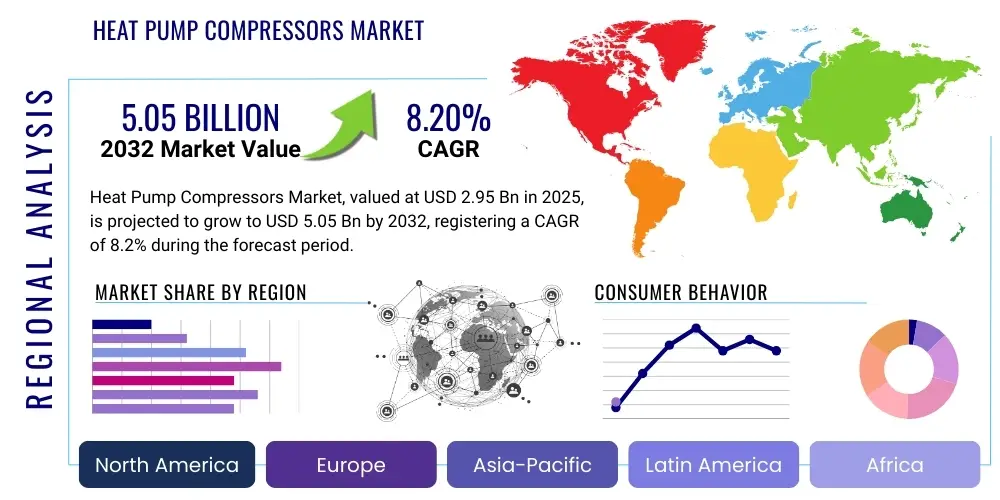

Heat Pump Compressors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427634 | Date : Oct, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Heat Pump Compressors Market Size

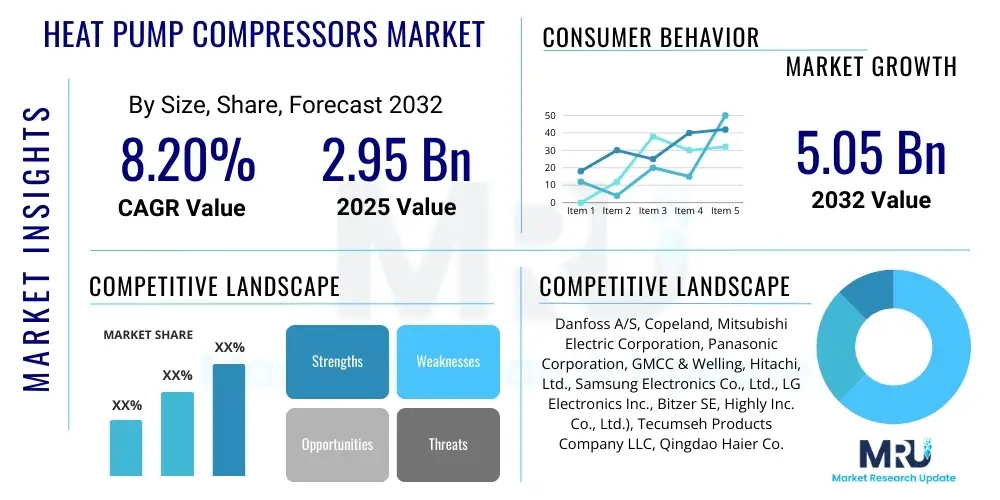

The Heat Pump Compressors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.2% between 2025 and 2032. The market is estimated at USD 2.95 Billion in 2025 and is projected to reach USD 5.05 Billion by the end of the forecast period in 2032.

Heat Pump Compressors Market introduction

The Heat Pump Compressors Market is a critical segment within the broader HVAC and renewable energy landscape, underpinning the functionality of modern heat pump systems. These compressors are electromechanical devices that transfer refrigerant vapor from a low-pressure side to a high-pressure side, increasing its temperature and pressure, which is essential for the heat transfer cycle in heat pumps. As the core component, the compressor dictates the efficiency, performance, and operational lifespan of a heat pump, enabling it to extract heat from ambient air, ground, or water and transfer it for space heating, cooling, or domestic hot water production. The market encompasses a variety of compressor types, including scroll, rotary, reciprocating, and screw, each tailored to specific application requirements and capacities.

Key applications for heat pump compressors span residential, commercial, and industrial sectors. In residential settings, they are integral to air-to-water, air-to-air, and ground-source heat pump systems used for home heating, cooling, and hot water. Commercial applications extend to office buildings, retail spaces, and hotels, where large-scale HVAC systems benefit from their energy efficiency. Industrially, heat pump compressors are increasingly employed in process heating, waste heat recovery, and large-scale climate control, offering substantial operational cost savings and reduced environmental impact. The widespread adoption of these technologies is driven by a global push for decarbonization and energy independence, as heat pumps offer a highly efficient alternative to traditional fossil fuel-based heating systems.

The primary benefits associated with heat pump compressors include superior energy efficiency, significantly lower carbon emissions, and long-term operational cost reductions for end-users. Their ability to deliver both heating and cooling from a single system provides versatility, while advancements in inverter technology and natural refrigerants further enhance their environmental credentials and performance. Major driving factors for market growth include stringent government regulations promoting energy-efficient building standards, escalating consumer demand for sustainable and cost-effective heating and cooling solutions, attractive government incentives and subsidies for heat pump installations, and continuous innovation in compressor technology to improve efficiency and reduce noise levels. The integration with smart home systems and renewable energy sources also contributes to their rising appeal.

Heat Pump Compressors Market Executive Summary

The Heat Pump Compressors Market is experiencing robust expansion, propelled by transformative business trends, evolving regional dynamics, and significant segment-specific advancements. Business trends indicate a strong emphasis on product innovation, with manufacturers investing heavily in research and development to enhance compressor efficiency, reliability, and compatibility with low global warming potential (GWP) refrigerants. There is a discernible trend towards consolidation among key players, alongside strategic partnerships aimed at expanding market reach and integrating advanced technologies such as IoT and AI for predictive maintenance and optimized performance. The shift towards variable speed and inverter-driven compressors is a cornerstone of this innovation, enabling greater energy savings and precise temperature control. Furthermore, the market is witnessing increased demand for heat pump systems that can seamlessly integrate with smart grid solutions and renewable energy infrastructure, reflecting a broader movement towards integrated energy management.

Regional trends highlight Europe and North America as leading markets due to aggressive decarbonization policies, substantial government incentives, and a mature infrastructure for heat pump adoption. These regions are characterized by high energy costs and a strong environmental consciousness, fostering rapid market penetration. Asia-Pacific, particularly China, Japan, and South Korea, represents a significant growth engine, driven by rapid urbanization, industrialization, and increasing disposable incomes that fuel demand for efficient climate control solutions. Governments in this region are also beginning to implement policies to reduce carbon footprints, although the pace of adoption varies. Emerging markets in Latin America, the Middle East, and Africa show considerable potential, with growing construction activities and a rising awareness of energy efficiency gradually contributing to market expansion, albeit from a smaller base.

Segment trends underscore the dominance of scroll compressors due to their compact size, efficiency, and quiet operation, making them highly suitable for residential and light commercial applications. However, rotary and reciprocating compressors continue to hold significant shares in specific niche applications, such as smaller capacity systems or robust industrial uses. The shift towards natural refrigerants like R290 (propane) and CO2 (R744) is a critical development across all compressor types, driven by environmental regulations aimed at phasing out high-GWP HFCs. This transition necessitates significant redesigns and technological adaptations for compressor manufacturers. Furthermore, variable speed compressors are gaining substantial traction across all capacity segments, offering superior part-load efficiency and enhanced user comfort, thereby redefining performance expectations within the market.

AI Impact Analysis on Heat Pump Compressors Market

The integration of Artificial intelligence (AI) is set to profoundly transform the heat pump compressors market, addressing common user questions about efficiency, reliability, and smart operation. Users frequently inquire about AIs potential to optimize energy consumption, predict maintenance needs, and enhance the overall lifespan and performance of heat pump systems. The core themes emerging from these inquiries revolve around leveraging AI for intelligent diagnostics, proactive issue resolution, real-time performance optimization, and seamless integration into smart home and building management systems. This advanced analytical capability is expected to significantly improve the user experience by offering more efficient, reliable, and user-friendly heat pump solutions, reducing operational costs and environmental impact, and enabling a new era of predictive and adaptive climate control.

- Predictive Maintenance: AI algorithms analyze operational data, such as vibration, temperature, and pressure, to detect anomalies and forecast potential compressor failures, enabling proactive maintenance and minimizing costly downtime.

- Energy Optimization: AI-driven control systems learn user patterns, external weather conditions, and energy tariffs to dynamically adjust compressor operation, maximizing energy efficiency and reducing electricity consumption.

- Enhanced Diagnostics: AI provides real-time fault detection and detailed diagnostic reports, helping service technicians identify and resolve issues more quickly and accurately, improving repair efficiency.

- Smart Control and Personalization: AI integrates with smart home ecosystems to offer personalized comfort settings, adapting heating and cooling based on occupancy, preferences, and external factors, ensuring optimal indoor climate.

- Performance Monitoring: AI platforms continuously monitor compressor performance metrics, identifying inefficiencies or deviations from optimal operation, providing insights for system improvements and prolonged operational life.

- Refrigerant Management: AI can optimize refrigerant charge and flow within the system, ensuring peak performance and compliance with environmental regulations by minimizing leaks and improving system balance.

- Design and Manufacturing: AI assists in the design phase by simulating various compressor configurations and material choices, accelerating product development and optimizing manufacturing processes for improved efficiency and cost-effectiveness.

DRO & Impact Forces Of Heat Pump Compressors Market

The Heat Pump Compressors Market is shaped by a complex interplay of drivers, restraints, and opportunities, significantly influenced by a range of impact forces. The primary drivers fueling market expansion include stringent government regulations promoting energy efficiency and decarbonization, particularly in Europe and North America, which mandate the adoption of low-carbon heating solutions. Escalating global energy prices are making heat pumps a more economically attractive alternative to traditional fossil fuel systems, driving consumer and commercial interest. Furthermore, a growing awareness regarding climate change and environmental sustainability is pushing consumers and businesses towards greener technologies, with government incentives and subsidies for heat pump installations further accelerating adoption rates. Technological advancements, such as the development of variable-speed compressors and enhanced refrigerant management systems, are continuously improving performance and reducing operational costs, thereby bolstering market demand.

Despite significant growth potential, the market faces several restraints. The high initial capital cost of heat pump systems, including the compressor and installation, remains a significant barrier for many potential buyers, particularly in cost-sensitive markets. The complexity of installation, often requiring specialized skills and extensive modifications to existing infrastructure, can deter homeowners and businesses. Limited consumer awareness and understanding of heat pump technology and its long-term benefits in some regions also hinder market penetration. Additionally, the availability and cost fluctuations of essential raw materials, along with potential supply chain disruptions, can impact manufacturing capabilities and product pricing. The reliance on electricity for operation, even if efficient, also presents a challenge in regions with unreliable or carbon-intensive power grids.

Opportunities for market growth are abundant, particularly in emerging economies where rapid urbanization and infrastructure development are creating new demand for efficient climate control solutions. The retrofitting of existing buildings with modern heat pump systems presents a substantial market opportunity, as older heating systems are phased out. Continuous innovation in compressor technology, including advancements in natural refrigerants (like R290 and CO2), IoT integration for smart control, and magnetic bearing technologies, promises higher efficiencies and broader application scopes. The increasing integration of heat pumps with renewable energy sources, such as solar PV, further enhances their appeal by enabling fully sustainable energy ecosystems. The overall market is also subject to impact forces, including the bargaining power of buyers who demand higher efficiency and lower costs, and the bargaining power of suppliers for critical components and raw materials. The threat of new entrants is moderate due to high R&D costs and intellectual property, while the threat of substitutes is low given the unique benefits of heat pump technology. Competitive rivalry among established players is intense, driving continuous innovation and market differentiation.

Segmentation Analysis

The Heat Pump Compressors Market is meticulously segmented to understand its intricate dynamics and diverse applications. This segmentation allows for a detailed analysis of market trends across various product types, capacities, refrigerants, and end-user applications, providing insights into specific market drivers, challenges, and opportunities. Understanding these segments is crucial for manufacturers to tailor their product offerings, for policymakers to design effective incentive programs, and for investors to identify high-growth areas within the expanding heat pump industry. Each segment exhibits unique characteristics and growth trajectories influenced by technological advancements, regulatory pressures, and evolving consumer preferences, collectively shaping the competitive landscape of the market.

- By Type:

- Scroll Compressors: Widely used in residential and light commercial heat pumps due to their high efficiency, compact size, and quiet operation.

- Rotary Compressors: Often found in smaller capacity heat pumps, known for their compact design and cost-effectiveness.

- Reciprocating Compressors: Traditional and robust, used in a variety of applications, though generally less efficient than scroll for similar capacities.

- Screw Compressors: Primarily for large commercial and industrial heat pump systems due to their high capacity and reliability.

- Other Compressors: Includes centrifugal and magnetic bearing compressors, representing niche or emerging technologies.

- By Capacity:

- Low Capacity: Typically below 5 kW, suitable for small residential units and domestic hot water.

- Medium Capacity: Ranging from 5 kW to 30 kW, ideal for larger residential and light commercial buildings.

- High Capacity: Above 30 kW, designed for large commercial and industrial applications requiring significant heating or cooling power.

- By Refrigerant Type:

- Hydrofluorocarbons (HFCs): Such as R410A and R134a, still prevalent but facing phase-down regulations due to high GWP.

- Hydrofluoroolefins (HFOs): Lower GWP alternatives, gaining traction as replacements for HFCs.

- Natural Refrigerants: Including CO2 (R744), Propane (R290), and Ammonia (R717), highly favored for their ultra-low GWP and high efficiency in specific applications.

- By Application:

- Residential: For space heating, cooling, and domestic hot water in homes and apartments.

- Commercial: For HVAC in offices, retail, hotels, and public buildings.

- Industrial: For process heating, large-scale climate control, and waste heat recovery in manufacturing and industrial facilities.

- By End-User:

- HVAC Systems: Integrated into heating, ventilation, and air conditioning systems for climate control.

- Water Heating: Dedicated heat pumps for producing domestic hot water.

- Industrial Process Heating: Used in various industrial processes requiring precise temperature control and energy recovery.

Heat Pump Compressors Market Value Chain Analysis

The value chain for the Heat Pump Compressors Market is an intricate network of interconnected stages, from raw material sourcing to final product delivery and after-sales support, collectively contributing to the creation and distribution of value. This chain begins with upstream analysis, focusing on the suppliers of essential raw materials and foundational components. These include manufacturers of specialized metals like copper, steel, and aluminum for compressor casings and internal components, as well as suppliers of electrical motors, seals, valves, and electronic controls. The quality, cost, and availability of these upstream inputs directly influence the manufacturing efficiency, performance, and overall cost-effectiveness of the compressors. Strong supplier relationships and strategic sourcing are critical for mitigating supply chain risks and ensuring a steady flow of high-quality materials.

The manufacturing stage involves the sophisticated assembly and testing of compressors, often integrating advanced technologies such as variable speed drives and specialized coatings to enhance durability and efficiency. This stage also includes significant investment in research and development to innovate new compressor designs, improve energy performance, and adapt to evolving refrigerant regulations. Once manufactured, compressors move into the distribution phase, which can involve both direct and indirect channels. Direct channels often include sales directly from compressor manufacturers to large original equipment manufacturers (OEMs) who integrate these compressors into their complete heat pump systems. This approach allows for closer collaboration and customization.

Indirect distribution channels involve a network of wholesalers, distributors, and retailers who supply heat pump compressors to smaller HVAC system integrators, installers, and service providers. These intermediaries play a crucial role in market penetration, providing logistics, localized support, and access to a broader customer base. Downstream analysis encompasses the heat pump manufacturers who are the primary integrators, incorporating compressors into their finished products for residential, commercial, and industrial applications. Further downstream are the HVAC system installers and contractors who purchase complete heat pump units and install them for end-users. This comprehensive value chain ensures that the highly specialized heat pump compressors reach their intended applications efficiently, supported by a network of services that include installation, maintenance, and repair, ultimately delivering energy-efficient heating and cooling solutions to a global market.

Heat Pump Compressors Market Potential Customers

The potential customer base for the Heat Pump Compressors Market is diverse and rapidly expanding, driven by a global imperative for energy efficiency and sustainable climate control solutions. At the core, these customers are end-users and buyers of the finished heat pump products, recognizing the compressor as the critical component enabling their systems. A significant segment comprises residential homeowners who seek to replace outdated fossil fuel heating systems with modern, energy-efficient heat pumps for space heating, cooling, and domestic hot water. These consumers are motivated by long-term energy cost savings, reduced carbon footprints, and increasing comfort levels, often influenced by government incentives and rebates that make the initial investment more palatable. The rise of smart home technologies also appeals to technologically savvy homeowners looking for integrated and automated climate control solutions.

Beyond the residential sector, commercial building owners and operators represent a substantial customer segment. This includes facilities such as office buildings, retail stores, hotels, schools, hospitals, and public institutions. For these customers, heat pump systems equipped with advanced compressors offer significant operational cost reductions due to lower energy consumption, compliance with green building certifications, and an enhanced indoor environment for occupants. The decision-making process in this segment often involves a careful analysis of total cost of ownership (TCO), return on investment (ROI), and regulatory compliance, with heat pump compressors providing a compelling case for efficiency and sustainability. Large-scale commercial projects, new constructions, and retrofitting existing HVAC infrastructure are key drivers of demand in this area.

Industrial facilities constitute another vital segment of potential customers, particularly those involved in manufacturing, processing, and other operations requiring precise temperature control or waste heat recovery. Industrial applications of heat pump compressors include process heating, cooling of machinery, and large-scale climate control for production environments. These customers are driven by the potential for significant energy savings, reduced operational expenses, and improvements in industrial process efficiency. The ability of advanced compressors to handle diverse refrigerants and operate under challenging industrial conditions makes them invaluable for optimizing energy use in complex industrial settings. Furthermore, government bodies and municipal organizations are increasingly investing in heat pump technology for public infrastructure, further expanding the customer landscape for these crucial components.

Heat Pump Compressors Market Key Technology Landscape

The Heat Pump Compressors Market is characterized by a dynamic and evolving technology landscape, continuously pushing the boundaries of efficiency, performance, and environmental sustainability. At the forefront of this innovation are variable speed drives (VSDs) or inverter technology, which allow compressors to operate at different speeds, precisely matching the heating or cooling load requirements. This capability significantly enhances energy efficiency by avoiding the energy waste associated with traditional on/off compressors, leading to substantial energy savings and improved comfort levels. The precise control offered by VSDs also reduces wear and tear, extending the lifespan of the compressor and the overall heat pump system. This technology is becoming a standard in high-efficiency heat pumps across residential and commercial applications.

Another critical area of technological advancement is the shift towards natural refrigerants such as CO2 (R744), Propane (R290), and Ammonia (R717). These refrigerants boast ultra-low global warming potential (GWP), aligning with stringent environmental regulations aimed at phasing out high-GWP HFCs. This transition necessitates significant engineering innovation in compressor design to handle the unique thermodynamic properties and higher operating pressures of natural refrigerants safely and efficiently. Manufacturers are developing specialized compressors optimized for CO2 systems, particularly for hot water applications, and for propane, which offers high efficiency in a range of temperatures. Research into new materials and lubricants is also crucial to ensure compatibility and longevity with these environmentally friendly alternatives.

Furthermore, the integration of smart technologies, including the Internet of Things (IoT) and advanced digital controls, is profoundly impacting the market. IoT-enabled compressors can transmit real-time operational data, allowing for remote monitoring, predictive maintenance, and optimized performance through cloud-based analytics. This connectivity facilitates early detection of potential issues, reduces downtime, and enables sophisticated control strategies that adapt to user preferences and external conditions. Magnetic bearings, though currently a niche technology, represent an advanced development, eliminating friction and wear associated with traditional bearings, leading to quieter operation, higher efficiency, and an extended operational life. These technological advancements collectively drive the evolution of heat pump compressors, making them more efficient, reliable, and environmentally friendly, thereby contributing significantly to global energy transition goals.

Regional Highlights

- Europe: Leading market due to ambitious decarbonization targets, strong governmental support, and substantial incentives for heat pump adoption. Countries like Germany, France, and Sweden are at the forefront, driving innovation and market penetration.

- North America: Experiencing significant growth, particularly in the US, fueled by increasing awareness, federal and state-level incentives (e.g., Inflation Reduction Act), and a growing demand for energy-efficient HVAC solutions.

- Asia-Pacific: Emerging as a high-growth region, propelled by rapid urbanization, industrialization, and increasing disposable incomes in countries like China, Japan, and South Korea, coupled with evolving environmental regulations.

- Latin America: Shows nascent but promising growth, driven by new construction, rising energy costs, and a gradual shift towards more sustainable building practices in major economies such as Brazil and Mexico.

- Middle East & Africa: Representing an untapped market with high potential, influenced by increasing infrastructure development, a growing focus on energy efficiency in new constructions, and diversification away from fossil fuels in some nations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Heat Pump Compressors Market.- Danfoss A/S

- Copeland (Emerson Electric Co.)

- Mitsubishi Electric Corporation

- Panasonic Corporation

- GMCC & Welling (Midea Group)

- Hitachi, Ltd.

- Samsung Electronics Co., Ltd.

- LG Electronics Inc.

- Bitzer SE

- Highly Inc. (Shanghai Highly (Group) Co., Ltd.)

- Tecumseh Products Company LLC

- Qingdao Haier Co., Ltd.

- Sanden Corporation

- Bristol Compressors International, LLC

- Frascold S.p.A.

Frequently Asked Questions

What is a heat pump compressor and how does it function?

A heat pump compressor is the essential component within a heat pump system responsible for circulating refrigerant and increasing its pressure and temperature. It compresses the low-pressure, low-temperature refrigerant vapor from the evaporator, causing its temperature and pressure to rise significantly. This high-pressure, high-temperature vapor then moves to the condenser, where it releases heat to the heating medium (air or water), thus facilitating the efficient transfer of thermal energy for heating or cooling applications.

What are the main types of compressors utilized in modern heat pumps?

Modern heat pumps primarily employ scroll, rotary, reciprocating, and screw compressors. Scroll compressors are highly popular for their efficiency, quiet operation, and reliability in residential and light commercial systems. Rotary compressors are compact and cost-effective for smaller units. Reciprocating compressors are robust for various applications, while screw compressors are favored for large commercial and industrial heat pump systems due to their high capacity and durability. Each type offers specific advantages depending on the applications capacity and performance requirements.

Why are heat pump compressors crucial for energy efficiency?

Heat pump compressors are crucial for energy efficiency because they enable the system to transfer heat rather than generate it, making them far more efficient than conventional heating methods. By compressing the refrigerant, they allow the heat pump to extract thermal energy from a colder source (like ambient air or ground) and release it at a higher temperature, effectively moving heat from one place to another. Advancements like variable speed drives (inverters) further enhance this efficiency by precisely matching the compressors output to the heating or cooling demand, minimizing energy waste.

What impact do refrigerants have on compressor technology and market trends?

Refrigerants have a profound impact on compressor technology and market trends, primarily driven by environmental regulations targeting global warming potential (GWP). The ongoing phase-down of high-GWP hydrofluorocarbons (HFCs) necessitates the development of compressors compatible with low-GWP alternatives, such as hydrofluoroolefins (HFOs) and natural refrigerants like CO2 (R744) and propane (R290). This shift pushes manufacturers to innovate in compressor design, materials, and safety features to accommodate the unique thermodynamic properties and operating pressures of these environmentally friendlier refrigerants, reshaping product development and market offerings.

How is the heat pump compressor market expected to evolve in the coming years?

The heat pump compressor market is expected to evolve significantly, driven by an increasing focus on energy efficiency, sustainability, and smart technology integration. Key trends include the widespread adoption of variable speed inverter compressors for optimal performance, a rapid transition towards natural refrigerants with ultra-low GWP, and the integration of AI and IoT for predictive maintenance and smart control. Furthermore, market growth will be bolstered by strong government incentives, increasing consumer awareness, and expanding applications across residential, commercial, and industrial sectors, solidifying heat pump compressors role in the global energy transition.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Air Source Heat Pump Compressors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Reciprocating Heat Pump Compressors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Hydronic Heat Pump Compressors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager