Industrial Ethernet Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430362 | Date : Nov, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Industrial Ethernet Market Size

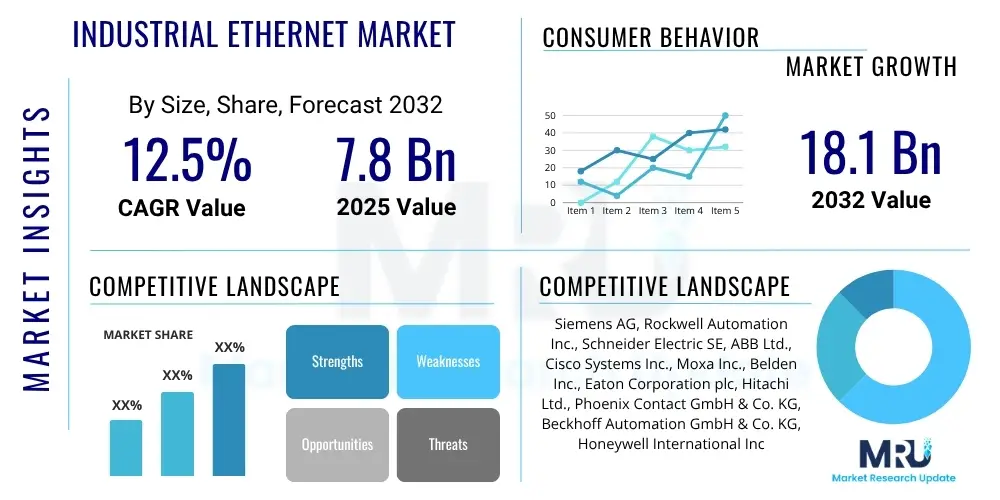

The Industrial Ethernet Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.5% between 2025 and 2032. The market is estimated at USD 7.8 Billion in 2025 and is projected to reach USD 18.1 Billion by the end of the forecast period in 2032.

Industrial Ethernet Market introduction

The Industrial Ethernet Market encompasses the network infrastructure and components designed for robust, real-time communication in industrial environments, contrasting with standard commercial Ethernet by offering enhanced durability, reliability, and deterministic capabilities crucial for operational technology (OT) systems. This advanced communication technology integrates IT and OT networks, enabling seamless data exchange across various industrial processes and equipment. It serves as the backbone for modern manufacturing, process control, and automation, facilitating the implementation of Industry 4.0 and Industrial Internet of Things (IIoT) initiatives.

Products within this market range from ruggedized switches, routers, gateways, and controllers to specialized cables and connectors, all engineered to withstand harsh industrial conditions such as extreme temperatures, vibrations, and electromagnetic interference. Major applications span across discrete manufacturing, process industries, energy, oil and gas, automotive, food and beverage, and transportation sectors, where reliable and high-speed data transfer is paramount for operational efficiency and safety. The inherent benefits of Industrial Ethernet include superior data transmission speeds, reduced latency, improved synchronization, scalability, and simplified network management, significantly boosting productivity and facilitating remote monitoring and diagnostics.

Driving factors for the market's growth are primarily the accelerating adoption of automation technologies, the widespread implementation of smart factory concepts, and the increasing need for real-time data analytics to optimize production processes. The continuous push for digital transformation across industries, coupled with the demand for predictive maintenance and enhanced operational visibility, further fuels the expansion of Industrial Ethernet solutions. Its ability to provide a unified communication platform across diverse industrial assets makes it an indispensable technology in the contemporary industrial landscape.

Industrial Ethernet Market Executive Summary

The Industrial Ethernet Market is experiencing robust expansion, fundamentally driven by pervasive business trends towards digital transformation, the establishment of smart factories, and the critical convergence of Information Technology (IT) and Operational Technology (OT) networks. These trends necessitate a reliable, high-speed, and secure communication backbone, which Industrial Ethernet inherently provides, enabling advanced automation, real-time data exchange, and the integration of IIoT devices. The market's trajectory is further influenced by the growing demand for operational efficiency, predictive maintenance capabilities, and enhanced production visibility across various industrial sectors globally, positioning Industrial Ethernet as a cornerstone technology for modern industrial operations.

Regional trends indicate significant dynamism, with Asia Pacific emerging as a dominant growth hub, propelled by rapid industrialization, extensive manufacturing activities, and substantial investments in automation technologies, particularly in countries like China, India, and Japan. North America continues to demonstrate leadership in technological innovation and early adoption, driven by strong aerospace, automotive, and oil and gas sectors, while Europe maintains a robust adoption rate, particularly in Germany, underpinned by strong Industry 4.0 initiatives and a mature manufacturing base. These regional disparities highlight diverse drivers and market penetration strategies for Industrial Ethernet providers, reflecting varying levels of industrial maturity and investment priorities.

Within the market's segmentation, component trends reveal a sustained demand for robust hardware like industrial switches, routers, and gateways, alongside a growing emphasis on intelligent software solutions for network management, SCADA, and MES, reflecting a holistic approach to network infrastructure. Furthermore, specific protocols such as PROFINET and EtherNet/IP continue to gain traction due to their widespread adoption and comprehensive ecosystems, while emerging technologies like Time-Sensitive Networking (TSN) are poised to revolutionize deterministic communication. The evolution of these segments underscores the market's continuous innovation aimed at addressing complex industrial communication challenges and meeting the escalating requirements for interconnected, efficient, and resilient industrial networks.

AI Impact Analysis on Industrial Ethernet Market

Users frequently inquire about how Artificial Intelligence (AI) can significantly enhance the capabilities of Industrial Ethernet, improve network efficiency, bolster cybersecurity, and enable novel applications within industrial settings. Key themes revolve around leveraging AI for predictive analytics in network management, optimizing data flow for real-time operations, and ensuring network integrity against evolving threats. Users express expectations that AI will not only automate complex network configurations and troubleshooting but also unlock new levels of operational intelligence by analyzing vast amounts of industrial data transmitted over Ethernet networks, leading to more autonomous and resilient industrial systems.

- AI-driven predictive maintenance for network infrastructure reduces downtime.

- Optimized data routing and traffic management improve network performance and reduce latency.

- Enhanced cybersecurity through AI-powered anomaly detection and threat response.

- Facilitation of autonomous operations and decision-making at the edge by analyzing real-time data.

- Improved resource allocation and energy efficiency in industrial networks.

- Enabling sophisticated data analytics for process optimization and quality control.

- Simplification of complex network configurations and troubleshooting through intelligent automation.

- Development of self-healing network capabilities through AI algorithms.

DRO & Impact Forces Of Industrial Ethernet Market

The Industrial Ethernet Market is profoundly shaped by a confluence of accelerating drivers, persistent restraints, emerging opportunities, and dynamic impact forces. Key drivers include the pervasive adoption of Industry 4.0 and the Industrial Internet of Things (IIoT), which demand high-speed, reliable, and deterministic communication networks for interconnected devices and systems. The escalating need for advanced automation in manufacturing, coupled with the critical requirement for real-time data for operational optimization and predictive analytics, further fuels market expansion. Additionally, the ongoing convergence of Information Technology (IT) and Operational Technology (OT) networks necessitates robust Industrial Ethernet solutions capable of bridging these previously disparate domains, offering a unified and secure communication infrastructure across the enterprise. These factors collectively push industries towards modernizing their communication backbones, favoring Industrial Ethernet for its superior capabilities over traditional fieldbus systems.

However, the market also faces notable restraints that can impede its growth trajectory. The substantial initial investment required for deploying Industrial Ethernet infrastructure, alongside the inherent complexity of integrating new systems with legacy equipment, often poses significant barriers for adoption, particularly for smaller and medium-sized enterprises. Concerns surrounding cybersecurity threats and data privacy are paramount, as the increasing connectivity of industrial networks creates new vulnerabilities that necessitate robust protection measures. Moreover, a prevailing lack of skilled workforce capable of designing, implementing, and maintaining complex Industrial Ethernet networks remains a critical challenge. These restraints necessitate innovative solutions and strategic planning from vendors to mitigate risks and facilitate broader market penetration, addressing both cost and technical proficiency gaps.

Despite the challenges, numerous opportunities are poised to drive the Industrial Ethernet Market forward. The emergence of Time-Sensitive Networking (TSN) is a transformative development, offering deterministic communication capabilities crucial for highly demanding applications and setting new standards for industrial network performance. The integration of 5G technology promises to unlock new possibilities for wireless industrial applications, providing unprecedented flexibility and mobility within smart factories. Furthermore, the burgeoning growth of edge computing and cloud integration in industrial environments enhances data processing capabilities closer to the source and enables scalable data storage and analytics. The expansion of Industrial Ethernet into new vertical markets, such as smart cities, critical infrastructure, and advanced logistics, presents significant growth avenues, diversifying its application scope. These opportunities, combined with the underlying impact forces, define a competitive landscape where innovation, strategic partnerships, and customer-centric solutions are vital for market success, constantly evolving to meet the complex demands of modern industry.

Segmentation Analysis

The Industrial Ethernet Market is comprehensively segmented across various dimensions to provide a granular understanding of its components, protocols, applications, and end-user industries. This segmentation helps in analyzing market dynamics, identifying growth opportunities, and understanding the varying demands across different sectors. The primary segments include components, which detail the hardware, software, and services constituting the network; protocols, which differentiate between the various communication standards used; applications, highlighting the specific industrial uses; and end-user industries, categorizing the sectors benefiting from Industrial Ethernet. Further segmentation by cable type offers insights into the physical infrastructure preferences.

- By Component:

- Hardware: Switches, Routers, Gateways, Hubs, Connectors, Adapters, Controllers, Others (Cables, Network Interface Cards)

- Software: SCADA, MES, HMI, Network Management Software, Data Acquisition Software

- Services: Installation, Maintenance & Support, Consulting, Training, System Integration

- By Protocol:

- PROFINET

- EtherNet/IP

- EtherCAT

- Modbus TCP

- CC-Link IE

- POWERLINK

- SERCOS III

- Others (FL-net, Vnet/IP, etc.)

- By Application:

- Factory Automation

- Process Automation

- Energy & Power

- Oil & Gas

- Automotive

- Food & Beverage

- Chemicals

- Water & Wastewater Management

- Transportation

- Mining

- Aerospace & Defense

- Pharmaceuticals & Biotechnology

- Logistics & Warehousing

- By End-User Industry:

- Manufacturing (Discrete, Process)

- Utilities

- Automotive

- Oil & Gas

- Metals & Mining

- Chemicals

- Food & Beverage

- Pharmaceuticals

- Aerospace & Defense

- Pulp & Paper

- Building Automation

- By Cable Type:

- Copper Cable

- Fiber Optic Cable

- Wireless (Emerging)

Value Chain Analysis For Industrial Ethernet Market

The value chain for the Industrial Ethernet Market begins with upstream activities involving the procurement and manufacturing of foundational components. This segment includes suppliers of semiconductors, specialized metals, polymers, and electronic components essential for creating ruggedized switches, routers, connectors, and controllers. These raw material and component providers are critical in defining the quality, cost, and availability of the basic building blocks of Industrial Ethernet systems. Their ability to innovate, ensure supply chain resilience, and meet specific industrial standards directly impacts the production capabilities of Industrial Ethernet equipment manufacturers. The competitive landscape at this stage is driven by technological advancements and the ability to produce high-performance, durable materials that can withstand harsh industrial environments.

Moving downstream, the value chain extends to the manufacturing, integration, and distribution of complete Industrial Ethernet solutions. This involves original equipment manufacturers (OEMs) who design and assemble the networking devices, protocol developers who ensure interoperability, and system integrators who customize and implement these solutions into complex industrial environments. Distribution channels play a crucial role in delivering products to end-users, encompassing both direct sales forces that handle large enterprise accounts and indirect channels such as distributors, value-added resellers (VARs), and solution providers. These indirect partners often offer localized support, specialized expertise, and tailored services, forming a critical link between technology providers and diverse industrial customers. The efficiency and reach of these distribution networks are vital for market penetration and customer accessibility.

Ultimately, the value chain culminates with the end-users and the provision of post-sales support and services. End-users, ranging from discrete and process manufacturers to utility companies and transportation sectors, leverage Industrial Ethernet for automation, control, and data acquisition. Post-sales services, including installation, maintenance, technical support, and training, are increasingly important for ensuring the long-term reliability and optimal performance of Industrial Ethernet networks. This stage often involves service providers and integrators who offer ongoing support and upgrades, contributing significantly to customer satisfaction and loyalty. The seamless flow of products and services through these upstream and downstream activities, supported by effective direct and indirect distribution, defines the overall efficiency and competitiveness of the Industrial Ethernet market value chain.

Industrial Ethernet Market Potential Customers

Potential customers for Industrial Ethernet products and services are diverse and span across nearly every sector undergoing digital transformation and automation initiatives. These end-users and buyers are primarily organizations that require robust, high-speed, and reliable communication infrastructure to connect operational technology (OT) with information technology (IT) systems, facilitate real-time data exchange, and enable advanced control processes. Manufacturing plants, both discrete and process, represent a significant customer base, leveraging Industrial Ethernet to implement smart factory concepts, enhance production line efficiency, and integrate robotics and autonomous systems. These include automotive assembly lines, food and beverage processing facilities, chemical plants, and pharmaceutical manufacturing sites, all of which depend on precise and synchronized operations.

Beyond traditional manufacturing, the utility sector, encompassing power generation, transmission, and distribution, as well as water and wastewater management, increasingly adopts Industrial Ethernet for smart grid applications, remote monitoring of infrastructure, and improved operational control. The oil and gas industry utilizes these networks for exploration, extraction, refining, and pipeline monitoring, demanding highly resilient communication in harsh environments. Transportation infrastructure, including railway systems, airport operations, and smart road networks, relies on Industrial Ethernet for traffic management, signaling, and passenger information systems, ensuring safety and efficiency. Furthermore, the growth of smart cities projects drives demand for interconnected public services and infrastructure, presenting new opportunities for Industrial Ethernet deployment.

Emerging and specialized sectors also contribute to the potential customer base. Logistics and warehousing operations implement Industrial Ethernet to manage automated storage and retrieval systems (AS/RS), conveyor belts, and robotic sorting systems, optimizing supply chain efficiency. Mining operations use ruggedized Industrial Ethernet for communication in demanding underground and open-pit environments, supporting automation and safety systems. Even industries such as marine and aerospace are adopting these solutions for onboard networking and ground control systems. The common thread among these varied end-users is the critical need for a communication backbone that can support the increasing complexity and interconnectedness of modern industrial operations, making Industrial Ethernet an indispensable technology for improving productivity, safety, and competitiveness across a broad spectrum of industries.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 7.8 Billion |

| Market Forecast in 2032 | USD 18.1 Billion |

| Growth Rate | 12.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, Rockwell Automation Inc., Schneider Electric SE, ABB Ltd., Cisco Systems Inc., Moxa Inc., Belden Inc., Eaton Corporation plc, Hitachi Ltd., Phoenix Contact GmbH & Co. KG, Beckhoff Automation GmbH & Co. KG, Honeywell International Inc., Advantech Co. Ltd., Mitsubishi Electric Corporation, Bosch Rexroth AG, Omron Corporation, Yokogawa Electric Corporation, Hirschmann Automation and Control GmbH, WAGO Kontakttechnik GmbH & Co. KG, Endress+Hauser Group Services AG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Ethernet Market Key Technology Landscape

The Industrial Ethernet Market's technology landscape is characterized by continuous innovation aimed at enhancing network performance, reliability, and security to meet the evolving demands of Industry 4.0 and IIoT. A pivotal technological advancement is Time-Sensitive Networking (TSN), a set of IEEE 802.1 standards that enable deterministic, real-time communication over standard Ethernet. TSN ensures guaranteed message delivery and ultra-low latency, making it ideal for motion control, robotics, and other time-critical applications that previously required specialized fieldbus systems. This technology is instrumental in bridging the gap between IT and OT, facilitating the seamless integration of diverse industrial applications onto a single, converged network. The adoption of TSN is expected to significantly drive market growth by enabling more advanced and synchronized industrial processes.

Another emerging technology gaining traction is Single Pair Ethernet (SPE), which extends Ethernet capabilities over a single pair of wires, reducing cabling costs, space, and weight, particularly beneficial for sensor-to-cloud applications and the integration of smaller devices in the field. SPE supports power delivery over data lines (PoDL) and offers a cost-effective solution for deploying Ethernet into the farthest corners of industrial plants and intelligent buildings. Concurrently, the integration of 5G wireless technology is transforming industrial communication, offering high bandwidth, low latency, and massive connectivity for mobile assets, remote monitoring, and flexible factory layouts. 5G complements wired Industrial Ethernet by providing wireless communication where cables are impractical, enabling highly dynamic and reconfigurable production environments, further pushing the boundaries of factory automation and operational flexibility.

Furthermore, the technology landscape is being shaped by advancements in industrial cybersecurity solutions, which are becoming increasingly critical as more OT systems connect to enterprise networks and the internet. These solutions include network segmentation, intrusion detection systems, secure remote access, and advanced authentication protocols designed specifically for industrial control systems (ICS). The adoption of OPC UA (Open Platform Communications Unified Architecture) continues to be significant as a robust, secure, and open standard for vertical and horizontal communication, facilitating data exchange between devices, machines, and cloud applications across different vendors. Additionally, the proliferation of edge computing platforms and cloud-native industrial solutions further enhances the processing and analytical capabilities of Industrial Ethernet networks, enabling real-time insights, predictive maintenance, and autonomous operations by distributing computational power closer to the data source.

Regional Highlights

- North America: This region is a leading adopter of Industrial Ethernet, driven by significant investments in smart manufacturing, advanced automation, and the integration of IIoT across sectors like automotive, aerospace, oil and gas, and food & beverage. The presence of major technology providers and a strong emphasis on industrial innovation contribute to its substantial market share.

- Europe: Characterized by mature industrial economies, particularly Germany's strong focus on Industry 4.0 initiatives, Europe exhibits high adoption rates. The region benefits from stringent regulatory frameworks, a robust manufacturing base, and extensive research and development in industrial automation, with significant uptake in automotive, chemicals, and machinery industries.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, fueled by rapid industrialization, expanding manufacturing sectors, and substantial government investments in smart factory projects in countries such as China, India, Japan, and South Korea. The increasing demand for automation in electronics, automotive, and consumer goods manufacturing drives significant market expansion.

- Latin America: An emerging market for Industrial Ethernet, Latin America shows increasing investment in infrastructure development, mining, and process industries. Economic growth and a growing recognition of the benefits of automation are slowly but steadily driving market adoption, particularly in countries like Brazil and Mexico.

- Middle East and Africa (MEA): This region is experiencing growth driven by diversification efforts away from oil and gas, with investments in smart city projects, infrastructure development, and industrial automation. Countries in the Gulf Cooperation Council (GCC) are leading the adoption, aiming to modernize their industrial bases and enhance operational efficiency.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Ethernet Market.- Siemens AG

- Rockwell Automation Inc.

- Schneider Electric SE

- ABB Ltd.

- Cisco Systems Inc.

- Moxa Inc.

- Belden Inc.

- Eaton Corporation plc

- Hitachi Ltd.

- Phoenix Contact GmbH & Co. KG

- Beckhoff Automation GmbH & Co. KG

- Honeywell International Inc.

- Advantech Co. Ltd.

- Mitsubishi Electric Corporation

- Bosch Rexroth AG

- Omron Corporation

- Yokogawa Electric Corporation

- Hirschmann Automation and Control GmbH

- WAGO Kontakttechnik GmbH & Co. KG

- Endress+Hauser Group Services AG

Frequently Asked Questions

What is Industrial Ethernet?

Industrial Ethernet refers to the use of Ethernet in an industrial environment with ruggedized components and specialized protocols to ensure reliable, real-time data communication for automation and control systems, differing from standard office Ethernet by its enhanced durability and deterministic performance.

What are the primary benefits of using Industrial Ethernet?

The main benefits include high-speed data transfer, improved network reliability and robustness, real-time communication capabilities, simplified integration with enterprise IT systems, scalability for future expansion, and reduced installation and maintenance costs compared to traditional fieldbus systems.

How does Industrial Ethernet differ from traditional office Ethernet?

Industrial Ethernet components are designed to withstand harsh industrial conditions such as extreme temperatures, vibrations, and electromagnetic interference. It also incorporates specific protocols and technologies like Time-Sensitive Networking (TSN) to ensure deterministic, real-time data delivery critical for industrial control, which standard Ethernet does not prioritize.

What are the key communication protocols used in Industrial Ethernet?

Key protocols include PROFINET, EtherNet/IP, EtherCAT, Modbus TCP, and CC-Link IE. These protocols extend standard Ethernet with industrial-specific capabilities to provide deterministic data exchange, facilitate device configuration, and ensure robust communication for control applications.

What role does Time-Sensitive Networking (TSN) play in the Industrial Ethernet Market?

TSN is crucial for Industrial Ethernet as it introduces deterministic capabilities to standard Ethernet, guaranteeing timely data delivery and ultra-low latency. This enables the convergence of IT and OT networks onto a single, synchronized infrastructure, supporting highly time-critical applications like motion control and robotics for Industry 4.0.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Industrial Ethernet Cables Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Industrial Ethernet Switch Market Size Report By Type (Managed and Unmanaged), By Application (Manufacturing, Electric and Power, Aerospace and Defense, Automotive and Transportation, Oil and Gas, and Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Industrial Ethernet Market Statistics 2025 Analysis By Application (Electric Power, Transportation, Oil & Gas), By Type (Ethemet/IP, PROFINET, EtherCAT, Mobbus TCP/IP, POWERLINK, Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Industrial Ethernet or IP Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Hardware, Software, Services), By Application (Automotive, Electrical and Electronics, Aerospace and Defense, Oil and Gas, Water and Wastewater, Food and Beverages, Pharmaceutical, Energy and Power Generation, Mining, Chemical, Petrochemicals and Fertilizers, Engineering/Fabrication), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

- Industrial Ethernet or IP Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Factory Automation, Supervisory Control), By Application (Discrete Industries, Process Industries), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager