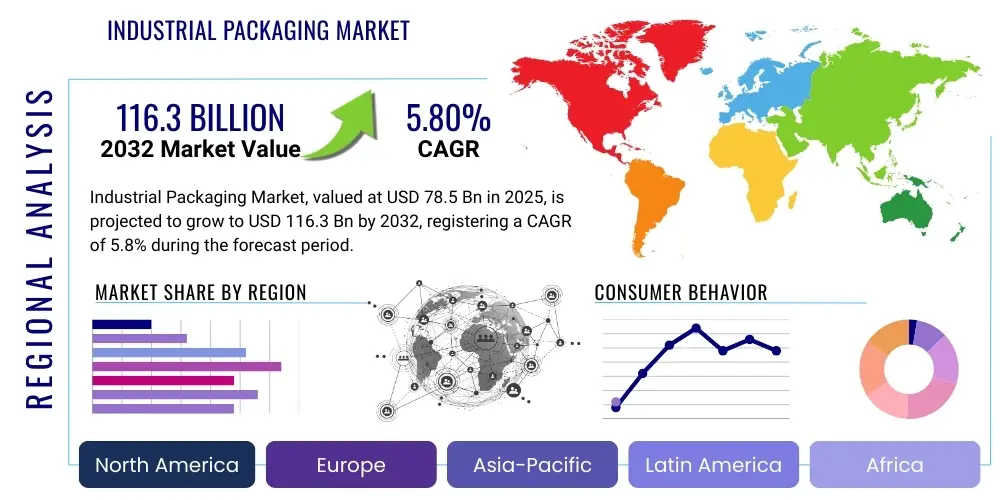

Industrial Packaging Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427754 | Date : Oct, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Industrial Packaging Market Size

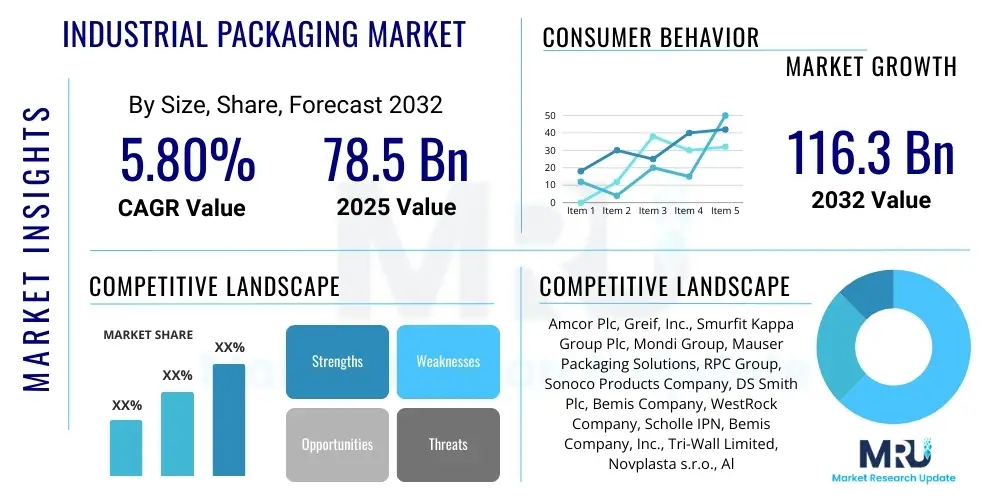

The Industrial Packaging Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 78.5 billion in 2025 and is projected to reach USD 116.3 billion by the end of the forecast period in 2032.

Industrial Packaging Market introduction

The Industrial Packaging Market encompasses a broad range of products designed for the safe and efficient containment, protection, and transportation of goods within industrial supply chains. These specialized packaging solutions are critical for managing bulk quantities of raw materials, intermediate products, and finished goods, ensuring their integrity from manufacturing sites to distribution centers and end-users. Unlike consumer packaging, industrial packaging prioritizes durability, capacity, and logistical efficiency, catering primarily to business-to-business (B2B) transactions across diverse sectors.

Key product types include drums, Intermediate Bulk Containers (IBCs), sacks, pails, crates, and specialized films, manufactured from materials such as plastic, metal, wood, and paperboard. These solutions find major applications in industries like chemicals, pharmaceuticals, food and beverage, agriculture, construction, and automotive, where they safeguard products against contamination, damage, and environmental factors. The inherent benefits of industrial packaging include enhanced product protection, optimized logistics, cost-effectiveness through bulk handling, and compliance with stringent safety and regulatory standards.

Driving factors for market growth include the robust expansion of global industrial production, the increasing complexity of supply chains demanding more resilient packaging, and the rising demand for bulk transportation solutions across emerging economies. Additionally, advancements in material science leading to more durable and sustainable packaging options, coupled with the growing emphasis on efficient warehousing and distribution, continue to fuel market expansion. The markets evolution is also shaped by technological integration, aiming for improved traceability and environmental performance.

Industrial Packaging Market Executive Summary

The Industrial Packaging Market is experiencing dynamic growth, driven by an expanding global manufacturing sector and increasingly intricate supply chain demands. Business trends indicate a strong focus on automation, sustainability, and digital integration within packaging operations, aiming to enhance efficiency, reduce costs, and minimize environmental impact. Companies are investing in advanced materials and smart packaging solutions to meet evolving regulatory requirements and customer expectations for product integrity and traceability.

Regional trends highlight the Asia Pacific as a dominant and rapidly growing market, propelled by rapid industrialization, urbanization, and burgeoning export activities, particularly in countries like China and India. North America and Europe continue to be significant markets, characterized by demand for high-performance, sustainable, and technologically advanced packaging solutions, driven by stringent environmental regulations and a focus on circular economy principles. Emerging economies in Latin America, the Middle East, and Africa are also showing promising growth, fueled by infrastructure development and increasing industrial output.

Segment trends reveal a sustained demand for plastic and metal packaging due to their durability and protective qualities, alongside a significant shift towards more eco-friendly options, including recycled content and biodegradable materials. Intermediate Bulk Containers (IBCs) and drums remain crucial for bulk liquid and semi-liquid transport, while sacks and flexible packaging solutions are gaining traction for dry goods dueowing to their cost-effectiveness and versatility. The food and beverage, chemical, and pharmaceutical industries continue to be primary end-users, with increasing demand for specialized, compliant, and secure packaging.

AI Impact Analysis on Industrial Packaging Market

Common user questions regarding AIs impact on the Industrial Packaging Market often revolve around efficiency gains, cost reductions, automation of complex processes, and improved sustainability. Users are keen to understand how AI can optimize packaging lines, enhance quality control, predict maintenance needs for machinery, and streamline supply chain logistics. Concerns frequently include the initial investment required, data privacy, and the need for skilled labor to manage AI-driven systems, balanced by expectations of significant operational improvements and a competitive edge.

AIs influence is transforming industrial packaging operations by enabling predictive analytics, sophisticated automation, and intelligent decision-making across the entire value chain. From optimizing material usage and reducing waste to enhancing product traceability and ensuring compliance, AI solutions offer a new paradigm for efficiency and sustainability. The integration of machine learning algorithms allows for real-time monitoring of packaging quality, proactive identification of equipment malfunctions, and dynamic adjustment of production schedules, leading to significant operational improvements and reduced downtime.

- Enhanced Automation: AI-powered robots and vision systems for precise sorting, packing, and quality inspection, reducing manual labor and errors.

- Predictive Maintenance: Algorithms analyze sensor data from packaging machinery to forecast potential failures, enabling proactive maintenance and minimizing downtime.

- Supply Chain Optimization: AI optimizes inventory management, warehouse layout, and logistics routes, leading to more efficient distribution of packaged goods.

- Quality Control: Machine vision systems with AI detect defects, ensuring higher quality standards and reducing product recalls.

- Waste Reduction: AI algorithms optimize material consumption and identify opportunities for reducing packaging waste throughout the production process.

- Demand Forecasting: Predictive AI models enhance accuracy in forecasting packaging material needs, preventing overstocking or shortages.

- Smart Packaging: Integration of AI with IoT sensors for real-time monitoring of package condition, temperature, and location during transit.

DRO & Impact Forces Of Industrial Packaging Market

The Industrial Packaging Market is shaped by a confluence of driving forces, inherent restraints, promising opportunities, and overarching impact forces. Key drivers include the consistent growth of global industrial output, particularly in manufacturing and processing sectors, which directly escalates the demand for robust and protective packaging solutions. Furthermore, the expansion of e-commerce into B2B sectors necessitates more resilient and trackable packaging for bulk goods, while increasing international trade volumes amplify the need for standardized and secure industrial packaging for cross-border logistics.

Restraints on market growth primarily stem from the volatility of raw material prices, particularly for plastics and metals, which can impact manufacturing costs and profit margins. Stringent environmental regulations and evolving sustainability mandates across various regions pose challenges, requiring significant investment in research and development for eco-friendly materials and processes. Additionally, the high initial capital expenditure associated with advanced packaging machinery and automation technologies can deter smaller manufacturers from adopting state-of-the-art solutions, potentially slowing market modernization.

Opportunities within the market are abundant, particularly in the realm of sustainable and smart packaging. The development of biodegradable plastics, recycled content materials, and reusable industrial packaging solutions presents significant growth avenues as industries strive for circular economy principles. The integration of IoT, AI, and blockchain technologies into packaging offers opportunities for enhanced traceability, real-time monitoring, and supply chain transparency. Emerging economies, with their ongoing industrialization and infrastructural development, also represent untapped potential for market expansion.

Impact forces such as technological advancements are profoundly reshaping the market, leading to innovations in material science, automated packaging lines, and digital monitoring systems. Regulatory pressures, especially those related to environmental protection and product safety, compel manufacturers to innovate and comply, influencing material choices and design. Moreover, shifting end-user preferences for lighter, more efficient, and environmentally responsible packaging solutions are compelling market players to adapt their offerings and invest in more sustainable practices, driving continuous evolution.

Segmentation Analysis

The Industrial Packaging Market is extensively segmented to provide a detailed understanding of its diverse components and applications. This segmentation allows for precise market analysis, highlighting specific growth areas, competitive landscapes, and technological advancements within each category. The primary segmentation criteria typically include material type, product type, and end-use industry, each reflecting distinct characteristics and market dynamics that influence overall market trends and strategic decision-making.

Each segment caters to unique requirements within the industrial supply chain, ranging from the fundamental protection of goods during transit to specialized containment for hazardous materials. Understanding these segments is crucial for manufacturers to tailor their product offerings, for distributors to optimize their supply chains, and for end-users to select the most appropriate and compliant packaging solutions for their specific operational needs. The ongoing evolution within these segments, driven by technological innovations and sustainability imperatives, continually reshapes the market landscape.

- By Material Type

- Plastic (e.g., HDPE, LDPE, PET)

- Metal (e.g., Steel, Aluminum)

- Wood (e.g., Plywood, Solid Wood)

- Paper & Paperboard (e.g., Corrugated Board, Solid Board)

- Others (e.g., Fabric, Composites)

- By Product Type

- Drums (e.g., Plastic Drums, Steel Drums, Fiber Drums)

- Intermediate Bulk Containers (IBCs) (e.g., Rigid IBCs, Flexible IBCs)

- Sacks (e.g., Woven Sacks, Paper Sacks, Plastic Sacks)

- Pails (e.g., Plastic Pails, Metal Pails)

- Crates and Boxes (e.g., Wooden Crates, Plastic Crates)

- Flexible Industrial Packaging (e.g., Industrial Bags, Wraps, Liners)

- Others (e.g., Industrial Films, Pallet Wraps)

- By End-Use Industry

- Chemicals and Petrochemicals

- Food and Beverage (B2B applications)

- Pharmaceuticals

- Agriculture and Horticulture

- Building and Construction

- Automotive

- Oil and Lubricants

- Others (e.g., Mining, Electronics, General Manufacturing)

Industrial Packaging Market Value Chain Analysis

The Industrial Packaging Markets value chain is a complex network spanning from raw material sourcing to the final end-user consumption and, increasingly, to end-of-life management. Upstream activities involve the extraction and processing of fundamental raw materials such as crude oil for plastics, iron ore for steel, timber for wood, and pulp for paperboard. Suppliers of these materials play a critical role, as their pricing and availability directly influence the cost structure and production capabilities of packaging manufacturers. Innovation in this segment often focuses on developing sustainable and cost-effective material alternatives.

Midstream activities are dominated by industrial packaging manufacturers who transform raw materials into finished packaging products like drums, IBCs, sacks, and pails. This stage involves significant investment in manufacturing technologies, including injection molding, blow molding, metal forming, and corrugated board production. Manufacturers also engage in research and development to enhance product durability, compliance with industry standards, and integration of smart features. The efficiency of production and adherence to quality control are paramount at this stage.

Downstream analysis focuses on the distribution channels and end-users. Industrial packaging reaches its customers primarily through direct sales from manufacturers for large-volume orders, or through a network of distributors and wholesalers who cater to smaller businesses or specific regional markets. The choice of distribution channel often depends on the product type, order volume, and geographic reach. End-users are diverse, including chemical manufacturers, food processors, pharmaceutical companies, construction firms, and automotive industries, each requiring specific packaging solutions tailored to their product characteristics and logistical needs. The after-sales service, including technical support and recycling services, also forms an important part of the downstream value chain.

Industrial Packaging Market Potential Customers

The Industrial Packaging Market serves a diverse array of end-users and buyers, spanning across nearly all manufacturing and processing sectors that require bulk or specialized containment and transport solutions. These potential customers are primarily B2B entities that purchase packaging not for retail display, but for the functional purpose of protecting, storing, and shipping their products efficiently and safely through complex supply chains. Their purchasing decisions are heavily influenced by factors such as product type, volume, regulatory compliance, logistical requirements, and increasingly, sustainability attributes.

Key potential customers include large-scale chemical and petrochemical companies that require robust drums, IBCs, and specialty containers for hazardous and non-hazardous liquids and solids. Manufacturers in the food and beverage industry, particularly those dealing with ingredients, concentrates, or bulk finished products, utilize industrial packaging for hygiene, preservation, and high-volume transport. The pharmaceutical sector relies on highly compliant and secure industrial packaging to ensure the integrity and safety of active pharmaceutical ingredients and bulk drug products, often requiring specific material certifications and track-and-trace capabilities.

Furthermore, the agricultural industry uses sacks and large bulk bags for fertilizers, seeds, and harvested crops, while the building and construction sector demands durable packaging for cement, aggregates, and various construction materials. Automotive original equipment manufacturers (OEMs) and their suppliers utilize industrial packaging for parts and components, often requiring specialized designs for protection during transit and assembly. The electronics industry, although traditionally associated with smaller packaging, also uses industrial solutions for bulk components and sub-assemblies. These diverse end-users drive continuous innovation in the industrial packaging market, pushing for more efficient, sustainable, and technologically integrated solutions.

Industrial Packaging Market Key Technology Landscape

The Industrial Packaging Market is undergoing a significant technological transformation, driven by demands for increased efficiency, enhanced sustainability, and improved product protection and traceability. Innovations in material science are at the forefront, with a strong focus on developing lighter yet stronger materials, incorporating recycled content, and creating biodegradable or compostable alternatives to traditional plastics. Advanced composites, multi-layer films with enhanced barrier properties, and smart coatings that offer anti-corrosion or antimicrobial benefits are becoming increasingly prevalent, extending product shelf-life and reducing waste.

Automation and robotics are revolutionizing industrial packaging lines, leading to higher throughput, reduced labor costs, and improved accuracy. Robotic arms are deployed for precise filling, sealing, palletizing, and de-palletizing tasks, while automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) optimize internal logistics and warehousing operations. Machine vision systems, often powered by Artificial Intelligence, are critical for real-time quality control, defect detection, and ensuring compliance with packaging standards, minimizing errors and improving product integrity before shipment.

The integration of digital technologies, such as the Internet of Things (IoT) and blockchain, is creating "smart" industrial packaging solutions. IoT sensors embedded within packaging or attached to containers provide real-time data on temperature, humidity, shock, and location during transit, offering unparalleled traceability and condition monitoring. Blockchain technology is being explored to create immutable records of a products journey through the supply chain, enhancing transparency, combating counterfeiting, and facilitating efficient recalls. These digital advancements are enabling a new era of data-driven decision-making and optimized supply chain management within the industrial packaging sector.

Regional Highlights

- Asia Pacific: This region stands as the largest and fastest-growing market for industrial packaging, primarily driven by rapid industrialization, robust manufacturing growth, and increasing trade activities in countries like China, India, Japan, and South Korea. The expanding chemical, pharmaceutical, and food processing industries, coupled with rising disposable incomes leading to higher consumption, fuel the demand for bulk and specialized packaging. Government initiatives supporting manufacturing and infrastructure development further accelerate market expansion.

- North America: A mature market characterized by significant technological adoption and a strong emphasis on sustainability and automation. The demand is fueled by the chemical, automotive, and food and beverage sectors, alongside a growing e-commerce penetration in B2B logistics. Investments in smart packaging and advanced materials for enhanced traceability and environmental performance are prominent trends. Stringent regulations regarding product safety and environmental impact also shape market dynamics here.

- Europe: This region is a key innovator in sustainable industrial packaging solutions, driven by rigorous environmental policies and a strong push towards a circular economy. Countries such as Germany, France, and the UK lead in adopting reusable packaging systems, high-recycled content materials, and advanced recycling technologies. The chemical, pharmaceutical, and manufacturing industries contribute significantly to market demand, with a focus on compliance, efficiency, and reducing carbon footprint.

- Latin America: An emerging market exhibiting considerable growth potential, spurred by industrial expansion, particularly in Brazil, Mexico, and Argentina. The agriculture, food and beverage, and construction sectors are major consumers of industrial packaging. Increasing foreign investments and improving infrastructure are contributing to market development, though challenges related to economic stability and infrastructure still exist.

- Middle East & Africa (MEA): This region is experiencing steady growth, propelled by investments in oil and gas, infrastructure development, and an expanding manufacturing base. The demand for industrial packaging is driven by the chemical, construction, and agricultural sectors. As economic diversification efforts continue, the market is expected to witness further expansion, with a growing focus on local production and import substitution.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Packaging Market.- Amcor Plc

- Greif, Inc.

- Smurfit Kappa Group Plc

- Mondi Group

- Mauser Packaging Solutions

- RPC Group (now part of Berry Global Group, Inc.)

- Sonoco Products Company

- DS Smith Plc

- Bemis Company (now part of Amcor Plc)

- WestRock Company

- Scholle IPN (now part of SIG Combibloc Group)

- Bemis Company, Inc.

- Tri-Wall Limited

- Novplasta s.r.o.

- Alpha Packaging

- International Paper

Frequently Asked Questions

What is industrial packaging?

Industrial packaging refers to specialized containers and materials designed for the protection, storage, and transport of bulk goods, raw materials, and finished products within business-to-business supply chains. It prioritizes durability, capacity, and logistical efficiency over retail aesthetics, serving industries like chemicals, food and beverage, pharmaceuticals, and construction.

What are the key drivers for the Industrial Packaging Markets growth?

Key drivers include the expansion of global industrial production, increased international trade, the growth of e-commerce in B2B sectors, and rising demand for efficient and safe bulk transportation solutions. Technological advancements in materials and automation also contribute significantly to market growth.

What are the primary types of industrial packaging?

The primary types of industrial packaging include drums (plastic, steel, fiber), Intermediate Bulk Containers (IBCs), sacks (woven, paper, plastic), pails, crates, and various forms of flexible industrial packaging like wraps and liners. These vary by material, capacity, and application.

How is sustainability impacting the Industrial Packaging Market?

Sustainability is a major impact force, driving innovation towards eco-friendly materials such as recycled plastics, biodegradable options, and reusable packaging systems. Manufacturers are focusing on reducing material usage, optimizing designs for recycling, and incorporating circular economy principles to meet evolving regulations and customer demand for greener solutions.

What role does technology play in modern industrial packaging?

Technology plays a crucial role through automation (robotics, AGVs), advanced material science (lighter, stronger, smarter materials), and digital integration (IoT sensors for real-time tracking, AI for predictive maintenance and quality control, blockchain for traceability). These innovations enhance efficiency, reduce costs, improve product protection, and streamline supply chain management.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Rigid Industrial Packaging Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Industrial Packaging Materials Market Statistics 2025 Analysis By Application (Food and Beverage Industries, Medical Industry, Cosmetics Industry, Electronics Industry, Others), By Type (Paper, Wood, Foam Resins, Plastics), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager