Jaw Crushers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427789 | Date : Oct, 2025 | Pages : 254 | Region : Global | Publisher : MRU

Jaw Crushers Market Size

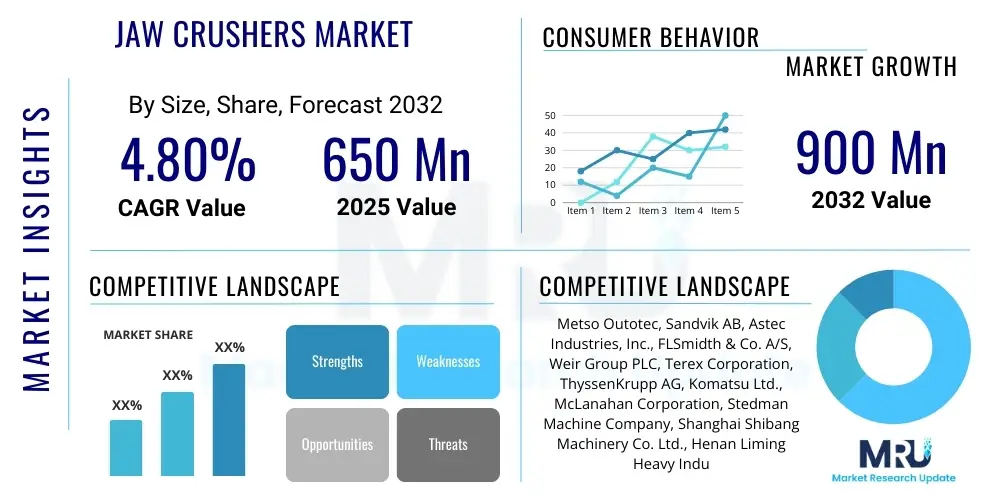

The Jaw Crushers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032. The market is estimated at USD 650 Million in 2025 and is projected to reach USD 900 Million by the end of the forecast period in 2032. This substantial growth is primarily driven by escalating demand from the global construction industry, particularly in infrastructure development and urbanization projects, which require vast quantities of crushed aggregates. Furthermore, the robust recovery and expansion of the mining sector, especially in emerging economies, are significant contributors to the market’s upward trajectory, necessitating efficient primary crushing equipment.

Jaw Crushers Market introduction

The Jaw Crushers Market encompasses the global sales and distribution of primary crushing equipment designed to reduce the size of large rocks and ore materials. Jaw crushers operate by compressing material between a fixed jaw and a movable jaw, utilizing a toggle mechanism or a hydraulic system to achieve the crushing action. These robust machines are integral to various heavy industries, providing foundational processing for subsequent material handling and refinement. Major applications span across the construction sector, where they produce aggregates for concrete and asphalt, and in the mining industry for processing various metallic and non-metallic ores. Benefits include their high reliability, low operational costs, and the ability to handle a wide range of feed materials, making them indispensable in quarrying, recycling, and mineral processing operations. Key driving factors for market expansion include accelerating infrastructure development, increasing demand for construction aggregates, growth in global mining activities, and the rising adoption of recycling practices for construction and demolition waste.

Jaw Crushers Market Executive Summary

The Jaw Crushers Market is experiencing robust growth, propelled by strong business trends in global infrastructure development and the revitalization of the mining sector. Technological advancements are leading to more efficient, durable, and environmentally compliant crushing solutions, enhancing productivity and reducing operational expenditures for end-users. Regional trends indicate significant expansion in Asia Pacific, driven by rapid urbanization and extensive construction projects, while North America and Europe demonstrate steady demand supported by recycling initiatives and infrastructure upgrades. Segment-wise, the market sees continued dominance from large-capacity crushers due to high-volume processing requirements in mining and quarrying, alongside growing demand for mobile and semi-mobile units offering operational flexibility. The integration of digital technologies and automation is also shaping segment preferences, optimizing machine performance and maintenance schedules. Overall, the market remains dynamic, characterized by continuous innovation aimed at improving efficiency, sustainability, and adaptability to diverse application needs.

AI Impact Analysis on Jaw Crushers Market

The integration of Artificial Intelligence (AI) within the Jaw Crushers Market is poised to revolutionize operational efficiency, predictive maintenance, and material processing optimization. Users are increasingly questioning how AI can enhance the longevity of their crushing equipment, improve throughput, and reduce energy consumption. Common concerns revolve around the cost of AI implementation, data privacy, and the technical expertise required to manage sophisticated AI systems. Expectations are high for AI to provide real-time performance monitoring, automated fault detection, and intelligent adjustments to crushing parameters based on material characteristics, ultimately leading to significant operational savings and improved safety. The industry anticipates AI to transform traditional maintenance schedules into proactive, data-driven strategies, moving away from reactive repairs.

Furthermore, stakeholders are keen to understand AIs role in optimizing the entire mineral processing value chain, extending beyond just the crushing stage. There is a strong interest in AI-powered material analysis, which could allow jaw crushers to operate with greater precision, achieving desired particle sizes with minimal energy expenditure and reduced wear on components. The potential for AI to integrate with other plant automation systems to create a fully autonomous or semi-autonomous crushing circuit is also a recurring theme, promising enhanced operational consistency and fewer human interventions in hazardous environments. This holistic approach to AI adoption is expected to redefine productivity benchmarks and resource utilization within the jaw crushing industry.

- AI-driven predictive maintenance optimizes crusher uptime by forecasting component failures.

- Real-time operational adjustments through AI algorithms enhance material throughput and energy efficiency.

- Automated diagnostics identify operational anomalies, reducing downtime and maintenance costs.

- Enhanced safety protocols by minimizing human intervention in hazardous crushing environments.

- AI-powered material characterization allows for precise crushing parameter adjustments.

- Integration with plant automation systems for semi-autonomous or fully autonomous crushing circuits.

- Optimized inventory management for spare parts based on predictive wear patterns.

- Improved sustainability through reduced energy consumption and optimized resource utilization.

DRO & Impact Forces Of Jaw Crushers Market

The Jaw Crushers Market is significantly influenced by a complex interplay of drivers, restraints, and opportunities, all shaping its trajectory and impact forces. A primary driver is the accelerating pace of global urbanization and infrastructure development, particularly in emerging economies, which necessitates vast quantities of aggregates for road construction, building projects, and smart city initiatives. This sustained demand for construction materials directly fuels the need for efficient primary crushing equipment. Additionally, the resurgence of mining activities worldwide, driven by the escalating demand for minerals and metals crucial for various industries including electronics, automotive, and renewable energy, further propels the market. Technological advancements, such as the development of more energy-efficient and durable jaw crushers, also act as key drivers by offering enhanced productivity and lower operational costs to end-users, incentivizing new investments and equipment upgrades across various sectors.

Despite these strong drivers, the market faces several restraints that could impede its growth. High initial capital investment required for purchasing jaw crushers, especially for large-scale operations, can be a significant barrier for smaller enterprises or new entrants. The fluctuating prices of raw materials, such as steel and other components used in manufacturing, can impact production costs and ultimately influence the final price of the equipment, affecting market competitiveness. Environmental regulations concerning noise pollution, dust emissions, and energy consumption in quarrying and mining operations also impose stringent requirements on crusher design and operation, potentially increasing compliance costs. The availability of skilled labor for operating and maintaining advanced crushing machinery further presents a challenge, particularly in regions with limited technical expertise.

However, substantial opportunities exist for market players to innovate and expand their footprint. The growing emphasis on recycling construction and demolition waste presents a lucrative opportunity for jaw crusher manufacturers, as these machines are crucial for processing recycled aggregates. The development of mobile and portable jaw crushers offers increased flexibility and reduced transportation costs for projects in remote or temporary sites, appealing to a broader customer base. Furthermore, the integration of Industry 4.0 technologies, including IoT, AI, and automation, into jaw crusher operations opens avenues for enhanced efficiency, predictive maintenance, and remote monitoring capabilities. These technological advancements can lead to smart crushing solutions, providing significant competitive advantages and fostering market expansion into new application areas, such as municipal solid waste processing or industrial waste reduction.

- Drivers:

- Rapid global urbanization and infrastructure development projects.

- Increasing demand for construction aggregates in residential, commercial, and industrial sectors.

- Growth in mining activities and mineral extraction worldwide.

- Technological advancements leading to more efficient and durable crushing equipment.

- Rising demand for recycled materials from construction and demolition waste.

- Restraints:

- High initial capital investment required for new crushing equipment.

- Stringent environmental regulations impacting operational costs and design.

- Volatility in raw material prices affecting manufacturing costs.

- Availability of skilled labor for operation and maintenance of advanced crushers.

- Competition from alternative crushing technologies or existing machinery.

- Opportunities:

- Emergence of the circular economy driving demand for recycling solutions.

- Development and adoption of mobile and portable jaw crushers for operational flexibility.

- Integration of IoT, AI, and automation for smart crushing operations.

- Expansion into niche applications like industrial waste processing and specialized mineral crushing.

- Growth in demand from developing economies for basic infrastructure and resource extraction.

Segmentation Analysis

The Jaw Crushers Market is comprehensively segmented based on various critical attributes, including product type, application, capacity, and mobility, providing a granular view of market dynamics and consumer preferences. This detailed segmentation allows manufacturers to tailor their product offerings to specific industry needs and helps end-users identify the most suitable crushing solutions for their operational requirements. By understanding the distinct characteristics and growth patterns within each segment, market participants can develop targeted strategies, optimize resource allocation, and enhance their competitive positioning. The segmentation reflects the diverse range of operational scales and material processing demands present across the mining, construction, and recycling industries, highlighting the versatility and adaptability of jaw crushing technology.

Product type segmentation typically differentiates between single toggle and double toggle jaw crushers, each offering distinct advantages in terms of crushing motion, wear patterns, and power consumption, catering to varied material characteristics and desired output qualities. Capacity segmentation categorizes crushers by their hourly processing tonnage, ranging from small-scale units for intermittent use to heavy-duty machinery for continuous, high-volume operations found in large quarries or mines. Application-based segmentation separates demand from mining, construction aggregates, recycling, and other industrial uses, underscoring the broad utility of these machines. Mobility, differentiating between stationary, mobile, and portable units, addresses the need for flexible deployment in diverse geographical and operational settings, significantly impacting logistics and setup costs for operators seeking adaptability in their projects.

- By Product Type:

- Single Toggle Jaw Crushers

- Double Toggle Jaw Crushers

- By Application:

- Mining & Quarrying

- Construction Aggregates

- Recycling (Construction & Demolition Waste)

- Mineral Processing

- Industrial Material Reduction

- By Capacity:

- Small Capacity (up to 100 TPH)

- Medium Capacity (100-300 TPH)

- Large Capacity (above 300 TPH)

- By Mobility:

- Stationary Jaw Crushers

- Mobile Jaw Crushers

- Portable Jaw Crushers

Jaw Crushers Market Value Chain Analysis

The value chain for the Jaw Crushers Market begins with upstream activities involving the sourcing and processing of raw materials such as high-grade steel, castings, and various mechanical and electronic components. Key suppliers in this stage include metal foundries, specialized component manufacturers, and electrical system providers who ensure the quality and availability of essential inputs. Manufacturers then engage in the design, engineering, and assembly of the jaw crushing units, leveraging advanced CAD/CAM technologies and precision manufacturing processes. This phase is critical for integrating durability, efficiency, and safety features into the final product. Research and development also play a significant role upstream, focusing on material science innovations, energy efficiency improvements, and the integration of smart technologies to enhance crusher performance and longevity.

Downstream analysis focuses on the distribution, sales, and post-sales support activities that deliver the finished jaw crushers to end-users. Distribution channels can be direct, involving manufacturers selling directly to large mining companies or construction conglomerates, often through dedicated sales teams and project managers. Indirect channels typically involve a network of authorized dealers, distributors, and agents who provide local sales, installation, and after-sales services, including spare parts, maintenance, and technical support. These intermediaries are vital for reaching a broader market, especially small to medium-sized enterprises and customers in remote regions. The effectiveness of the after-sales service and the availability of genuine spare parts are critical determinants of customer satisfaction and repeat business, forming a substantial part of the long-term value proposition.

The value chain also encompasses the vital role of logistics and transportation, ensuring the timely and safe delivery of heavy machinery to diverse operational sites globally. Financing and leasing services, often offered by manufacturers or third-party financial institutions, facilitate easier acquisition for customers facing significant capital expenditures. Finally, the end-users themselves, comprising mining companies, quarry operators, construction firms, and recycling plants, complete the value chain by utilizing the jaw crushers for their intended applications. Their feedback often loops back to manufacturers, driving continuous product improvement and innovation. The efficiency and optimization of each stage in this value chain directly impact the overall market competitiveness, cost-effectiveness, and customer satisfaction within the jaw crushers industry.

- Upstream Analysis:

- Raw Material Sourcing (steel, castings, wear parts)

- Component Manufacturing (motors, bearings, hydraulics, electrical systems)

- Research & Development (design, material science, technology integration)

- Manufacturing & Assembly:

- Design Engineering (CAD/CAM)

- Precision Fabrication & Machining

- Assembly & Quality Control

- Downstream & Distribution:

- Direct Sales (to large enterprises, project-based)

- Indirect Sales (via dealers, distributors, agents)

- Logistics & Transportation

- Financing & Leasing Services

- Post-Sales Services:

- Installation & Commissioning

- After-Sales Support & Technical Assistance

- Spare Parts & Consumables Supply

- Maintenance & Repair Services

- Training & Operational Guidance

Jaw Crushers Market Potential Customers

The primary potential customers for jaw crushers are diverse entities operating in industries that require the size reduction of hard and abrasive materials. These end-users are typically characterized by their need for robust, high-capacity, and reliable equipment to process large volumes of rock, ore, or recycled materials efficiently. Mining companies, for instance, form a significant customer base, relying on jaw crushers as the initial stage in their mineral processing circuits to break down run-of-mine ore into smaller, manageable pieces before further refinement. Their purchasing decisions are often driven by factors such as throughput capacity, wear resistance, energy efficiency, and the ability to operate continuously in harsh environments, directly impacting their overall production costs and profitability.

Another substantial segment of potential customers includes quarry operators and construction aggregate producers. These companies are responsible for extracting and processing natural rock formations to produce a range of aggregates vital for concrete, asphalt, road bases, and other construction applications. For this group, key purchasing criteria often involve the ability to produce consistent particle sizes, minimize fines, and operate with high reliability to meet tight project deadlines. The demand from this segment is directly correlated with infrastructure spending, urbanization trends, and the overall health of the construction industry. The need for both stationary plants for long-term operations and mobile units for flexible deployment across various sites makes this a dynamic customer base.

Beyond traditional mining and construction, other significant potential customers include recycling facilities that process construction and demolition (C&D) waste, industrial companies involved in waste management, and certain specialized manufacturing plants that require material pre-processing. For recycling applications, jaw crushers are essential for breaking down concrete, asphalt, bricks, and other construction debris into reusable aggregates, supporting circular economy initiatives. These customers prioritize versatility, ease of maintenance, and the ability to handle a mixed feed of materials with varying hardness and contaminants. The growing environmental regulations and the increasing cost of virgin materials are compelling these industries to invest in efficient crushing solutions, thereby expanding the customer landscape for jaw crusher manufacturers.

- Mining Companies: For primary crushing of various metallic and non-metallic ores, coal, and minerals.

- Quarry Operators: Engaged in extracting and processing natural stone for aggregates.

- Construction Aggregate Producers: Supplying crushed stone for roads, buildings, and infrastructure.

- Recycling Facilities: Processing construction and demolition (C&D) waste into reusable materials.

- Industrial Waste Management Companies: For reducing the size of industrial by-products and waste.

- Contractors & Rental Companies: Offering crushing services or equipment rental for diverse projects.

- Cement Manufacturers: Crushing limestone and other raw materials for cement production.

- Glass and Ceramics Industries: For crushing cullet and raw materials for processing.

Jaw Crushers Market Key Technology Landscape

The Jaw Crushers Market is characterized by a continuously evolving technological landscape, driven by the persistent demand for increased efficiency, durability, and operational intelligence. A core technological focus remains on the enhancement of crushing chamber design and jaw plate metallurgy. Innovations in jaw plate profiles, such as those incorporating corrugated or super-grip designs, aim to improve feed acceptance, reduce material slippage, and optimize the crushing action for a more consistent product shape and size. Simultaneously, advancements in wear-resistant materials, including manganese steel alloys with specific heat treatments, extend the lifespan of wear parts, significantly reducing maintenance frequency and operational costs. The integration of robust hydraulic systems for setting adjustments and overload protection further enhances machine reliability and ease of operation, allowing for quick modifications to adapt to varying feed material characteristics.

Beyond mechanical improvements, the market is increasingly adopting digital and automation technologies to elevate performance and management. The incorporation of advanced sensor technology allows for real-time monitoring of key operational parameters such as bearing temperature, vibration levels, and power consumption. This data is critical for implementing predictive maintenance strategies, enabling operators to anticipate potential failures and schedule interventions proactively, thereby maximizing uptime. Furthermore, the development of intelligent control systems, often leveraging programmable logic controllers (PLCs) and human-machine interfaces (HMIs), facilitates precise control over crushing parameters, enabling automated adjustments to achieve desired output specifications and optimize energy usage. These systems contribute to a more autonomous and efficient crushing process, reducing the need for constant manual oversight.

The latest wave of technological advancements centers on the integration of Industry 4.0 principles, including the Internet of Things (IoT) and Artificial Intelligence (AI). IoT connectivity allows jaw crushers to transmit operational data to cloud-based platforms, enabling remote monitoring, performance analytics, and fleet management from any location. AI algorithms are being developed to analyze vast datasets, predict optimal crushing settings, identify patterns in wear, and even suggest preventative maintenance actions. Mobile and portable crushing solutions are also benefiting from these advancements, with designs focusing on ease of transport, rapid setup, and integrated power units for self-sufficient operation. These technologies collectively aim to deliver smarter, more resilient, and environmentally sustainable crushing solutions, addressing the industrys evolving demands for higher productivity and lower environmental impact.

- Advanced Crushing Chamber Design: Optimized jaw plate profiles (e.g., corrugated, super-grip) for improved material flow and crushing efficiency.

- Enhanced Metallurgy: Utilization of high-grade manganese steel and other wear-resistant alloys for extended jaw plate and liner lifespan.

- Hydraulic Adjustment Systems: For precise and rapid setting adjustments, overload protection, and efficient tramp iron release.

- Automated Control Systems (PLC & HMI): For real-time monitoring, remote operation, and intelligent control of crushing parameters.

- Sensor Integration: Monitoring of vibration, temperature, pressure, and power consumption for predictive maintenance and performance optimization.

- Internet of Things (IoT) Connectivity: Remote monitoring, data analytics, and fleet management through cloud-based platforms.

- Artificial Intelligence (AI) & Machine Learning: For predictive maintenance, operational optimization, and autonomous parameter adjustments.

- Energy Efficiency Improvements: Designs focused on reducing power consumption and optimizing motor efficiency.

- Mobile & Portable Crushing Solutions: Integrated chassis, self-contained power units, and quick setup for flexible deployment.

- Dust Suppression & Noise Reduction Technologies: Addressing environmental compliance and operational safety.

Regional Highlights

The global Jaw Crushers Market exhibits significant regional variations in demand, driven by differing economic growth rates, infrastructure development priorities, and mining activities across continents. Asia Pacific stands out as the largest and fastest-growing market, primarily fueled by the rapid industrialization, urbanization, and massive infrastructure projects underway in countries like China, India, and Southeast Asian nations. These regions are experiencing unprecedented construction booms, necessitating substantial quantities of aggregates, which directly translates into high demand for primary crushing equipment. Additionally, the regions rich mineral resources and expanding mining sectors contribute significantly to market growth, with an emphasis on both large-scale stationary plants and versatile mobile crushing solutions to meet diverse operational needs across varied terrains and project scales.

North America and Europe represent mature markets for jaw crushers, characterized by steady demand driven by infrastructure maintenance, urban renewal projects, and a strong focus on recycling initiatives. In North America, the emphasis is on upgrading aging infrastructure, expanding transportation networks, and managing construction and demolition waste efficiently. European markets, similarly, are propelled by strict environmental regulations fostering the use of recycled aggregates and by investments in sustainable urban development. These regions prioritize energy-efficient equipment, advanced automation, and solutions that comply with stringent emission and noise standards. Innovation in mobile crushing technology and digital integration for optimizing operational efficiency are key trends in these established markets, reflecting a shift towards more sophisticated and environmentally conscious crushing solutions.

Latin America, the Middle East, and Africa are emerging as promising markets for jaw crushers, driven by their significant untapped mineral resources and burgeoning infrastructure development plans. Countries in Latin America are witnessing increased investments in mining operations, particularly for copper, iron ore, and gold, thereby boosting demand for heavy-duty crushing equipment. The Middle Easts ambitious vision for smart cities and diversification from oil-based economies is generating substantial construction activity, requiring new crushing plants. In Africa, the vast mineral wealth, coupled with improving economic conditions and investments in basic infrastructure, positions it as a high-potential market. These regions are characterized by a growing need for robust, reliable, and often cost-effective crushing solutions suitable for challenging operating conditions and diverse material types, driving both new equipment sales and a demand for comprehensive after-sales support.

- Asia Pacific: Largest and fastest-growing market due to rapid urbanization, extensive infrastructure projects (China, India, Southeast Asia), and robust mining sectors.

- North America: Mature market with steady demand for infrastructure upgrades, urban development, and a strong focus on recycling construction materials.

- Europe: Characterized by stringent environmental regulations, driving demand for efficient, low-emission crushers and recycled aggregate production.

- Latin America: Emerging market with increasing investments in mining (copper, iron ore) and infrastructure development.

- Middle East & Africa: High-potential region fueled by ambitious infrastructure projects, urbanization initiatives, and significant mineral wealth exploitation.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Jaw Crushers Market.- Metso Outotec

- Sandvik AB

- Astec Industries, Inc.

- FLSmidth & Co. A/S

- Weir Group PLC

- Terex Corporation

- ThyssenKrupp AG

- Komatsu Ltd.

- McLanahan Corporation

- Stedman Machine Company

- Shanghai Shibang Machinery Co. Ltd.

- Henan Liming Heavy Industry Science & Technology Co., Ltd.

- Zhengzhou Zenith Mining Machinery Co., Ltd.

- SBM Mineral Processing GmbH

- Telsmith, Inc.

- KPI-JCI and Astec Mobile Screens

- HAZEMAG & Eprich GmbH

Frequently Asked Questions

What is a jaw crusher and how does it work?

A jaw crusher is a primary crushing machine used to reduce the size of large rocks and ore. It operates by compressing material between a stationary jaw and a movable jaw, utilizing mechanical force to break the material. The material is fed into the top of the crushing chamber and is gradually crushed as it moves downwards towards the discharge opening, where the final product exits.

What are the main applications of jaw crushers?

Jaw crushers are predominantly used in the mining industry for crushing various ores and minerals, in the construction sector for producing aggregates for concrete, asphalt, and road bases, and in recycling operations for processing construction and demolition waste. They are also employed in quarrying, mineral processing plants, and various industrial material reduction applications.

What types of jaw crushers are available in the market?

The main types include single toggle jaw crushers and double toggle jaw crushers. Single toggle crushers offer a simpler design and are often used for general crushing, while double toggle crushers provide a more consistent crushing action suitable for hard and abrasive materials. Additionally, crushers are categorized by mobility as stationary, mobile, or portable units to suit different operational needs.

How does AI impact the efficiency and maintenance of jaw crushers?

AI significantly enhances jaw crusher efficiency and maintenance through predictive analytics, real-time operational adjustments, and automated diagnostics. AI-powered systems can forecast component failures, optimize crushing parameters for improved throughput and energy consumption, and identify anomalies, thereby reducing downtime, extending equipment lifespan, and lowering operational costs.

What factors influence the cost and return on investment for jaw crushers?

The cost of a jaw crusher is influenced by its capacity, mobility, technological features, and manufacturer. Key factors impacting ROI include initial capital expenditure, operational costs (energy, wear parts, labor), maintenance frequency, material throughput, product quality, and the market value of the crushed aggregates or minerals. Efficient operation and predictive maintenance are crucial for maximizing ROI.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Jaw Crushers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Jaw Crushers Market Size Report By Type (Less than 300tph, 300tph-800tph, More than 800tph), By Application (Mining, Construction), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Jaw Crushers Market Statistics 2025 Analysis By Application (Mining, Construction), By Type (Less Than 300tph, 300tph-800tph, More Than 800tph), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager