Marine Fuel Filter Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429924 | Date : Nov, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Marine Fuel Filter Market Size

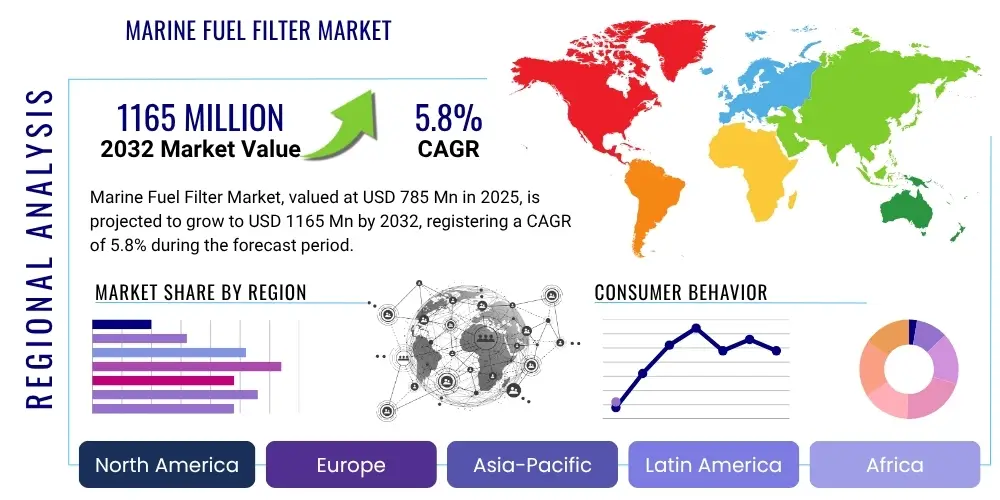

The Marine Fuel Filter Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 785 million in 2025 and is projected to reach USD 1165 million by the end of the forecast period in 2032.

Marine Fuel Filter Market introduction

The Marine Fuel Filter Market encompasses the global industry involved in the manufacturing, distribution, and sale of filtration systems designed to remove contaminants from marine fuels. These filters are crucial for ensuring the smooth and efficient operation of marine engines, protecting sensitive engine components from damage caused by impurities such as water, sediment, rust, and microbial growth. The demand for marine fuel filters is intrinsically linked to the global maritime industry, including commercial shipping, recreational boating, offshore vessels, and naval applications. Proper fuel filtration is essential for complying with increasingly stringent environmental regulations concerning emissions and maintaining engine longevity and reliability.

Marine fuel filters serve to prevent engine malfunctions, reduce maintenance costs, and extend the lifespan of marine propulsion systems. The product range includes primary filters (separators), secondary filters (fine filters), and specialized filters for different fuel types, such as marine diesel oil (MDO), heavy fuel oil (HFO), and alternative fuels. Major applications span across various vessel types, from large container ships and tankers to fishing boats, yachts, and naval vessels. The primary benefit of these filters is enhanced operational efficiency and reduced downtime for marine operators. Key driving factors include the expansion of global trade, increasing maritime traffic, the modernization of existing fleets, and the continuous evolution of fuel quality standards and environmental legislation.

Marine Fuel Filter Market Executive Summary

The Marine Fuel Filter Market is experiencing steady growth driven by the sustained expansion of global maritime trade and increasing regulatory pressure for cleaner marine operations. Business trends indicate a strong focus on developing more efficient and durable filtration solutions capable of handling diverse fuel types, including low-sulfur fuels and biofuels. The market is characterized by technological advancements aimed at improving filtration efficiency, extending service intervals, and integrating monitoring capabilities for predictive maintenance. Additionally, demand for retrofit solutions for older vessels remains significant as shipowners seek to comply with new emission standards and improve operational performance.

Regional trends reveal robust growth in Asia Pacific, propelled by the region's dominance in shipbuilding and maritime logistics, particularly in countries like China, South Korea, and Japan. Europe and North America also represent mature markets with consistent demand, driven by stringent environmental regulations and a focus on upgrading existing fleets with advanced filtration technologies. Emerging markets in Latin America, the Middle East, and Africa are showing increasing potential as maritime infrastructure develops and trade volumes rise. Segment trends highlight a growing preference for multi-stage filtration systems and coalescing filters, capable of effectively removing both particulate matter and water from fuel, which is vital for engine protection. The commercial shipping segment continues to be the largest contributor, while the recreational boating sector also provides consistent demand for smaller, specialized filter units.

AI Impact Analysis on Marine Fuel Filter Market

Users frequently inquire about how artificial intelligence can optimize marine fuel filter performance, maintenance schedules, and overall engine health. Common questions revolve around the potential for AI to predict filter clogging, identify fuel quality issues proactively, and streamline inventory management for filter replacements. There is also interest in whether AI can integrate with existing vessel management systems to provide real-time data on fuel cleanliness and consumption. Users are keen to understand if AI-driven diagnostics could reduce human intervention in filter maintenance, thereby lowering operational costs and improving safety. Expectations are high for AI to transform reactive maintenance into predictive strategies, enhancing the reliability and efficiency of marine propulsion systems and ensuring compliance with environmental regulations more effectively.

- AI driven predictive maintenance for filter replacement.

- Real time fuel quality monitoring and contamination detection.

- Optimization of filter efficiency based on operational data.

- Integration with vessel management systems for holistic engine health.

- Enhanced supply chain management for filter parts.

- Automated diagnostics for identifying fuel system issues.

- Improved compliance reporting through data analytics.

- Reduced operational costs through optimized maintenance.

DRO & Impact Forces Of Marine Fuel Filter Market

The Marine Fuel Filter Market is primarily driven by the expanding global maritime trade, which necessitates a larger and more active fleet of vessels requiring reliable fuel filtration. Stricter environmental regulations, such as the IMO 2020 sulfur cap and upcoming greenhouse gas emission targets, are compelling shipowners to adopt more advanced filtration systems to handle new fuel blends and ensure engine efficiency and compliance. The increasing focus on engine longevity and performance, coupled with the rising cost of marine fuel and engine repairs, further encourages investment in high-quality fuel filtration to prevent contamination and damage. Technological advancements in filter media and design, offering improved separation efficiency and longer service life, also act as significant drivers, promoting upgrades and new installations across the fleet.

However, the market faces restraints such as the fluctuating prices of raw materials used in filter manufacturing, which can impact production costs and market pricing. The initial capital investment required for installing advanced filtration systems, especially for smaller vessel operators, can be a barrier. Additionally, the fragmented nature of the marine industry, with a diverse range of vessel types and operational requirements, poses challenges for standardization and widespread adoption of advanced solutions. Opportunities within the market include the growing demand for retrofit solutions in older vessels to meet new regulatory standards and the increasing adoption of alternative fuels (LNG, methanol, ammonia) that require specialized filtration. The push towards digitalization and smart shipping also presents opportunities for integrating smart filter systems with onboard diagnostic capabilities. The collective impact forces of environmental compliance, operational efficiency, and technological innovation are shaping the market, pushing manufacturers to develop more robust, intelligent, and sustainable filtration solutions.

Segmentation Analysis

The Marine Fuel Filter Market is comprehensively segmented based on various factors including the type of filter, the material used in manufacturing, the vessel type it serves, and its application. This segmentation provides a granular view of the market dynamics, allowing for a detailed analysis of demand patterns, technological preferences, and growth opportunities across different categories. Understanding these segments is crucial for manufacturers to tailor their product offerings and for stakeholders to identify niche markets and strategic investment areas within the broader marine industry.

- By Filter Type

- Primary Fuel Filters/Fuel Water Separators

- Secondary Fuel Filters/Fine Filters

- Duplex Fuel Filters

- Coalescing Filters

- Specialty Fuel Filters (e.g., for HFO, alternative fuels)

- By Material

- Metal Filters (e.g., stainless steel, aluminum)

- Polymer Filters

- Composite Filters

- By Vessel Type

- Commercial Vessels (e.g., Cargo Ships, Tankers, Bulk Carriers, Container Ships)

- Recreational Vessels (e.g., Yachts, Cruise Ships, Powerboats)

- Offshore Vessels (e.g., OSVs, AHTS, PSVs)

- Naval Vessels

- Fishing Vessels

- By Application

- Fuel Filtration for Main Engines

- Fuel Filtration for Auxiliary Engines/Generators

- Fuel Transfer and Bunkering Systems

- By Fuel Type

- Marine Diesel Oil (MDO)

- Heavy Fuel Oil (HFO)

- Low Sulfur Fuel Oil (LSFO)

- Biofuels

- Alternative Fuels (e.g., LNG, Methanol, Ammonia - specific filtration requirements)

- By Sales Channel

- OEM (Original Equipment Manufacturer)

- Aftermarket

Value Chain Analysis For Marine Fuel Filter Market

The value chain for the Marine Fuel Filter Market begins with upstream activities involving the sourcing of raw materials, such as filter media (cellulose, synthetic fibers, composites), metals for housing (steel, aluminum), and polymers for various components. Key suppliers in this stage are manufacturers of specialized filter papers, synthetic filtration materials, and precision metal fabricators. The quality and availability of these raw materials directly influence the performance and cost of the final fuel filter products. Innovation in upstream material science, particularly in developing more efficient and environmentally friendly filter media, is critical for competitive advantage in this segment.

Midstream activities encompass the manufacturing and assembly of the fuel filters, where design, engineering, and quality control processes are paramount. Companies in this stage focus on advanced manufacturing techniques, assembly line efficiency, and product testing to ensure filters meet stringent marine industry standards. Downstream activities involve distribution channels, which include both direct and indirect routes. Direct sales are often facilitated through original equipment manufacturers (OEMs) for new vessel constructions or directly to large shipping companies. Indirect distribution involves a network of distributors, wholesalers, and marine service providers who cater to the aftermarket segment, supplying filters for maintenance, repair, and overhaul (MRO) activities. This dual channel approach ensures broad market penetration, addressing both new installations and ongoing operational needs of the global marine fleet.

Marine Fuel Filter Market Potential Customers

The primary potential customers for marine fuel filters are diverse and span the entire maritime industry, from individual boat owners to multinational shipping conglomerates and national naval forces. These end-users share a common requirement for reliable and efficient fuel filtration to protect their valuable engine assets and ensure uninterrupted operations. Commercial shipping companies represent a significant customer base, encompassing operators of container ships, bulk carriers, oil tankers, chemical tankers, and general cargo vessels, all of whom prioritize engine reliability and compliance with stringent environmental regulations to maintain profitable operations. Fishing fleet operators, whose livelihoods depend on continuous vessel operation in often challenging conditions, are also key purchasers.

Another crucial segment consists of shipbuilders and marine engine manufacturers, who procure fuel filters as original equipment for new vessel constructions and engine installations. This OEM channel is vital for securing long-term supply agreements and establishing product presence from the outset. Beyond commercial vessels, the recreational boating sector, including yacht owners, powerboat enthusiasts, and cruise line operators, forms a substantial customer segment, particularly for specialized and high-performance filters. Offshore vessel operators, supporting oil and gas exploration and production, and naval forces, requiring robust and dependable filtration for their strategic assets, further contribute to the diverse customer landscape. Each customer group has specific needs regarding filter capacity, durability, maintenance frequency, and compliance, dictating tailored product offerings and service strategies from filter manufacturers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 785 Million |

| Market Forecast in 2032 | USD 1165 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Parker Hannifin Corporation, MANN HUMMEL, Donaldson Company Inc., Cummins Inc., Caterpillar Inc., Wärtsilä Corporation, GEA Group AG, MAHLE GmbH, RWO GmbH, Boll Filter Protection Systems GmbH, Alfa Laval AB, Mitsubishi Kakoki Kaisha, Ltd., Andritz AG, SKF Marine (Blohm Voss), Facet International, Separ Filter, Racor (Parker Hannifin), Daikin Industries, Ltd., Fram Filter, Delphi Technologies |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Marine Fuel Filter Market Key Technology Landscape

The technology landscape for the Marine Fuel Filter Market is continuously evolving, driven by the need for enhanced performance, compliance with environmental regulations, and improved operational efficiency. One of the primary technological advancements lies in multi-stage filtration systems that combine fuel water separators with fine particulate filters, providing comprehensive protection against both water and solid contaminants. These systems often incorporate advanced coalescing elements and hydrophobic filter media to achieve superior water removal efficiency, critical for modern common-rail diesel engines that are highly sensitive to water in fuel. Furthermore, the development of synthetic and composite filter media offers higher dirt-holding capacity, longer service intervals, and improved flow rates compared to traditional cellulose-based filters, leading to reduced maintenance and operational costs.

Another significant area of innovation involves the integration of smart technologies. This includes sensors for real-time monitoring of differential pressure across the filter, indicating clogging levels, and sensors to detect water content and fuel quality. These smart filters can communicate data to vessel management systems, enabling predictive maintenance strategies and alerting operators to potential issues before they cause engine damage or operational downtime. Automated back-flushing or self-cleaning filter systems are also gaining traction, particularly for heavy fuel oil applications, where frequent cleaning is required to manage sludge accumulation. Moreover, designs are adapting to the specific requirements of alternative fuels like LNG, methanol, and ammonia, necessitating specialized materials and designs to handle different fuel properties and ensure safety and efficiency.

Regional Highlights

- Asia Pacific: Dominates the market due to extensive shipbuilding activities, major shipping routes, and high growth in maritime trade in countries like China, South Korea, Japan, and Singapore. The region's increasing energy consumption and rising demand for raw material transportation also fuel the market.

- Europe: A mature market characterized by stringent environmental regulations, significant investment in fleet modernization, and a strong presence of key maritime equipment manufacturers in countries such as Germany, Norway, and the Netherlands. Emphasis on high-quality and advanced filtration solutions.

- North America: Stable demand driven by a large recreational boating sector, active offshore oil and gas industry, and continuous upgrades in commercial shipping fleets. Regulatory compliance and a focus on operational efficiency are key drivers in the US and Canada.

- Latin America: Emerging market with growing maritime trade, particularly in resource-rich nations like Brazil and Mexico. Development of port infrastructure and increasing demand for commercial shipping services are contributing to market expansion.

- Middle East and Africa (MEA): Experiencing growth propelled by expanding oil and gas industry, strategic shipping lanes, and developing maritime logistics hubs, especially in the UAE and Saudi Arabia. Investment in naval fleets also presents opportunities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Marine Fuel Filter Market.- Parker Hannifin Corporation

- MANN HUMMEL

- Donaldson Company Inc.

- Cummins Inc.

- Caterpillar Inc.

- Wärtsilä Corporation

- GEA Group AG

- MAHLE GmbH

- RWO GmbH

- Boll Filter Protection Systems GmbH

- Alfa Laval AB

- Mitsubishi Kakoki Kaisha, Ltd.

- Andritz AG

- SKF Marine (Blohm Voss)

- Facet International

- Separ Filter

- Racor (Parker Hannifin)

- Daikin Industries, Ltd.

- Fram Filter

- Delphi Technologies

Frequently Asked Questions

What is the primary function of a marine fuel filter?

The primary function of a marine fuel filter is to remove contaminants such as water, sediment, rust, and microbial growth from marine fuels, protecting engine components and ensuring efficient operation.

How often should marine fuel filters be replaced?

Replacement intervals for marine fuel filters vary depending on the engine manufacturer's recommendations, fuel quality, operating conditions, and filter type, but generally range from 250 to 500 engine hours or annually.

What is the impact of IMO 2020 regulations on marine fuel filter demand?

IMO 2020 regulations, mandating lower sulfur content in marine fuels, increased the demand for advanced fuel filters capable of handling new fuel blends and preventing issues like fuel incompatibility and microbial growth.

Are there smart fuel filters available for marine applications?

Yes, smart fuel filters are available with integrated sensors for real-time monitoring of differential pressure, water content, and fuel quality, enabling predictive maintenance and data integration with vessel management systems.

Which region dominates the Marine Fuel Filter Market?

The Asia Pacific region currently dominates the Marine Fuel Filter Market, driven by its robust shipbuilding industry, extensive maritime trade routes, and significant economic growth in key countries.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager