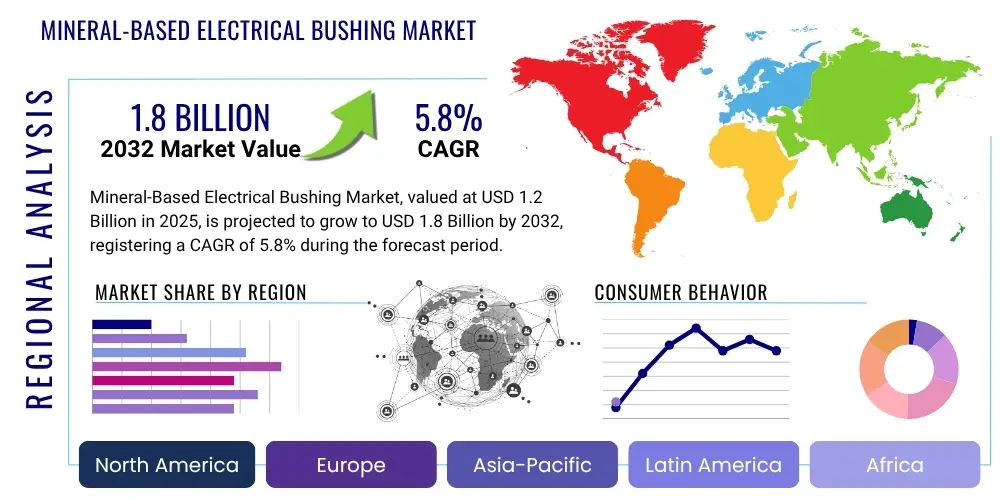

Mineral-Based Electrical Bushing Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428789 | Date : Oct, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Mineral-Based Electrical Bushing Market Size

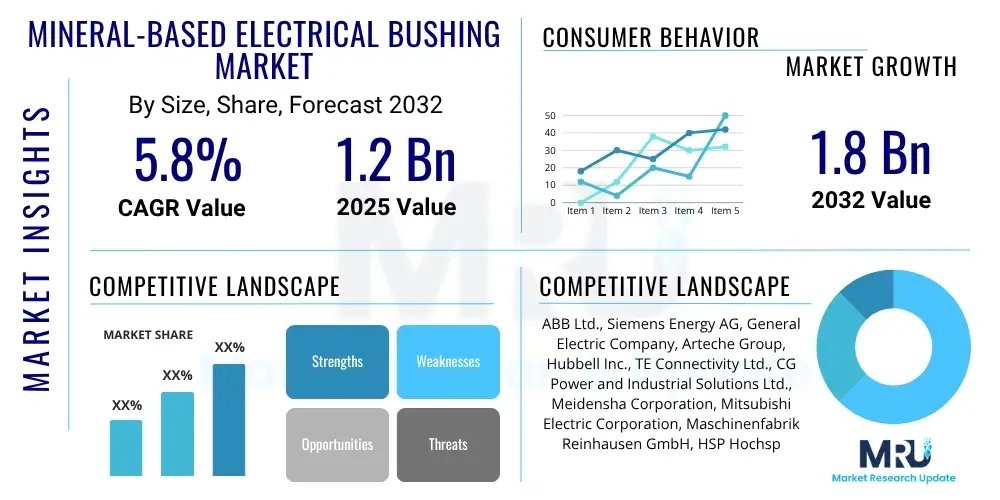

The Mineral-Based Electrical Bushing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 1.2 Billion in 2025 and is projected to reach USD 1.8 Billion by the end of the forecast period in 2032.

Mineral-Based Electrical Bushing Market introduction

Mineral-based electrical bushings are critical components in electrical power systems, designed to insulate and safely conduct electrical current through a grounded barrier, typically between a high-voltage conductor and the grounded tank or enclosure of electrical equipment. These bushings primarily utilize mineral-based materials such as porcelain, steatite, or various ceramic compounds, along with oil-impregnated paper (OIP) or resin-impregnated paper (RIP) for internal insulation, encased within a robust housing. Their fundamental role is to prevent electrical flashover and ensure reliable power transmission and distribution across diverse voltage levels, maintaining the integrity and safety of the entire electrical grid infrastructure.

The product range encompasses a variety of designs, including solid-type bushings, condenser bushings, and oil-filled bushings, each tailored for specific operational environments and voltage requirements from medium to ultra-high voltage applications. Major applications span across power transformers, circuit breakers, switchgear, substations, and high-voltage transmission lines, serving as indispensable interfaces for connecting electrical apparatus to the wider network. The inherent benefits of mineral-based bushings include exceptional dielectric strength, superior mechanical robustness, excellent thermal stability, and long operational lifespans, contributing to the reliability and efficiency of electrical systems globally.

The market is predominantly driven by the escalating demand for electricity worldwide, fueled by rapid industrialization and urbanization in developing economies, alongside the critical need for grid modernization and infrastructure upgrades in mature markets. Furthermore, the global transition towards renewable energy sources necessitates significant investments in new transmission and distribution infrastructure, where these bushings play a vital role in connecting renewable power generation facilities to the existing grid. Regulatory mandates for improved grid stability, safety standards, and environmental considerations also significantly influence product development and market expansion.

Mineral-Based Electrical Bushing Market Executive Summary

The Mineral-Based Electrical Bushing Market is experiencing robust growth, propelled by several key business, regional, and segment trends. Business trends highlight a significant shift towards smart grid integration, demanding bushings capable of handling higher efficiencies, greater reliability, and incorporating advanced monitoring capabilities. There is also an increasing focus on the development of dry-type and eco-friendly insulating materials to mitigate environmental concerns associated with traditional oil-filled bushings. Furthermore, manufacturers are investing in automation and digitalization across their production processes to enhance precision, reduce lead times, and improve overall product quality, responding to the stringent requirements of the energy sector for zero-defect components and longer operational lifespans.

Regionally, Asia-Pacific dominates the market, driven by rapid industrial expansion, extensive grid infrastructure projects, and significant investments in renewable energy initiatives, particularly in countries like China and India. North America and Europe are witnessing steady growth, primarily fueled by the replacement of aging infrastructure, upgrades to existing transmission and distribution networks, and the integration of distributed renewable generation. Emerging economies in Latin America, the Middle East, and Africa are also contributing to market expansion through ongoing electrification projects and infrastructure development, although at a comparatively slower pace. The regional dynamics are also influenced by local regulatory frameworks and government incentives for sustainable energy solutions.

Segment-wise, high-voltage and ultra-high voltage bushings are projected to exhibit the fastest growth, reflecting the global trend towards long-distance power transmission and the establishment of super grids. By insulation type, composite bushings are gaining traction due to their lightweight properties, superior pollution performance, and enhanced mechanical strength compared to traditional porcelain. However, oil-impregnated paper (OIP) and resin-impregnated paper (RIP) insulation continue to hold substantial market shares, especially in critical high-power applications where their proven reliability is paramount. End-user demand is strongest from power utilities and transmission and distribution companies, with industrial applications and renewable energy sectors showing increasing procurement volumes for specialized bushing solutions.

AI Impact Analysis on Mineral-Based Electrical Bushing Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize the lifecycle of mineral-based electrical bushings, particularly concerning predictive maintenance, design optimization, quality assurance, and supply chain management. The key themes revolve around expectations for AI to enhance operational reliability, extend asset life, reduce maintenance costs, and accelerate innovation in product development. Users are interested in understanding how AI algorithms can analyze sensor data from bushings to forecast potential failures, optimize material usage during manufacturing, improve quality inspection processes, and streamline the logistics of spare parts, thereby contributing to a more resilient and efficient electrical infrastructure. Concerns often include data security, the complexity of implementation, and the need for standardized data protocols across diverse equipment types and manufacturers.

- AI-driven predictive maintenance for early fault detection and reduced downtime.

- Optimization of bushing designs and material selection using generative AI algorithms.

- Enhanced quality control through AI-powered visual inspection and anomaly detection during manufacturing.

- Improved supply chain efficiency and inventory management for raw materials and finished products.

- Development of smart bushings with integrated AI for real-time performance monitoring.

- Data analytics for understanding operational stresses and improving product longevity.

- Automated diagnostics for faster troubleshooting and maintenance scheduling.

DRO & Impact Forces Of Mineral-Based Electrical Bushing Market

The Mineral-Based Electrical Bushing Market is shaped by a confluence of driving forces, significant restraints, and emerging opportunities that collectively determine its growth trajectory and competitive landscape. Key drivers include the ever-increasing global demand for electricity, which necessitates the expansion and reinforcement of power transmission and distribution networks, especially in rapidly industrializing regions. The global push towards integrating renewable energy sources, such as solar and wind power, into national grids further fuels demand for reliable high-voltage components like bushings to connect these new generation facilities. Moreover, the urgent need to replace aging electrical infrastructure in developed economies, coupled with government initiatives for grid modernization and smart grid deployment, provides a steady impetus for market growth. These factors underscore the essential role of robust and efficient electrical bushings in supporting a stable and evolving power infrastructure.

However, the market also faces considerable restraints. The relatively high initial cost associated with manufacturing and installing high-quality mineral-based electrical bushings, particularly for ultra-high voltage applications, can be a barrier for some projects, especially in cost-sensitive markets. The complex and precision-driven manufacturing processes involved, along with the stringent quality control requirements, contribute to higher production costs and longer lead times. Furthermore, the volatility in raw material prices, such as metals, ceramics, and specialty oils, can impact profit margins and introduce supply chain uncertainties. Environmental regulations pertaining to materials used in manufacturing and the disposal of older, oil-filled bushings also present challenges, pushing manufacturers towards more sustainable yet potentially more expensive alternatives. Economic slowdowns or geopolitical instabilities can further dampen investment in infrastructure projects, thereby affecting market demand.

Despite these restraints, significant opportunities abound for market players. The ongoing trend towards smart grid integration and the digitalization of power infrastructure creates demand for advanced bushings equipped with sensors and monitoring capabilities, offering a pathway for product innovation and value addition. The development of High Voltage Direct Current (HVDC) transmission systems for long-distance power transfer opens up new applications for specialized HVDC bushings, a high-growth segment. Research and development in advanced materials, including new ceramic composites and dry-type insulation technologies, promise improved performance, reduced maintenance, and enhanced environmental compatibility. Furthermore, the potential for customization to meet specific project requirements, particularly in large-scale industrial applications and bespoke power generation facilities, allows manufacturers to differentiate their offerings and capture niche markets, contributing to market diversification and sustainable growth.

Segmentation Analysis

The Mineral-Based Electrical Bushing Market is extensively segmented to reflect the diverse applications, technical specifications, and end-user requirements within the global electrical power industry. This segmentation provides a granular view of market dynamics, enabling stakeholders to understand specific growth pockets, competitive landscapes, and technological trends across different product categories and operational environments. The primary segmentation criteria include voltage level, insulation type, application, and end-user, each offering critical insights into market structure and future potential.

- By Voltage Level

- Low Voltage (up to 1 kV)

- Medium Voltage (1 kV to 72.5 kV)

- High Voltage (72.5 kV to 300 kV)

- Ultra-High Voltage (Above 300 kV)

- By Insulation Type

- Oil-Impregnated Paper (OIP) Bushings

- Resin-Impregnated Paper (RIP) Bushings

- Resin-Impregnated Synthetic (RIS) Bushings

- Porcelain Bushings

- Composite Bushings (e.g., Polymer-Housed)

- Gas-Insulated Bushings (e.g., SF6)

- By Application

- Transformers (Power Transformers, Distribution Transformers)

- Circuit Breakers

- Switchgear

- Capacitors

- Rectifiers

- Industrial Equipment

- Transmission Lines

- By End-User

- Power Utilities

- Industrial (Manufacturing, Oil & Gas, Mining, etc.)

- Renewable Energy (Solar Farms, Wind Farms)

- Railways & Transportation

- Commercial & Residential (for substation components)

Value Chain Analysis For Mineral-Based Electrical Bushing Market

The value chain for the Mineral-Based Electrical Bushing Market is intricate, involving multiple stages from raw material sourcing to end-user deployment and aftermarket services. The upstream segment primarily involves suppliers of essential raw materials, including high-grade ceramic minerals like feldspar, quartz, and alumina for porcelain and steatite; specialty papers and resins for OIP and RIP insulation; conductive metals such as copper and aluminum for conductors; and insulating oils. These suppliers play a critical role in ensuring the quality, availability, and cost-effectiveness of foundational components. The quality of these upstream materials directly impacts the performance, reliability, and lifespan of the final bushing product, necessitating strong supplier relationships and rigorous quality checks.

Moving downstream, the value chain encompasses the manufacturing processes, which involve highly specialized engineering and assembly, followed by rigorous testing and quality assurance procedures. Manufacturers often integrate various stages, from material preparation and insulation winding to housing assembly and final electrical testing. The distribution channels for mineral-based electrical bushings are typically a blend of direct and indirect approaches. For large-scale power utility projects, bespoke high-voltage applications, or strategic partnerships, direct sales and long-term contracts with Original Equipment Manufacturers (OEMs) and major power utilities are prevalent. This direct approach allows for customization, specialized technical support, and comprehensive project management, building strong relationships with key customers.

Conversely, for standard medium-voltage bushings, replacement parts, or smaller industrial applications, indirect distribution channels such as a network of authorized distributors, electrical equipment wholesalers, and system integrators are frequently employed. These intermediaries provide localized inventory, quicker delivery times, and basic technical support, catering to a broader customer base. Aftermarket services, including installation support, maintenance, and repair, also form a crucial part of the value chain, ensuring the long-term operational integrity of the bushings. Both direct and indirect channels require robust logistical capabilities to handle the size, weight, and fragility of these specialized electrical components, ensuring safe and timely delivery to diverse geographic locations and demanding installation sites globally.

Mineral-Based Electrical Bushing Market Potential Customers

The primary potential customers and end-users of mineral-based electrical bushings are diverse, reflecting their critical role across the entire electrical power infrastructure. These components are indispensable for entities involved in power generation, transmission, and distribution, as well as large industrial consumers requiring stable and reliable electricity supply. The largest segment of buyers comprises national and regional power utilities, including government-owned and privately operated entities responsible for maintaining and expanding electricity grids. These utilities continuously invest in new substations, transmission lines, and equipment upgrades to meet growing demand and enhance grid resilience. Their procurement decisions are heavily influenced by product reliability, regulatory compliance, and long-term cost of ownership.

Beyond utilities, major equipment manufacturers, specifically Original Equipment Manufacturers (OEMs) of power transformers, circuit breakers, and switchgear, constitute a significant customer base. These OEMs integrate bushings into their finished products, making their purchasing decisions dependent on compatibility, performance specifications, and the ability of bushing suppliers to meet stringent manufacturing schedules and quality standards. Industrial customers, particularly those in heavy manufacturing, oil and gas, mining, and metals processing, also represent important end-users. These industries operate large electrical systems and substations that require high-performance bushings to ensure uninterrupted power supply for their critical operations, often demanding custom solutions for harsh environments. The increasing deployment of renewable energy projects, such as large-scale solar farms and wind power installations, has also created a new and rapidly growing segment of potential customers, as these facilities require high-voltage bushings to connect their generation assets to the main grid.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.2 Billion |

| Market Forecast in 2032 | USD 1.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., Siemens Energy AG, General Electric Company, Arteche Group, Hubbell Inc., TE Connectivity Ltd., CG Power and Industrial Solutions Ltd., Meidensha Corporation, Mitsubishi Electric Corporation, Maschinenfabrik Reinhausen GmbH, HSP Hochspannungsgeräte GmbH, Pfiffner Messwandler AG, Alstom SA, Toshiba Corporation, Weidmann Electrical Technology AG, Hitachi Energy Ltd., Gama Elektrik A.S., Trench Group, Bharat Heavy Electricals Limited, Preformed Line Products Company |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Mineral-Based Electrical Bushing Market Key Technology Landscape

The technology landscape for the Mineral-Based Electrical Bushing Market is characterized by a continuous evolution focused on enhancing performance, reliability, and environmental sustainability. Traditional oil-impregnated paper (OIP) bushings, while proven and widely used, are gradually being complemented or replaced by more advanced solutions. Resin-impregnated paper (RIP) and resin-impregnated synthetic (RIS) bushings represent a significant technological leap, offering dry-type insulation with advantages such as reduced fire risk, lower environmental impact due to the absence of mineral oil, and improved partial discharge performance. These technologies utilize epoxy or silicone resins to impregnate fibrous materials, providing excellent dielectric and mechanical properties, suitable for a wide range of voltage applications from medium to ultra-high voltage. The manufacturing process for RIP/RIS involves winding, impregnation under vacuum, and curing, requiring precise control to ensure void-free insulation and optimal electrical characteristics.

Another prominent technological trend is the adoption of composite bushings, often featuring a fiberglass-reinforced epoxy tube with silicone rubber sheds. These bushings offer superior pollution performance, are lightweight, resistant to vandalism, and have excellent hydrophobic properties, making them ideal for challenging environmental conditions. The development of advanced ceramic materials, such as high-purity alumina and zirconia-toughened ceramics, continues to refine porcelain bushings, improving their mechanical strength and resistance to thermal shock. Furthermore, gas-insulated bushings, typically utilizing SF6 gas or alternative eco-friendly gases, are gaining traction, especially in Gas Insulated Switchgear (GIS) applications where compactness and excellent insulation properties are paramount. Innovations in material science are also leading to the development of bio-degradable insulating oils and solid dielectric materials to address environmental concerns associated with traditional mineral oils.

Digitalization and smart technology integration are also becoming integral to the bushing landscape. This includes the incorporation of sensors for real-time monitoring of temperature, partial discharge, and insulation health, enabling predictive maintenance and enhancing operational longevity. The use of advanced computational fluid dynamics (CFD) and finite element analysis (FEA) in the design phase allows for optimized electrical field distribution, improved thermal management, and enhanced mechanical robustness, leading to more compact and efficient bushing designs. Automated manufacturing processes and advanced testing methodologies are further contributing to the consistent quality and reliability of these critical electrical components. The focus is increasingly on creating maintenance-free, smart, and environmentally sustainable bushing solutions that can withstand extreme operational conditions while supporting the reliability of modern power grids.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market due to extensive investments in grid expansion, urbanization, industrialization, and rapid growth in renewable energy projects, particularly in China, India, and Southeast Asian countries. The region's increasing electricity consumption necessitates robust transmission and distribution infrastructure development.

- North America: Exhibits steady growth driven by the urgent need to replace aging power infrastructure, modernize grids with smart technologies, and integrate new renewable energy sources. Government initiatives and investments in infrastructure upgrades are key market drivers.

- Europe: Characterized by significant investments in smart grid technologies, cross-border grid interconnections, and the expansion of offshore wind power. The focus on reducing carbon emissions and enhancing grid reliability fuels demand for advanced and eco-friendly bushing solutions.

- Latin America: Expected to show moderate growth as countries invest in improving their electrical infrastructure, expanding access to electricity, and developing their renewable energy potential. Brazil and Mexico are key markets in this region.

- Middle East and Africa (MEA): Emerging as a growth market with increasing investments in power generation capacity, grid expansion projects, and the development of large-scale renewable energy initiatives, particularly in the GCC countries and parts of Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Mineral-Based Electrical Bushing Market.- ABB Ltd.

- Siemens Energy AG

- General Electric Company

- Arteche Group

- Hubbell Inc.

- TE Connectivity Ltd.

- CG Power and Industrial Solutions Ltd.

- Meidensha Corporation

- Mitsubishi Electric Corporation

- Maschinenfabrik Reinhausen GmbH

- HSP Hochspannungsgeräte GmbH

- Pfiffner Messwandler AG

- Alstom SA

- Toshiba Corporation

- Weidmann Electrical Technology AG

- Hitachi Energy Ltd.

- Gama Elektrik A.S.

- Trench Group

- Bharat Heavy Electricals Limited

- Preformed Line Products Company

Frequently Asked Questions

What is a mineral-based electrical bushing?

A mineral-based electrical bushing is a crucial insulated device that allows an electrical conductor to pass safely through a grounded barrier, such as a transformer tank or switchgear enclosure, while maintaining electrical insulation between the conductor and the ground. They are typically made from materials like porcelain, ceramic, or polymer composites, often combined with oil or resin-impregnated paper for internal insulation.

Why are mineral-based electrical bushings important for power grids?

Mineral-based electrical bushings are vital because they ensure the safe and reliable transmission of electricity by preventing electrical flashovers and short circuits at critical connection points. Their robust insulation and mechanical support properties are essential for maintaining the operational integrity and longevity of high-voltage equipment, contributing to overall grid stability and efficiency.

What factors are driving the growth of the Mineral-Based Electrical Bushing Market?

Key drivers include the global increase in electricity demand, significant investments in grid infrastructure expansion and modernization, the integration of renewable energy sources into existing grids, and the necessity to replace aging electrical components in developed nations. Rapid industrialization and urbanization, particularly in emerging economies, also contribute substantially to market growth.

What are the main challenges faced by the Mineral-Based Electrical Bushing Market?

Major challenges include the high initial manufacturing and installation costs, the complexity of production processes requiring specialized expertise, volatility in raw material prices, and stringent environmental regulations concerning insulating materials. Additionally, economic uncertainties and geopolitical factors can impact infrastructure project investments, posing further restraints.

What are the emerging technological trends in electrical bushings?

Emerging trends include the shift towards dry-type and composite insulation technologies (RIP, RIS, polymer-housed) for enhanced safety and environmental benefits, the integration of smart sensors for real-time monitoring and predictive maintenance, and advancements in materials science to develop more compact, efficient, and eco-friendly bushing solutions for smart grid and HVDC applications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Industrial Mineral-Based Electrical Bushing Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Utility Scale Mineral-Based Electrical Bushing Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager