Particle Board Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428897 | Date : Oct, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Particle Board Market Size

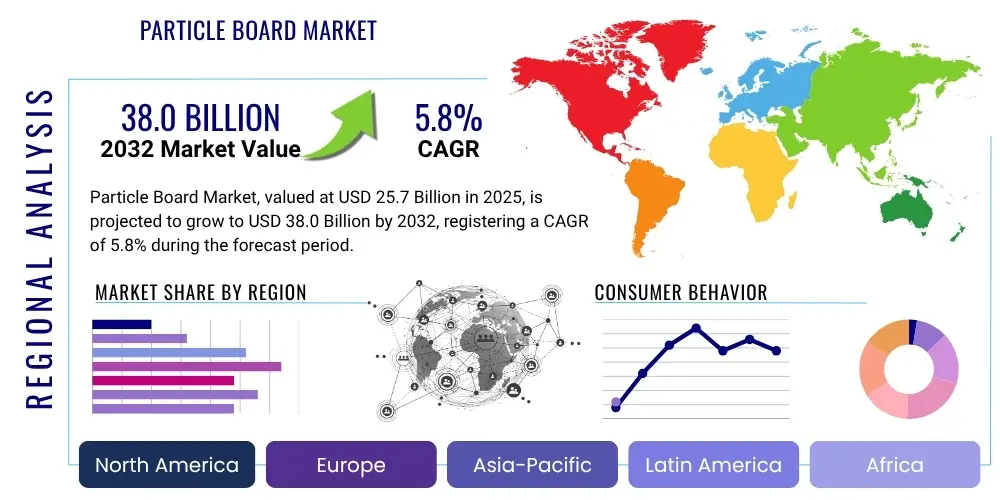

The Particle Board Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 25.7 Billion in 2025 and is projected to reach USD 38.0 Billion by the end of the forecast period in 2032.

Particle Board Market introduction

The Particle Board Market encompasses the global production, distribution, and consumption of particle board, a composite wood product manufactured from wood particles, such as wood chips, sawdust, or agricultural waste products, bonded together with a synthetic resin under heat and pressure. This engineered wood product is widely recognized for its versatility, cost-effectiveness, and resource efficiency, making it a staple in various industries. Its market growth is intrinsically linked to the expansion of urbanization, construction activities, and the global furniture industry, which continuously seek affordable and functional material solutions.

Particle board serves as a crucial material across a multitude of applications, including the manufacturing of furniture like cabinets, tables, and wardrobes, as well as in construction for flooring underlayment, wall panels, roofing sheathing, and partition walls. Its benefits extend beyond mere cost savings, offering properties such as consistent dimensions, a smooth surface suitable for lamination, and a relatively lightweight structure compared to solid wood. The process of its creation also champions sustainability by utilizing wood waste and agricultural residues, contributing to a reduction in deforestation and promoting a circular economy within the timber industry.

Key driving factors for the particle board market include robust growth in residential and commercial construction worldwide, particularly in developing economies, coupled with an increasing demand for ready-to-assemble and modular furniture. Additionally, advancements in binder technologies, leading to lower formaldehyde emissions and improved moisture resistance, are enhancing the appeal and applicability of particle board, aligning with stricter environmental regulations and consumer preferences for safer building materials.

Particle Board Market Executive Summary

The global Particle Board Market is experiencing dynamic shifts, characterized by evolving business trends, significant regional expansion, and diversification across various segments. Businesses are increasingly focusing on sustainable production methods, including the adoption of formaldehyde-free binders and the utilization of a wider range of recycled wood and agricultural waste, in response to growing environmental consciousness and stringent regulatory frameworks. Innovation in surface finishing technologies and product customization is also a prominent trend, enabling particle board to cater to diverse aesthetic and functional requirements in interior design and furniture manufacturing. Manufacturers are investing in advanced manufacturing processes to enhance product quality, durability, and performance characteristics, such as improved moisture and fire resistance.

Regionally, the Asia Pacific (APAC) continues to dominate the market, driven by rapid urbanization, substantial infrastructure development, and a burgeoning middle class fueling demand for housing and consumer goods, including furniture. Europe maintains a strong focus on sustainable and high-quality particle board, with stringent environmental standards influencing production practices and fostering innovation in eco-friendly materials. North America is witnessing steady growth, primarily attributed to renovation activities, new home construction, and the demand for cost-effective building materials. Emerging economies in Latin America, the Middle East, and Africa are also showing promising growth trajectories, supported by increasing investment in construction and expanding industrial bases.

In terms of segments, the furniture sector remains the largest application area for particle board, with its affordability and ease of processing making it ideal for mass production. The construction industry segment is also expanding significantly, driven by demand for interior applications like partition walls, false ceilings, and flooring underlayment. Furthermore, there is a rising demand for specialized particle board types, such as moisture-resistant and fire-retardant variants, expanding its utility in more demanding environments. The market is also segmented by density and raw material, with wood-based particle board holding the largest share, while agricultural residue-based boards are gaining traction due to sustainability advantages.

AI Impact Analysis on Particle Board Market

The integration of Artificial Intelligence (AI) into the Particle Board Market is emerging as a critical transformative force, addressing common user questions related to optimizing production efficiency, enhancing product quality, and ensuring sustainability. Users frequently inquire about AI's potential to streamline complex manufacturing processes, reduce waste, and improve the consistency of particle board properties. There is a strong expectation that AI can provide solutions for real-time monitoring of production lines, predictive maintenance of machinery, and intelligent management of raw material inputs, ultimately leading to significant cost savings and improved operational throughput. The key themes revolve around achieving higher levels of automation, precision, and data-driven decision-making throughout the entire value chain, from sourcing to distribution, aiming to meet stringent industry standards and evolving consumer demands more effectively.

- AI-driven process optimization for reduced waste and energy consumption.

- Enhanced quality control through machine vision and sensor-based defect detection.

- Predictive maintenance of machinery, minimizing downtime and increasing operational efficiency.

- Optimized raw material blending and resin application for superior product consistency.

- Advanced demand forecasting and supply chain management for improved inventory and logistics.

- Development of new material formulations with AI-guided experimentation for novel properties.

DRO & Impact Forces Of Particle Board Market

The Particle Board Market is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, collectively shaping its trajectory and competitive landscape. Key drivers include accelerated urbanization across developing nations, which fuels massive construction and infrastructure projects, thereby increasing the demand for cost-effective building materials. Concurrently, the burgeoning global furniture manufacturing industry, characterized by a continuous need for affordable, versatile, and lightweight components for ready-to-assemble and modular furniture, significantly propels the market. Furthermore, a growing emphasis on sustainable construction and green building initiatives worldwide encourages the adoption of particle board, owing to its composition from recycled wood and agricultural waste, positioning it as an environmentally responsible choice over virgin timber products.

However, the market also faces considerable restraints that temper its growth. The volatility of raw material prices, particularly for wood chips, sawdust, and synthetic resins, introduces cost uncertainties for manufacturers, impacting profitability and pricing strategies. Stringent environmental regulations, especially concerning formaldehyde emissions from certain types of binders, necessitate investment in advanced, low-emission technologies and alternative bonding agents, adding to production costs. Moreover, intense competition from substitute materials like Medium-Density Fiberboard (MDF) and plywood, which often offer superior strength or moisture resistance, presents a continuous challenge for market share. Particle board's inherent susceptibility to moisture damage and its relatively lower strength compared to solid wood or plywood in certain applications also limit its broader utilization.

Despite these challenges, numerous opportunities exist for market expansion and innovation. The development and commercialization of advanced particle board variants, such as those with enhanced moisture resistance, fire retardancy, and improved structural integrity, can open up new application avenues and improve market perception. Embracing circular economy principles through increased recycling of wood waste and the exploration of novel agricultural residues as raw material sources can further bolster sustainability credentials and raw material security. Furthermore, penetrating emerging markets with growing construction sectors and rising disposable incomes offers substantial growth potential, while continuous research and development into eco-friendly binders and manufacturing efficiencies present avenues for competitive differentiation and long-term viability. These impact forces collectively dictate market dynamics, requiring strategic adaptability from industry players.

Segmentation Analysis

The Particle Board Market is comprehensively segmented across several crucial dimensions, allowing for a detailed understanding of its varied applications, product characteristics, and raw material compositions. This segmentation aids in identifying specific market niches, understanding consumer preferences, and developing targeted marketing and product development strategies. The primary segmentation criteria include the type of particle board, its diverse applications across industries, the raw materials utilized in its production, and its density classification, each offering distinct properties and market appeal.

- By Type

- Single-layer Particle Board

- Multi-layer Particle Board

- Graded-density Particle Board

- By Application

- Furniture (Cabinets, Tables, Wardrobes)

- Flooring Underlayment

- Wall Panels

- Roofing Sheathing

- Packaging Material

- Interior Decoration

- Construction (Partition Walls, False Ceilings)

- Door Cores

- By Raw Material

- Wood Chips

- Sawdust

- Agricultural Residues (Bagasse, Rice Husks, Cotton Stalks)

- Recycled Wood

- By Density

- Low-Density Particle Board (LDPB)

- Medium-Density Particle Board (MDPB)

- High-Density Particle Board (HDPB)

Value Chain Analysis For Particle Board Market

The value chain of the Particle Board Market spans from the sourcing of raw materials to the final distribution to end-users, involving a series of sequential activities that add value at each stage. The upstream segment primarily focuses on raw material procurement, which includes wood waste such as sawdust, wood chips, and shavings from sawmills and forestry operations, as well as an increasing proportion of agricultural residues like bagasse and rice husks. This stage also involves the supply of critical binding agents like urea-formaldehyde, melamine-formaldehyde, and phenol-formaldehyde resins, along with various additives such as waxes, fire retardants, and water repellents. Efficient sourcing and quality control at this initial stage are paramount to ensuring the consistent quality and cost-effectiveness of the final product, necessitating strong relationships with timber industries and chemical suppliers.

Following raw material procurement, the manufacturing process transforms these inputs into particle board through several stages including particle preparation (chipping, drying, screening), mixing with resins and additives, mat formation, hot pressing, and subsequent finishing operations like sanding and cutting. This stage is capital-intensive and heavily relies on advanced machinery and technology for optimal efficiency and product quality. The midstream of the value chain also includes product innovation and research and development activities aimed at improving board properties, developing new eco-friendly binders, and creating value-added products like laminated or veneered particle board, which enhances their aesthetic appeal and functional characteristics for diverse applications.

The downstream segment involves the distribution and sales of particle board to various end-users. Distribution channels are typically diverse, encompassing direct sales to large-scale furniture manufacturers and construction companies, indirect sales through wholesalers, distributors, and retailers for smaller businesses and individual customers, and increasingly, online sales platforms. The end-users primarily comprise the furniture industry, residential and commercial construction sectors, interior design firms, and packaging material producers. The effectiveness of the distribution network and the proximity to major consumption centers are critical for minimizing logistics costs and ensuring timely product delivery, thereby enhancing market penetration and customer satisfaction. Both direct and indirect channels play crucial roles, with direct sales facilitating customized orders and strong B2B relationships, while indirect channels provide broader market reach and cater to diverse customer needs.

Particle Board Market Potential Customers

The Particle Board Market serves a broad spectrum of potential customers and end-users, driven by the product's versatility, cost-effectiveness, and adaptability across numerous applications. The primary beneficiaries of particle board are entities within the furniture manufacturing industry, ranging from large-scale producers of flat-pack and ready-to-assemble furniture to bespoke cabinet makers. These manufacturers heavily rely on particle board for components such as cabinet bodies, table tops, wardrobe panels, drawer bottoms, and shelving units due to its consistent dimensions, smooth surface for lamination, and structural stability, allowing for efficient mass production and diverse design options.

Another significant customer segment is the construction sector, including both residential and commercial builders, as well as interior contractors and renovation companies. Particle board finds extensive use in various interior applications such as flooring underlayment, wall partitioning, ceiling panels, subflooring, and decorative wall claddings. Its application here is valued for its insulation properties, ease of installation, and cost advantages compared to solid wood, making it an attractive choice for non-structural interior elements in modern buildings. Architects and interior designers also play a crucial role as influencers and direct buyers, specifying particle board in their projects for its design flexibility and environmental attributes when sourced responsibly.

Beyond these major sectors, other potential customers include the packaging industry, where particle board is used for creating sturdy shipping crates and protective elements, and the exhibition and display industry, which utilizes it for constructing temporary structures, booths, and signage. DIY enthusiasts and small-scale carpenters also represent a valuable segment, purchasing particle board from retail outlets for various home improvement and craft projects due to its workability and affordability. The diverse needs of these end-users, from large industrial requirements to individual consumer projects, collectively define the extensive customer base for the Particle Board Market, encouraging manufacturers to offer a range of products tailored to specific functional and aesthetic demands.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 25.7 Billion |

| Market Forecast in 2032 | USD 38.0 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Kronospan, Arauco, Egger, Fantoni Group, Kastamonu Entegre, Weyerhaeuser, Louisiana-Pacific Corporation, Georgia-Pacific, Roseburg Forest Products, Greenpanel Industries Ltd., Century Plyboards (India) Ltd., Action TESA, Daiken Corporation, Norbord (West Fraser Timber Co. Ltd.), Interprint GmbH, Pfleiderer Group, Sonae Arauco, Swedspan (IKEA Industry), Tolko Industries, Unilin Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Particle Board Market Key Technology Landscape

The Particle Board Market's technological landscape is continuously evolving, driven by the need for enhanced product performance, increased production efficiency, and improved environmental sustainability. One of the most significant advancements is in continuous pressing technology, which allows for uninterrupted production of particle board sheets, leading to higher output volumes, improved surface quality, and greater dimensional stability compared to traditional multi-opening presses. This technology also offers better control over board density profiles, enabling the creation of graded-density boards that are optimized for specific applications.

Another crucial area of technological development lies in the formulation of innovative binders and resins. There is a strong industry shift towards formaldehyde-free or low-formaldehyde emission resins, such as pMDI (polymeric methylene diphenyl diisocyanate) or soy-based adhesives, in response to stringent health and environmental regulations and growing consumer demand for greener products. These advanced gluing systems not only reduce harmful emissions but also often contribute to superior bonding strength and moisture resistance. Furthermore, advancements in wood particle preparation, including sophisticated drying and screening systems, ensure optimal particle size and moisture content, which are critical for uniform board formation and consistent quality.

Surface lamination and finishing technologies also represent a vital part of the market's technological progress. High-pressure laminates (HPL) and low-pressure laminates (LPL) are increasingly applied to particle board surfaces to enhance their durability, scratch resistance, and aesthetic appeal, mimicking natural wood grains, stone textures, or contemporary designs. Furthermore, the integration of automation and digitalization, including advanced process control systems and IoT sensors, allows for real-time monitoring, data analysis, and predictive maintenance in manufacturing plants, optimizing operational efficiency, reducing waste, and ensuring consistent product specifications. Specialized treatments for moisture resistance, fire retardancy, and anti-bacterial properties are also being developed and integrated into the manufacturing process, expanding the functional scope and application areas of particle board products.

Regional Highlights

- North America: This region demonstrates stable demand driven by a robust housing market, significant renovation and remodeling activities, and the popularity of ready-to-assemble furniture. Key players focus on sustainable sourcing and technological advancements to meet environmental standards and consumer preferences for eco-friendly products.

- Europe: Characterized by stringent environmental regulations, Europe is a leader in developing and adopting low-emission and sustainable particle board products. The region's strong furniture design and manufacturing industry, coupled with an emphasis on circular economy principles, drives innovation and demand for high-quality, eco-certified particle board.

- Asia Pacific (APAC): The largest and fastest-growing market, propelled by rapid urbanization, massive infrastructure development projects, and a booming residential construction sector, particularly in countries like China, India, and Southeast Asian nations. The region's large manufacturing base for furniture also contributes significantly to demand, alongside increasing disposable incomes.

- Latin America: This region presents emerging opportunities with increasing investments in infrastructure and construction, coupled with growing residential housing projects. Economic development and urbanization are gradually driving the adoption of particle board for affordable and efficient construction and furniture solutions.

- Middle East and Africa (MEA): Growth in MEA is fueled by ambitious construction and development projects, particularly in Gulf Cooperation Council (GCC) countries, alongside rising demand for housing and commercial spaces. The region is witnessing an increase in furniture manufacturing and import of particle board to support these expanding sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Particle Board Market.- Kronospan

- Arauco

- Egger

- Fantoni Group

- Kastamonu Entegre

- Weyerhaeuser

- Louisiana-Pacific Corporation

- Georgia-Pacific

- Roseburg Forest Products

- Greenpanel Industries Ltd.

- Century Plyboards (India) Ltd.

- Action TESA

- Daiken Corporation

- Norbord (West Fraser Timber Co. Ltd.)

- Interprint GmbH

- Pfleiderer Group

- Sonae Arauco

- Swedspan (IKEA Industry)

- Tolko Industries

- Unilin Group

Frequently Asked Questions

What is particle board made of?

Particle board is an engineered wood product manufactured from wood particles, such as wood chips, sawdust, and shavings, or agricultural residues like bagasse, which are mixed with a synthetic resin adhesive and then pressed under heat to form rigid panels. It is a cost-effective and environmentally friendly alternative to solid wood.

Is particle board environmentally friendly?

Particle board is considered environmentally friendly due to its composition, which typically includes recycled wood waste and agricultural residues, reducing the demand for virgin timber. Many manufacturers also focus on using low-formaldehyde or formaldehyde-free binders to minimize emissions and enhance its sustainability profile.

What are the main applications of particle board?

Particle board has diverse applications, primarily in the furniture industry for cabinets, tables, and wardrobes, and in construction for interior uses such as flooring underlayment, wall panels, ceiling tiles, and partition walls. It is also used in packaging, interior decoration, and as a core material for doors.

How does particle board compare to MDF or plywood?

Particle board is generally less expensive and lighter than MDF (Medium-Density Fiberboard) and plywood. While MDF offers a smoother surface and better machinability, and plywood provides superior strength and moisture resistance, particle board excels in cost-effectiveness and utilization of waste materials. Its properties vary with density, but it is typically less durable than its counterparts, especially in high-moisture environments.

What factors drive the particle board market?

The particle board market is primarily driven by rapid urbanization, significant growth in the global construction industry, increasing demand for affordable and ready-to-assemble furniture, and a growing emphasis on sustainable building materials. Technological advancements in production processes and binder chemistries also contribute to market expansion by improving product quality and environmental performance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Particle Board Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Slack Wax Market Size Report By Type (Slack Wax LMO, Slack Wax MMO, Slack Wax SPO), By Application (Candle, Particle Board & MDF, Polishing, Sealing), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Particle Board in Furniture Market Statistics 2025 Analysis By Application (Home Furniture, Commercial Furniture), By Type (Fire-rated, Moisture-resistant, Standard), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Slack Wax Market Statistics 2025 Analysis By Application (Candle, Particle Board & MDF, Polishing, Sealing), By Type (Slack Wax LMO, Slack Wax MMO, Slack Wax SPO), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Cement Bonded Particle Board Market Statistics 2025 Analysis By Application (Furniture, Ceiling, Siding, Packages), By Type (Below 6 mm, 8-18mm, 20-30mm, Above 30 mm), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager