Plastic Drums Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428625 | Date : Oct, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Plastic Drums Market Size

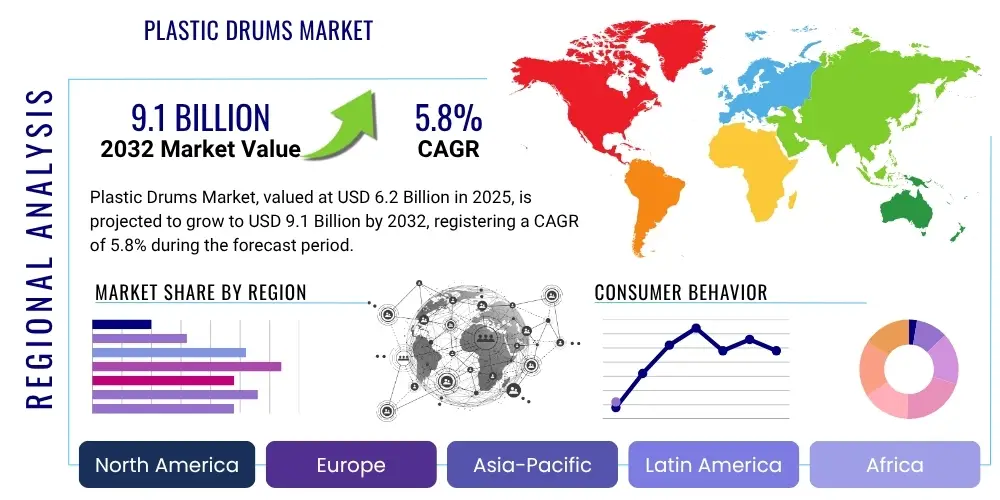

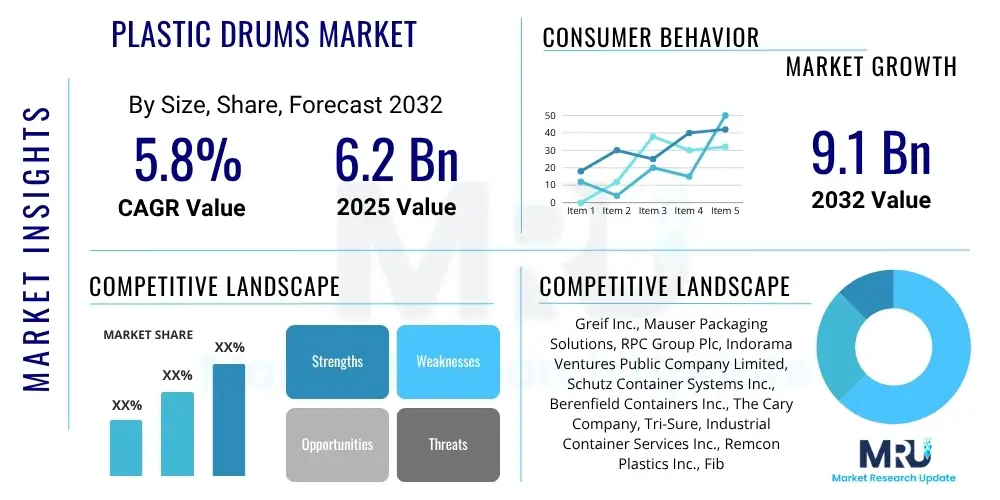

The Plastic Drums Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 6.2 Billion in 2025 and is projected to reach USD 9.1 Billion by the end of the forecast period in 2032.

Plastic Drums Market introduction

The Plastic Drums Market encompasses the production and distribution of cylindrical containers predominantly made from high-density polyethylene (HDPE), designed for the safe and efficient storage and transportation of a diverse range of liquid and solid materials. These robust containers are critical components in industrial packaging, offering a lightweight yet durable alternative to traditional metal drums. Their inherent chemical resistance and ease of handling contribute significantly to their widespread adoption across various sectors, addressing modern industrial demands for reliable and cost-effective packaging solutions. The market is continuously evolving with advancements in material science and manufacturing processes, aiming for enhanced performance and environmental sustainability.

Plastic drums are characterized by their superior strength-to-weight ratio, resistance to corrosion, and impermeability, making them ideal for sensitive contents such as chemicals, pharmaceuticals, and food products. Available in various capacities, from small containers to large industrial drums, they serve a broad spectrum of logistical and storage needs. Key product types include tight-head drums for liquids and open-head drums for solids or viscous materials, each engineered to meet specific application requirements. The versatility and protective qualities of plastic drums underline their indispensable role in global supply chains, ensuring product integrity from manufacturing facilities to end-user consumption points. They often feature various closures, including screw caps, bungs, and lever-lock rings, to prevent leakage and tampering.

Major applications of plastic drums span critical industries such as chemicals and solvents, food and beverages, pharmaceuticals, petroleum and lubricants, and water treatment. The benefits derived from using plastic drums are substantial, including their exceptional durability, cost-effectiveness due to lower production and shipping weights, and reusability, which supports circular economy initiatives. Driving factors for market growth include the robust expansion of the chemical industry, increasing demand for packaged foods, stringent regulations for hazardous material transport requiring secure containment, and the logistical advantages offered by their uniform dimensions and stackability. Furthermore, the growing e-commerce sector and global industrialization are fueling sustained demand for reliable bulk packaging solutions.

Plastic Drums Market Executive Summary

The Plastic Drums Market is experiencing dynamic shifts driven by evolving industrial needs, sustainability mandates, and technological advancements. Business trends indicate a strong move towards automation in manufacturing processes, leading to increased production efficiency and consistency in drum quality. There is a growing emphasis on incorporating recycled plastics and developing lighter weight drums to reduce material consumption and carbon footprint, aligning with global environmental concerns and corporate social responsibility initiatives. Furthermore, manufacturers are exploring smart packaging solutions, integrating IoT sensors for tracking contents, temperature, and location, thereby enhancing supply chain transparency and security. Consolidation among key players and strategic partnerships aimed at expanding regional reach and product portfolios are also prominent business strategies observed across the market landscape.

From a regional perspective, the Asia Pacific region continues to dominate the Plastic Drums Market, propelled by rapid industrialization, burgeoning manufacturing sectors, and increasing consumption across chemicals, food, and pharmaceutical industries in countries like China and India. North America and Europe demonstrate mature markets characterized by stable demand and a strong focus on regulatory compliance, product innovation, and the adoption of advanced materials for enhanced performance and safety. Latin America and the Middle East and Africa regions are emerging as significant growth hubs, driven by infrastructure development, expansion of local industries, and growing demand for bulk packaging solutions in sectors such as petroleum, mining, and agriculture. Each region presents unique opportunities and challenges influenced by local economic conditions, regulatory frameworks, and sustainability goals.

Segmentation trends highlight the increasing preference for high-density polyethylene (HDPE) drums due to their superior chemical resistance, impact strength, and recyclability. The market is segmented by capacity, with larger capacity drums (200-250 liters) holding a substantial share, catering to industrial bulk storage and transport requirements, while smaller drums serve specific niche applications. Tight-head drums are favored for hazardous liquids, ensuring leak-proof containment, whereas open-head drums are essential for viscous materials, powders, and solids, facilitating easy filling and dispensing. End-use industries such as chemicals, food and beverages, and pharmaceuticals are consistently growing, each driving demand for specialized drum types that meet their specific product integrity and safety standards. The sustained growth of these sectors is a primary catalyst for the overall expansion of the plastic drums market.

AI Impact Analysis on Plastic Drums Market

User inquiries regarding AI's impact on the Plastic Drums Market frequently center on how artificial intelligence can optimize production efficiency, enhance supply chain management, improve material science for plastics, and contribute to sustainable practices, including advanced recycling and predictive maintenance. Users are keenly interested in understanding if AI can lead to more resilient, cost-effective, and environmentally friendly drum manufacturing. Key themes include the automation of quality control, predictive analytics for demand forecasting and inventory management, and the potential for AI-driven material innovation to create lighter yet stronger drums or to better process recycled content. Concerns often revolve around the investment required for AI implementation, data security, and the necessity for a skilled workforce capable of managing AI-integrated systems within traditional manufacturing environments.

- AI-powered predictive maintenance: Optimizes machinery uptime, reducing production downtime and operational costs by forecasting equipment failures.

- Automated quality control: AI vision systems detect defects in plastic drums during production, ensuring higher product quality and reducing waste.

- Supply chain optimization: AI algorithms enhance logistics, route planning, and inventory management, leading to faster delivery and reduced transportation costs.

- Material innovation and recycling: AI assists in developing novel polymer compositions, improving material strength and chemical resistance, and optimizing plastic waste sorting and recycling processes.

- Demand forecasting: AI-driven analytics provide more accurate predictions of market demand, enabling manufacturers to optimize production schedules and minimize overproduction.

- Energy efficiency in manufacturing: AI systems monitor and optimize energy consumption in blow molding and injection molding processes, leading to reduced operational expenses.

- Smart drum development: Integration of AI with IoT sensors in drums enables real-time tracking, temperature monitoring, and content integrity verification, enhancing product safety and security.

DRO & Impact Forces Of Plastic Drums Market

The Plastic Drums Market is significantly influenced by a complex interplay of drivers, restraints, opportunities, and inherent impact forces. Key drivers include the escalating demand from various end-use industries such as chemicals, food and beverages, and pharmaceuticals, all requiring robust and reliable bulk packaging solutions for storage and transport. The ongoing globalization of trade and the expansion of logistics networks further fuel the need for standardized and durable packaging like plastic drums. Furthermore, the cost-effectiveness and reusability of plastic drums, coupled with their superior chemical resistance compared to metal alternatives, position them favorably in a competitive market. Economic growth across emerging economies also plays a crucial role, stimulating industrial production and subsequently, the demand for industrial packaging. Regulatory frameworks that mandate safe handling and transport of hazardous materials often prefer specific drum types, further impacting market dynamics. Technological advancements in blow molding and material science, leading to the production of lighter yet stronger drums, are consistently contributing to market expansion. The increasing focus on hygiene and product integrity, particularly in the food and pharmaceutical sectors, ensures sustained demand for high-quality, uncontaminated plastic drums. This continuous push for efficiency and safety across global supply chains forms the bedrock of market growth for plastic drums.

Segmentation Analysis

The Plastic Drums Market is comprehensively segmented to provide a detailed understanding of its various facets, allowing for targeted strategic planning and market analysis. These segments typically categorize the market based on raw material, product type, capacity, end-use industry, and geographical region. This granular segmentation helps in identifying specific growth pockets, understanding consumer preferences within different applications, and assessing the competitive landscape more accurately. For instance, the distinction between high-density polyethylene (HDPE) and other plastics is crucial due to HDPE's dominant market share and favorable properties. Similarly, the difference between tight-head and open-head drums dictates their suitability for various contents, from volatile liquids to viscous solids. Analyzing these segments individually and in combination provides stakeholders with actionable insights into market dynamics and future trajectories.

- By Material:

- High-Density Polyethylene (HDPE)

- Low-Density Polyethylene (LDPE)

- Polypropylene (PP)

- Other Plastics (e.g., PET, PVC)

- By Product Type:

- Tight-Head Drums (Closed Top)

- Open-Head Drums (Removable Lid)

- By Capacity:

- Below 50 Liters

- 50-100 Liters

- 101-200 Liters

- Above 200 Liters (e.g., 200-250 Liters)

- By End-Use Industry:

- Chemicals and Solvents

- Food and Beverages

- Pharmaceuticals

- Petroleum and Lubricants

- Water Treatment

- Agriculture

- Other Industrial Applications

- By Region:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Plastic Drums Market

The value chain for the Plastic Drums Market commences with upstream analysis, focusing on the procurement of raw materials and primary manufacturing processes. The principal raw material is typically high-density polyethylene (HDPE) resin, which is sourced from petrochemical companies. Other plastics such as LDPE and PP are also utilized, though less commonly for drums. Key players in this upstream segment include major chemical and polymer producers who supply the plastic granules. The cost and availability of these raw materials are critical determinants of profitability for drum manufacturers. Additionally, machinery manufacturers providing blow molding and injection molding equipment, as well as mold fabricators, form a crucial part of the upstream segment, enabling the conversion of raw plastic resins into finished drum products. Strategic relationships with raw material suppliers are vital for ensuring stable supply and mitigating price volatility, which can significantly impact production costs and market competitiveness.

Moving further along the value chain, the manufacturing segment involves converting plastic resins into drums through processes like blow molding and injection molding. Manufacturers like Greif, Mauser Packaging Solutions, and indorama Ventures are involved in this stage, leveraging advanced machinery and technical expertise to produce high-quality drums that meet diverse industry standards and specifications. Following production, drums enter the distribution channel, which can be direct or indirect. Direct channels involve manufacturers selling directly to large end-users or distributors with established long-term contracts. This approach is often adopted for bulk orders and specialized requirements, allowing for greater control over sales and customer relationships. The direct distribution model enables manufacturers to build strong relationships with key clients and offer tailored solutions, fostering brand loyalty and repeat business opportunities.

Indirect distribution channels involve a network of wholesalers, retailers, and third-party logistics (3PL) providers who bridge the gap between manufacturers and smaller or geographically dispersed end-users. These intermediaries play a crucial role in market penetration, especially in regional markets where manufacturers might not have a direct presence. 3PL providers often manage warehousing, transportation, and last-mile delivery, offering cost-effective and efficient solutions for a broad customer base. Downstream analysis encompasses the diverse end-use industries that purchase and utilize plastic drums, including chemicals, food and beverages, pharmaceuticals, petroleum, and agriculture. These end-users typically focus on factors such as drum durability, chemical compatibility, regulatory compliance, and cost-effectiveness. The overall value chain is driven by demand from these industries and influenced by global economic conditions, environmental regulations, and technological advancements in both material science and manufacturing processes, creating a dynamic and interconnected market ecosystem.

Plastic Drums Market Potential Customers

Potential customers for the Plastic Drums Market are extensive and diverse, primarily comprising industries that require reliable and robust bulk packaging for liquids, semi-solids, or powders. The chemical industry represents a significant segment, with manufacturers of industrial chemicals, solvents, acids, and bases being major buyers. These companies rely on plastic drums for their superior chemical resistance, ensuring the safe containment and transportation of potentially corrosive or hazardous materials, thereby complying with stringent safety regulations. The versatility of plastic drums allows them to cater to a wide array of chemical products, from specialty chemicals to commodity chemicals, facilitating their secure movement across global supply chains. Manufacturers of agrochemicals, including fertilizers and pesticides, also constitute a substantial customer base, requiring drums that can withstand outdoor conditions and protect product integrity. The inherent durability and long lifespan of plastic drums make them an economical choice for these industrial applications.

Another crucial segment of potential customers is the food and beverage industry, where plastic drums are utilized for storing and transporting ingredients such as syrups, fruit concentrates, edible oils, and dairy products. For this sector, drums must meet strict hygiene and food-grade safety standards, often being manufactured from virgin HDPE approved for food contact. The pharmaceutical industry is also a key end-user, requiring sterile and high-quality plastic drums for active pharmaceutical ingredients (APIs), excipients, and bulk drug intermediates. These drums must adhere to pharmaceutical guidelines, ensuring product purity and preventing contamination. The petroleum and lubricants sector uses plastic drums for motor oils, industrial lubricants, and other petroleum-based products, valuing their resistance to hydrocarbons and impact strength, which are critical during storage and transit. The ability of plastic drums to prevent leakage and ensure product integrity is paramount for these sensitive applications.

Beyond these major sectors, other significant end-users include the water treatment industry for chemicals used in purification processes, the construction industry for sealants and admixtures, and various manufacturing industries for industrial oils, greases, and waste collection. Companies involved in commodity trading, freight forwarding, and third-party logistics also represent key buyers, as they require packaging for consolidated shipments across different industries. The reusability and recyclability of plastic drums appeal to customers who are increasingly focused on sustainability and reducing their environmental footprint. Ultimately, any business involved in the bulk handling, storage, or transportation of liquid or solid materials, whether hazardous or non-hazardous, represents a potential customer for the Plastic Drums Market, continually seeking efficient, safe, and cost-effective packaging solutions to maintain operational continuity and product quality.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 6.2 Billion |

| Market Forecast in 2032 | USD 9.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Greif Inc., Mauser Packaging Solutions, RPC Group Plc, Indorama Ventures Public Company Limited, Schutz Container Systems Inc., Berenfield Containers Inc., The Cary Company, Tri-Sure, Industrial Container Services Inc., Remcon Plastics Inc., Fibrosan, Werit Kunststoffwerke W. Schneider GmbH & Co. KG, Great Western Containers Inc., Drumco of Arkansas, Myers Container LLC, Con-Tech International, E-Con Packaging, Pacific Compaction, Consolidated Container Company, Plastipak Holdings Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plastic Drums Market Key Technology Landscape

The Plastic Drums Market is underpinned by several key manufacturing technologies that enable the production of durable, cost-effective, and compliant containers. The most prominent technology is blow molding, specifically extrusion blow molding, which involves extruding molten plastic into a parison (a hollow tube) and then inflating it inside a mold to form the drum. This method is highly efficient for producing large, hollow parts like drums and barrels, allowing for continuous high-volume production with excellent consistency in wall thickness and structural integrity. Advancements in blow molding include multi-layer co-extrusion, which allows for the creation of drums with barrier properties, protecting contents from oxygen or moisture ingress, and enhancing chemical resistance for hazardous materials. Manufacturers are continually investing in more energy-efficient blow molding machines and optimizing cycle times to boost productivity and reduce operational costs.

Another significant technology utilized in the market is injection molding, primarily for producing drum components such as caps, bungs, and fittings. While full drums are typically blow molded, injection molding offers precision and complex geometry capabilities essential for critical sealing components. Recent technological advancements include robotics and automation integration into both blow molding and injection molding lines, which enhance precision, reduce labor costs, and improve safety in manufacturing environments. These automated systems can handle material loading, mold clamping, part ejection, and secondary operations like trimming and leak testing, ensuring high-quality output with minimal human intervention. Furthermore, the development of advanced polymer science contributes to the technology landscape, with research focusing on creating lighter, stronger, and more sustainable plastic resins, including those derived from recycled content or bio-based sources.

The rise of Industry 4.0 concepts is also transforming the plastic drums manufacturing landscape, with the adoption of smart manufacturing technologies. This includes the implementation of IoT sensors within production machinery to monitor performance, predict maintenance needs, and collect real-time data for process optimization. Data analytics and artificial intelligence (AI) are being applied to analyze this data, leading to improved material usage, reduced waste, and enhanced overall equipment effectiveness (OEE). Beyond manufacturing, technologies for enhanced sustainability are gaining traction, such as advanced mechanical and chemical recycling processes for plastic drums, which aim to close the loop on plastic waste and promote a circular economy. The ability to track and trace drums throughout their lifecycle using digital identifiers or embedded chips also represents an evolving technological trend, enhancing supply chain visibility and product security. These technological advancements collectively drive efficiency, sustainability, and innovation within the Plastic Drums Market.

Regional Highlights

- North America: This region presents a mature market characterized by stringent safety and environmental regulations, particularly for the transport of hazardous chemicals. The demand is steady, driven by established chemical, pharmaceutical, and food processing industries. Innovation focuses on sustainable solutions, lightweighting, and advanced material performance to meet high industry standards and environmental goals.

- Europe: Europe is another mature market with a strong emphasis on sustainability, circular economy initiatives, and adherence to REACH regulations. Countries like Germany, France, and the UK are key contributors. Demand is consistent from the chemical, automotive, and food sectors, with a growing trend towards drums made from recycled content and improved reusability.

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market for plastic drums, propelled by rapid industrialization, burgeoning manufacturing capabilities, and increasing domestic consumption in countries such as China, India, and Southeast Asian nations. The region's growth is driven by expanding chemical production, food and beverage processing, and pharmaceutical manufacturing, with significant investments in new production facilities.

- Latin America: This region is experiencing steady growth, fueled by industrial development and increasing trade activities, particularly in Brazil and Mexico. Demand for plastic drums comes from the agricultural, chemical, and petroleum sectors. Market expansion is supported by improving economic conditions and increased foreign investment in manufacturing and infrastructure.

- Middle East and Africa (MEA): The MEA region offers emerging opportunities, primarily driven by the expansion of the petrochemical industry, increasing investment in manufacturing, and growing demand from agriculture and water treatment sectors. Countries in the GCC region and South Africa are key markets, focusing on developing local production capabilities and meeting regional industrial needs. The market is influenced by infrastructure projects and economic diversification efforts.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plastic Drums Market.- Greif Inc.

- Mauser Packaging Solutions

- RPC Group Plc

- Indorama Ventures Public Company Limited

- Schutz Container Systems Inc.

- Berenfield Containers Inc.

- The Cary Company

- Tri-Sure

- Industrial Container Services Inc.

- Remcon Plastics Inc.

- Fibrosan

- Werit Kunststoffwerke W. Schneider GmbH & Co. KG

- Great Western Containers Inc.

- Drumco of Arkansas

- Myers Container LLC

- Con-Tech International

- E-Con Packaging

- Pacific Compaction

- Consolidated Container Company

- Plastipak Holdings Inc.

Frequently Asked Questions

What are the primary applications of plastic drums?

Plastic drums are predominantly used for the storage and transportation of bulk liquids and solids across various industries. Key applications include chemicals and solvents, food ingredients, pharmaceutical raw materials, petroleum products, and agricultural compounds due to their chemical resistance and durability.

Which material is most commonly used for manufacturing plastic drums?

High-Density Polyethylene (HDPE) is the most widely used material for manufacturing plastic drums. Its superior chemical resistance, impact strength, and favorable weight-to-strength ratio make it ideal for industrial packaging applications, ensuring the safe containment of diverse contents.

How do environmental regulations impact the Plastic Drums Market?

Environmental regulations significantly influence the market by driving demand for sustainable solutions. This includes mandating increased use of recycled content, promoting reusability, and encouraging advanced recycling technologies, pushing manufacturers towards greener production practices and products.

What is the projected growth rate for the Plastic Drums Market?

The Plastic Drums Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. This growth is primarily driven by expanding industrial sectors and increasing demand for efficient bulk packaging solutions globally.

What are the key technological advancements in plastic drum manufacturing?

Key technological advancements include enhanced blow molding processes for improved material efficiency, automation and robotics for precision manufacturing, and the integration of IoT for smart drums. There is also a focus on advanced recycling techniques and the development of sustainable polymer formulations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager