Process Instrumentation Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431093 | Date : Nov, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Process Instrumentation Market Size

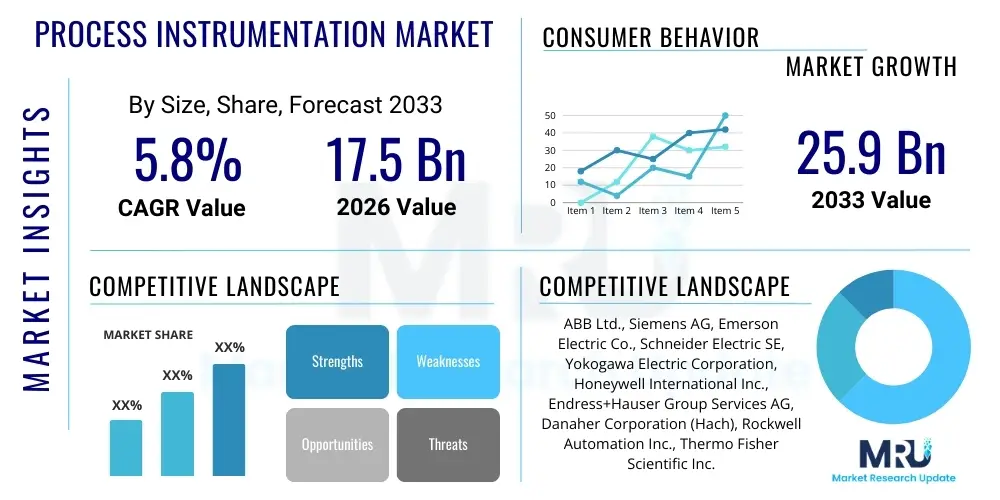

The Process Instrumentation Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 21.5 billion in 2025 and is projected to reach USD 34.3 billion by the end of the forecast period in 2032.

Process Instrumentation Market introduction

The Process Instrumentation Market encompasses a wide array of devices and systems designed to measure, monitor, control, and analyze various physical and chemical parameters within industrial processes. These instruments are fundamental to ensuring the safe, efficient, and reliable operation of manufacturing plants across diverse sectors. Products typically include sensors, transmitters, controllers, control valves, analyzers, and recorders, each playing a crucial role in maintaining optimal process conditions and product quality. The sophistication of these instruments ranges from basic field devices to advanced integrated control systems.

Major applications of process instrumentation span critical industries such as oil and gas, chemicals, pharmaceuticals, food and beverage, power generation, and water and wastewater treatment. In these sectors, process instrumentation is essential for tasks like precise temperature regulation in chemical reactors, accurate flow measurement in pipelines, level detection in storage tanks, and pressure monitoring in high-pressure systems. The ability to precisely control these variables directly impacts operational safety, environmental compliance, and the consistency of the final product, making these technologies indispensable for modern industrial operations.

The benefits derived from advanced process instrumentation are extensive, including enhanced operational efficiency, improved product quality and consistency, increased plant safety, reduced waste, and adherence to stringent regulatory standards. Driving factors for market growth include the escalating demand for industrial automation, the imperative for improved resource efficiency and energy conservation, and the stringent regulatory frameworks governing environmental protection and industrial safety. Furthermore, the ongoing digitalization of industrial processes and the integration of advanced analytics are propelling the market forward, transforming traditional operations into highly optimized and data-driven environments.

Process Instrumentation Market Executive Summary

The Process Instrumentation Market is currently experiencing robust growth, driven by an accelerating global trend towards industrial automation and the continuous pursuit of operational excellence across manufacturing sectors. Key business trends indicate a significant shift towards smart instrumentation, characterized by enhanced connectivity, embedded intelligence, and the capability for real-time data analysis. This move aligns with broader Industry 4.0 initiatives, where the seamless integration of devices, data, and decentralized decision-making processes is paramount. Companies are increasingly investing in digital solutions to optimize production, minimize downtime, and reduce operational costs, making advanced process instrumentation a central component of their digital transformation strategies.

Regional trends highlight the Asia Pacific region as the most dynamic growth hub, fueled by rapid industrialization, burgeoning manufacturing sectors, and substantial investments in infrastructure development, particularly in countries like China, India, and Southeast Asian nations. North America and Europe, while mature markets, continue to demonstrate steady growth, primarily driven by the adoption of advanced and smart instrumentation technologies, a focus on upgrading existing facilities, and strict regulatory compliance requirements. The Middle East and Africa, along alongside Latin America, are also showing promising growth potential, spurred by investments in oil and gas, mining, and water infrastructure projects, which necessitate sophisticated process control solutions.

Segment trends reveal that sensors and transmitters continue to dominate the market due to their foundational role in data acquisition, providing the critical inputs for all subsequent control actions. However, the fastest-growing segments are anticipated to be advanced analytical instruments and smart control valves, propelled by the increasing demand for precise process monitoring, predictive maintenance capabilities, and intelligent control systems that can adapt to dynamic operating conditions. The widespread adoption of wireless communication protocols and cloud-based platforms is also reshaping the market, enabling more flexible and scalable instrumentation architectures, and thereby fostering new opportunities for innovation and competitive differentiation among market participants.

AI Impact Analysis on Process Instrumentation Market

User inquiries concerning the impact of Artificial Intelligence (AI) on the Process Instrumentation Market frequently center on its potential to revolutionize operational efficiency, predictive capabilities, and decision-making processes. Common questions explore how AI can enhance the accuracy and reliability of measurements, optimize control loops, facilitate predictive maintenance, and integrate seamlessly with existing legacy systems. There is a strong user expectation that AI will lead to more autonomous operations, allowing plants to respond dynamically to changing conditions with minimal human intervention. Additionally, concerns often arise regarding the complexity of integrating AI, data security implications, the need for specialized skills, and the return on investment for such advanced technological adoptions.

The key themes emerging from this analysis suggest that users anticipate AI will move process instrumentation beyond traditional control towards intelligent, self-optimizing systems. The emphasis is on leveraging AI for advanced pattern recognition, anomaly detection, and prescriptive analytics, which can preemptively identify potential equipment failures or process deviations before they escalate into costly problems. This shift is expected to improve overall equipment effectiveness (OEE), enhance product quality consistency, and significantly reduce operational downtime, thereby transforming the maintenance paradigm from reactive to highly proactive and intelligent.

Ultimately, the overarching expectation is that AI will make process instrumentation more resilient, adaptive, and intelligent, capable of deriving actionable insights from vast amounts of process data. While users acknowledge the transformative potential, they also express a need for clearer pathways for implementation, standardized integration protocols, and robust cybersecurity measures to safeguard sensitive operational data. The market is poised for an evolution where AI-driven insights will be crucial for optimizing energy consumption, reducing environmental footprint, and enabling smarter, more sustainable industrial operations in the long term.

- Enhanced predictive maintenance and fault detection, minimizing unplanned downtime.

- Optimized process control through adaptive algorithms and real-time data analysis.

- Improved anomaly detection, identifying subtle deviations invisible to traditional methods.

- Increased operational efficiency and energy consumption reduction.

- Automated decision-making for faster response to process changes.

- Better resource utilization and waste minimization.

- Enhanced data analysis and interpretation from multiple sensor inputs.

- Facilitation of digital twin technology for virtual process simulation and optimization.

- Development of self-calibrating and self-diagnosing instrumentation.

- New cybersecurity challenges and requirements for AI-integrated systems.

- Need for a skilled workforce capable of deploying and managing AI solutions.

- Potential for fully autonomous industrial plants in the future.

- Greater integration of disparate systems for a holistic view of operations.

- Personalized process optimization recommendations for operators.

- Reduced human error in monitoring and control tasks.

DRO & Impact Forces Of Process Instrumentation Market

The Process Instrumentation Market is significantly shaped by a dynamic interplay of drivers, restraints, opportunities, and various impact forces that influence its growth trajectory and evolutionary path. The primary drivers include the escalating global demand for industrial automation across manufacturing sectors seeking to enhance efficiency, reduce labor costs, and improve safety standards. The advent of Industry 4.0 and the Industrial Internet of Things (IIoT) further accelerate this demand, pushing for smarter, connected, and data-driven instrumentation. Additionally, stringent regulatory frameworks concerning environmental protection, quality control, and workplace safety compel industries to adopt advanced instrumentation for accurate monitoring and compliance reporting, fostering innovation and market expansion.

However, the market also faces considerable restraints that temper its growth. The high initial capital investment required for implementing sophisticated process instrumentation and integrated control systems can be a significant barrier, particularly for small and medium-sized enterprises. The complexity associated with integrating new, advanced instrumentation with existing legacy systems presents technical challenges and necessitates specialized expertise, leading to potential implementation delays and increased costs. Furthermore, cybersecurity concerns are growing as more instrumentation becomes connected, posing risks of data breaches and operational disruptions, which require robust protective measures and continuous vigilance, adding to the operational overhead.

Despite these challenges, numerous opportunities are propelling the market forward. The increasing adoption of advanced analytics, artificial intelligence, and machine learning capabilities offers substantial potential for predictive maintenance, real-time optimization, and enhanced decision-making in industrial processes. The rise of digital twin technology allows for virtual commissioning and continuous optimization, providing new avenues for instrumentation suppliers. Moreover, the expanding industrial base in emerging economies and the imperative for sustainable manufacturing practices, including energy efficiency and reduced resource consumption, create fertile ground for innovative and energy-efficient process instrumentation solutions, opening new markets and application areas for vendors.

Segmentation Analysis

The Process Instrumentation Market is extensively segmented across various parameters including product type, application, industry, and technology, providing a granular view of market dynamics and growth opportunities. This detailed segmentation helps in understanding the diverse needs of end-users and the specialized offerings of manufacturers, enabling targeted market strategies. Each segment reflects unique characteristics in terms of demand drivers, technological advancements, and competitive landscapes, underpinning the complex ecosystem of industrial measurement and control.

The segmentation by product type typically includes a wide range of devices such as sensors and transmitters for fundamental data acquisition, control valves and actuators for manipulating process variables, and analytical instruments for precise material composition analysis. Further breakdowns consider recorders, controllers, and specialized instruments catering to specific process requirements. This categorization is crucial for understanding the foundational components that form the backbone of industrial control systems and the varying degrees of sophistication and integration they offer within an operational environment.

When analyzing the market by application, categories like flow, level, pressure, and temperature measurement are prominent, reflecting the most common physical parameters that need precise monitoring and control in industrial settings. The industry segmentation covers major sectors such as oil and gas, chemicals, power generation, food and beverage, pharmaceuticals, metals and mining, and water and wastewater treatment, each exhibiting distinct instrumentation requirements due to their unique operational challenges, regulatory environments, and product specificities. The technology segment addresses the adoption of advanced features like wireless connectivity, IoT integration, and smart diagnostics, showcasing the market's progression towards more intelligent and interconnected solutions.

- By Product Type

- Sensors and Transmitters

- Temperature Transmitters

- Pressure Transmitters

- Flow Transmitters

- Level Transmitters

- pH and Conductivity Transmitters

- Humidity Transmitters

- Density Transmitters

- Control Valves

- Globe Valves

- Ball Valves

- Butterfly Valves

- Diaphragm Valves

- Gate Valves

- Plug Valves

- Actuators (Pneumatic, Electric, Hydraulic)

- Analyzers

- Gas Analyzers

- Liquid Analyzers (pH, Conductivity, Oxygen, Turbidity)

- Chromatographs

- Spectrophotometers

- Moisture Analyzers

- Recorders and Controllers

- Data Loggers

- Chart Recorders

- Programmable Logic Controllers (PLCs)

- Distributed Control Systems (DCS)

- Supervisory Control and Data Acquisition (SCADA) Systems

- Single Loop Controllers

- Other Instrumentation (e.g., Positioners, Converters, Signal Conditioners)

- Sensors and Transmitters

- By Application

- Flow Measurement

- Level Measurement

- Pressure Measurement

- Temperature Measurement

- Analytical Measurement (pH, Conductivity, Oxygen, etc.)

- Data Acquisition and Control

- Safety and Environmental Monitoring

- By Industry Vertical

- Oil and Gas

- Chemical and Petrochemical

- Power Generation

- Water and Wastewater Treatment

- Food and Beverage

- Pharmaceutical and Biotechnology

- Metals and Mining

- Pulp and Paper

- Textile

- Building Automation

- Semiconductor and Electronics

- Others (e.g., Automotive, Marine)

- By Technology

- Wired Instrumentation

- Wireless Instrumentation

- Smart Instrumentation

- IoT and IIoT Enabled Devices

Value Chain Analysis For Process Instrumentation Market

The value chain for the Process Instrumentation Market is intricate, involving multiple stages from raw material sourcing to end-user application and after-sales support. The upstream analysis begins with the procurement of fundamental raw materials such as specialized metals, plastics, semiconductors, and electronic components essential for manufacturing sensors, transmitters, and various control devices. Suppliers in this segment are crucial for providing high-quality, reliable, and often custom-fabricated components that meet stringent industrial standards. Their ability to deliver on time and to specification directly impacts the manufacturing efficiency and cost-effectiveness of instrumentation producers, forming the bedrock of the entire value chain.

Moving downstream, the value chain encompasses the core activities of process instrumentation manufacturers who design, assemble, calibrate, and test the final products. This stage also includes software developers who create the sophisticated algorithms and user interfaces for control systems, data analytics platforms, and HMI (Human Machine Interface) solutions. Post-manufacturing, the products flow through various distribution channels to reach the end-users. These channels can be broadly categorized into direct and indirect routes. Direct sales involve manufacturers selling directly to large industrial clients, often accompanied by comprehensive technical support, installation services, and training programs, fostering strong customer relationships.

Indirect distribution channels typically involve a network of authorized distributors, resellers, and system integrators. Distributors stock a wide range of products and cater to smaller clients or provide local access to instruments. System integrators play a pivotal role by combining various instruments, software, and control systems to create complete, customized automation solutions tailored to specific plant requirements. These integrators often provide consultancy, installation, commissioning, and ongoing maintenance services, acting as a crucial link between product manufacturers and diverse end-users. The efficiency and effectiveness of these distribution channels are paramount for market penetration and customer satisfaction, ensuring that advanced instrumentation reaches the plants that need it most for optimized operations.

Process Instrumentation Market Potential Customers

The potential customer base for the Process Instrumentation Market is exceptionally broad and diverse, primarily comprising industries that rely heavily on precise control, monitoring, and analysis of various physical and chemical processes to produce goods or services. These end-users, or buyers of the product, are typically large-scale manufacturing and processing plants across multiple sectors where operational efficiency, safety, product quality, and regulatory compliance are paramount. The fundamental need to automate, optimize, and secure complex industrial operations drives the demand for sophisticated instrumentation across these varied environments.

Key segments of potential customers include the oil and gas industry, where process instrumentation is critical for exploration, production, refining, and distribution activities to ensure safety, efficiency, and environmental compliance in highly volatile environments. Similarly, the chemical and petrochemical sectors are major consumers, utilizing instrumentation for reactor control, blend operations, and quality assurance in the production of a vast array of chemicals. The power generation sector, encompassing thermal, nuclear, and renewable energy plants, depends on these instruments for turbine control, boiler management, and grid stability, ensuring reliable and efficient electricity supply.

Beyond these heavy industries, the food and beverage sector requires precise instrumentation for recipe management, pasteurization, fermentation, and packaging to maintain hygiene standards and consistent product quality. Pharmaceutical and biotechnology companies use process instrumentation extensively for highly regulated processes such as fermentation, purification, and sterile manufacturing, where even minute deviations can have significant implications for product efficacy and safety. Furthermore, the water and wastewater treatment industries are vital customers, leveraging instrumentation for monitoring water quality, flow rates, and chemical dosing to ensure public health and environmental protection. This extensive and critical dependence makes the industrial plant operators, process engineers, maintenance managers, and R&D teams within these sectors the primary purchasers and beneficiaries of process instrumentation solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 21.5 Billion |

| Market Forecast in 2032 | USD 34.3 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, ABB Ltd., Emerson Electric Co., Honeywell International Inc., Schneider Electric SE, Yokogawa Electric Corporation, Rockwell Automation Inc., Endress+Hauser Group Services AG, Fuji Electric Co., Ltd., KROHNE Messtechnik GmbH, WIKA Alexander Wiegand SE & Co. KG, Dwyer Instruments LLC, Omega Engineering Inc., Brooks Instrument LLC, Thermo Fisher Scientific Inc., Danaher Corporation (including Hach, Pall), Azbil Corporation, General Electric (GE), Metso Outotec Corporation, Bürkert Fluid Control Systems. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Process Instrumentation Market Key Technology Landscape

The Process Instrumentation Market is continuously evolving, driven by rapid advancements in several key technologies that are fundamentally reshaping how industrial processes are measured, monitored, and controlled. A significant trend is the pervasive integration of the Industrial Internet of Things (IIoT) and cloud computing, enabling instruments to not only collect vast amounts of data but also transmit it wirelessly to centralized platforms for real-time analysis and remote management. This connectivity facilitates unprecedented levels of transparency and control across entire operational landscapes, moving beyond localized control to enterprise-wide optimization and predictive capabilities, thereby dramatically improving operational visibility and efficiency.

Further enhancing this connectivity is the widespread adoption of advanced sensor technologies, including Micro-Electro-Mechanical Systems (MEMS) and sophisticated analytical sensors, which offer higher accuracy, greater reliability, and smaller footprints. These sensors are increasingly integrated with embedded intelligence, allowing for on-device data processing and self-diagnostics, reducing the reliance on external computational power and improving response times. Wireless communication protocols such as WirelessHART and ISA100.11a are becoming standard, offering flexible and cost-effective deployment in harsh industrial environments where traditional wired installations are impractical or prohibitively expensive, leading to more agile and scalable instrumentation networks.

The application of Artificial Intelligence (AI) and Machine Learning (ML) algorithms represents another critical technological shift, transforming raw process data into actionable insights. AI-powered analytics are enabling predictive maintenance, anomaly detection, and advanced process optimization, allowing systems to learn from operational history and make autonomous adjustments to improve performance and prevent failures. Additionally, the development and deployment of digital twin technology are gaining traction, providing virtual replicas of physical assets and processes. This allows for simulation, testing, and optimization of instrumentation and control strategies in a virtual environment before physical implementation, significantly reducing risks and accelerating innovation cycles in the dynamic landscape of modern industrial operations.

Regional Highlights

- North America: This region represents a mature and technologically advanced market for process instrumentation. Growth is primarily driven by the continuous upgrade of existing infrastructure, strict environmental regulations, and the robust adoption of Industry 4.0 initiatives in sectors like oil and gas, chemicals, and pharmaceuticals. Companies in North America are investing heavily in smart sensors, wireless connectivity, and AI-driven analytics to enhance efficiency and maintain a competitive edge, focusing on high-value, sophisticated instrumentation solutions.

- Europe: The European market is characterized by stringent regulatory standards, a strong emphasis on sustainability, and a high degree of industrial automation, particularly in countries like Germany and the UK. The region is a hub for innovation in process instrumentation, with significant investments in research and development for energy-efficient solutions and advanced control systems. The adoption of smart manufacturing practices and circular economy principles is further propelling the demand for highly precise and integrated instrumentation technologies across diverse industries.

- Asia Pacific (APAC): APAC is the fastest-growing market, propelled by rapid industrialization, massive infrastructure development, and increasing foreign investments in manufacturing across countries such as China, India, Japan, and South Korea. The burgeoning demand from chemical, food and beverage, power generation, and water treatment sectors, combined with the region's focus on scaling production capabilities, drives substantial uptake of both foundational and advanced process instrumentation. The competitive landscape in APAC also encourages localized production and cost-effective solutions.

- Latin America: This region exhibits significant growth potential, primarily influenced by investments in natural resources extraction, particularly in the oil and gas and mining sectors, as well as an expanding manufacturing base. Countries like Brazil, Mexico, and Argentina are gradually adopting modern process instrumentation to improve operational efficiency and safety. While market maturity is lower compared to developed regions, the ongoing industrialization and infrastructure projects present considerable opportunities for market expansion, especially for robust and adaptable instrumentation.

- Middle East and Africa (MEA): The MEA market is heavily influenced by the dominant oil and gas industry, which accounts for a substantial share of instrumentation demand for exploration, production, and refining operations. Beyond oil and gas, diversification efforts in manufacturing, water desalination, and power generation are creating new avenues for process instrumentation. Countries such as Saudi Arabia, UAE, and South Africa are leading in adopting advanced technologies to enhance operational resilience and meet growing industrial demands, focusing on high-reliability and specialized instrumentation for demanding environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Process Instrumentation Market.- Siemens AG

- ABB Ltd.

- Emerson Electric Co.

- Honeywell International Inc.

- Schneider Electric SE

- Yokogawa Electric Corporation

- Rockwell Automation Inc.

- Endress+Hauser Group Services AG

- Fuji Electric Co., Ltd.

- KROHNE Messtechnik GmbH

- WIKA Alexander Wiegand SE & Co. KG

- Dwyer Instruments LLC

- Omega Engineering Inc.

- Brooks Instrument LLC

- Thermo Fisher Scientific Inc.

- Danaher Corporation

- Azbil Corporation

- General Electric (GE)

- Metso Outotec Corporation

- Bürkert Fluid Control Systems

Frequently Asked Questions

What is process instrumentation and its primary purpose?

Process instrumentation refers to a range of devices and systems used in industrial plants to measure, monitor, control, and analyze physical and chemical parameters such as temperature, pressure, flow, and level. Its primary purpose is to ensure the safe, efficient, and consistent operation of industrial processes, optimize production, and maintain product quality by providing accurate real-time data and automated control capabilities.

How does process instrumentation contribute to industrial efficiency and safety?

Process instrumentation significantly enhances industrial efficiency by enabling precise control over various operational parameters, reducing waste, optimizing resource consumption, and minimizing downtime through predictive maintenance. For safety, it provides critical monitoring and alarm functions, detecting hazardous conditions early and facilitating automated shutdowns, thereby protecting personnel, equipment, and the environment from potential risks and catastrophic failures.

What are the key technological trends shaping the Process Instrumentation Market?

Key technological trends include the pervasive integration of the Industrial Internet of Things (IIoT) and cloud computing for enhanced connectivity and data analytics, the adoption of Artificial Intelligence (AI) and Machine Learning (ML) for predictive maintenance and optimization, advanced sensor technologies offering higher accuracy, and the increasing use of wireless communication protocols and digital twin technology for simulation and virtual commissioning.

Which industries are the major consumers of process instrumentation products?

The major consumers of process instrumentation products span a wide array of industries including oil and gas, chemical and petrochemical, power generation, water and wastewater treatment, food and beverage, pharmaceutical and biotechnology, and metals and mining. These sectors rely on precise control and monitoring for their core operations, product quality, safety, and regulatory compliance requirements.

What are the main challenges faced by the Process Instrumentation Market?

The primary challenges include the high initial capital investment required for advanced systems, the complexity of integrating new instrumentation with existing legacy infrastructure, growing cybersecurity concerns related to connected devices, and a persistent shortage of skilled professionals capable of deploying, managing, and maintaining sophisticated instrumentation and control systems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Process Instrumentation Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Process Instrumentation Equipments Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (SCADA, DCS, PLS, MES), By Application (Household, Automotive, Aircraft, Laboratory Instrumentation, Other), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager