Water-Based Adhesive Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429498 | Date : Nov, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Water-Based Adhesive Market Size

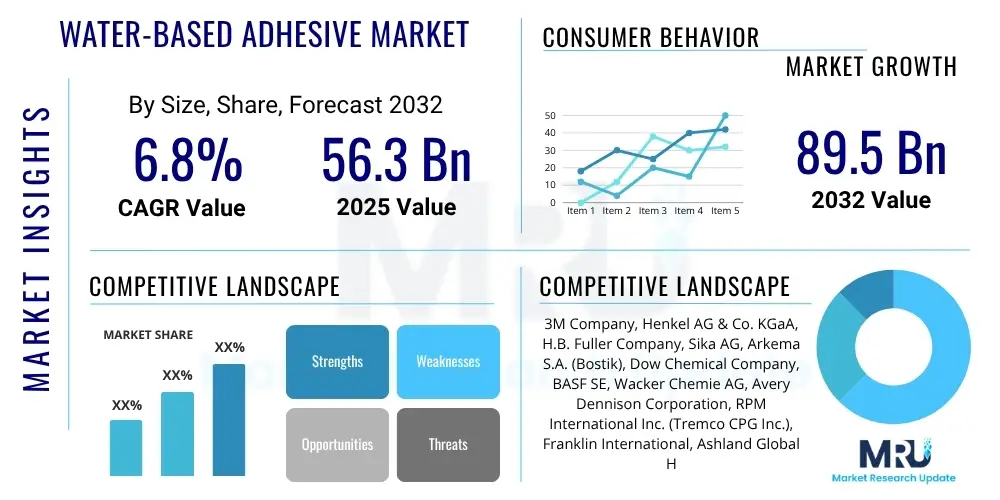

The Water-Based Adhesive Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 56.3 billion in 2025 and is projected to reach USD 89.5 billion by the end of the forecast period in 2032.

Water-Based Adhesive Market introduction

The Water-Based Adhesive Market encompasses a broad range of bonding solutions where polymers are dispersed in water as a carrier medium, rather than organic solvents. These adhesives are gaining significant traction across various industrial and consumer applications due to their environmentally friendly profile, characterized by low volatile organic compound (VOC) emissions, non-flammability, and ease of cleanup. The product descriptions typically highlight their versatility in bonding diverse substrates, including paper, cardboard, wood, plastics, and certain metals, making them indispensable across industries seeking sustainable and safer alternatives to traditional solvent-based systems. Their inherent benefits, such as reduced health hazards for workers and compliance with stringent environmental regulations, underpin their increasing adoption.

Major applications for water-based adhesives span critical sectors including packaging, where they are vital for carton sealing, laminations, and labeling due to their rapid setting and strong adhesion properties. In the construction industry, they are used for flooring, wall coverings, and insulation. The automotive sector utilizes them for interior trim and textile bonding, while woodworking benefits from their strong bond in furniture assembly and veneer applications. The textile industry employs these adhesives for fabric lamination and non-woven manufacturing. These diverse applications underscore the product's adaptability and performance across a spectrum of manufacturing processes, consistently meeting industry demands for reliable and sustainable bonding solutions.

Several driving factors are propelling the growth of the Water-Based Adhesive Market. Foremost among these are the escalating environmental concerns and the subsequent proliferation of strict regulations aimed at reducing VOC emissions and promoting eco-friendly manufacturing processes globally. Consumers' increasing demand for sustainable products also influences manufacturers to adopt greener solutions throughout their supply chains. Furthermore, continuous advancements in polymer science and adhesive formulation are enhancing the performance characteristics of water-based adhesives, allowing them to compete effectively with solvent-based and hot-melt alternatives in terms of bond strength, durability, and application speed. This technological progress, coupled with growing awareness of worker safety, positions water-based adhesives as a preferred choice for future industrial and commercial needs.

Water-Based Adhesive Market Executive Summary

The Water-Based Adhesive Market is undergoing a significant transformation, driven by a confluence of evolving business trends. Industry participants are increasingly investing in research and development to innovate high-performance water-based formulations that can meet the demanding requirements of various end-use sectors, including automotive, construction, and electronics. This strategic focus on innovation aims to overcome historical limitations associated with water-based systems, such as slower drying times and lower initial tack in certain applications. Additionally, there is a clear trend towards market consolidation, with larger chemical companies acquiring smaller specialized adhesive manufacturers to expand their product portfolios and geographical reach, thereby enhancing their competitive edge and fostering economies of scale. Sustainability initiatives and circular economy principles are also shaping business strategies, pushing companies to develop bio-based and recyclable water-based adhesives, further aligning with global environmental goals.

Regional trends indicate robust growth in emerging economies, particularly across the Asia Pacific (APAC) region. Countries like China, India, and Southeast Asian nations are witnessing rapid industrialization, urbanization, and increasing manufacturing activities, which translates into a surging demand for adhesives in packaging, construction, and automotive industries. This growth is often supported by less stringent environmental regulations compared to developed regions, though awareness is steadily rising. Conversely, North America and Europe, characterized by mature markets, are experiencing growth primarily driven by stringent environmental policies, such as the European Union's REACH regulations and the US EPA's directives, which compel industries to transition from solvent-based to water-based alternatives. These developed regions are also at the forefront of adopting advanced water-based adhesive technologies and specialty formulations for high-value applications, demonstrating a shift towards premium and customized solutions.

Segmentation trends within the Water-Based Adhesive Market reveal dynamic shifts in demand across different product types and applications. Acrylic-based water adhesives, known for their versatility, excellent adhesion, and weather resistance, continue to dominate a substantial share of the market, finding extensive use in tapes, labels, and construction. Vinyl acetate emulsions, including PVAc, are critical for woodworking and packaging due to their cost-effectiveness and good bonding properties. Polyurethane dispersions (PUDs) are gaining traction in flexible packaging, automotive interiors, and textile lamination, offering superior flexibility and strength. Application-wise, the packaging segment remains the largest consumer, driven by the booming e-commerce sector and the need for efficient and sustainable packaging solutions. The construction and automotive sectors are also significant growth drivers, propelled by infrastructure development and the increasing adoption of lightweight materials, where water-based adhesives offer effective bonding solutions while meeting stringent safety and environmental standards.

AI Impact Analysis on Water-Based Adhesive Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Water-Based Adhesive Market frequently revolve around optimizing formulation, enhancing production efficiency, improving quality control, and driving sustainable innovation. Key themes include the potential for AI to accelerate research and development cycles by predicting material properties and optimizing ingredient ratios, thereby reducing trial-and-error and speeding up time-to-market for novel adhesive solutions. Users are also concerned with how AI can revolutionize manufacturing processes through predictive maintenance, real-time quality monitoring, and automated process adjustments, leading to reduced waste and improved resource efficiency. Expectations often focus on AI's capability to analyze complex datasets to identify patterns that lead to superior product performance or more environmentally benign formulations, addressing industry demands for both innovation and sustainability. Concerns sometimes emerge around the initial investment costs and the need for specialized data infrastructure and expertise to effectively implement AI technologies within adhesive manufacturing operations.

- AI can significantly accelerate the discovery and optimization of new water-based adhesive formulations by predicting material interactions and performance characteristics, reducing extensive laboratory testing.

- Predictive analytics powered by AI can enhance manufacturing efficiency by optimizing production parameters, minimizing downtime, and preventing defects in real-time.

- AI-driven quality control systems can continuously monitor adhesive properties during production, ensuring consistent product quality and adherence to specifications, thereby reducing batch variations.

- The use of machine learning algorithms can help in identifying and sourcing more sustainable or bio-based raw materials, enabling the development of truly eco-friendly water-based adhesives.

- AI can optimize supply chain logistics for raw materials and finished products, leading to cost reductions, improved inventory management, and more efficient distribution channels within the adhesive market.

- Automated inspection systems utilizing computer vision and AI can precisely identify application errors or bonding imperfections, improving the final product's reliability and integrity.

DRO & Impact Forces Of Water-Based Adhesive Market

The Water-Based Adhesive Market is significantly shaped by a robust set of drivers, primarily centered around environmental mandates and the global shift towards sustainable industrial practices. Stringent government regulations worldwide, particularly in North America and Europe, increasingly limit volatile organic compound (VOC) emissions from industrial processes, thereby compelling manufacturers to adopt water-based adhesive solutions. This regulatory pressure is a major catalyst, as companies seek compliance while maintaining operational efficiency. Beyond regulation, growing consumer awareness and demand for eco-friendly products across sectors like packaging and construction are pushing brand owners to incorporate sustainable materials, including water-based adhesives, into their value chains. The inherent safety advantages, such as non-flammability and reduced worker exposure to hazardous chemicals, also make water-based adhesives a preferred choice in diverse manufacturing environments. Furthermore, continuous innovation in polymer science has led to the development of high-performance water-based formulations that offer comparable or even superior bonding strength and durability to their solvent-based counterparts, expanding their applicability across more demanding industrial uses.

However, the market also faces notable restraints that can impede its growth. One significant challenge is the performance limitations of certain water-based adhesives in specific high-stress or extreme environmental applications where solvent-based or hot-melt adhesives may still offer superior immediate tack, water resistance, or heat resistance. Longer drying and curing times associated with water evaporation can slow down production lines, particularly in high-volume manufacturing settings, posing an operational efficiency challenge for some industries. Additionally, the sensitivity of water-based formulations to freezing temperatures during storage and transportation can lead to product degradation, requiring specialized handling and logistical considerations that add to costs. Price competition from conventional adhesive types, especially in developing markets where environmental regulations are less strict, also represents a restraint. Overcoming these performance and operational challenges requires ongoing technological advancements and tailored solutions for specific end-use requirements.

Despite these restraints, significant opportunities are present that can drive substantial market expansion. The rapid industrialization and urbanization in emerging economies across Asia Pacific and Latin America are fueling demand for adhesives in construction, packaging, and automotive industries, offering vast untapped potential for water-based solutions. The increasing adoption of bio-based materials and the development of bio-degradable water-based adhesives present a substantial opportunity for sustainable product differentiation and market penetration into eco-conscious segments. Furthermore, the integration of smart manufacturing technologies, including automation and advanced dispensing systems, can mitigate the issue of longer drying times by optimizing application processes and enabling faster throughput. Research into novel cross-linking technologies and polymer modifications is also creating opportunities to enhance the performance attributes of water-based adhesives, making them suitable for an even broader range of specialized and high-performance applications. The confluence of regulatory support, technological innovation, and evolving market demands positions water-based adhesives for continued growth as a preferred bonding solution.

Segmentation Analysis

The Water-Based Adhesive Market is meticulously segmented across various parameters, including resin type, application, and end-use industry, to provide a comprehensive understanding of its intricate dynamics and growth trajectories. This granular segmentation allows for targeted analysis of market drivers, restraints, and opportunities within specific niches, reflecting the diverse requirements and performance demands across different sectors. Understanding these segments is crucial for manufacturers to tailor their product offerings, for distributors to optimize their supply chains, and for investors to identify high-growth areas. The primary classifications by resin type highlight the chemical diversity and functional capabilities of these adhesives, while application-based segmentation emphasizes their utility in various bonding scenarios, and end-use industry segmentation directly links adhesive consumption to industrial activity and growth.

- By Resin Type

- Acrylic Adhesives: Known for versatility, weather resistance, and strong adhesion on various substrates, used in tapes, labels, construction, and automotive.

- Vinyl Acetate Adhesives (PVAc, EVA): Cost-effective, good for paper, wood, and textiles; widely used in packaging, woodworking, and non-woven fabrics.

- Polyurethane Dispersions (PUDs): Offer flexibility, durability, and chemical resistance; used in automotive, textiles, flexible packaging, and footwear.

- Epoxy Adhesives: Provide high strength, chemical, and heat resistance; used in construction, electronics, and composites for structural bonding.

- SBR Latex Adhesives: Offer good flexibility and adhesion to various surfaces, common in carpet backings, construction, and laminations.

- Natural Rubber Latex Adhesives: Derived from natural sources, used in specific applications like medical tapes and fabric bonding.

- Starch-based Adhesives: Environmentally friendly, biodegradable, primarily used in paper and packaging.

- Protein-based Adhesives: Bio-based alternatives, gaining traction in specialized packaging and woodworking.

- Other Resin Types: Including polyester, polyamide, and specialty polymers for niche applications.

- By Application

- Packaging: Carton sealing, laminating, labeling, flexible packaging, rigid packaging.

- Construction: Flooring (adhesives for carpet, vinyl, wood), wall coverings, insulation, roofing, tiling.

- Automotive: Interior trim, headliners, seating, door panels, weather stripping, lightweight component assembly.

- Woodworking: Furniture assembly, veneer bonding, panel lamination, cabinetry.

- Textiles: Fabric lamination, non-woven fabrics, garment assembly, carpet manufacturing.

- Footwear: Shoe assembly, component bonding, sole attachment.

- Tapes & Labels: Pressure-sensitive adhesives for various industrial and consumer tapes and labels.

- Medical & Hygiene: Disposable medical devices, wound care, hygiene products (diapers, feminine hygiene).

- Consumer & DIY: Craft adhesives, home repairs, general purpose bonding.

- Electronics: Component encapsulation, display assembly, cable bonding.

- Industrial Assembly: General manufacturing, appliance assembly, composite bonding.

- By End-Use Industry

- Food & Beverage: Packaging for food, beverage cartons, labeling.

- Building & Construction: Residential, commercial, and infrastructure projects.

- Automotive & Transportation: Light vehicles, commercial vehicles, aerospace interiors.

- Furniture & Woodworking: Residential furniture, office furniture, architectural millwork.

- Textile & Apparel: Technical textiles, fashion apparel, home furnishings.

- Healthcare & Medical: Hospitals, clinics, medical device manufacturing.

- Paper & Pulp: Printing, publishing, corrugated packaging.

- Electronics & Electrical: Consumer electronics, industrial electronics.

- Consumer Goods: Personal care, household products, toys.

- Other Industries: Arts & crafts, sports equipment, marine.

Value Chain Analysis For Water-Based Adhesive Market

The value chain for the Water-Based Adhesive Market is a complex network involving several key stages, beginning with the upstream sourcing of raw materials. This initial phase involves suppliers of essential chemical components such as monomers (e.g., acrylics, vinyl acetate), polymers (e.g., polyvinyl acetate, acrylic polymers, polyurethanes), natural latex, and various additives including thickeners, emulsifiers, tackifiers, and defoamers. Manufacturers of these base chemicals and specialty additives form the foundation of the supply chain, providing crucial ingredients to adhesive formulators. Quality control and consistent supply from these upstream players are paramount, as the performance and cost-effectiveness of the final water-based adhesive product directly depend on the quality and availability of these raw materials. Fluctuations in raw material prices or supply chain disruptions can significantly impact the production costs and market competitiveness of adhesive manufacturers.

Following the procurement of raw materials, the value chain progresses to the manufacturing and formulation of the water-based adhesives. This stage involves sophisticated chemical processes where raw materials are blended, polymerized, and emulsified to create the final adhesive product with specific properties tailored for diverse applications. Adhesive manufacturers invest heavily in research and development to innovate new formulations that meet evolving performance requirements and comply with environmental standards. After manufacturing, the products move into distribution channels, which can be direct or indirect. Direct channels involve adhesive manufacturers selling directly to large industrial end-users, fostering closer relationships and offering customized solutions. This approach often involves technical support and bespoke formulations for specific production lines.

Indirect distribution channels involve a network of distributors, wholesalers, and retailers who play a critical role in reaching a broader customer base, particularly small to medium-sized enterprises and consumer markets. These intermediaries provide warehousing, logistics, and often localized technical support, making products accessible to a wider array of end-users across different geographical regions. The downstream segment of the value chain consists of the various end-use industries such as packaging, construction, automotive, woodworking, and textiles, which incorporate water-based adhesives into their manufacturing processes. The efficiency and effectiveness of the entire value chain are critically dependent on seamless coordination and collaboration between all stakeholders, from raw material suppliers to the ultimate end-users, ensuring that high-quality, sustainable water-based adhesive solutions are delivered efficiently to meet market demand.

Water-Based Adhesive Market Potential Customers

The Water-Based Adhesive Market serves a highly diverse and extensive range of potential customers, spanning numerous industrial and commercial sectors globally. These end-users or buyers are primarily entities that require effective, reliable, and increasingly sustainable bonding solutions for their manufacturing processes or product assemblies. The packaging industry represents a colossal segment of potential customers, including food and beverage companies, e-commerce giants, and general consumer goods manufacturers, all of whom rely on water-based adhesives for carton sealing, laminating films, labeling, and constructing corrugated boxes. The demand here is driven by the sheer volume of packaged goods and the imperative for efficient, environmentally compliant packaging that ensures product integrity and consumer safety.

Beyond packaging, the construction and building sector is another major customer base, encompassing residential and commercial builders, flooring contractors, and manufacturers of building materials such as insulation panels, gypsum boards, and wall coverings. These customers utilize water-based adhesives for applications like installing various types of flooring (carpet, vinyl, wood), bonding insulation, and securing decorative finishes, valuing their low VOC content for indoor air quality and ease of application. The automotive and transportation industry also constitutes significant potential customers, including vehicle manufacturers and component suppliers who use water-based adhesives for bonding interior trim, headliners, seating, and lightweight composite materials, driven by the need for enhanced safety, reduced weight, and compliance with increasingly strict interior air quality standards.

Furthermore, the woodworking and furniture industry, textile and apparel manufacturers, and producers of consumer goods and DIY products are substantial potential customers. Furniture makers use water-based adhesives for assembling components, bonding veneers, and laminating panels, favoring their strong, durable bonds and suitability for various wood types. Textile manufacturers employ them for fabric lamination, non-woven applications, and garment assembly, seeking flexibility and wash resistance. In the medical and hygiene sector, companies producing disposable diapers, feminine hygiene products, and medical dressings are increasingly adopting water-based adhesives due to their skin-friendly properties and non-toxicity. This broad spectrum of end-users underscores the pervasive utility and growing importance of water-based adhesives as a sustainable and versatile bonding technology across the global economy.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 56.3 billion |

| Market Forecast in 2032 | USD 89.5 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, Henkel AG & Co. KGaA, H.B. Fuller Company, Sika AG, Arkema S.A. (Bostik), Dow Chemical Company, BASF SE, Wacker Chemie AG, Avery Dennison Corporation, RPM International Inc. (Tremco CPG Inc.), Franklin International, Ashland Global Holdings Inc., DIC Corporation, Lord Corporation (Parker Hannifin), Jowat SE, Pidilite Industries Ltd., Synthomer Plc, Toyo Ink SC Holdings Co., Ltd., Georgia-Pacific Chemicals LLC, Momentive Performance Materials Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Water-Based Adhesive Market Key Technology Landscape

The Water-Based Adhesive Market is characterized by a dynamic and evolving technology landscape, where continuous innovation is crucial for overcoming performance limitations and meeting diverse industry demands. A primary focus lies in advanced polymerization techniques that enable the creation of specialized polymer dispersions with enhanced properties. This includes emulsion polymerization processes that yield finely tuned particle sizes and distributions, leading to improved film formation, increased cohesive strength, and better adhesion to challenging substrates. Researchers are also exploring hybrid polymer technologies, combining the benefits of different polymer chemistries, such as acrylics and polyurethanes, to achieve a synergistic effect that results in adhesives with superior flexibility, durability, and resistance to environmental factors. These advancements are critical for expanding the application scope of water-based adhesives into more demanding end-use segments.

Another significant area of technological advancement involves the development of high-performance additive chemistry. This includes novel rheology modifiers that allow for precise control over viscosity and application characteristics, improving spreadability and preventing sagging. New tackifiers are being formulated to enhance initial grab and wet strength, addressing one of the historical drawbacks of some water-based systems. Furthermore, the integration of advanced cross-linking agents is enabling the development of water-based adhesives that offer superior water resistance, heat resistance, and chemical resistance after curing, thereby making them suitable for applications previously dominated by solvent-based alternatives. These chemical innovations are directly contributing to the closing of the performance gap between water-based and traditional adhesive systems, driving their broader adoption across industries.

Beyond material science, significant technological strides are also being made in application and curing technologies. Innovations in application equipment, such as precision dispensing systems and spray technologies, are optimizing the deposition of water-based adhesives, ensuring uniform coverage and minimizing waste. The development of faster drying and curing systems, sometimes incorporating forced air, infrared heating, or specialized chamber designs, is helping to mitigate the issue of longer open times, thereby increasing production line speeds and efficiency. Furthermore, there is a growing trend towards incorporating smart manufacturing principles, including automation, sensor technology, and data analytics, into adhesive production and application processes. This allows for real-time monitoring of adhesive performance, process optimization, and predictive maintenance, ensuring consistent quality and maximizing operational throughput. The synergy of advanced material science and application technology is propelling the water-based adhesive market forward, delivering more efficient, high-performance, and sustainable bonding solutions.

Regional Highlights

- North America: This region represents a mature market for water-based adhesives, driven by stringent environmental regulations, particularly those from the Environmental Protection Agency (EPA) and various state-level initiatives aimed at reducing VOC emissions. The robust construction and packaging sectors, alongside the thriving automotive industry with its focus on lightweighting and sustainable manufacturing, are key demand generators. Continuous innovation in high-performance formulations and the presence of major industry players further solidify North America's market position, with significant adoption in specialty applications.

- Europe: Europe is a leader in adopting water-based adhesives, primarily due to rigorous environmental policies like the REACH regulation, which heavily restricts the use of hazardous substances. The regions strong focus on sustainability, circular economy principles, and green building initiatives fuels demand across construction, automotive, and textile industries. Germany, France, and the UK are prominent markets, characterized by advanced manufacturing capabilities and a preference for eco-friendly industrial solutions. Investment in bio-based adhesive research is also particularly strong here.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region in the Water-Based Adhesive Market, propelled by rapid industrialization, urbanization, and significant growth in manufacturing sectors, including packaging, construction, automotive, and consumer goods. Countries like China, India, Japan, and South Korea are experiencing substantial demand due to increasing production volumes and improving economic conditions. While environmental regulations are less stringent in some parts compared to Western counterparts, there is a growing awareness and gradual shift towards sustainable adhesive solutions, making it a pivotal region for future market expansion.

- Latin America: This region exhibits steady growth, primarily influenced by expanding manufacturing activities in packaging, construction, and automotive industries in countries such as Brazil, Mexico, and Argentina. The increasing foreign investments in manufacturing facilities and rising domestic consumption are contributing to the demand for water-based adhesives. While environmental regulations are still developing, there is a clear trend towards adopting more sustainable industrial practices, driven by global market trends and local sustainability initiatives.

- Middle East and Africa (MEA): The MEA region is experiencing emerging growth in the water-based adhesive market, fueled by infrastructure development projects, especially in the construction sector, and a growing packaging industry. Countries in the GCC region, particularly Saudi Arabia and UAE, are investing heavily in diversification away from oil, leading to increased manufacturing activities. While the market is currently smaller compared to other regions, rising environmental awareness and the import of advanced manufacturing technologies from Europe and North America are expected to drive future adoption of water-based adhesive solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Water-Based Adhesive Market.- 3M Company

- Henkel AG & Co. KGaA

- H.B. Fuller Company

- Sika AG

- Arkema S.A. (Bostik)

- Dow Chemical Company

- BASF SE

- Wacker Chemie AG

- Avery Dennison Corporation

- RPM International Inc. (Tremco CPG Inc.)

- Franklin International

- Ashland Global Holdings Inc.

- DIC Corporation

- Lord Corporation (Parker Hannifin)

- Jowat SE

- Pidilite Industries Ltd.

- Synthomer Plc

- Toyo Ink SC Holdings Co., Ltd.

- Georgia-Pacific Chemicals LLC

- Momentive Performance Materials Inc.

Frequently Asked Questions

What are the primary benefits of using water-based adhesives?

Water-based adhesives offer significant advantages, including low volatile organic compound (VOC) emissions, non-flammability, easy cleanup with water, reduced health and safety risks for workers, and compliance with stringent environmental regulations, making them a sustainable and safer alternative to solvent-based systems.

Which industries are the largest consumers of water-based adhesives?

The packaging industry is the largest consumer, utilizing water-based adhesives for carton sealing, laminations, and labeling. Other major consumers include the construction sector for flooring and wall coverings, the automotive industry for interior components, and woodworking for furniture assembly.

What are the main challenges facing the Water-Based Adhesive Market?

Key challenges include potentially longer drying and curing times compared to solvent-based or hot-melt adhesives, performance limitations in certain high-stress or moisture-rich applications, and sensitivity to freezing temperatures during storage and transportation, which can impact product integrity.

How do environmental regulations impact the growth of water-based adhesives?

Environmental regulations, such as VOC emission limits and substance restrictions, are a primary driver for market growth. These regulations compel manufacturers across industries to transition from traditional solvent-based adhesives to more environmentally friendly water-based alternatives to ensure compliance and promote sustainability.

What role does technological innovation play in the Water-Based Adhesive Market?

Technological innovation is crucial, focusing on developing advanced polymer formulations, specialty additives, and rapid curing systems. These advancements enhance bond strength, durability, water resistance, and application speed, enabling water-based adhesives to compete effectively in high-performance and specialized applications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Water-based Adhesive Applicators Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Adhesive Manufacturing Tank Cleaning Market Statistics 2025 Analysis By Application (Water-Based Adhesive Tank, Reactive Adhesive Tank, Hot Melt Adhesive Tank, Solvent-Based Adhesive Tank), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager