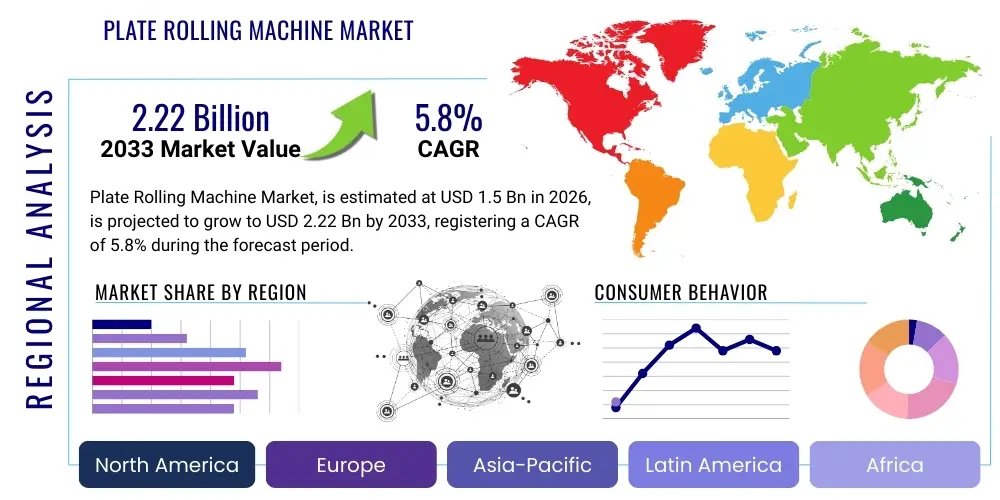

Plate Rolling Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437305 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Plate Rolling Machine Market Size

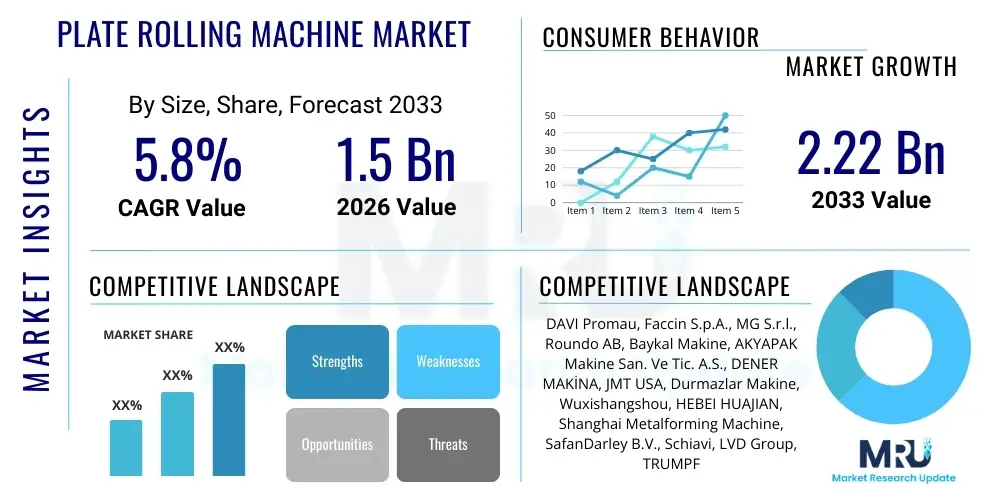

The Plate Rolling Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.22 Billion by the end of the forecast period in 2033.

Plate Rolling Machine Market introduction

Plate rolling machines, also known as plate bending machines or roll benders, are essential heavy industrial equipment used for forming cylindrical, conical, or curved shapes from flat metal plates or sheets. These machines are crucial in numerous fabrication processes, transforming rigid metallic structures into functional components required across key infrastructure and manufacturing sectors. The fundamental principle involves feeding the metal plate between a set of heavy-duty rollers, typically three or four, which apply pressure and stress the material beyond its elastic limit, resulting in permanent deformation and the desired curvature. Precision, material compatibility, and tonnage capacity are defining characteristics that dictate the application range of any specific plate rolling machine.

The market encompasses various machine configurations, including pyramid-style three-roll machines (cost-effective for thinner plates), variable geometry four-roll machines (offering higher precision and faster operation, particularly for thick materials), and specialized multi-axis machines designed for complex conical geometries. Major applications span heavy industries such as shipbuilding, where large hulls and tanks are formed; energy sectors, involving the fabrication of pressure vessels, boilers, and heat exchangers; and infrastructure projects, including pipeline construction and bridge fabrication. The ability of these machines to handle high-strength steel, stainless steel, and various alloys efficiently and accurately positions them as indispensable tools in modern manufacturing environments.

Driving factors for this market include the global resurgence in infrastructure development, particularly in emerging economies, alongside rigorous demand from the oil and gas sector and the expanding renewable energy infrastructure (wind tower manufacturing). The benefits provided by advanced plate rolling technology, such as reduced material waste, improved rolling speed through automation, and enhanced safety features compliant with stringent industrial standards, further propel market expansion. Manufacturers are continuously integrating CNC (Computer Numerical Control) systems to increase repeatability and precision, thereby catering to the complex requirements of high-tolerance industries like aerospace and defense.

Plate Rolling Machine Market Executive Summary

The Plate Rolling Machine Market is characterized by robust growth, primarily driven by accelerated industrialization in the Asia Pacific region and sustained investment in capital goods across North America and Europe. Business trends indicate a noticeable shift towards high-performance hydraulic four-roll machines, which offer superior pre-bending capabilities and increased efficiency compared to traditional mechanical three-roll variants. Technological innovation, especially the integration of advanced sensors and predictive maintenance capabilities (part of Industry 4.0 protocols), is a central theme, allowing manufacturers to optimize machine uptime and throughput. The competitive landscape is moderately fragmented, featuring a mix of globally dominant manufacturers specializing in heavy-duty equipment and regional players focusing on mid-range, cost-effective solutions for local fabrication shops.

Regional trends highlight Asia Pacific, led by China and India, as the foremost growth engine, owing to massive public and private sector investments in infrastructure, automotive production, and shipbuilding capacity expansion. Europe maintains a strong presence, driven by demand for highly precise machines required for sophisticated applications in the energy and aerospace sectors, focusing heavily on automation and energy efficiency standards. Meanwhile, North America is witnessing steady demand fueled by the modernization of aging industrial infrastructure and increased domestic oil and gas processing activities. The market's resilience is intrinsically linked to global steel production and fabrication activity.

Segment trends underscore the increasing preference for hydraulic rolling machines due to their flexibility, ease of control, and capacity for handling thicker plates with greater accuracy. In terms of application, the shipbuilding and construction sectors remain the largest consumers, although the renewable energy segment (specifically wind tower manufacturing) is projected to exhibit the highest Compound Annual Growth Rate over the forecast period. Furthermore, the market is segmenting based on operational complexity, with highly automated CNC-controlled systems gaining traction among large-scale fabricators seeking reduced operational variability and higher component quality.

AI Impact Analysis on Plate Rolling Machine Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Plate Rolling Machine Market predominantly revolve around three key areas: optimizing the rolling process for complex geometries, minimizing material waste, and implementing predictive maintenance to reduce costly downtime. Users are concerned about how AI-driven simulation tools can predict spring-back effects in exotic materials, thus improving first-pass yield and reducing trial-and-error rolling. Furthermore, there is significant interest in AI's role in autonomous quality control, using computer vision systems integrated into the rolling process to detect surface defects or dimensional inconsistencies in real-time. Expectations center on AI enhancing the operational lifespan of the machinery and enabling true adaptive manufacturing where the machine settings automatically adjust based on material input variability, moving far beyond traditional CNC automation.

The integration of AI algorithms is poised to transform plate rolling from a highly skilled, experience-dependent operation into a streamlined, data-driven process. By analyzing vast datasets—including material properties, machine vibration patterns, operational loads, and ambient temperatures—AI can create highly accurate models for optimal roll positioning and speed. This capability is particularly critical when working with high-tensile steel or specialized alloys, where precise control over the bending radius is essential to maintain structural integrity and meet stringent regulatory standards. Ultimately, AI adoption is expected to improve component consistency, significantly boost manufacturing throughput, and lower the reliance on specialized operators for routine tasks.

Moreover, AI contributes significantly to the aftermarket service segment by enabling advanced predictive failure analysis. Instead of relying on scheduled maintenance or reacting to failure, AI models monitor machine health indicators in real-time, forecasting component failure (such as roller bearing wear or hydraulic system degradation) with high accuracy. This allows maintenance to be scheduled proactively, minimizing unplanned interruptions and maximizing machine availability, which is crucial given the high capital expenditure associated with these heavy machines. This shift toward intelligent asset management is driving the competitiveness of manufacturers who offer connected, AI-enabled rolling solutions.

- AI optimizes rolling parameters automatically based on material characteristics and desired geometry, minimizing spring-back errors.

- Predictive maintenance algorithms use machine learning to forecast component failure, reducing unplanned downtime by up to 30%.

- Computer vision and AI enable real-time quality inspection during rolling, ensuring dimensional accuracy and surface defect detection.

- AI-driven simulation tools reduce the need for physical prototypes, accelerating the setup time for new bending applications.

- Autonomous process adjustment allows machines to adapt to variations in plate thickness or material hardness instantly.

DRO & Impact Forces Of Plate Rolling Machine Market

The Plate Rolling Machine Market is dynamically influenced by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively shape the competitive landscape and investment decisions. Primary drivers include the massive global investment in critical infrastructure, specifically in bridge construction, pipeline networks, and storage tank fabrication, alongside the rapid expansion of the energy sector, particularly the manufacturing of renewable energy components like large offshore wind towers requiring substantial plate rolling capacity. These macroeconomic factors create a steady, high-volume demand stream for both new machinery and the replacement of older, less efficient equipment. The shift toward automated, precision-driven manufacturing processes further mandates the adoption of advanced rolling technologies, pushing fabricators to upgrade their capabilities.

However, the market faces significant restraints that temper growth projections. Foremost among these is the considerable initial capital expenditure required for purchasing high-capacity, sophisticated plate rolling machines, which poses a major barrier to entry for smaller fabrication shops. Additionally, the operational complexity and the global scarcity of skilled labor proficient in operating and maintaining advanced CNC-controlled rolling equipment remain critical challenges. Economic volatility, particularly the fluctuation in raw material prices (steel and aluminum), can lead to project delays or cancellations in end-user industries like shipbuilding, consequently dampening machine procurement. Furthermore, the stringent quality and safety standards, particularly in nuclear and aerospace applications, necessitate costly certifications and compliance measures, adding to the overall cost structure.

Opportunities within the market largely center on technological advancements aligned with Industry 4.0 principles. The development of intelligent rolling solutions—featuring integrated IoT sensors, cloud connectivity, and sophisticated diagnostic tools—allows manufacturers to offer value-added services such as remote monitoring and performance optimization. Furthermore, increasing demand for machines capable of handling high-strength, low-alloy (HSLA) steels and exotic materials utilized in specialized chemical processing and defense industries opens lucrative niche segments. The global focus on energy transition, specifically the production of hydrogen tanks and specialized pressure vessels, presents a long-term, high-growth opportunity for manufacturers investing in specialized rolling machine designs. The impact forces are thus heavily skewed towards technological adoption and infrastructure spending, while high upfront costs act as a perpetual gravitational restraint.

Segmentation Analysis

The Plate Rolling Machine Market is highly fragmented and segmented based on multiple critical factors, including the type of machine configuration, the mechanism of operation, and the end-use application. Understanding these segments is crucial for market participants to tailor product offerings and marketing strategies effectively. The core segmentation by type revolves around 3-roll, 4-roll, and specialized machines, with the 4-roll segment increasingly preferred for its operational efficiency, better pre-bending capabilities, and the need for only a single insertion of the plate, reducing labor and time. These types cater to varying levels of precision and plate thickness requirements.

Operational segmentation defines the machine’s power source, encompassing hydraulic, mechanical, and electro-mechanical systems. Hydraulic machines dominate the market due to their superior power delivery, smooth operation, and flexibility in managing varying plate thicknesses and materials. Mechanical machines, while simpler and often cheaper, are gradually losing market share, particularly in heavy fabrication sectors, as modern fabrication demands precise, variable force application, which hydraulics efficiently provide. The shift is towards integrating these systems with advanced CNC controls to maximize repeatability across production batches.

The largest application segments remain Construction and Shipbuilding, which utilize the highest tonnage capacity machines for large-scale structural components and marine hulls, respectively. However, the fastest-growing application segment is the Renewable Energy sector, specifically driven by the necessity for precision rolling of thick, high-strength steel plates used in large wind tower sections. Other significant applications include aerospace, where extreme precision for lightweight alloys is paramount, and the pressure vessel industry, requiring tight tolerances for safety and regulatory compliance.

- By Type:

- 3-Roll Plate Rolling Machine (Double Pinch, Variable Geometry)

- 4-Roll Plate Rolling Machine (Preferred for accuracy and speed)

- Specialized Cone Rolling Machines

- By Operation/Mechanism:

- Hydraulic Plate Rolling Machines (Dominant Segment)

- Mechanical Plate Rolling Machines

- Electro-Mechanical Plate Rolling Machines

- By Application:

- Shipbuilding

- Construction and Fabrication (Infrastructure, Bridge Building)

- Oil and Gas (Pipeline and Tank Fabrication)

- Pressure Vessels and Boilers

- Aerospace and Defense

- Renewable Energy (Wind Tower Manufacturing)

- By Control:

- Manual

- CNC (Computer Numerical Control)

Value Chain Analysis For Plate Rolling Machine Market

The value chain for the Plate Rolling Machine Market begins with upstream activities focused on securing high-quality, durable raw materials. These materials primarily include specialized, high-grade steel for the machine frames and rollers, along with critical components like high-performance hydraulic cylinders, precision bearings, and advanced electronic control systems (PLCs/CNCs). Successful manufacturers maintain strong relationships with global steel suppliers and component vendors to ensure supply chain stability and quality control, as the performance and longevity of the rolling machine directly depend on the integrity of these inputs. Manufacturing processes are highly specialized, requiring advanced machining capabilities, rigorous quality assurance, and assembly expertise to handle the sheer size and required precision of the components.

The midstream involves the core manufacturing and assembly of the machines, where engineering excellence determines competitive advantage. This stage includes designing the complex mechanical linkages, integrating sophisticated hydraulic and electrical control systems, and rigorously testing the machines to meet specific tonnage and precision requirements. Distribution channels represent a critical link to the downstream market. For large, high-value capital equipment like plate rolling machines, the distribution strategy often relies on a mix of direct sales teams engaging with major end-users (e.g., shipyards or large fabricators) and a network of specialized, authorized dealers or distributors. These dealers typically provide regional warehousing, technical expertise, installation support, and essential after-sales services, acting as the indirect channel.

Downstream activities center on deployment, installation, operator training, and continuous after-sales service and maintenance. Given the high cost and complexity of plate rolling machines, post-sale support is a key differentiator. Manufacturers increasingly offer remote diagnostics, spare parts delivery, and long-term service contracts to ensure maximum uptime for their customers. The efficiency of this value chain, from raw material sourcing to final installation and servicing, directly impacts the total cost of ownership for the end-user and determines the long-term profitability and reputation of the machine manufacturer.

Plate Rolling Machine Market Potential Customers

Potential customers for plate rolling machines are concentrated within industries requiring heavy metal fabrication, characterized by the need to shape thick, rigid metallic sheets into curved forms for structural or containment purposes. The primary end-users are large-scale industrial fabricators and manufacturers focused on capital goods. Shipyards represent a massive customer base, utilizing these machines to form the massive curved sections of ship hulls, submarines, and offshore drilling platforms, demanding machines with extremely high tonnage capacity and wide working widths to handle large, thick plates efficiently.

Another significant customer segment is the pressure vessel and boiler manufacturing industry. Companies in this sector require high-precision rolling machines to create perfectly cylindrical shells for storage tanks, heat exchangers, reactors, and industrial boilers. Given the inherent safety risks associated with pressure applications, these customers prioritize machines capable of achieving minimal distortion and high repeatability, often requiring advanced features like adaptive crowning systems to compensate for roller deflection when rolling heavy plates.

Furthermore, infrastructure and construction companies, alongside those involved in the energy sector, constitute a steady stream of demand. This includes fabricators creating steel components for bridges, large-diameter piping systems, and crucial components for the rapidly expanding wind energy industry, where rolling long, conical sections for wind towers demands specialized, high-tolerance rolling machines. The varying needs—from speed and volume (shipbuilding) to precision and material compatibility (aerospace/pressure vessels)—require manufacturers to offer a diversified product portfolio.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.22 Billion |

| Growth Rate | CAGR 5.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | DAVI Promau, Faccin S.p.A., MG S.r.l., Roundo AB, Baykal Makine, AKYAPAK Makine San. Ve Tic. A.S., DENER MAKİNA, JMT USA, Durmazlar Makine, Wuxishangshou, HEBEI HUAJIAN, Shanghai Metalforming Machine, SafanDarley B.V., Schiavi, LVD Group, TRUMPF GmbH, Ermaksan, Haeusler AG, White Bear Machine Tool Co., MVD Inan. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plate Rolling Machine Market Key Technology Landscape

The contemporary technological landscape of the Plate Rolling Machine Market is dominated by advanced automation and precision control systems designed to meet the rigorous demands of modern fabrication. Computer Numerical Control (CNC) technology is now standard across medium to high-end machines, providing unparalleled repeatability and accuracy compared to manual or simple PLC controls. Modern CNC interfaces offer intuitive programming, allowing operators to input complex geometrical parameters directly, enabling the machine to calculate the precise roll movements needed to achieve the target curvature while compensating for factors like material elasticity (spring-back). This shift towards high-level automation is critical for industries like aerospace and high-pressure vessel fabrication where dimensional tolerance errors are unacceptable.

A second major technological trend involves the development and implementation of adaptive crowning systems. When rolling very wide or very thick plates, the immense forces involved can cause the work rolls to deflect, leading to inconsistencies in the curvature across the plate width. Adaptive crowning systems automatically or semi-automatically adjust the curvature of the rollers (often through hydraulic pressure application to supporting bearings) to counteract this deflection, ensuring uniform bending throughout the length of the plate. This technology is particularly vital in large-capacity 4-roll machines used for infrastructure projects and wind tower manufacturing, where the dimensions are substantial and precision is non-negotiable.

Furthermore, Industry 4.0 integration, characterized by the Internet of Things (IoT) and advanced sensor technology, is rapidly reshaping the maintenance and operational efficiency of plate rolling machines. Integrated sensors monitor machine performance metrics such as roll parallelism, hydraulic pressure, vibration, and temperature in real-time. This data is transmitted to cloud-based platforms, facilitating predictive maintenance programs and remote diagnostics. Features like laser alignment and automated plate centering systems further enhance efficiency by reducing setup time and operator error, ensuring the competitive advantage rests with manufacturers who can successfully leverage digital connectivity for superior performance monitoring and service delivery.

Regional Highlights

- Asia Pacific (APAC): APAC is the undisputed leader in the Plate Rolling Machine Market, accounting for the largest share of both revenue and volume. This dominance is attributed to rapid industrial expansion, massive government spending on infrastructure development (especially in China, India, and Southeast Asia), and the region's concentration of global shipbuilding and automotive manufacturing hubs. China, in particular, drives demand for high-capacity machines necessary for domestic construction and energy projects. The push for localized manufacturing and increasing foreign direct investment in fabrication plants further solidify APAC's growth trajectory.

- Europe: The European market is characterized by high demand for specialized, high-precision, and technologically advanced machines. Countries like Germany, Italy, and Turkey are key manufacturing centers for plate rolling equipment, focusing heavily on export to global markets. Demand within Europe is stable, driven by the need for advanced fabrication in the aerospace, nuclear energy, and specialized automotive sectors, prioritizing machines with superior CNC integration, energy efficiency, and safety compliance.

- North America: North America represents a mature yet steadily growing market. Growth is primarily fueled by the modernization and replacement of aging machinery and sustained investment in the oil and gas infrastructure, coupled with defense and aerospace spending. The focus here is on robust, durable machines capable of handling high-strength alloys, with a growing emphasis on automation to mitigate high domestic labor costs. The US tax incentives and infrastructure revitalization plans are expected to boost capital expenditure on fabrication equipment.

- Middle East and Africa (MEA): MEA exhibits strong potential, primarily due to large-scale investments in energy infrastructure (oil, gas, and petrochemical refining facilities) and diversification projects away from hydrocarbon dependency. Saudi Arabia and the UAE are major demand centers, requiring rolling machines for pipeline construction, refinery component fabrication, and commercial building projects. Market growth is closely tied to the successful execution of large government-backed industrial projects.

- Latin America: The market in Latin America is more volatile, constrained by economic fluctuations but driven by natural resource extraction and limited infrastructure investment, particularly in Brazil and Mexico. Demand is concentrated in the energy and mining sectors, requiring durable machines suitable for harsh operating environments, though price sensitivity often favors mid-range and refurbished equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plate Rolling Machine Market.- DAVI Promau S.r.l.

- Faccin S.p.A.

- MG S.r.l.

- Roundo AB

- Baykal Makine San. Ve Tic. A.S.

- AKYAPAK Makine San. Ve Tic. A.S.

- DENER MAKİNA

- JMT USA (Joint Machine Tools)

- Durmazlar Makine

- Wuxishangshou Machinery Co., Ltd.

- HEBEI HUAJIAN Group

- Shanghai Metalforming Machine Tool Works Co., Ltd.

- SafanDarley B.V.

- Schiavi Srl

- LVD Group

- TRUMPF GmbH + Co. KG (Indirectly through fabrication solutions)

- Ermaksan Makine Sanayi Ve Ticaret A.S.

- Haeusler AG

- White Bear Machine Tool Co.

- MVD Inan Makine

Frequently Asked Questions

Analyze common user questions about the Plate Rolling Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected growth rate (CAGR) for the Plate Rolling Machine Market between 2026 and 2033?

The Plate Rolling Machine Market is anticipated to exhibit a Compound Annual Growth Rate (CAGR) of 5.8% during the forecast period from 2026 to 2033, driven primarily by infrastructure investments and manufacturing automation.

Which type of plate rolling machine is currently dominating the market in terms of operational efficiency and precision?

The Hydraulic 4-Roll Plate Rolling Machine segment dominates due to its superior efficiency, minimal pre-bending required, high degree of precision, and suitability for high-volume, thick-plate fabrication across key sectors like shipbuilding and energy.

Which geographical region is the largest market shareholder for plate rolling machines?

Asia Pacific (APAC), particularly driven by industrialization in China and India, holds the largest market share owing to extensive infrastructure projects, robust shipbuilding activities, and high automotive production volumes.

How is Industry 4.0 influencing the design and functionality of modern plate rolling machines?

Industry 4.0 is facilitating the integration of CNC controls, IoT sensors, and AI-driven software, enabling features such as predictive maintenance, remote diagnostics, and automated parameter optimization to maximize machine uptime and output quality.

What are the primary factors restraining the growth of the Plate Rolling Machine Market?

Key restraints include the extremely high initial capital investment required for heavy-duty machinery, which limits adoption among smaller enterprises, and the persistent shortage of skilled labor needed to operate and maintain advanced CNC rolling systems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager