Rice Milling Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432637 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Rice Milling Market Size

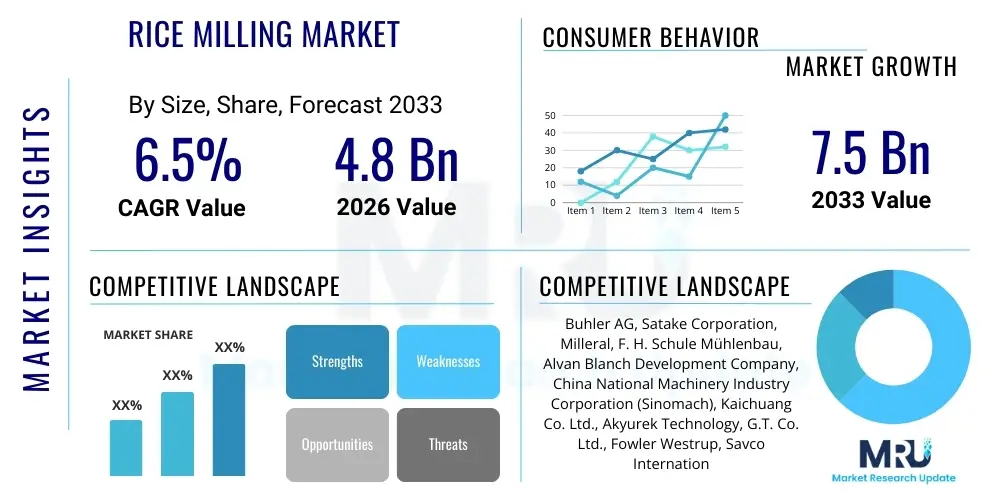

The Rice Milling Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 4.8 Billion in 2026 and is projected to reach USD 7.5 Billion by the end of the forecast period in 2033.

Rice Milling Market introduction

The Rice Milling Market encompasses the industrial machinery, equipment, and related services essential for processing raw paddy into consumable polished rice. This crucial industry segment serves as the nexus between rice cultivation and global food supply, involving complex stages such as cleaning, de-husking, polishing, grading, and sorting. The increasing global population, coupled with rising disposable incomes, particularly in Asia Pacific, drives the fundamental demand for processed rice products. Rice milling operations range from small-scale traditional mills to large, fully automated industrial complexes, focusing on efficiency, minimal grain breakage, and high-quality output to meet stringent international consumer standards.

The core product within this market includes various milling components such as paddy cleaners, de-stoners, rubber roll huskers, paddy separators, whiteners/polishers, and sophisticated color sorters. These machines are designed to optimize the yield of head rice while maximizing the recovery of marketable by-products like bran and broken rice, which are utilized in animal feed and oil extraction industries. Major applications span commercial rice processing units, institutional buyers, and integrated food manufacturing companies aiming to produce specific rice variants, including brown rice, white rice, parboiled rice, and specialty aromatic rice tailored for domestic and international consumption patterns.

Driving factors fueling market expansion include rapid urbanization in developing economies, leading to a shift from traditional manual milling practices to mechanized and automated systems. Furthermore, global emphasis on food safety and quality mandates the adoption of advanced milling technologies that ensure reduced contamination and consistent grain quality. The growing investment by governments and private entities in modernizing agricultural infrastructure and establishing high-capacity processing zones further solidifies the market’s growth trajectory, positioning rice milling as a technologically evolving sector vital for global food security.

Rice Milling Market Executive Summary

The global Rice Milling Market is experiencing significant transformation, driven by a confluence of technological advancements and shifting consumption habits. Business trends highlight a strong movement towards integrated milling solutions that offer end-to-end processing efficiency, minimizing labor costs and maximizing energy efficiency. Key industry players are focusing on mergers and acquisitions to consolidate market share and expand their global footprint, particularly in high-growth regions like Southeast Asia and South Asia. Furthermore, the emphasis on sustainability is prompting manufacturers to develop equipment that reduces water usage and energy consumption, aligning with broader corporate social responsibility goals and regulatory pressures.

Regionally, Asia Pacific maintains overwhelming dominance in the market due to its high rice production and consumption volumes; countries such as India, China, Vietnam, and Thailand represent the epicenter of rice milling activity. However, emerging regional trends show increasing investment in modern milling technology across Africa and Latin America, driven by efforts to improve local food processing capabilities and reduce reliance on imported processed rice. North America and Europe, while smaller in volume, drive demand for specialized, high-precision milling equipment, particularly advanced optical sorters and packaging machinery, to serve niche markets focused on organic and premium rice varieties.

Segmentation trends reveal that the Automatic Rice Mills segment is anticipated to witness the fastest growth, largely replacing older semi-automatic and traditional units, owing to superior operational speed and reduced maintenance complexity. In terms of capacity, medium to large capacity mills (5-15 tons per hour and above 15 tons per hour) are capturing increased market share as processors seek economies of scale. Technology-wise, color sorting machines and sophisticated grading equipment are seeing massive uptake due to their critical role in ensuring export-quality consistency, thereby reinforcing the trend towards high-tech automation across the rice milling value chain.

AI Impact Analysis on Rice Milling Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Rice Milling Market predominantly center on quality control, operational efficiency, and predictive maintenance. Common questions revolve around whether AI-powered vision systems can reliably replace human inspection for grain quality, how machine learning algorithms optimize milling parameters for different paddy varieties, and the extent to which AI can predict equipment failures, thus minimizing downtime. Users express high expectations for AI to solve persistent challenges related to inconsistent quality grading, energy wastage, and the high labor requirement associated with older milling setups. The analysis confirms a strong industry expectation that AI integration will fundamentally shift the industry from reactive maintenance and subjective quality checks to proactive, data-driven operational management, ensuring higher yield and reduced operational expenses.

- AI-Powered Quality Grading: Utilizes deep learning models for real-time analysis of broken grains, chalkiness, discoloration, and foreign materials, providing objective and consistent quality classification, significantly exceeding human visual accuracy.

- Predictive Maintenance: AI algorithms analyze sensor data (vibration, temperature, power draw) from milling machinery to forecast component failure, allowing for scheduled repairs and preventing costly unexpected shutdowns.

- Process Optimization: Machine learning models adjust parameters (pressure, flow rate, speed) of polishers and whiteners automatically based on raw paddy characteristics, maximizing the yield of head rice and minimizing energy consumption per ton processed.

- Automated Blending and Batching: AI facilitates precise blending of different rice lots to meet specific market quality requirements and maintains consistency across large production batches.

- Enhanced Traceability: Utilizes AI and blockchain integration to track rice origins, processing history, and quality metrics throughout the supply chain, meeting consumer and regulatory demands for transparency.

DRO & Impact Forces Of Rice Milling Market

The dynamics of the Rice Milling Market are shaped by powerful Drivers, Restraints, and Opportunities (DRO), which collectively exert significant Impact Forces influencing strategic decision-making and investment across the industry. The primary drivers include the necessity for enhanced food security globally, rapid technological modernization to meet export quality standards, and the escalating demand for highly refined and specialty rice products. These forces push the industry towards automation and higher-capacity machinery. Conversely, key restraints involve the high initial capital expenditure required for installing modern, fully automated milling plants, particularly challenging for small and medium-sized enterprises (SMEs), and volatility in raw paddy prices, which affects processor profitability and investment capacity.

Opportunities for growth are largely concentrated in the development of energy-efficient and low-emission milling technologies, leveraging smart manufacturing principles (Industry 4.0) to gain a competitive edge. Furthermore, the untapped potential in developing regions, especially in Africa and parts of South America, offers substantial opportunities for market expansion through infrastructure development and technology transfer. The market is also seeing opportunities arising from the processing of rice by-products, such as rice bran oil and high-value feed ingredients, diversifying revenue streams for mill owners.

The impact forces currently defining the market trajectory are dominated by the push for high-precision sorting technologies (color sorters) due to increasingly stringent quality regulations in international trade, making advanced equipment a mandatory prerequisite for global competitiveness. The secondary impact force is the pressure to reduce operational costs through automation; companies that adopt integrated and efficient milling processes gain substantial cost advantages over those relying on outdated, labor-intensive systems. These combined forces mandate continuous technology upgrades, positioning innovation as the central theme for survival and growth in the contemporary rice milling landscape.

Segmentation Analysis

The Rice Milling Market segmentation provides a granular view of market structure based on type, capacity, and technology adopted. Understanding these segments is critical for manufacturers designing targeted equipment and for processors planning capacity expansion. The market is fundamentally segmented by the degree of automation utilized in the plants, ranging from traditional small-scale units to fully automated, integrated systems that minimize human intervention. Capacity segmentation is vital as it directly correlates with economic feasibility and target market scale, spanning small, medium, and large industrial operations. Technology-based segmentation highlights the adoption rates of advanced machinery, crucial for quality enhancement and operational throughput.

The Type segment typically distinguishes between Automatic, Semi-Automatic, and Traditional/Manual Mills. Automatic mills, representing the cutting edge, handle all stages of processing with computerized control, ensuring high consistency and minimal breakage. The Capacity segment is often divided into less than 5 tons per hour (Small), 5 to 15 tons per hour (Medium), and greater than 15 tons per hour (Large). The trend favors medium to large capacity mills due to economies of scale and the ability to serve large domestic and export contracts. Technological segmentation focuses on specific machinery, with color sorters and advanced polishers being the primary drivers of technology adoption.

This structured segmentation allows market participants to tailor their strategies, focusing on providing bespoke solutions for regional requirements—for instance, promoting small-scale, robust machinery in regions with limited capital and infrastructure, while pushing integrated, high-throughput systems in established export hubs like Thailand or India. The continued shift towards automated, large-capacity mills underscores the industrial maturity and consolidation occurring within the global rice processing ecosystem.

- By Type:

- Automatic Rice Mills

- Semi-Automatic Rice Mills

- Traditional/Manual Mills

- By Capacity:

- Small Capacity (Less than 5 Tonnes per Hour)

- Medium Capacity (5 - 15 Tonnes per Hour)

- Large Capacity (Above 15 Tonnes per Hour)

- By Component:

- Paddy Cleaners

- De-Stoners

- Paddy Husking Machines (Huskers)

- Paddy Separators

- Rice Whiteners and Polishers

- Color Sorters

- Grading Machines

- Storage Silos and Conveyors

- By Application/End-Use:

- Commercial Rice Producers

- Food Processing Industries

- Government/Cooperative Processing Centers

- By Geography:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Rice Milling Market

The Rice Milling Market value chain begins significantly upstream, rooted in the procurement of raw materials, primarily paddy (unhulled rice), and the manufacturing of specialized machinery. Upstream activities involve agricultural inputs, cultivation practices that determine paddy quality, and the sourcing of high-precision components (like optical sensors, specialized rubber, and durable steel) required for mill construction. Manufacturers of milling machinery must maintain strong relationships with component suppliers globally to ensure technological superiority and cost-effective production. The efficiency of the upstream logistics in delivering the raw paddy to the milling plant gates directly impacts the utilization rate and profitability of the mill operation.

The core midstream activity is the rice milling process itself, which transforms the rough paddy into marketable rice and various by-products. This stage is where value addition is maximized through efficient husking, precise polishing, and rigorous quality sorting using advanced technology. The midstream success hinges on minimizing grain breakage (maximizing ‘head rice’ yield) and optimizing energy consumption. The integration of modern machinery, such as high-definition color sorters and standardized grading systems, is critical here, ensuring the output meets the specific aesthetic and quality standards required by discerning domestic and international buyers.

Downstream analysis focuses on the distribution channels, market consumption, and end-users. Distribution channels are typically a combination of direct sales to large institutional buyers and indirect routes through wholesalers, distributors, and retailers. Direct sales dominate the channels for large export volumes. Furthermore, the downstream includes the utilization of by-products—rice bran is processed for oil extraction or animal feed, and broken rice is sold to breweries or processed food manufacturers. Efficient logistics, standardized packaging, and effective branding are essential downstream elements driving consumer pull and market penetration, ensuring the final processed rice reaches diverse global consumers.

Rice Milling Market Potential Customers

The primary end-users and potential buyers for rice milling equipment and integrated services are diverse, spanning large commercial agricultural corporations, regional cooperative societies, and governmental food security agencies. Commercial rice producers, often operating at scale, constitute the largest customer base, consistently demanding high-capacity, fully automated milling solutions to serve mass retail and export markets. These customers require robust machinery capable of continuous operation and precise quality control, justifying significant capital expenditure to maintain high throughput and low operating costs.

A secondary, yet rapidly growing, customer segment includes specialized food processing industries and private label manufacturers. These buyers often require milling equipment tailored for specialty rice variants (e.g., Basmati, Jasmine, organic rice) and systems capable of handling smaller, specialized batches with extremely high purity requirements. For these customers, the emphasis is less on sheer volume and more on quality assurance components like high-resolution color sorters and gentle polishing mechanisms to preserve the integrity and aroma of premium grains.

Furthermore, state-run and cooperative processing centers in developing nations represent significant potential customers, often procuring medium-capacity, durable, and relatively easy-to-maintain semi-automatic equipment. Driven by mandates to improve local agricultural yield quality and ensure national food reserves, these entities are typically backed by government subsidies or international development aid, presenting unique tendering opportunities for equipment manufacturers focused on reliability and localized service support.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.8 Billion |

| Market Forecast in 2033 | USD 7.5 Billion |

| Growth Rate | CAGR 6.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Buhler AG, Satake Corporation, Milleral, F. H. Schule Mühlenbau, Alvan Blanch Development Company, China National Machinery Industry Corporation (Sinomach), Kaichuang Co. Ltd., Akyurek Technology, G.T. Co. Ltd., Fowler Westrup, Savco International, Patkon, PETKUS Technologie GmbH, Usher Agro Ltd., Lushan WinTone Engineering Co., Ltd., ZKI, Zhengzhou VOS Machinery Equipment Co., Ltd., Jining Fuyuan Machinery Manufacturing Co., Ltd., Jiangsu Liangyou International Mechanical Engineering Co. Ltd., and AVIC International Holding Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rice Milling Market Key Technology Landscape

The Rice Milling Market technology landscape is characterized by a rapid shift towards high-precision automation and digitalization, moving far beyond simple mechanical separation. Core technology advancements are centered around optimizing the three main stages: pre-cleaning/de-stoning, hulling/whitening, and sorting/grading. In the hulling and whitening stage, manufacturers are continuously innovating rubber roll materials and abrasive mechanisms to minimize broken kernels (head rice reduction) while maximizing output speed, often integrating sophisticated sensors to monitor friction and temperature in real-time, preventing overheating and quality degradation.

The most significant technological driver remains the deployment of advanced Optical Sorting Machines (Color Sorters). Modern sorters utilize high-definition CCD cameras, complex algorithms, and often Near-Infrared (NIR) or X-ray technology to detect minute defects, chalky grains, foreign materials, and subtle color inconsistencies that manual or older mechanical systems cannot capture. This technology is indispensable for rice exporters who must adhere to stringent quality thresholds. Furthermore, continuous flow and modular design principles are being applied to entire milling complexes, allowing for flexible configuration and easier maintenance, catering to diverse production scales and rice types.

Emerging technologies focus on integrating Industry 4.0 principles, including the Internet of Things (IoT) sensors and Supervisory Control and Data Acquisition (SCADA) systems, to enable remote monitoring, energy consumption optimization, and data-driven process adjustment. This digital transformation aims not only to enhance operational efficiency but also to improve sustainability by minimizing waste and energy use. The development of specialized technology for parboiled rice processing and fortified rice production further highlights the specialized and complex nature of the modern rice milling technological ecosystem, ensuring high-value product streams are maintained efficiently.

Regional Highlights

- Asia Pacific (APAC): APAC is the unquestionable leader in the Rice Milling Market, accounting for the largest share globally, driven by being the world's primary region for both rice production and consumption. Countries like China, India, Indonesia, Vietnam, and Thailand require constant upgrades to their milling infrastructure to meet vast domestic demand and maintain dominance in the international export market. The region’s growth is fueled by government initiatives promoting agricultural modernization and substantial private investment in large-scale, automated processing facilities to enhance export quality and food security measures. The adoption of advanced color sorters and high-capacity polishers is exceptionally high here.

- North America: This region holds a mature yet niche market focused heavily on precision, quality, and specialized rice milling (e.g., organic, non-GMO, specialty long-grain). The market is dominated by fewer, but larger, highly automated mills that prioritize operational efficiency and sophisticated IT integration, including advanced inventory management and quality assurance systems. Demand in North America primarily centers on replacing outdated equipment with energy-efficient, high-throughput machinery and leveraging advanced robotic systems for packaging and palletizing.

- Europe: Similar to North America, the European market is characterized by stringent quality regulations and a focus on premium and specialized rice imports and limited domestic production (primarily in Italy and Spain). European millers invest heavily in the latest sorting technology and highly hygienic, stainless steel equipment to comply with rigorous EU food safety standards. The market growth here is driven less by capacity expansion and more by technological innovation aimed at optimizing energy use and ensuring absolute product purity.

- Latin America (LATAM): LATAM represents a growing market, particularly in countries like Brazil, Argentina, and Peru, where efforts to increase self-sufficiency and improve agricultural supply chains are underway. The demand is increasing for medium-capacity, semi-automatic, and automatic mills capable of reliably processing locally grown paddy varieties. Government support for agricultural development and infrastructure projects is a key factor driving investment in new milling installations and modernization projects.

- Middle East and Africa (MEA): The MEA region, while highly reliant on rice imports, is showing accelerating growth in domestic milling capabilities, especially in West Africa (e.g., Nigeria, Ghana) and Egypt, driven by import substitution policies. The market demand is predominantly for small to medium-scale, durable, and easily operable milling units suitable for local cooperative and smaller commercial ventures. Technology transfer and the need for basic, robust hulling and polishing equipment are major themes in this developing regional market.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rice Milling Market.- Buhler AG

- Satake Corporation

- Milleral

- F. H. Schule Mühlenbau

- Alvan Blanch Development Company

- China National Machinery Industry Corporation (Sinomach)

- Kaichuang Co. Ltd.

- Akyurek Technology

- G.T. Co. Ltd.

- Fowler Westrup

- Savco International

- Patkon

- PETKUS Technologie GmbH

- Usher Agro Ltd.

- Lushan WinTone Engineering Co., Ltd.

- ZKI

- Zhengzhou VOS Machinery Equipment Co., Ltd.

- Jining Fuyuan Machinery Manufacturing Co., Ltd.

- Jiangsu Liangyou International Mechanical Engineering Co. Ltd.

- AVIC International Holding Corporation

Frequently Asked Questions

Analyze common user questions about the Rice Milling market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected growth rate (CAGR) of the Rice Milling Market?

The Rice Milling Market is projected to exhibit a Compound Annual Growth Rate (CAGR) of 6.5% between the years 2026 and 2033, driven primarily by global food security needs and continuous technological adoption in Asia Pacific.

Which technological innovation is having the largest impact on modern rice milling efficiency?

Optical sorting machines, commonly known as color sorters, represent the most impactful innovation, utilizing high-definition cameras and AI algorithms to maximize head rice yield and ensure exceptional quality consistency required for competitive international export markets.

Which geographical region dominates the global Rice Milling Market?

Asia Pacific (APAC) dominates the global Rice Milling Market, largely due to its high volume of production and consumption, with major contributors including China, India, and Southeast Asian nations continuously investing in large-capacity automatic milling infrastructure.

What are the primary challenges faced by rice mill operators when modernizing facilities?

The primary challenges include the substantial high initial capital investment required for purchasing fully automated machinery and the subsequent need for skilled technical personnel capable of operating and maintaining sophisticated, computerized milling systems and ensuring reliable energy supply.

How does the segmentation by capacity influence strategic purchasing decisions?

Capacity segmentation, particularly the shift towards medium (5-15 TPH) and large (>15 TPH) mills, influences purchasing decisions by emphasizing economies of scale, justifying investment in higher-cost automated systems to achieve competitive production throughput and lower operational costs per ton.

The rigorous analysis of the Rice Milling Market reveals a sector defined by necessary technological advancement to meet escalating global demands for high-quality, consistently processed rice. The drive towards automated and integrated milling solutions, bolstered by AI and IoT applications, is reshaping the competitive landscape. Key industry leaders are focusing intensely on developing machinery that not only increases yield and reduces breakage but also improves energy efficiency and complies with stringent international food safety standards, particularly within the dominant Asia Pacific region. The high barrier to entry due to capital cost remains a restraint, yet the compelling opportunity for optimized operations and diversified by-product utilization continues to attract significant investment, positioning the market for sustained, robust growth over the forecast period.

Technological differentiation among key players, especially in the realm of optical sorting and predictive maintenance features, will be the determining factor in market leadership. Companies that successfully implement comprehensive service models and localized support networks in emerging markets, such as Latin America and Africa, are expected to capture significant latent demand. Furthermore, regulatory frameworks emphasizing food traceability and sustainability are compelling millers to adopt transparent, digitally integrated supply chain solutions, thus driving the market toward increased digitalization and high-tech capital deployment. The fundamental growth trajectory remains positive, underpinned by population dynamics and the enduring role of rice as a staple global food source.

Future market evolution is anticipated to involve deeper integration of milling operations with external supply chain partners, facilitated by big data analytics, allowing millers to adapt quickly to changing paddy supply quality and fluctuating global commodity prices. Emphasis will be placed on developing modular and scalable milling solutions that can be rapidly deployed and adapted across varying regional infrastructure conditions. The specialization of milling techniques for health-focused rice varieties, such as brown rice and low-GI options, presents new, premium revenue streams, demanding milling equipment capable of gentler, customized processing techniques. This combination of mass-market efficiency improvements and high-value specialization will define the innovation agenda in the coming years.

From an investment perspective, the market stability inherent in the food processing sector makes rice milling an attractive area, particularly for venture capital focused on industrial automation and food technology. The replacement cycle for core milling equipment, coupled with the need for capacity expansion in developing economies, guarantees a sustained demand flow for machinery manufacturers. Strategic positioning near major rice cultivation belts and establishing strong partnerships with large agricultural cooperatives are essential strategies for securing long-term contracts and sustained revenue generation. The global focus on reducing post-harvest losses further accentuates the critical role and continued expansion potential of modern rice milling technology worldwide.

The shift from traditional semi-automatic mills to fully integrated, automated systems reflects the industry’s response to labor shortages, rising energy costs, and the absolute necessity of minimizing human error in quality control. Automated systems ensure consistent processing parameters, which is essential for branding and maintaining consumer trust, especially for export-oriented businesses. This trend is accelerating the obsolescence of older machinery, creating a robust secondary market for equipment sales and servicing, and further propelling the primary market for cutting-edge technology. Manufacturers who offer energy recovery systems and by-product conversion equipment are finding increasing favor, addressing the dual corporate objectives of sustainability and profitability in a resource-conscious global economy.

Geopolitical stability in key rice-producing regions is a variable that influences the market profoundly; supply chain disruptions necessitate diversified milling capacity across multiple regions. This requirement encourages investment in milling infrastructure outside traditional Asian hubs, leading to moderate growth projections in regions such as Latin America and Africa. Furthermore, advancements in specialized handling equipment, such as sophisticated pneumatic conveying systems and hygienic storage silos, are becoming standard requirements, ensuring the integrity of the rice grain from harvest through packaging, fulfilling the highest standards of food hygiene demanded by modern retailers and institutional purchasers globally. The overall market narrative remains strongly linked to global dietary habits and the imperative for industrial-scale food security management.

The complexity of modern rice milling extends into waste management, where technological solutions are needed to efficiently process rice hulls and bran. Environmental regulations are increasingly driving the market toward equipment that facilitates the conversion of rice husk into biomass fuel or specialized industrial materials, transforming waste products into valuable resources. This move towards circular economy principles within the rice milling sector provides further avenues for revenue diversification and reinforces the market's long-term sustainability profile. Machine manufacturers are responding by integrating specialized briquetting, pelletizing, and oil extraction modules directly into the milling plant design, offering turnkey solutions to maximize processor profitability and environmental compliance.

Consumer preferences for specific rice characteristics, such as precise grain length, low percentage of broken kernels, and particular aroma retention (for specialty rice), necessitate the adoption of customizable milling programs and advanced sensor technology. The software component of modern milling systems is becoming as critical as the hardware, allowing millers to tailor processing intensity based on the input paddy quality and the desired output specification. This bespoke processing capability is a key differentiator in high-value markets. Manufacturers providing integrated software platforms for operational visibility, quality tracking, and inventory control are gaining significant competitive leverage across major rice processing centers globally.

Market projections indicate that the medium-capacity segment (5-15 TPH) will see robust growth, particularly in rapidly urbanizing developing nations, as it offers a balance between capital efficiency and operational scale. These mills cater effectively to regional distribution needs and serve as crucial nodes in decentralized food supply networks. The ability of equipment suppliers to provide financing options, comprehensive training, and long-term maintenance contracts is often the deciding factor in securing large-scale orders within this segment, especially where local technical expertise may be limited. This strategic focus on support services highlights the evolution of the rice milling market beyond simple equipment sales to integrated solution provisioning.

The analysis of the competitive landscape shows that technological leaders like Satake Corporation and Buhler AG continue to set industry benchmarks, particularly in optical sorting and fully automated milling lines. However, regional manufacturers, especially those based in China and India, are increasingly challenging this dominance by offering cost-effective and robust alternatives tailored to local paddy varieties and operational environments. This dynamic competition drives continuous price-performance improvements across the global market. Successful market penetration strategies increasingly rely on a deep understanding of regional rice consumption preferences and regulatory mandates, requiring highly localized product offerings and marketing approaches from all key industry stakeholders.

The future resilience of the rice milling sector is intrinsically linked to its capacity for continuous innovation in water and energy efficiency. Traditional milling processes are often highly water and energy intensive. New technologies, such as advanced dry milling techniques and recuperative energy systems within polishers, are gaining traction as processors look to mitigate rising utility costs and meet sustainability targets. Government subsidies and global initiatives promoting sustainable agriculture are providing financial incentives for the adoption of such green technologies, further accelerating their market uptake and contributing to the overall maturity and responsibility of the global rice processing industry.

Finally, the security of the milling infrastructure against external threats, including cyber-attacks on automated control systems and physical security challenges, is emerging as a vital concern. As mills become more digitized, the reliance on operational technology (OT) security increases. Manufacturers are now integrating cybersecurity protocols into their SCADA systems and remote diagnostics platforms, recognizing that maintaining system integrity is paramount to ensuring continuous, uninterrupted food production. This shift signifies the market's acknowledgment that the risks associated with digitalization must be proactively managed to protect essential global food production assets.

The rice milling market continues its strong expansion trajectory, heavily reliant on the demand from Asia, but progressively diversifying into other regions. The necessity for advanced automation is becoming non-negotiable for large-scale operations aiming for global competitiveness. The convergence of machine learning, high-resolution optics, and sustainable engineering practices is not just improving quality control but is fundamentally transforming the economic model of rice processing globally. This modernization wave, though capital intensive, promises substantial returns through enhanced yield, reduced operational costs, and the ability to capture premium pricing for superior, consistently graded rice products.

Investment in research and development is focused on improving the durability and performance of consumable parts, such as rubber rollers and polishing screens, which are subjected to high wear and tear. Extending the lifespan of these components reduces maintenance frequency and lowers the total cost of ownership (TCO) for millers. Furthermore, the push for modular system design allows millers to easily scale operations or replace individual components without overhauling the entire facility, offering flexibility that appeals particularly to medium-sized enterprises facing fluctuating market demands and investment cycles.

The impact of climate change on paddy quality is also influencing technology development. Increasingly erratic weather patterns can lead to variability in harvested paddy characteristics (moisture content, kernel hardness). Modern milling technology must be capable of automatically compensating for these variations through adaptive processing algorithms, ensuring uniform final product quality regardless of the raw material input condition. This capability underscores the move toward truly intelligent milling systems that leverage real-time data analysis to optimize output and minimize processing losses under dynamic operational environments.

In summary, the Rice Milling Market is a high-technology industrial sector critical to global food security. Driven by population growth and stringent quality demands, the market is aggressively adopting automation, AI-driven quality assurance, and sustainable operational practices. While APAC remains the geographical powerhouse, technological diffusion is expanding globally, ensuring that modern, efficient milling capabilities become the standard across all major rice-producing and processing nations, thus guaranteeing the robust projected growth rate through 2033.

The regulatory environment across various regions, particularly concerning pesticide residues and heavy metal contamination in rice, necessitates superior cleaning and sorting technologies. Millers must adopt machinery that not only sorts based on appearance but also utilizes sensor technology to ensure compliance with strict health and safety thresholds. This regulatory pressure acts as a powerful non-market driver, compelling continuous investment in the most advanced, high-specification cleaning and sorting equipment available, thereby favoring manufacturers with robust research and development capabilities in sensor technology and data analytics for quality verification.

The competitive strategy of market leaders increasingly involves offering comprehensive solution packages, including training, financing, maintenance, and system upgrades, rather than simply selling machinery. This holistic approach builds long-term customer loyalty and provides stable revenue streams through service contracts, mitigating the risks associated with cyclical capital expenditure in the industry. These value-added services are particularly effective in securing market share in emerging economies where local technical expertise and reliable maintenance infrastructure are often underdeveloped, offering a compelling proposition for risk-averse commercial operators.

The trend towards specialized rice products, such as fortified rice kernels (FRK) mandated by some governments to combat malnutrition, is creating a demand for specialized blending and coating equipment integrated into the milling line. This requires precise dosing and gentle handling to incorporate micronutrients without damaging the rice kernel structure. Manufacturers integrating such fortification capabilities are tapping into government procurement programs and public health initiatives, opening up a high-volume, socially impactful market segment distinct from traditional commercial milling operations.

Ultimately, the Rice Milling Market's future hinges on its ability to integrate sustainability with productivity. As environmental concerns escalate, efficient resource management—minimizing water use, maximizing energy efficiency, and ensuring responsible waste disposal—will become critical success factors. Suppliers offering ‘green’ milling solutions will gain a distinct competitive advantage, aligning with the global corporate mandate for Environmental, Social, and Governance (ESG) compliance, which increasingly dictates major capital procurement decisions by large commercial rice producers and food multinationals.

The robust market structure, coupled with continuous technological innovation focused on operational excellence and quality output, strongly supports the projected growth trajectory of the Rice Milling Market, affirming its status as an essential and evolving segment of the global agricultural technology sector. The strategic adoption of digitalization and advanced automation across the processing chain is crucial for stakeholders aiming to capitalize on the sustained global demand for staple food products. This necessity ensures that capital flows will continue to favor modernization and expansion throughout the forecast period.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Rice Milling Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Rice Milling Market Size Report By Type (Below 50 Ton, 50-150 Ton, Above 150 Ton), By Application (Commercial, Home Use), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Rice Milling Machines Market Statistics 2025 Analysis By Application (Industrial, Family Workshop), By Type (Below 50 Ton, 50-150 Ton, Above 150 Ton), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager