Smectite Clays Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433170 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Smectite Clays Market Size

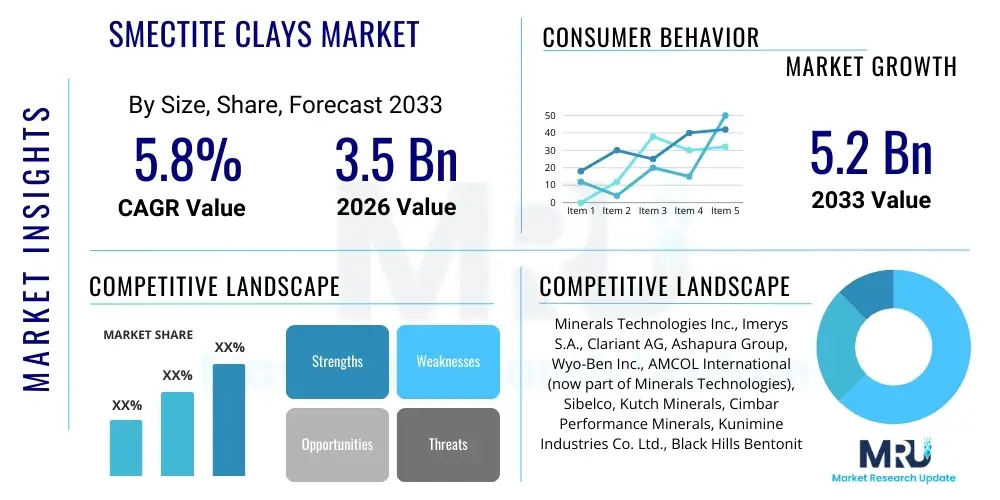

The Smectite Clays Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 5.2 Billion by the end of the forecast period in 2033.

Smectite Clays Market introduction

The Smectite Clays Market encompasses the production, processing, and distribution of a unique group of 2:1 phyllosilicate minerals characterized by their expansive lattice structure, high cation exchange capacity, and significant surface area. This mineral group, which primarily includes montmorillonite, bentonite, hectorite, saponite, and nontronite, derives its functional versatility from its exceptional ability to absorb water and swell, forming thixotropic gels and providing excellent binding and sealing properties. These inherent characteristics make smectite clays indispensable across a vast spectrum of industrial applications, ranging from highly specialized drilling fluids in the energy sector to fundamental components in civil engineering and environmental remediation. The market's growth trajectory is intrinsically linked to global industrialization, particularly in emerging economies where infrastructure development and resource exploration activities are accelerating.

Smectite clays are fundamentally aluminosilicates, distinguished by layers of tetrahedral silica sheets sandwiching a central octahedral alumina or magnesia sheet. The presence of isomorphic substitution within these sheets, where lower-valence cations replace higher-valence ones (e.g., Mg2+ substituting for Al3+), results in a net negative charge on the surface of the clay layers. This charge is neutralized by interlayer exchangeable cations, which are loosely held and readily available for interaction with surrounding environments, dictating the clay’s exceptional swelling and absorption capabilities. Bentonite, the most commercially dominant smectite, is primarily composed of montmorillonite and is widely sought after for its rheological control in liquid suspensions. Its industrial use spans diverse sectors, where it functions as a lubricant, stabilizer, binder, absorbent, and filler.

Major applications of smectite clays are heavily concentrated in the oil and gas drilling industry, where they are crucial components of drilling muds used to cool the drill bit, transport cuttings to the surface, and stabilize the borehole wall. Furthermore, their applications extend significantly into foundry processes, where they serve as binders for molding sand; in construction and civil engineering, where they are utilized for geotechnical barriers and landfill liners due to their low permeability; and in the cosmetics and pharmaceutical industries, where their absorbent and gelling properties are leveraged for product formulation. The market benefits from strong driving factors such as increasing global demand for energy, rigorous environmental regulations necessitating improved waste management techniques, and rising consumer preference for natural ingredient formulations in personal care products. However, the market faces constraints related to supply chain logistics and the high energy requirements associated with processing the raw clay materials.

- Product Description: Smectite clays are 2:1 phyllosilicates known for high expandability, high cation exchange capacity (CEC), and thixotropic behavior, with major types including bentonite and montmorillonite.

- Major Applications: Oil and gas drilling fluids, foundry sand binders, geotechnical barriers (e.g., landfill liners), cat litter, cosmetics, and pharmaceutical excipients.

- Key Benefits: Excellent rheological control, superior binding strength, high adsorption capacity for toxins and moisture, and low hydraulic conductivity.

- Driving Factors: Accelerated infrastructure projects globally, robust demand from the oil and gas sector, expansion of cosmetics and personal care manufacturing, and increasing stringent environmental regulations.

Smectite Clays Market Executive Summary

The Smectite Clays Market is experiencing sustained growth driven by macroeconomic factors, including accelerated urbanization in Asia Pacific and consistent demand from core legacy industries. Business trends indicate a shift towards advanced modification techniques, such as organo-modification and acid activation, to enhance the functional properties of natural smectites, thereby creating high-value nanocomposite materials utilized in advanced manufacturing, paints, and protective coatings. Leading companies are focusing on vertical integration, securing high-quality clay reserves, and optimizing processing efficiencies to maintain competitive pricing amid fluctuating energy costs. Furthermore, sustainable sourcing and processing practices are emerging as critical differentiators, responding to heightened regulatory scrutiny and corporate responsibility goals, particularly in the European and North American markets.

Regional trends highlight the Asia Pacific (APAC) region as the dominant market in terms of volume consumption and the fastest-growing market by value. This rapid expansion is primarily fueled by massive infrastructure investments in China and India, particularly in civil engineering, road construction, and the energy sector (both traditional drilling and renewable energy projects requiring specialized materials). North America and Europe, while mature markets, maintain high revenue share due to the established oil and gas industries and the pervasive use of smectites in high-value applications, such as pharmaceuticals and sophisticated environmental remediation systems. Regulatory frameworks regarding waste disposal and groundwater protection in these developed regions further bolster the demand for high-performance sealing materials derived from smectite clays.

Segment trends underscore the criticality of the bentonite type, which holds the largest market share due to its versatility and high availability. Within application segments, the drilling fluids sector remains the primary revenue generator, directly correlating with global upstream exploration activities. However, the fastest growth is anticipated within the environmental applications segment, driven by the global imperative to manage hazardous waste, purify contaminated water sources, and implement effective landfill containment systems. Simultaneously, the burgeoning cosmetics and personal care segment shows robust potential, spurred by consumer trends favoring natural, mineral-based ingredients for facial masks, thickeners, and stabilization agents. Suppliers are increasingly catering to highly specialized niche demands, offering customized smectite formulations optimized for specific industrial performance metrics, such as viscosity index stability at extreme temperatures or specific pharmaceutical purity levels.

AI Impact Analysis on Smectite Clays Market

User queries regarding the impact of Artificial Intelligence (AI) on the Smectite Clays Market frequently revolve around optimizing mineral extraction, enhancing the functional characteristics of processed clays, and streamlining the complex supply chain logistics inherent in global bulk mineral trade. Key concerns center on whether AI can accurately predict variations in raw material quality based on geological survey data, thereby reducing waste and operational costs. Users also inquire about AI's role in developing novel, tailor-made smectite formulations for advanced applications, such as high-performance adsorbents or drug delivery systems, requiring precise control over interlayer spacing and surface modification. The expectation is that AI-driven predictive maintenance in processing plants and optimized freight routing will lead to significant reductions in operational expenditure and improved market responsiveness, ensuring high-quality material delivery exactly when required by end-users.

AI's primary influence will manifest in the upstream activities of the smectite value chain, particularly in geological exploration and resource management. Machine learning algorithms can analyze vast datasets, including seismic surveys, spectral analysis, and historical extraction data, to predict the location, purity, and volume of smectite deposits with far greater accuracy than traditional methods. This predictive capability minimizes exploratory drilling, significantly lowering costs and environmental impact, and ensures a more stable, long-term supply pipeline for major market participants. Furthermore, AI-powered image analysis and sensor data can be deployed on conveyor belts during initial processing to instantaneously sort and grade raw clay materials, ensuring consistent quality feedstock for downstream purification and modification processes, which is crucial for high-specification applications like pharmaceuticals.

In the processing and application phase, AI is poised to revolutionize formulation science. Utilizing AI and computational chemistry, researchers can simulate the interaction of smectite surfaces with various organic modifiers or active pharmaceutical ingredients (APIs). This simulation capability drastically reduces the need for costly and time-consuming laboratory trials, accelerating the development of novel nanocomposites, high-efficacy drug carriers, and customized rheological additives. For instance, in drilling fluids, AI models can continuously analyze downhole sensor data to recommend real-time adjustments to the mud composition, including the exact concentration of bentonite, ensuring optimal performance and well stability under dynamic pressure and temperature conditions. This integration transforms smectite from a simple bulk commodity into a precisely engineered performance material.

- AI-enhanced geological modeling improves accuracy in identifying high-purity smectite reserves, reducing exploration expenditure.

- Machine learning optimizes bulk mineral processing lines, ensuring consistent quality control and impurity removal for high-specification end-uses.

- Predictive analytics minimizes supply chain risks by forecasting demand fluctuations and optimizing inventory levels across geographically dispersed storage facilities.

- Computational chemistry and AI accelerate the development of organo-modified smectite nanocomposites by simulating material interactions.

- AI-driven monitoring systems in drilling operations allow for real-time rheological adjustments of bentonite-based drilling muds, maximizing efficiency.

DRO & Impact Forces Of Smectite Clays Market

The Smectite Clays Market is primarily propelled by robust demand drivers stemming from global energy requirements and critical environmental mandates. The resurgence in oil and gas exploration and production activities worldwide directly translates into increased consumption of smectite-based drilling fluids, a cornerstone application. Concurrently, increasing regulatory requirements for environmental protection, particularly concerning landfill lining, groundwater contamination prevention, and wastewater treatment, necessitate the use of high-performance, impermeable barriers and highly adsorptive clays. These drivers, coupled with continuous population growth and associated demand for infrastructure (roads, bridges, residential areas) utilizing smectite-based soil stabilizers and cement additives, create a strong, diversified demand profile ensuring market resilience.

However, the market faces significant restraints that necessitate strategic management. The heavy reliance on raw material extraction leads to inherent environmental concerns and requires extensive permitting processes, which can be time-consuming and costly. Furthermore, the market structure, characterized by bulk transportation and high energy-intensive processing (especially thermal drying and calcination), makes it highly susceptible to fluctuations in global energy prices and escalating logistical costs, particularly for intercontinental shipping. The availability of synthetic alternatives or substitute materials, such as specialized polymers or attapulgite clay in certain applications, also poses a moderate restraint, potentially capping growth in specific high-end segments where performance outweighs cost considerations.

Opportunities for growth are concentrated in the development of specialized, modified smectite products and geographical expansion into untapped markets. The utilization of nano-clay technology, where smectites are intercalated or exfoliated to create ultra-performance nanocomposites, opens lucrative opportunities in advanced plastics, fire retardants, and sophisticated barrier packaging materials. Furthermore, the agricultural sector presents a significant untapped opportunity, leveraging smectites as soil conditioners, nutrient carriers, and feed additives to improve animal health and crop yield efficiency. The increasing trend towards using natural and mineral-based ingredients in developing nations provides a strategic avenue for market penetration, positioning smectites as sustainable and cost-effective alternatives to chemical compounds.

Segmentation Analysis

The Smectite Clays Market is comprehensively segmented based on Type, Application, and End-User Industry, reflecting the diverse physical properties and functional roles smectites play across different economic sectors. Analysis of these segments is vital for strategic planning, as market performance varies significantly depending on the specific characteristics of the clay mineral—for example, the high water absorption capacity of montmorillonite versus the specific salt resistance of saponite—and the rigorous performance requirements of the end-user industry, such as the high-shear stability needed in drilling or the strict purity standards required for pharmaceutical excipients. Understanding the interplay between these segments allows for targeted product development and market positioning.

- By Type: Montmorillonite, Bentonite (Sodium Bentonite, Calcium Bentonite), Hectorite, Saponite, Nontronite, Others.

- By Application: Drilling Fluids and Mud, Foundry and Casting, Civil Engineering and Construction, Cat Litter, Adsorbents and Filtering Agents, Cosmetics and Personal Care, Pharmaceuticals and Medical, Agriculture and Animal Feed, Others (e.g., Detergents, Paints).

- By End-User Industry: Oil and Gas, Civil Engineering and Infrastructure, Manufacturing (Foundry/Metal Casting), Environmental Management (Waste & Water Treatment), Consumer Goods, Agriculture.

Value Chain Analysis For Smectite Clays Market

The value chain for smectite clays commences with upstream analysis focusing on geological exploration and raw material extraction. Exploration involves identifying economically viable deposits, often requiring significant capital investment in land rights and mining equipment. Once located, the raw clay is extracted via open-pit mining methods, followed by initial crushing and drying processes. This upstream stage is characterized by high fixed costs and geographical concentration, meaning that the efficiency of logistics from the mine site to the processing facility critically influences final product cost. Key industry players often possess captive mines to ensure quality control and supply security, integrating the first two stages of the value chain.

The midstream processing phase involves extensive refining, purification, and modification steps tailored to the specific end-user application. Processing includes grinding, separation (to remove non-clay impurities like quartz), thermal activation (drying or calcining), and chemical treatments such as acid activation or organo-modification. Acid activation enhances the clay’s surface area for uses like bleaching earth, while organo-modification (using quaternary ammonium salts) makes the clay compatible with organic solvents, essential for applications in coatings and plastics. The distribution channel is bifurcated: bulk, low-value products (like foundry or cat litter grades) use high-volume, cost-effective direct or third-party logistics to major industrial hubs, whereas highly specialized, small-volume products (like pharmaceutical-grade smectites) require specialized, temperature-controlled, direct distribution paths to ensure purity and certification compliance.

Downstream analysis centers on the utilization and integration of processed smectites into final consumer or industrial products. Direct sales are prevalent when major buyers, such as international oil and gas service companies or large construction firms, purchase high volumes directly from processors under long-term contracts. Indirect distribution relies on regional distributors and specialty chemical brokers who manage localized inventory and cater to smaller, diverse end-users, such as regional cosmetics manufacturers or small foundries. The final value captured is significantly higher for custom-modified smectites and nano-clays compared to standard bentonite commodities, reflecting the investment in technology and expertise required during the midstream modification phase, ensuring a robust market for specialized mineral processing expertise.

Smectite Clays Market Potential Customers

The primary customers for smectite clays span several fundamental industrial sectors, dictated by the functional requirements of the material, primarily binding, absorption, and rheological control. The largest consumption base belongs to the Oil and Gas exploration sector, where smectites, particularly sodium bentonite, are mandatory components of drilling muds used to maintain hydrostatic pressure, carry rock cuttings, and stabilize the borehole. These customers, including major drilling contractors and oilfield service companies, demand vast quantities of clay with specific rheological profiles that must perform reliably under high-pressure and high-temperature conditions deep underground.

A second major customer group comprises Civil Engineering and Infrastructure companies, along with environmental management organizations. These buyers utilize smectites for barrier systems, such as hydraulic barriers in landfill construction, slurry wall stabilization for foundation work, and sealing subterranean tunnels and dams. For these applications, the key requirement is low permeability and high swelling capacity to ensure long-term, effective containment and stability. Specific regulatory compliance for environmental projects dictates the grade and purity of the smectite clay utilized, making government and municipal environmental bodies important indirect influencers of purchasing specifications.

Further substantial customer segments include the Manufacturing sector, particularly foundry operations that use smectite (often calcium bentonite) as a binder for molding sand, and the Consumer Goods sector, comprising pet care (cat litter manufacturers) and cosmetics/personal care companies. Cosmetic manufacturers seek high-purity clays for facial masks and thickeners, valuing the natural origin and excellent sensory profile. The diversity of these end-users ensures that demand remains broad, although purchasing decisions are based on highly specific criteria, ranging from bulk cost efficiency for foundry use to extreme chemical purity and fine particle size for cosmetic and pharmaceutical incorporation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 5.2 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Minerals Technologies Inc., Imerys S.A., Clariant AG, Ashapura Group, Wyo-Ben Inc., AMCOL International (now part of Minerals Technologies), Sibelco, Kutch Minerals, Cimbar Performance Minerals, Kunimine Industries Co. Ltd., Black Hills Bentonite, Volclay International, Laviosa Minerals, Bentonit KFT, G & W Mineral Resources, Lhoist Group, Elementis plc, BASF SE, CETCO, Tolsa Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Smectite Clays Market Key Technology Landscape

The technological landscape of the Smectite Clays Market is dominated by advancements in mineral processing, modification chemistry, and nano-technology aimed at enhancing purity and functionality. Traditional technologies focused primarily on simple drying, grinding, and sizing to meet bulk commodity standards for applications like cat litter or basic foundry binders. However, modern industrial requirements demand precise control over the clay's physicochemical properties. Key technological developments now revolve around acid activation, which involves treating the clay with mineral acids to significantly increase its specific surface area and porosity, making the resulting product, often called bleaching earth, highly effective for refining vegetable oils and petroleum products by adsorbing impurities.

A crucial area of innovation is the development of organo-modified smectites, commonly known as organoclays. This technology involves chemically exchanging the native inorganic cations in the clay interlayer space with quaternary ammonium organic cations. This modification renders the normally hydrophilic smectite surfaces hydrophobic and organophilic, allowing them to disperse effectively in organic systems like polymers, paints, and solvents. Organoclays are vital components in producing nanocomposites, where the exfoliated clay layers provide superior mechanical strength, barrier properties, and flame retardancy when dispersed within a polymer matrix. This technology positions smectite clays as advanced materials rather than mere fillers, driving high-value growth in specialized industries.

Furthermore, purification techniques are constantly evolving, particularly for food-grade and pharmaceutical-grade smectites, such as high-purity magnesium aluminum silicates. These processes utilize sophisticated methods like hydrocyclone separation, magnetic separation, and flotation to achieve extremely low impurity levels and consistent particle size distribution. The objective is to meet rigorous regulatory standards (e.g., FDA, pharmacopeia standards) regarding heavy metal contamination and microbial load. The integration of continuous process monitoring, often leveraging sensor technology and data analytics, ensures that these high-purity standards are maintained economically throughout the large-scale manufacturing environment, securing the market position of smectites in demanding medical and food applications.

Regional Highlights

Regional dynamics are critical in defining the Smectite Clays Market, largely due to the geographically specific nature of clay deposits and regional industrial demand profiles. Asia Pacific (APAC) stands out as the primary growth engine, fueled by unprecedented rates of infrastructure development, particularly in China, India, and Southeast Asian nations. These countries exhibit massive demand for construction materials, civil engineering stabilizing agents, and essential raw materials for their expanding manufacturing bases, including foundries and specialty chemical production. Furthermore, the region is witnessing increasing activity in unconventional gas exploration, bolstering demand for high-performance drilling fluids.

- Asia Pacific (APAC): Dominates market volume due to high demand from construction, booming oil and gas exploration in countries like China and India, and rising environmental remediation projects.

- North America: A mature market characterized by high consumption of premium, modified smectites. Strong reliance on drilling muds for deep-water and shale gas operations, coupled with established demand from the foundry and advanced environmental sectors.

- Europe: Focuses heavily on high-value applications, including pharmaceuticals, high-end cosmetics, and specialized environmental barriers, driven by stringent quality standards and sustainable material initiatives.

- Latin America (LATAM): Growth is tied to fluctuating energy exploration cycles in Brazil and Mexico, alongside agricultural expansion where smectites are increasingly used as soil amendments and animal feed additives.

- Middle East and Africa (MEA): High growth potential, driven almost entirely by extensive oil and gas activities in the Arabian Peninsula and North Africa, creating consistent, high-volume demand for drilling-grade bentonite and other rheology modifiers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Smectite Clays Market.- Minerals Technologies Inc.

- Imerys S.A.

- Clariant AG

- Ashapura Group

- Wyo-Ben Inc.

- Sibelco

- Kutch Minerals

- Cimbar Performance Minerals

- Kunimine Industries Co. Ltd.

- Black Hills Bentonite

- Volclay International

- Laviosa Minerals SpA

- Bentonit KFT

- G & W Mineral Resources

- Lhoist Group

- Elementis plc

- BASF SE

- CETCO (Colloid Environmental Technologies Company)

- Tolsa Group

- The Gremida Group

Frequently Asked Questions

Analyze common user questions about the Smectite Clays market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary differences between sodium bentonite and calcium bentonite?

Sodium bentonite exhibits superior swelling capacity and thixotropic properties when hydrated, making it ideal for drilling muds, sealing, and geotechnical barriers. Calcium bentonite, conversely, has lower swelling but higher adsorption capacity, making it preferred for bleaching earth, animal feed, and cat litter applications.

How is the Smectite Clays Market influenced by the global oil and gas industry?

The market is strongly linked to the oil and gas sector, as high-grade sodium bentonite is a critical component of water-based drilling fluids. Increased exploration and drilling activity, especially in unconventional resources, directly correlates with higher demand and revenue growth for smectite suppliers.

What is an organoclay and what are its main commercial applications?

An organoclay is a smectite clay chemically modified using quaternary ammonium salts, rendering it compatible with organic polymers and solvents. Its main commercial applications include high-performance rheology modification in paints, coatings, adhesives, and as a component in polymer nanocomposites for improved barrier properties.

Which geographic region currently leads the consumption of smectite clays, and why?

The Asia Pacific (APAC) region leads in consumption volume, primarily driven by massive governmental investments in civil engineering, infrastructure development, and rapidly expanding industrial manufacturing sectors requiring bulk minerals for foundries and construction projects.

Are smectite clays considered sustainable materials in industrial use?

Yes, smectite clays are generally considered sustainable due to their natural mineral origin and biodegradability. They are increasingly used in environmental applications (like landfill sealing and water purification) as a non-toxic, effective solution, though the energy intensity of processing remains a management consideration.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager