Sodium Hexametaphosphate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439611 | Date : Jan, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Sodium Hexametaphosphate Market Size

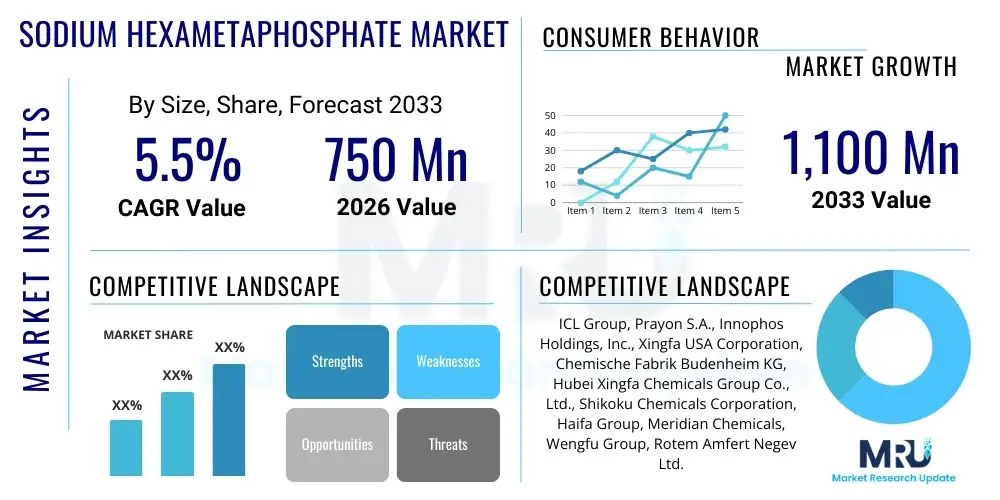

The Sodium Hexametaphosphate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.7% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.88 Billion by the end of the forecast period in 2033.

Sodium Hexametaphosphate Market introduction

The Sodium Hexametaphosphate (SHMP) market is a vital segment within the specialty chemicals industry, driven by its versatile applications across numerous sectors. SHMP, a complex phosphate salt, is highly valued for its exceptional chelating, sequestering, dispersing, and deflocculating properties. These characteristics make it indispensable in enhancing the performance and stability of a wide range of products and industrial processes, playing a crucial role in modern manufacturing and consumer goods.

The product's primary function as a water treatment agent, where it effectively sequesters metal ions and prevents scale formation, represents a significant demand driver. Beyond water treatment, SHMP finds extensive use in the food and beverage industry as an emulsifier, thickener, leavening agent, and preservative, contributing to product texture, shelf life, and overall quality. Its ability to modify protein structures and improve dough rheology makes it particularly valuable in meat processing and bakery applications.

Furthermore, the market's growth is propelled by its applications in detergents, ceramics, mining, textiles, and oil & gas. In detergents, SHMP enhances cleaning efficiency by softening water and dispersing dirt particles. In ceramics, it acts as a deflocculant to improve slurry flow. The escalating demand from these diverse end-use industries, coupled with global population growth and increasing industrialization, particularly in developing economies, are key factors fueling the Sodium Hexametaphosphate market expansion. The increasing focus on water resource management and stringent wastewater treatment regulations further solidify its market position and potential for sustained growth.

Sodium Hexametaphosphate Market Executive Summary

The Sodium Hexametaphosphate market is experiencing robust growth, primarily influenced by evolving business trends, distinct regional dynamics, and significant shifts within its diverse application segments. A key business trend shaping the market is the increasing emphasis on product purity and specific grades, with food-grade SHMP commanding premium pricing due to stricter regulatory standards and rising consumer awareness regarding food safety and quality. Manufacturers are also focusing on optimizing production processes to enhance efficiency and reduce environmental impact, often exploring sustainable sourcing of raw materials and energy-efficient manufacturing techniques. Furthermore, market consolidation through mergers and acquisitions is observed as larger players seek to expand their geographic footprint, diversify product portfolios, and achieve economies of scale, leading to a more streamlined and competitive landscape.

From a regional perspective, Asia-Pacific continues to dominate the SHMP market, driven by rapid industrialization, burgeoning population growth, and substantial investments in water treatment infrastructure and food processing industries, particularly in countries like China and India. North America and Europe, while mature markets, demonstrate steady demand, largely due to stringent environmental regulations bolstering the water treatment sector and advanced food manufacturing practices. These regions are also witnessing increased adoption of specialty SHMP formulations tailored for specific high-performance applications. The Middle East & Africa and Latin America are emerging as promising markets, characterized by developing industrial bases and growing needs for improved water management and food preservation technologies, indicating future growth potential.

Segment-wise, the water treatment application holds the largest share, propelled by global water scarcity concerns, industrial expansion, and the necessity for effective scale and corrosion inhibition in municipal and industrial water systems. The food and beverage segment is projected to exhibit strong growth, fueled by rising demand for processed and packaged foods, extended shelf life requirements, and the functional benefits of SHMP in various food formulations. Other significant segments such as detergents, ceramics, and mining also contribute substantially to market revenue, with innovation in product formulation and application-specific grades further driving segment expansion. The interplay of these business, regional, and segmental trends paints a dynamic and opportunity-rich landscape for the Sodium Hexametaphosphate market throughout the forecast period.

AI Impact Analysis on Sodium Hexametaphosphate Market

Users frequently inquire about how artificial intelligence (AI) can revolutionize the traditional chemical manufacturing processes, especially concerning efficiency, cost reduction, and sustainability in the Sodium Hexametaphosphate market. Key themes include AI's role in optimizing raw material utilization, enhancing energy efficiency during synthesis, improving quality control through predictive analytics, and streamlining complex supply chains. There is also significant interest in AI's potential to accelerate research and development for novel SHMP formulations or more sustainable production routes, as well as its application in demand forecasting to minimize waste and improve inventory management. Stakeholders are keen to understand how AI can lead to smarter factories, more resilient supply networks, and ultimately, a more competitive and environmentally responsible SHMP industry.

- Predictive Maintenance: AI-powered sensors and analytics predict equipment failures in manufacturing plants, reducing downtime and maintenance costs, ensuring continuous SHMP production.

- Process Optimization: Machine learning algorithms optimize reaction conditions (temperature, pressure, pH) in SHMP synthesis, improving yield, purity, and energy efficiency.

- Supply Chain Management: AI enhances demand forecasting, inventory management, and logistics, ensuring timely delivery of raw materials and finished SHMP products, minimizing stockouts and waste.

- Quality Control: AI-driven vision systems and sensors enable real-time detection of impurities or deviations in SHMP production, ensuring consistent product quality and reducing batch rejections.

- R&D Acceleration: AI facilitates the discovery of new SHMP formulations or alternative, greener synthesis pathways by simulating chemical reactions and predicting material properties.

- Energy Management: AI optimizes energy consumption across manufacturing operations by identifying inefficiencies and suggesting adjustments, contributing to cost savings and sustainability goals.

- Environmental Monitoring: AI helps monitor and manage wastewater treatment processes by optimizing SHMP dosage and identifying potential pollutants, ensuring compliance with environmental regulations.

DRO & Impact Forces Of Sodium Hexametaphosphate Market

The Sodium Hexametaphosphate market is significantly influenced by a complex interplay of drivers, restraints, and opportunities, collectively forming its impact forces. A primary driver is the accelerating demand from the global water treatment industry, fueled by increasing industrialization, urbanization, and a pressing need for effective solutions to combat water scarcity and pollution. SHMP's efficacy as a chelating and sequestering agent makes it indispensable in preventing scale formation and corrosion in water systems, from municipal supplies to industrial cooling towers. Concurrently, the burgeoning food and beverage sector, especially in emerging economies, contributes substantially to market growth due as SHMP is widely used as an emulsifier, thickener, and preservative to improve product texture, stability, and shelf life in processed foods, meat products, and dairy.

Despite these strong drivers, the market faces notable restraints. Volatility in the prices of key raw materials, particularly phosphoric acid (derived from phosphate rock) and soda ash, can significantly impact production costs and profit margins for SHMP manufacturers. Environmental concerns surrounding phosphorus discharge and its potential contribution to eutrophication in aquatic ecosystems pose regulatory challenges and may lead to calls for alternative, phosphorus-free solutions in certain applications. Furthermore, the availability of substitutes, while not entirely analogous in all functionalities, can present competitive pressure in specific application areas, potentially limiting SHMP's market expansion in some segments.

Nevertheless, the market is rich with opportunities that can mitigate restraints and foster sustained growth. The development of advanced, more environmentally friendly SHMP production technologies and sustainable sourcing practices for raw materials can enhance the market's appeal and regulatory compliance. Expanding applications in specialty chemicals, such as in advanced materials, pharmaceuticals, and personal care products, open new revenue streams. Moreover, the robust industrial growth in developing regions, coupled with increasing investments in infrastructure and food processing capabilities, represents significant untapped potential. Strategic innovation in product formulations to offer enhanced performance and address specific customer needs, alongside geographic market expansion, are key strategies that market players can leverage to capitalize on these opportunities and navigate the prevailing impact forces effectively.

Segmentation Analysis

The Sodium Hexametaphosphate market is comprehensively segmented to provide granular insights into its diverse applications, forms, and grades, enabling a precise understanding of market dynamics and growth opportunities across various end-use industries. This segmentation is crucial for market participants to identify lucrative niches, tailor product offerings, and develop targeted marketing strategies. Each segment is influenced by distinct demand drivers, regulatory environments, and competitive landscapes, contributing uniquely to the overall market trajectory.

- By Application:

- Water Treatment: Encompassing industrial and municipal water purification, scale inhibition, and corrosion control. This is a dominant segment due to global water scarcity and industrial growth.

- Food & Beverages: Used as an emulsifier, thickener, leavening agent, and preservative in processed foods, meat, dairy, and bakery products.

- Detergents & Cleaners: Acts as a builder and water softener, enhancing cleaning efficiency in household and industrial cleaning products.

- Ceramics: Utilized as a deflocculant to improve slurry flow and reduce water content in ceramic production.

- Mining: Employed for mineral flotation and dispersion of ore slurries.

- Textiles: Used in dyeing and finishing processes as a sequestering agent.

- Others: Includes applications in oil & gas, pulp & paper, pharmaceuticals, and personal care.

- By Form:

- Powder: The most common form, offering ease of handling and dissolution, suitable for various applications.

- Granular: Provides reduced dust and improved flowability, preferred in certain industrial processes.

- Liquid: Specialty formulations, often pre-dissolved for specific applications requiring precise dosing.

- By Grade:

- Food Grade: Meets stringent purity standards for consumption, widely used in food and pharmaceutical industries.

- Technical Grade: Used for industrial applications where less stringent purity is acceptable, such as water treatment and detergents.

Value Chain Analysis For Sodium Hexametaphosphate Market

The value chain for the Sodium Hexametaphosphate market is a multi-stage process, beginning with the sourcing of fundamental raw materials and extending through complex manufacturing to diverse end-user applications. Understanding this chain is crucial for identifying cost efficiencies, points of vulnerability, and opportunities for integration or optimization. The upstream segment primarily involves the extraction and processing of critical raw materials which are essential for SHMP synthesis, forming the bedrock of the entire supply structure.

The upstream analysis centers on key raw materials such as phosphoric acid and soda ash. Phosphoric acid is typically derived from phosphate rock through wet processes or thermal processes, while soda ash (sodium carbonate) is sourced from natural deposits (trona) or manufactured synthetically. Suppliers of these raw materials, often large chemical or mining companies, exert significant influence over the cost structure of SHMP production. Fluctuations in their prices, driven by global demand, geopolitical factors, and energy costs, directly impact the profitability of SHMP manufacturers. Therefore, securing stable and cost-effective raw material supplies is a critical strategic imperative for SHMP producers.

The midstream of the value chain involves the manufacturing of Sodium Hexametaphosphate, typically through the thermal condensation of monosodium phosphate. This energy-intensive process requires specialized equipment and expertise. Manufacturers invest heavily in R&D to optimize synthesis routes, improve product purity, and enhance energy efficiency, often focusing on developing specific grades (food-grade, technical-grade) and forms (powder, granular) to meet varied market demands. Post-manufacturing, the product moves into distribution channels, which can be direct or indirect. Direct channels involve manufacturers selling directly to large industrial end-users, fostering closer relationships and customized solutions. Indirect channels utilize a network of distributors, agents, and wholesalers to reach a broader customer base, especially smaller enterprises or those in geographically diverse locations, offering logistical support and localized inventory management.

The downstream analysis focuses on the end-user industries, which are the ultimate consumers of SHMP. These include municipal and industrial water treatment facilities, food and beverage manufacturers, detergent producers, ceramic industries, mining operations, and textile manufacturers. The diverse requirements of these end-users drive demand for specific SHMP properties and grades. Understanding the needs, regulatory environments, and consumption patterns of these downstream segments is vital for manufacturers to tailor their product offerings, provide technical support, and effectively capture market share. The effectiveness of the distribution channel, whether direct sales to large corporations or indirect through distributors to smaller entities, plays a pivotal role in ensuring timely delivery and market penetration, ultimately connecting the product efficiently from its source to its final application.

Sodium Hexametaphosphate Market Potential Customers

The Sodium Hexametaphosphate market serves a broad and diverse range of potential customers across multiple industrial and commercial sectors, each leveraging SHMP's unique chemical properties to enhance their products and processes. Understanding these end-users and their specific needs is paramount for manufacturers and suppliers to effectively position their offerings, develop tailored solutions, and penetrate new market segments. The product's versatility as a chelating, sequestering, and dispersing agent makes it indispensable in applications ranging from enhancing food quality to ensuring industrial operational efficiency and environmental compliance.

Key potential customers include entities within the water treatment industry, which forms the largest segment. Municipal water treatment plants and industrial facilities (e.g., power generation, chemical processing, oil & gas) rely heavily on SHMP for scale inhibition, corrosion control, and water softening. These customers seek high-purity, consistent SHMP to protect their infrastructure, improve operational longevity, and meet stringent regulatory standards for water quality. Their purchasing decisions are often driven by product efficacy, cost-effectiveness, and the supplier's technical support and reliability.

Another significant customer base resides in the food and beverage industry. Food manufacturers utilize SHMP as an emulsifier, thickener, preservative, and texturizer in a wide array of products, including processed meats, seafood, dairy products, beverages, and bakery items. These customers demand food-grade SHMP that complies with strict food safety regulations (e.g., FDA, EFSA standards) and contributes to desired sensory attributes and extended shelf life of their products. Detergent and cleaning product manufacturers also represent a substantial customer segment, using SHMP as a builder and water softener to boost cleaning performance. Beyond these primary sectors, potential customers include manufacturers in the ceramics industry (for deflocculation of slurries), mining companies (for mineral flotation and dispersion), textile producers (as a sequestering agent), and specialized chemical formulators across various industrial applications. Each of these customer groups presents distinct requirements regarding product specifications, packaging, volume, and supply chain logistics, necessitating a flexible and customer-centric approach from SHMP market participants.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.88 Billion |

| Growth Rate | 5.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Prayon S.A., Innophos Holdings Inc., ICL Group Ltd., Aditya Birla Chemicals (Thailand) Ltd., Sichuan Chuanfa Phosphorus Chemical Co., Ltd., Wengfu Group, Hubei Xingfa Chemicals Group Co., Ltd., Merck KGaA, ReePhos Chemical Co., Ltd., Haifa Group, Ascent Chemicals, Chemische Fabrik Budenheim KG, Recochem Inc., Spectrum Chemical Manufacturing Corp., Solvay S.A., J. M. Huber Corporation, Guangdong Guanghua Sci-Tech Co., Ltd., Hindustan Chemical Company, Quzhou Lianhe Chemical Co., Ltd., Changzhou Dahua Chemical Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sodium Hexametaphosphate Market Key Technology Landscape

The Sodium Hexametaphosphate market's technological landscape is continuously evolving, driven by the imperative to enhance production efficiency, reduce environmental footprint, and develop advanced formulations to meet specific end-user demands. The core manufacturing technology primarily involves the thermal condensation of monosodium phosphate, a process that requires precise control over temperature and reaction time to yield the desired polymeric phosphate. Innovations in this foundational process aim to optimize energy consumption, improve product yield, and ensure higher purity levels, especially for food-grade applications, where stringent quality standards are paramount. Research into novel catalysts and reaction conditions is ongoing to make this synthesis more economically viable and environmentally benign.

Beyond the primary synthesis, a significant part of the technological focus is on purification and formulation techniques. Advanced filtration and crystallization technologies are employed to remove impurities and achieve the high purity required for various applications. For food and beverage industries, specialized drying and grinding technologies are crucial to produce SHMP in desired particle sizes and forms (e.g., fine powder, granular) that ensure optimal solubility and functionality in food matrices. Furthermore, coating technologies are being explored to encapsulate SHMP, providing controlled release properties or enhanced stability in specific environments, which can be advantageous in sensitive applications or for extending shelf life.

The development of sustainable production methods represents another critical technological frontier. This includes exploring alternative, greener raw material sources, optimizing phosphorus utilization to minimize waste, and implementing closed-loop systems to recycle by-products. Companies are also investing in digital technologies and automation, such as advanced process control systems, to monitor and regulate manufacturing parameters in real-time, thereby ensuring consistent product quality and operational safety. This technological evolution not only addresses current market needs but also anticipates future demands for high-performance, cost-effective, and environmentally responsible Sodium Hexametaphosphate products, ensuring the market's long-term viability and competitiveness.

Regional Highlights

The Sodium Hexametaphosphate market exhibits distinct regional dynamics, influenced by varying levels of industrialization, regulatory frameworks, population growth, and access to raw materials. Each region contributes uniquely to global demand and supply, shaping the overall market landscape.

- Asia Pacific (APAC): This region stands as the largest and fastest-growing market for Sodium Hexametaphosphate. Countries like China and India are at the forefront, driven by rapid industrial expansion, escalating urbanization, significant investments in water treatment infrastructure, and a burgeoning food and beverage processing sector. The presence of numerous SHMP manufacturers, coupled with robust demand from agriculture and manufacturing industries, further fuels market growth.

- North America: A mature market characterized by stringent environmental regulations, particularly concerning water quality and wastewater treatment. Demand for SHMP is stable, propelled by its extensive use in municipal and industrial water treatment, as well as in the food processing and detergent industries. Innovation in sustainable SHMP applications and advanced formulations is a key trend in this region.

- Europe: Similar to North America, Europe is a mature market with high demand from the water treatment, food and beverage, and cleaning product sectors. Strict regulatory policies, especially regarding phosphorus discharge, drive innovation towards more efficient and environmentally friendly SHMP solutions. Germany, France, and the UK are key contributors to the European market.

- Latin America: This region is witnessing steady growth, largely due to expanding industrial bases, increasing population, and growing awareness of water management issues. Brazil and Mexico are significant markets, with demand primarily stemming from water treatment, agriculture, and food preservation applications.

- Middle East and Africa (MEA): An emerging market experiencing substantial growth, particularly in water-stressed countries where SHMP is crucial for desalination plants and industrial water systems. Increasing investments in infrastructure development, coupled with a growing food processing industry, are driving market expansion in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sodium Hexametaphosphate Market.- Prayon S.A.

- Innophos Holdings Inc.

- ICL Group Ltd.

- Aditya Birla Chemicals (Thailand) Ltd.

- Sichuan Chuanfa Phosphorus Chemical Co., Ltd.

- Wengfu Group

- Hubei Xingfa Chemicals Group Co., Ltd.

- Merck KGaA

- ReePhos Chemical Co., Ltd.

- Haifa Group

- Ascent Chemicals

- Chemische Fabrik Budenheim KG

- Recochem Inc.

- Spectrum Chemical Manufacturing Corp.

- Solvay S.A.

- J. M. Huber Corporation

- Guangdong Guanghua Sci-Tech Co., Ltd.

- Hindustan Chemical Company

- Quzhou Lianhe Chemical Co., Ltd.

- Changzhou Dahua Chemical Co., Ltd.

Frequently Asked Questions

What is Sodium Hexametaphosphate (SHMP) and its primary uses?

Sodium Hexametaphosphate (SHMP) is a complex phosphate salt primarily used as a sequestrant, chelating agent, and dispersant. Its main applications include water treatment (preventing scale and corrosion), food processing (as an emulsifier, thickener, and preservative), and in detergents (as a water softener).

What are the key factors driving the growth of the SHMP market?

The SHMP market growth is primarily driven by increasing global demand from the water treatment sector due to industrialization and urbanization, expanding applications in the food and beverage industry for enhanced product quality and shelf life, and its critical role in various industrial processes like detergents, ceramics, and mining.

Which region dominates the Sodium Hexametaphosphate market?

Asia Pacific currently dominates the Sodium Hexametaphosphate market. This dominance is attributed to rapid industrial growth, significant investments in water infrastructure, and a booming food processing industry in countries such as China and India, leading to high production and consumption rates.

What are the main restraints impacting the SHMP market?

Key restraints include the volatility in raw material prices, particularly for phosphoric acid, environmental concerns regarding phosphorus discharge and its potential to cause eutrophication, and the availability of alternative chemical substitutes in certain application areas, which can exert competitive pressure.

How is AI expected to impact the Sodium Hexametaphosphate manufacturing process?

AI is anticipated to significantly impact SHMP manufacturing by optimizing production processes for higher yield and purity, enabling predictive maintenance for reduced downtime, enhancing supply chain efficiency through improved forecasting, and accelerating research and development for sustainable formulations and new applications. This leads to cost savings and improved environmental performance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Sodium Hexametaphosphate Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Sodium Hexametaphosphate Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Food Grade, Technical Grade), By Application (Food Application, Indusial Application), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager