Sodium Methylate Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437780 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Sodium Methylate Market Size

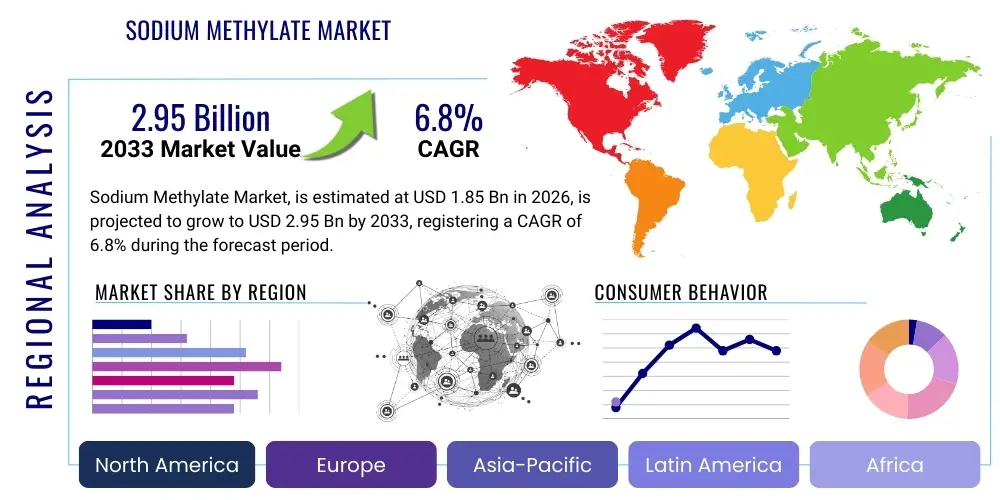

The Sodium Methylate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 2.95 Billion by the end of the forecast period in 2033.

Sodium Methylate Market introduction

Sodium Methylate, also known as sodium methoxide (NaOCH3), is a crucial chemical compound derived from the reaction of sodium with methanol. It exists typically as a white, free-flowing powder or dissolved in methanol as a colorless solution. This compound functions as a strong base and a nucleophilic reagent, making it indispensable across various industrial applications, particularly in transesterification processes. Its high reactivity, coupled with its ability to act as an effective catalyst, defines its market significance.

The primary driver for the Sodium Methylate market is the burgeoning global demand for biodiesel. Sodium methylate is the most widely utilized catalyst for the transesterification of vegetable oils and animal fats into fatty acid methyl esters (FAME), which constitutes biodiesel. Beyond energy, it plays a vital role in the fine chemical and pharmaceutical industries, serving as a condensation agent, methylation agent, or catalyst in the synthesis of complex molecules, vitamins, and specialized antibiotics. Furthermore, its use extends to the agrochemical sector for the production of pesticides and herbicides, highlighting its versatility as a core chemical intermediate.

Key benefits of using sodium methylate include enhanced reaction efficiency, high purity yield in synthesis processes, and cost-effectiveness compared to alternative catalysts, particularly in large-scale biodiesel production. Driving factors underpinning market expansion include stringent environmental regulations promoting biofuel consumption, increasing complexity in pharmaceutical synthesis requiring high-purity reagents, and technological advancements improving the safe handling and transportation of this highly reactive chemical.

Sodium Methylate Market Executive Summary

The Sodium Methylate market exhibits robust growth driven primarily by the sustained global emphasis on sustainable energy and the subsequent demand spike from the biodiesel industry, particularly in regions enforcing high blending mandates like Europe and parts of Asia Pacific. Business trends indicate a shift toward higher-purity, solid-form sodium methylate to mitigate transportation costs and handling risks associated with methanol solutions, alongside significant investments in captive production facilities by large-scale chemical producers and biodiesel manufacturers seeking supply chain stability. Consolidation among smaller regional players and strategic collaborations focusing on advanced catalyst delivery systems characterize the competitive landscape.

Regionally, Asia Pacific (APAC) is emerging as the fastest-growing market, propelled by rapid industrialization in China and India, increased pharmaceutical manufacturing outsourcing, and emerging biodiesel programs. North America maintains a mature market position, characterized by advanced chemical processing and significant demand from the polymer and specialty chemicals sectors. Europe, despite facing regulatory pressure on certain chemical usages, remains a dominant consumer due to its strong commitment to biofuel targets and established fine chemical industry, driving steady demand for high-grade catalysts.

Segment trends reveal that the application segment is dominated by biodiesel production, which accounts for the largest share by volume. However, the pharmaceutical and agrochemical segments are expected to show the highest growth rates due to the increasing complexity of synthesis pathways and the need for specialized reagents. By type, the Sodium Methylate solution segment holds the majority share currently due to ease of dosing and reaction efficiency in liquid processes, but the solid/powder form is gaining traction for logistical advantages in distant markets.

AI Impact Analysis on Sodium Methylate Market

User queries regarding AI’s impact on the Sodium Methylate market primarily revolve around optimizing chemical synthesis efficiency, ensuring safety in hazardous material handling, and enhancing predictive maintenance for large-scale reactors and storage infrastructure. Common concerns also touch upon how AI can mitigate supply chain disruptions affecting key raw materials like methanol and sodium. Users expect AI to reduce operational costs, increase product consistency, and provide smarter risk management protocols related to the inherent volatility and corrosivity of sodium methylate. The overarching theme is the integration of digital twins and machine learning to achieve process intensification and improve reaction selectivity, ultimately boosting profitability and sustainability in manufacturing.

AI and machine learning algorithms are being increasingly deployed in complex chemical production facilities to model and predict optimal reaction parameters for sodium methylate synthesis, allowing manufacturers to maximize yield and purity while minimizing energy consumption. By analyzing real-time sensor data from reactors, AI systems can dynamically adjust temperature, pressure, and dosing rates of precursors (sodium and methanol), significantly reducing the margin for error and waste generation. This optimization is crucial given the exothermic nature and high reactivity of the synthesis process.

Furthermore, AI-driven predictive maintenance systems are transforming the management of critical infrastructure, such as specialized storage tanks and pipelines required for sodium methylate solutions, which are highly corrosive. By identifying subtle anomalies in vibration or temperature patterns, AI prevents catastrophic equipment failures, thereby enhancing worker safety and minimizing production downtime. In logistics, AI optimizes complex global supply chains, forecasting demand fluctuations in the highly volatile biodiesel market and ensuring timely procurement of methanol, leading to more resilient operations.

- AI optimizes transesterification reaction conditions for maximum biodiesel yield.

- Predictive maintenance schedules enhance safety and operational uptime of highly corrosive storage facilities.

- Machine learning models improve reaction selectivity in complex pharmaceutical synthesis using sodium methylate.

- AI-driven supply chain management forecasts raw material (methanol, sodium) price volatility and demand shifts.

- Digital twins simulate production lines, accelerating process intensification and scaling of novel sodium methylate synthesis methods.

- Automated quality control systems use computer vision and AI to ensure the consistency and purity of the solid sodium methylate product.

DRO & Impact Forces Of Sodium Methylate Market

The Sodium Methylate market dynamics are fundamentally shaped by the vigorous regulatory push towards renewable energy adoption (Driver) countered by the significant operational complexities associated with handling a highly reactive and hazardous substance (Restraint), presenting continuous opportunities for specialized technology development in emerging application areas (Opportunity). The interconnected nature of the energy sector, pharmaceutical outsourcing trends, and raw material supply chain volatility constitutes the primary Impact Forces determining market trajectory over the forecast period. Regulatory mandates, especially those related to carbon emission reduction and biofuel blending ratios across major economies, exert the strongest upward force on demand, directly correlating market growth with policy stability.

Key drivers include the indispensable role of sodium methylate as a catalyst in large-scale biodiesel production, driven by government incentives and blending targets in Europe, North America, and parts of Asia. Additionally, the increasing focus on complex Active Pharmaceutical Ingredients (APIs) and fine chemical synthesis requires high-purity, strong bases like sodium methylate, contributing to its stable demand from the life science sector. The relatively low cost and high efficiency of sodium methylate compared to alternatives like potassium methylate or enzymatic catalysts further solidify its market dominance in transesterification.

Conversely, major restraints involve the classification of sodium methylate as a hazardous material, necessitating expensive, specialized storage, handling, and transportation logistics, particularly for its highly flammable and corrosive solution form. Fluctuation in the price and supply of raw materials—specifically methanol—due to its linkage with natural gas markets, poses a significant constraint on production costs. Opportunities are predominantly found in developing novel applications in polymerization (e.g., polyurethanes, specialized resins) and in utilizing solid sodium methylate in emerging economies where sophisticated liquid handling infrastructure may be lacking, simplifying distribution and use. The development of safer, encapsulated forms of the catalyst also represents a high-potential opportunity.

Segmentation Analysis

The Sodium Methylate market is strategically segmented based on its physical form (Type), the industrial sector utilizing it (Application), and geographical region (Geography). This segmentation allows for precise analysis of demand patterns, technological preferences, and growth hot spots. The Type segmentation distinguishes between the solid/powder form and the solution (typically 30% w/w in methanol), each preferred based on the specific industrial process requirements—liquids for continuous flow processes and solids for applications requiring anhydrous conditions or simplified logistics. The Application segment reveals the strong dependence of the market on the energy sector, while also highlighting the high-value, rapid-growth potential offered by the specialty chemicals and life sciences industries.

The largest volume consumption lies within the Biodiesel application due to the massive scale of biofuel production globally, where sodium methylate acts as the principal transesterification catalyst. However, segments like Pharmaceuticals demand extremely high purity grades, commanding premium pricing and higher profitability margins. Agrochemicals and Polymerization represent stable, mature markets where sodium methylate facilitates crucial synthesis steps, such as initiating polymerization reactions or acting as a reagent in pesticide manufacture. Understanding these segments is crucial for manufacturers looking to diversify their portfolio beyond the highly competitive biodiesel supply chain.

- Type:

- Sodium Methylate Solution (e.g., 30% in Methanol)

- Sodium Methylate Solid (Powder)

- Application:

- Biodiesel Production

- Pharmaceuticals

- Agrochemicals (Pesticides and Herbicides)

- Specialty Chemicals

- Polymerization Catalysis

- Others (Dyes, Pigments)

- Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Sodium Methylate Market

The Sodium Methylate value chain begins with the upstream procurement of essential raw materials: elemental sodium and high-purity methanol. The stability and cost-effectiveness of this supply are paramount, as methanol prices are often linked to natural gas market fluctuations. Key upstream suppliers include major sodium manufacturers and petrochemical giants producing methanol. The manufacturing process itself involves highly controlled, exothermic reactions that necessitate specialized reactor technology and stringent safety protocols due to the reactive nature of the inputs and the final product. Production is generally highly centralized, favoring manufacturers with integrated methanol or chlor-alkali facilities.

The midstream focuses on synthesis, purification, and formulation into either solution or solid form. Transportation and storage constitute a major cost center in the midstream due to the corrosive and flammable properties of the product, requiring specialized ISO tanks, corrosion-resistant drums, and detailed safety documentation. Distribution channels for sodium methylate are dual: Direct sales dominate large-volume biodiesel consumers who require consistent, bulk supply delivered directly to their production sites, often via dedicated pipelines or road tankers. Indirect sales, involving chemical distributors and regional agents, cater primarily to the smaller-volume specialty chemicals, pharmaceutical, and agrochemical segments.

The downstream segment encompasses the final end-use applications. Biodiesel producers are the largest consumers, integrating the product directly into their transesterification reactors. Pharmaceutical companies utilize the product as a high-purity reagent, often in smaller, precise quantities. The efficiency of the distribution network and the ability of the manufacturer to meet stringent quality and purity standards are critical factors determining success in the downstream, particularly for the high-value specialty and pharma markets which demand specific certifications and supply traceability.

Sodium Methylate Market Potential Customers

The primary potential customers for sodium methylate are large-scale industrial entities engaged in high-volume chemical synthesis or renewable energy production. The biodiesel sector represents the largest consumer base, comprising integrated oil and gas companies, independent renewable fuel producers, and agricultural cooperatives that operate transesterification plants globally. These customers prioritize cost, consistent quality, and reliable, high-volume supply chains, often preferring long-term contracts for the sodium methylate solution form to minimize handling complexities and ensure seamless operational flow.

The second major category includes pharmaceutical and fine chemical manufacturers. These companies purchase high-purity sodium methylate, often in the solid or anhydrous solution form, for use in organic synthesis pathways, including the manufacture of high-value active pharmaceutical ingredients (APIs), vitamins (like Vitamin B1), and specialized chemical intermediates. Their purchasing decisions are driven less by bulk cost and more by purity certifications, traceability, and adherence to stringent regulatory standards such as Good Manufacturing Practice (GMP).

Finally, the agrochemical and polymer industries serve as stable, continuous demand sources. Agrochemical companies utilize it for specific methylation or cyclization steps in producing insecticides and herbicides. Polymer manufacturers, especially those producing polyurethane foams or specialized resins, use sodium methylate as a catalyst or initiator. These diverse end-users emphasize product consistency and technical support in handling the catalyst safely and effectively within their specialized reaction systems.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 2.95 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Evonik Industries AG, Merck KGaA, Avantor Inc., Albemarle Corporation, Gelest Inc., Supra Chemicals, Zibo Xusen Chemical Co. Ltd., Jiangsu Tianjiayi Chemical Co. Ltd., Shandong Xinya New Material Co. Ltd., Luxi Chemical Group Co. Ltd., Chemtex Speciality Limited, Newtop Chemical Co. Ltd., TCI Chemicals (India) Pvt. Ltd., Otto Chemie Pvt. Ltd., Shaanxi Jinshan Chemical Co. Ltd., Central Glass Co. Ltd., Jining Hongyu Chemical Co. Ltd., Changyi Hongda Chemical Co. Ltd., Jilin Zhongxin Chemical Group Co. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sodium Methylate Market Key Technology Landscape

The technology landscape for the Sodium Methylate market is dominated by advancements in synthesis methods aimed at increasing purity, improving energy efficiency, and enhancing safety during manufacturing. The two primary industrial production routes involve either the direct reaction of elemental sodium with methanol or, less commonly, the electrochemical route. Modern manufacturing facilities focus on highly automated, closed-loop reactor systems to precisely control the highly exothermic reaction between sodium and methanol. This control minimizes impurities and optimizes heat recovery, contributing to overall cost efficiency and ensuring consistent product quality, which is critical for demanding pharmaceutical applications.

A significant technological focus is placed on the solidification and handling of the product. While the methanol solution form is simpler to manufacture, the solid powder form (anhydrous sodium methylate) offers substantial logistical advantages, particularly for intercontinental shipping. Technology development here centers on spray drying or rotary drying techniques to achieve high-purity, stable powder particles that minimize agglomeration and retain high reactivity upon re-dissolution. Innovation in packaging, such as using specialized inert gas purged containers and bulk bag handling systems, further facilitates the safe transportation of the corrosive and moisture-sensitive solid form.

Furthermore, technology related to downstream application efficiency, specifically in biodiesel production, is evolving. Continuous transesterification processes are increasingly replacing batch reactors, requiring manufacturers to supply highly stable and precisely concentrated sodium methylate solutions suitable for continuous dosing systems. The integration of advanced sensor technology and process analytics (often supported by AI) is becoming standard practice to monitor catalyst effectiveness in real-time and optimize reaction kinetics, thereby maximizing the conversion rate of triglycerides into FAME and reducing process downtime. The development of micro-reactor technology is also being explored for safer, smaller-scale, distributed production, reducing the risks associated with centralized large-scale handling of the raw material sodium.

Regional Highlights

The global Sodium Methylate market demonstrates distinct regional dynamics heavily influenced by biofuel policies, chemical manufacturing prowess, and pharmaceutical industry growth trajectories.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, driven by the expanding chemical manufacturing base in China and India, which are rapidly becoming global hubs for API and agrochemical production. Government efforts in Southeast Asian countries like Indonesia and Malaysia to promote palm oil-based biodiesel, coupled with substantial domestic consumption of specialty chemicals, ensure surging demand. Investment in large-scale synthesis capacity within China is a key growth factor, shifting manufacturing dominance eastward.

- Europe: Europe represents a mature and major consumer base, primarily due to rigorous Renewable Energy Directives (RED) mandating significant blending of biodiesel into transport fuels. Germany, France, and Spain are leading markets. While facing slower growth compared to APAC, the European market commands high value, driven by demand for premium, high-purity grades required by its established pharmaceutical and fine chemical industries. Strict REACH regulations influence product formulation and safety standards, requiring high compliance from suppliers.

- North America: North America holds a substantial share, propelled by the U.S. Renewable Fuel Standard (RFS) and the dominance of major chemical conglomerates. The market is characterized by technological sophistication, with significant usage not only in biodiesel but also in advanced polymerization processes (e.g., catalysts for specialized resins) and high-end specialty chemicals. Demand stability is high, supported by integrated supply chains and advanced infrastructure for hazardous chemical handling.

- Latin America (LATAM): LATAM, particularly Brazil and Argentina, is critical due to its massive soybean and sugarcane-based biodiesel industry. Brazil is a global biofuel powerhouse, translating into robust and non-negotiable demand for sodium methylate catalysts. Market growth is closely tied to domestic agricultural output and governmental mandates supporting biofuel independence.

- Middle East and Africa (MEA): This region is an emerging market. Growth is currently limited but accelerating, driven by the diversification of economies away from crude oil, leading to nascent biofuel projects and increasing investment in domestic fine chemical production in countries like Saudi Arabia and the UAE. Logistics and regulatory fragmentation remain challenges, making the solid form of sodium methylate often preferred here.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sodium Methylate Market.- BASF SE

- Evonik Industries AG

- Merck KGaA

- Avantor Inc.

- Albemarle Corporation

- Gelest Inc.

- Supra Chemicals

- Zibo Xusen Chemical Co. Ltd.

- Jiangsu Tianjiayi Chemical Co. Ltd.

- Shandong Xinya New Material Co. Ltd.

- Luxi Chemical Group Co. Ltd.

- Chemtex Speciality Limited

- Newtop Chemical Co. Ltd.

- TCI Chemicals (India) Pvt. Ltd.

- Otto Chemie Pvt. Ltd.

- Shaanxi Jinshan Chemical Co. Ltd.

- Central Glass Co. Ltd.

- Jining Hongyu Chemical Co. Ltd.

- Changyi Hongda Chemical Co. Ltd.

- Jilin Zhongxin Chemical Group Co. Ltd.

Frequently Asked Questions

Analyze common user questions about the Sodium Methylate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary driver of demand for Sodium Methylate globally?

The primary driver is the large-scale production of biodiesel, where Sodium Methylate acts as the most efficient and cost-effective catalyst for the transesterification process of vegetable oils and animal fats into fatty acid methyl esters (FAME).

How do the solid and solution forms of Sodium Methylate differ in application?

Sodium Methylate solution (typically 30% in methanol) is preferred in continuous industrial processes like high-volume biodiesel manufacturing due to ease of dosing. The solid/powder form is used when anhydrous conditions are required or for logistical benefits, as it eliminates methanol transport and handling challenges.

What are the main risks associated with handling and storing Sodium Methylate?

Sodium Methylate is a highly hazardous material. The primary risks include high corrosivity, flammability (especially the methanol solution), and high reactivity with moisture, which can release flammable gases and cause thermal hazards, necessitating specialized, inert-atmosphere storage and handling equipment.

Which geographical region exhibits the fastest growth potential for the Sodium Methylate market?

Asia Pacific (APAC), particularly China and India, is the fastest-growing region. This growth is fueled by massive expansion in pharmaceutical outsourcing, rising domestic agrochemical production, and emerging government initiatives promoting biofuel adoption across Southeast Asia.

Beyond biodiesel, what are the key high-value applications for Sodium Methylate?

High-value applications include its use as a strong base and reagent in the synthesis of complex Active Pharmaceutical Ingredients (APIs), various vitamins, and fine chemical intermediates, where its purity and high reactivity are indispensable for selective synthesis pathways.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Solid of Sodium Methylate Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Solid of Sodium Methylate Market Statistics 2025 Analysis By Application (Pharmaceutical Industry, Biodiesel Industry, Edible Catalyst and Analytical Reagent Industry), By Type (Sodium Metal Process(Sodium Metal Methanol As Raw Materials), Caustic-Based Process(Caustic Soda Methanol As Raw Materials)), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager