Sodium Phenoxyacetate Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437891 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Sodium Phenoxyacetate Market Size

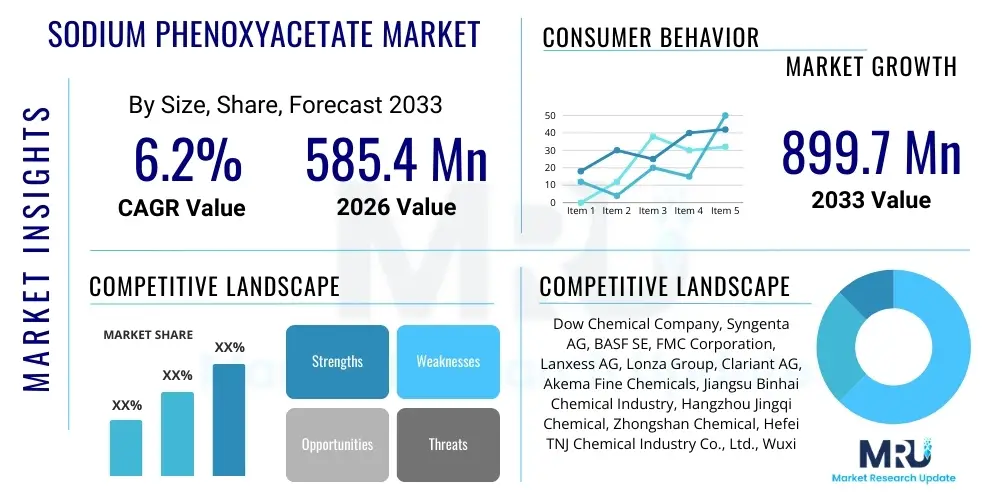

The Sodium Phenoxyacetate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2026 and 2033. The market is estimated at USD 585.4 Million in 2026 and is projected to reach USD 899.7 Million by the end of the forecast period in 2033. This consistent growth trajectory is primarily attributed to its expanding application base in the cosmetics and personal care industry, where it functions effectively as a broad-spectrum preservative, replacing less desirable alternatives. Furthermore, its crucial role as an intermediate in the synthesis of various agrochemicals, particularly certain types of plant growth regulators and herbicides, secures its industrial relevance and drives steady demand, especially in high-growth agricultural economies across Asia Pacific.

Sodium Phenoxyacetate Market introduction

Sodium phenoxyacetate, the sodium salt of phenoxyacetic acid, is a chemical compound primarily recognized for its functional properties as a vital chemical intermediate and a potent preservative. Chemically, it is derived from the reaction between phenol, chloroacetic acid, and a sodium base. Its high solubility in water and effectiveness across a wide pH range make it highly valued in specialized industrial applications. The market dynamics are intricately linked to the regulatory landscape governing preservatives in consumer goods and the overall growth trajectory of the global agricultural sector, specifically the demand for advanced crop protection solutions that utilize this chemical as a precursor.

The product is extensively utilized across several key industries. In the non-agricultural sectors, its primary use is in cosmetics, toiletries, and pharmaceutical formulations, where it acts as a preservative to inhibit the growth of bacteria, molds, and yeast, thereby extending product shelf life and ensuring consumer safety. This application is particularly sensitive to consumer trends favoring mild, yet effective, preservation systems. In the agricultural domain, sodium phenoxyacetate serves as a foundational building block for the synthesis of various high-efficacy phenoxy herbicides and plant hormones, contributing significantly to modern farming practices aimed at maximizing yield and crop quality. The versatility and low toxicity profile compared to some historical alternatives solidify its position as a crucial component in contemporary chemical manufacturing.

Major benefits driving the market include its proven efficacy against a wide spectrum of microbial contaminants, regulatory acceptance in numerous global jurisdictions when used within specified concentration limits, and its relative cost-effectiveness in large-scale production. Driving factors underpinning current market expansion include the burgeoning demand for processed and packaged consumer goods requiring sophisticated preservation, the increasing global population necessitating higher agricultural output supported by advanced agrochemicals, and continuous R&D activities focused on optimizing synthetic routes to enhance purity and reduce production costs, making the derived end-products more competitive in the global marketplace. The structural integrity and chemical reactivity of sodium phenoxyacetate position it as an indispensable resource for specialized synthetic processes across multiple vertical markets.

Sodium Phenoxyacetate Market Executive Summary

The Sodium Phenoxyacetate Market exhibits robust potential driven by twin engines: stable demand from the personal care industry for preservation solutions and escalating consumption in the agrochemical synthesis sector, particularly in emerging economies focused on agricultural intensification. Current business trends indicate a strong focus on sustainable manufacturing practices and sourcing high-purity grades to meet stringent regulatory requirements in the cosmetics and pharmaceutical industries. Geographically, Asia Pacific remains the dominant growth region due to vast agricultural land, rapid urbanization boosting demand for packaged consumer products, and the presence of significant manufacturing hubs for both agrochemicals and cosmetics ingredients. North America and Europe, while mature markets, emphasize innovation in non-toxic and environmentally benign derivatives, often prioritizing supply chain transparency and regulatory compliance regarding residual levels in end products.

Segment trends highlight the dominance of the technical grade segment by volume, fueled primarily by the agrochemical industry for herbicide manufacturing. However, the high-purity or cosmetic grade segment is experiencing the fastest revenue growth due to premium pricing and the rapid expansion of the global beauty and wellness market. Regional trends show a bifurcated market structure: Western markets focus on high-value, low-volume specialty applications, while Eastern markets concentrate on large-volume, cost-competitive production and application in agriculture. Investment in new production capacity is largely concentrated in Southeast Asia and India, leveraging lower operational costs and proximity to major end-user manufacturing facilities.

The market faces operational challenges related to the volatility of raw material prices, specifically phenol and chloroacetic acid, which can impact profitability margins for manufacturers. Furthermore, increasing regulatory scrutiny globally regarding the potential environmental impact of chemical intermediates necessitates ongoing product stewardship and investment in cleaner synthesis technologies. Despite these challenges, the favorable balance between microbial efficacy and consumer safety acceptance in the personal care industry, coupled with the indispensable role in synthesizing key herbicides, ensures the sustained attractiveness and stability of the Sodium Phenoxyacetate market throughout the forecast period, positioning it as a fundamental element in modern chemical and agricultural supply chains.

AI Impact Analysis on Sodium Phenoxyacetate Market

User inquiries regarding AI's influence on the Sodium Phenoxyacetate market commonly center on optimizing synthesis pathways, predicting raw material volatility, and accelerating product development in derivative markets such as novel herbicides or specialized preservatives. Users are concerned with how AI can streamline complex organic synthesis reactions, reduce energy consumption in production, and provide better predictive modeling for supply chain disruptions, particularly those affecting key precursors like phenol. There is also significant interest in leveraging machine learning algorithms to screen for potential toxicity or environmental impact of sodium phenoxyacetate derivatives more rapidly than traditional wet-lab testing, ensuring faster compliance with evolving global regulations and speeding up the market entry for safer, high-efficacy agrochemical products. The primary expectation is that AI will enhance operational efficiency and regulatory predictability, rather than fundamentally altering the chemical itself.

- AI-driven optimization of reaction conditions (temperature, pressure, catalyst selection) to maximize yield and purity of sodium phenoxyacetate.

- Machine learning (ML) models predicting fluctuations in raw material costs (phenol, chloroacetic acid) for proactive procurement strategies.

- AI application in automated quality control and spectroscopic analysis, ensuring stringent purity standards for pharmaceutical and cosmetic grades.

- Predictive toxicology and environmental fate modeling of phenoxy derivatives, accelerating regulatory approval and minimizing R&D timelines.

- Optimization of supply chain logistics and inventory management, minimizing storage costs and reducing lead times for global distribution.

DRO & Impact Forces Of Sodium Phenoxyacetate Market

The Sodium Phenoxyacetate Market is significantly influenced by a blend of robust drivers, critical restraints, and substantial opportunities, collectively shaping the competitive landscape and growth trajectory. Key drivers include the robust expansion of the global personal care and cosmetics sector, which relies heavily on effective and certified preservative systems, alongside the enduring necessity for high-performance agrochemicals derived from phenoxy precursors to secure global food supply amid diminishing arable land. Opportunities are emerging primarily from the increasing global focus on controlled-release formulations in agriculture and the rising consumer preference for minimally preserved products in the food and beverage industry, which indirectly pressures formulators in cosmetics to adopt proven, yet mild, preservatives like sodium phenoxyacetate due to its established track record and lower sensitization profile compared to some paraben alternatives.

Restraints, however, pose tangible hurdles. The market faces constraints related to the volatility and upward pressure on the price of crucial feedstocks, notably phenol, which is subject to fluctuating petrochemical market dynamics. Furthermore, the stringent and constantly evolving regulatory environment, especially in Europe and North America, regarding the concentration limits and approved uses of chemical preservatives and agrochemical intermediates demands continuous compliance efforts and significant investment in dossier updates and toxicological studies. There is also a persistent threat of substitution, particularly in the preservative segment, where green chemistry initiatives and consumer demand for natural ingredients drive research into plant-derived antimicrobial agents, although sodium phenoxyacetate currently maintains a favorable efficacy-cost ratio.

These drivers, restraints, and opportunities exert significant impact forces across the value chain. Demand for high-purity product (Driver) pushes manufacturers towards continuous process improvements and investment in advanced purification techniques (Impact Force). Conversely, feedstock price volatility (Restraint) pressures manufacturers to vertically integrate or enter into long-term procurement contracts (Impact Force). The key opportunity lies in capitalizing on the shift towards specialty agrochemical applications, which commands higher margins and provides market resilience against potential regulatory setbacks in the consumer goods segment. Strategic market participants are focusing on regional diversification to mitigate dependence on specific regulatory blocs and feedstock sources, thus stabilizing profitability and ensuring sustained growth.

Segmentation Analysis

The Sodium Phenoxyacetate Market segmentation provides a critical view of the diverse end-user requirements and product specifications that drive market demand and pricing structures. The market is primarily segmented based on Grade (Technical Grade and High Purity Grade), Application (Agrochemicals, Cosmetics and Personal Care, Pharmaceuticals, and Others), and Region. The differentiation in grades is crucial, as the high-purity segment, often required for cosmetics and injectables, demands significantly more rigorous quality control and fetches higher prices compared to the technical grade used predominantly in bulk chemical synthesis for agriculture. Analyzing these segments helps stakeholders tailor production capabilities and marketing strategies effectively to capture maximum value across the diverse value chain segments.

In terms of application, the agrochemicals sector historically accounts for the largest volume share, utilizing sodium phenoxyacetate as a key intermediate in the manufacture of phenoxyacetic acid herbicides, which are widely deployed globally for weed control in major crops like corn, rice, and wheat. Conversely, the cosmetics and personal care segment, while smaller in volume, is the fastest-growing segment by value, reflecting the robust expansion of global beauty markets and the need for effective, safe, and globally accepted preservative systems in formulations ranging from creams and lotions to shampoos and wipes. The pharmaceutical application, though niche, demands the highest purity levels and is subject to the most stringent regulatory oversight, providing stability but limited volume growth.

Understanding these segments is essential for forecasting market behavior. For instance, the demand for Technical Grade is intrinsically linked to global agricultural policy and crop price cycles, whereas the demand for High Purity Grade is more dependent on disposable income trends and consumer safety regulations within the beauty industry. Furthermore, regional segmentation reveals significant disparities in consumption patterns; Asia Pacific leads in agricultural consumption, while Europe and North America demonstrate higher per capita usage in premium personal care products, emphasizing the necessity for localized strategies to address distinct market maturity levels and regulatory frameworks.

- Grade:

- Technical Grade

- High Purity Grade (Cosmetic/Pharmaceutical)

- Application:

- Agrochemicals (Herbicides, Plant Growth Regulators)

- Cosmetics and Personal Care (Preservative)

- Pharmaceuticals (Intermediate, Preservative)

- Others (Dye intermediates, Specialty Chemicals)

- Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Sodium Phenoxyacetate Market

The value chain for the Sodium Phenoxyacetate Market is segmented into upstream material sourcing, core manufacturing, distribution, and downstream consumption by end-use industries. Upstream analysis focuses heavily on the procurement of primary raw materials: phenol, chloroacetic acid, and sodium hydroxide. The cost structure and reliability of the supply chain for these petrochemical-derived inputs significantly dictate the final product cost and market pricing power of manufacturers. Fluctuations in crude oil prices directly impact phenol synthesis costs, making input price risk management a crucial component of competitive advantage for primary producers of sodium phenoxyacetate. Effective long-term contracts and strategic inventory management are essential to mitigate the inherent volatility in the upstream segment.

The core manufacturing stage involves the specialized chemical reaction processes, including etherification and neutralization, typically requiring controlled environments and adherence to strict quality protocols, particularly for high-purity grades. Distribution channel analysis reveals a dual structure: direct sales for large-volume technical grade purchasers (e.g., major agrochemical companies) and indirect sales through specialized chemical distributors and formulators for fragmented end-user markets like cosmetics and small pharmaceutical compounding facilities. Indirect channels provide market reach and technical support for smaller buyers, whereas direct channels offer cost efficiency and tighter supply control for bulk users. Geographical proximity between manufacturing hubs and end-use formulation centers is critical for optimizing logistics and maintaining product quality.

Downstream analysis identifies the major consumption centers, primarily agrochemical formulation plants and cosmetics manufacturing units. The purchasing decisions of these end-users are driven by product efficacy, consistency, regulatory compliance, and price. Direct customer relationships are vital in the agrochemical segment where product customization (e.g., solubility features) might be required, while the cosmetics segment emphasizes certifications (e.g., COSMOS, ECOCERT compatibility) and documentation transparency. Ultimately, the market benefits from strong integration between manufacturers and downstream formulators, ensuring that the specialized needs for preservation or chemical synthesis are met efficiently, thereby accelerating time-to-market for finished goods.

Sodium Phenoxyacetate Market Potential Customers

Potential customers for Sodium Phenoxyacetate are highly diversified, reflecting its essential role as both a preservative and a chemical intermediate across industrial boundaries. The primary end-users fall into two major categories: large multinational corporations specializing in agrochemical synthesis and formulation, and manufacturers within the personal care, cosmetics, and toiletry sectors requiring reliable preservation solutions. Agrochemical giants purchase the technical grade in high volumes for the synthesis of 2,4-D (2,4-dichlorophenoxyacetic acid) and related phenoxy herbicides, making them anchor tenants in the market. These customers prioritize consistency, bulk pricing, and secure, high-volume supply contracts due to the campaign-based nature of agricultural production cycles.

The second substantial customer base includes global and regional cosmetic formulators and Contract Manufacturing Organizations (CMOs) serving the beauty industry. These buyers specifically require the high-purity, often designated 'cosmetic grade', which guarantees low impurities and high stability suitable for direct inclusion in consumer products. For this segment, regulatory documentation, low odor profiles, and compatibility with other formulation ingredients are paramount purchase criteria, often outweighing marginal price differences. The shift towards water-based, natural ingredient cosmetic formulations, which are highly susceptible to microbial contamination, continuously drives demand from this customer cluster.

A smaller, but critically important, potential customer segment includes specialty pharmaceutical companies and fine chemical manufacturers. These entities utilize sodium phenoxyacetate as an intermediate in the synthesis of specialized drug compounds or as a component in certain injectable or topical preparations requiring pharmaceutical-grade purity. This segment demands the most stringent quality control (GMP compliance) and is highly sensitive to regulatory changes, requiring manufacturers to maintain impeccable auditing standards. Additionally, manufacturers of specialty dyes and some textile processing aids represent niche, albeit stable, consumers utilizing the compound for its unique chemical reactivity in specific industrial processes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 585.4 Million |

| Market Forecast in 2033 | USD 899.7 Million |

| Growth Rate | 6.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dow Chemical Company, Syngenta AG, BASF SE, FMC Corporation, Lanxess AG, Lonza Group, Clariant AG, Akema Fine Chemicals, Jiangsu Binhai Chemical Industry, Hangzhou Jingqi Chemical, Zhongshan Chemical, Hefei TNJ Chemical Industry Co., Ltd., Wuxi Qiandeng Chemical Co., Ltd., Spectrum Chemical Manufacturing Corp., TCI Chemicals (India) Pvt. Ltd., Merck KGaA, Santa Cruz Biotechnology, Inc., Tokyo Chemical Industry Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Sodium Phenoxyacetate Market Key Technology Landscape

The manufacturing process for sodium phenoxyacetate is based on the Williamson ether synthesis, involving the reaction of phenoxyacetic acid or its immediate precursors with a sodium source. While the foundational chemical pathway is mature, the technology landscape focuses primarily on enhancing process efficiency, improving product purity, and implementing sustainable manufacturing methods to comply with modern environmental standards. Key technological advancements center around continuous flow chemistry, replacing traditional batch processing. Continuous flow reactors offer superior temperature and pressure control, leading to higher conversion rates, reduced side product formation, and energy savings, which are critical for cost-competitive high-volume technical grade production. Furthermore, these automated systems enhance safety and consistency, addressing operational risks inherent in large-scale chemical synthesis.

For the high-purity grades required by the cosmetics and pharmaceutical sectors, the technological emphasis shifts towards advanced purification and separation techniques. Technologies such as high-performance liquid chromatography (HPLC) and specialized crystallization methods are employed to remove trace impurities, unreacted starting materials, and potential byproducts to meet stringent regulatory specifications regarding heavy metals and residual solvents. Manufacturers are also increasingly adopting Process Analytical Technology (PAT) tools, including real-time spectroscopic monitoring (e.g., FTIR, Raman spectroscopy), to continuously verify product composition and quality throughout the synthesis and purification stages, ensuring batch-to-batch consistency and minimizing waste.

Furthermore, a growing technological trend involves green chemistry principles, specifically the exploration of less hazardous solvent systems or solvent-free reactions to reduce the environmental footprint associated with manufacturing. Research is ongoing into catalytic routes that might lower the reaction temperature or pressure, thereby reducing energy intensity. Investment in advanced wastewater treatment systems capable of neutralizing or recycling the effluent generated during the production process is also becoming a mandatory technological component, especially in highly regulated regions like Europe, signaling a shift towards environmentally responsible chemical production across the industry.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant and fastest-growing region, driven by its massive agricultural sector demanding phenoxy herbicides and the rapid expansion of domestic cosmetics and personal care manufacturing hubs, particularly in China and India. Government initiatives supporting agricultural modernization and a growing middle class with higher consumption of packaged consumer goods fuel unparalleled market growth.

- North America: A mature market characterized by high regulatory oversight and premium product focus. Demand is stable, primarily driven by large agrochemical companies requiring consistent technical grade supply and a strong market for high-end, high-purity cosmetic preservatives emphasizing safety and efficacy.

- Europe: Highly regulated market focused on sustainability and consumer safety. Growth is moderate, steered by the pharmaceutical industry and stringent EU regulations that favor well-documented preservatives. The region leads in adopting green chemistry technologies for sodium phenoxyacetate synthesis.

- Latin America (LATAM): Exhibits strong growth potential, largely tied to the significant agricultural output in countries like Brazil and Argentina, which drives consistent demand for agrochemical intermediates. Economic fluctuations and localized regulatory variations influence market speed.

- Middle East and Africa (MEA): Emerging market primarily driven by infrastructural investment in chemical manufacturing and increasing domestic demand for personal care products, often reliant on imports or local formulation using imported raw materials.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Sodium Phenoxyacetate Market.- Dow Chemical Company

- Syngenta AG

- BASF SE

- FMC Corporation

- Lanxess AG

- Lonza Group

- Clariant AG

- Akema Fine Chemicals

- Jiangsu Binhai Chemical Industry

- Hangzhou Jingqi Chemical

- Zhongshan Chemical

- Hefei TNJ Chemical Industry Co., Ltd.

- Wuxi Qiandeng Chemical Co., Ltd.

- Spectrum Chemical Manufacturing Corp.

- TCI Chemicals (India) Pvt. Ltd.

- Merck KGaA

- Santa Cruz Biotechnology, Inc.

- Tokyo Chemical Industry Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Sodium Phenoxyacetate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of Sodium Phenoxyacetate in commercial products?

Sodium Phenoxyacetate primarily functions as a critical chemical intermediate in the synthesis of high-volume phenoxyacetic acid herbicides (agrochemicals) and as a broad-spectrum, effective preservative in cosmetics, personal care products, and specialized pharmaceutical formulations, ensuring microbial stability and extended shelf life.

How do regulatory trends impact the market for cosmetic grade Sodium Phenoxyacetate?

Regulatory trends, particularly in Europe and North America, mandate high purity, detailed toxicological profiles, and usage concentration limits. This drives demand for high-purity, well-documented grades and pressures manufacturers to invest in continuous compliance and advanced quality control systems, favoring established suppliers with robust data.

Which geographical region represents the largest consumer of Technical Grade Sodium Phenoxyacetate?

The Asia Pacific (APAC) region is the largest consumer of Technical Grade Sodium Phenoxyacetate. This dominance is attributed to the extensive presence of large-scale agricultural operations and significant local manufacturing capacity for agrochemicals, where the compound is heavily utilized for producing herbicides.

What are the main raw materials used in the production of Sodium Phenoxyacetate?

The main raw materials essential for manufacturing Sodium Phenoxyacetate are phenol, chloroacetic acid, and sodium hydroxide. The price volatility of phenol, a petrochemical derivative, significantly impacts the overall production cost structure and market pricing.

Is Sodium Phenoxyacetate considered environmentally safe, driving its market acceptance?

When used within specified regulatory limits, particularly in preservative applications, it offers an effective safety profile. Market acceptance is high due to its proven efficacy-to-cost ratio and relatively low environmental persistence compared to some legacy chemicals, though the industry is continuously innovating towards greener synthesis methods.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager