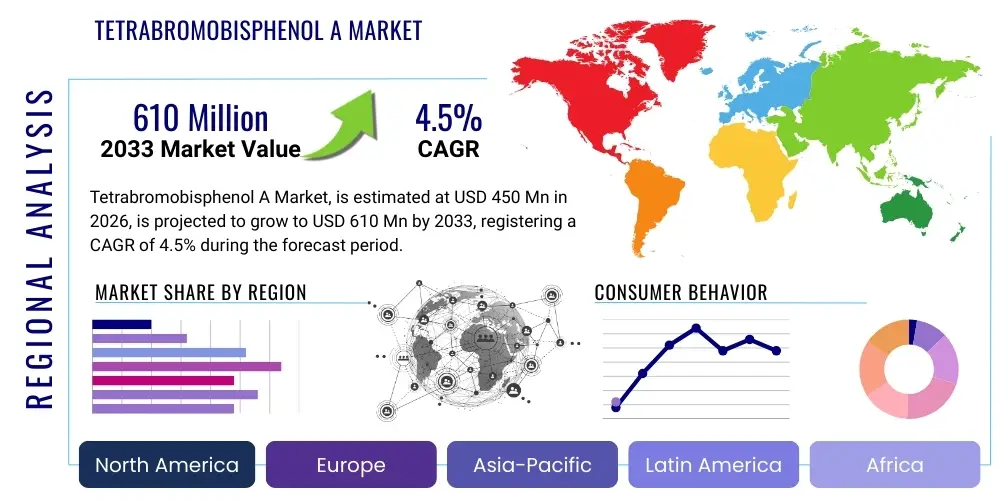

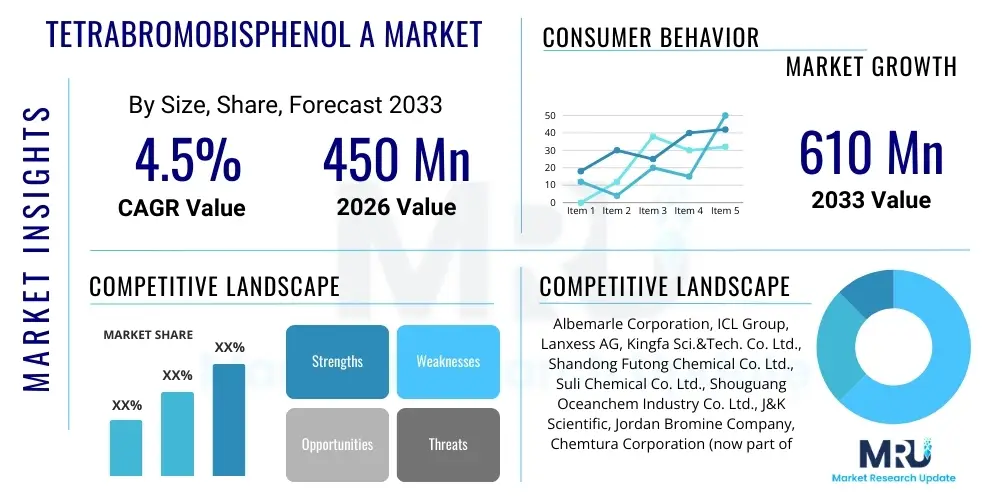

Tetrabromobisphenol A Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440312 | Date : Jan, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Tetrabromobisphenol A Market Size

The Tetrabromobisphenol A Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 1.52 billion in 2026 and is projected to reach USD 2.10 billion by the end of the forecast period in 2033. This steady expansion is primarily fueled by the increasing demand from the electronics and electrical industries, which heavily rely on TBBPA for flame retardancy in printed circuit boards (PCBs) and other electronic components. Despite regulatory pressures and environmental concerns, the indispensable role of TBBPA in ensuring product safety and meeting stringent fire resistance standards in critical applications continues to drive its market trajectory.

Tetrabromobisphenol A Market introduction

Tetrabromobisphenol A (TBBPA) is a crucial brominated flame retardant primarily used to impart fire resistance to a wide range of materials. Chemically, it is an organic compound with the formula (Br2C6H2(CH3)2)C(C6H4(OH)2). Its efficacy in preventing the ignition and spread of fires has made it indispensable in various industrial sectors, particularly where robust safety standards are paramount. TBBPA functions by interrupting the combustion process in the gaseous phase, thereby delaying or preventing material ignition and reducing the rate of flame spread. This mechanism is critical for enhancing the overall fire safety profile of numerous commercial and consumer products.

The major applications of TBBPA span across the electronics and electrical industry, construction, and transportation sectors. It is extensively utilized as a reactive flame retardant in epoxy resins for printed circuit boards (PCBs), where it is chemically integrated into the polymer matrix, ensuring long-term flame retardancy without leaching. Beyond PCBs, TBBPA finds application in thermoplastics such as polycarbonate, acrylonitrile-butadiene-styrene (ABS), and high-impact polystyrene (HIPS), as well as in unsaturated polyester resins and textile back coatings. Its versatility allows it to be incorporated into diverse material formulations, providing essential fire protection properties.

The primary benefits of TBBPA include its high bromine content, leading to excellent flame retardant efficiency, and its ability to be reacted into polymers, which minimizes migration and improves product performance and environmental profile compared to additive flame retardants. Driving factors for the TBBPA market include the continuous growth of the global electronics industry, increasing demand for fire-safe materials in building and construction, stringent fire safety regulations worldwide, and the expansion of data centers and automotive electronics requiring enhanced fire protection. These factors collectively underscore TBBPA's enduring importance in modern industrial applications, even as research into alternative flame retardants continues.

Tetrabromobisphenol A Market Executive Summary

The Tetrabromobisphenol A (TBBPA) market is characterized by a complex interplay of steady demand from critical sectors and evolving regulatory landscapes. Business trends indicate a sustained requirement for TBBPA, particularly in the electronics industry for printed circuit boards (PCBs) and in various plastic applications, driven by continuous innovation and the proliferation of electronic devices. However, manufacturers are increasingly investing in research and development to offer reactive TBBPA derivatives and to explore more environmentally benign production processes, addressing growing concerns regarding halogenated compounds. Strategic partnerships and acquisitions aimed at strengthening supply chains and expanding product portfolios are also prominent business trends, alongside efforts to optimize manufacturing efficiency to maintain competitive pricing in a globally fragmented market.

Regionally, the Asia Pacific continues to dominate the TBBPA market, primarily due to the concentration of electronics manufacturing hubs in countries like China, South Korea, Japan, and Taiwan. Rapid urbanization, significant infrastructure development, and a less stringent regulatory environment compared to Western markets also contribute to the region's substantial market share. North America and Europe, while representing mature markets, are characterized by stringent environmental regulations and a strong emphasis on the development and adoption of halogen-free or more sustainable flame retardant alternatives. Despite these pressures, TBBPA maintains a strong foothold in specialized applications where its performance cannot be easily matched, leading to a dynamic regional market characterized by innovation in compliance and application-specific solutions.

In terms of segmentation, the epoxy resins segment, largely driven by PCB manufacturing, remains the largest application area for TBBPA. Its chemical integration into epoxy matrices offers excellent durability and fire resistance, making it crucial for electronic devices. The market also sees significant contributions from thermoplastics and unsaturated polyesters, which utilize TBBPA to meet fire safety standards in consumer goods, automotive parts, and construction materials. There is a discernible trend towards reactive flame retardants over additive ones, reflecting industry efforts to minimize potential environmental impact and improve material longevity. This shift, coupled with continued demand for high-performance flame retardancy, shapes the growth patterns across different application segments, reinforcing TBBPA's essential role despite ongoing scrutiny.

AI Impact Analysis on Tetrabromobisphenol A Market

The integration of Artificial Intelligence (AI) across various industrial sectors is beginning to profoundly influence the Tetrabromobisphenol A (TBBPA) market, addressing both operational efficiencies and strategic R&D challenges. Users commonly inquire about how AI can optimize TBBPA production processes, mitigate environmental concerns, and accelerate the development of next-generation flame retardants. Key themes include AI's potential in predictive maintenance for manufacturing equipment, enhancing supply chain transparency and resilience, and enabling advanced material discovery. There is significant expectation that AI will provide solutions for improving the sustainability profile of TBBPA, through optimized synthesis routes and better waste management, alongside its role in personalizing customer solutions by predicting specific application needs. Concerns often revolve around the initial investment required for AI infrastructure, data privacy in collaborative research, and the ethical implications of autonomous decision-making in chemical manufacturing.

- AI-driven optimization of TBBPA synthesis processes can lead to improved reaction yields, reduced energy consumption, and minimized waste generation, directly contributing to lower operational costs and a more sustainable manufacturing footprint.

- Predictive analytics powered by AI can enhance supply chain management for TBBPA raw materials (bromine, bisphenol A) and finished products, forecasting demand fluctuations and potential disruptions to ensure stable supply and efficient distribution channels globally.

- AI algorithms can accelerate the discovery and design of novel flame retardant compounds, including TBBPA derivatives or halogen-free alternatives, by simulating molecular interactions and predicting performance characteristics, drastically shortening R&D cycles.

- The use of AI in quality control allows for real-time monitoring of TBBPA purity and consistency during production, ensuring compliance with stringent industry standards and enhancing the reliability of the end product for critical applications like PCBs.

- AI-enabled environmental monitoring systems can track and analyze TBBPA emissions and byproducts more effectively, aiding manufacturers in adhering to environmental regulations and proactively identifying areas for pollution reduction and waste treatment improvements.

- Market intelligence gathered and analyzed by AI can provide deeper insights into emerging application trends, regulatory changes, and competitive landscapes, enabling TBBPA producers to make more informed strategic decisions and identify new growth opportunities.

- AI can optimize logistics and warehousing for TBBPA, reducing transportation costs and lead times through intelligent route planning and inventory management, thereby improving overall market responsiveness and customer satisfaction.

DRO & Impact Forces Of Tetrabromobisphenol A Market

The Tetrabromobisphenol A (TBBPA) market is influenced by a diverse set of Drivers, Restraints, and Opportunities, collectively forming the critical impact forces shaping its trajectory. A primary driver is the relentless growth of the global electronics industry, particularly the demand for printed circuit boards (PCBs) in smartphones, computers, and consumer electronics, all of which require reliable flame retardancy to meet safety standards. Additionally, the increasing focus on fire safety in building and construction codes, coupled with urbanization trends and infrastructure development in emerging economies, significantly bolsters the demand for TBBPA in various plastic applications, coatings, and textiles. The high efficacy and cost-effectiveness of TBBPA as a flame retardant continue to make it a preferred choice in applications where safety cannot be compromised, further driving its market adoption.

Despite these strong drivers, the TBBPA market faces substantial restraints, predominantly stemming from escalating environmental and health concerns associated with brominated flame retardants. Stringent regulations, such as REACH in Europe and RoHS directives, often restrict or ban certain brominated compounds, pushing industries to seek halogen-free alternatives. This regulatory pressure, combined with growing consumer awareness and preference for eco-friendly products, creates a significant headwind for TBBPA manufacturers. The potential for bioaccumulation and persistence in the environment, along with perceived health risks, has led to a cautious approach by some end-users and governments, challenging the traditional market dominance of TBBPA and necessitating continuous innovation to address these concerns.

However, these challenges also present significant opportunities for market evolution and growth. The development of reactive TBBPA forms, which are chemically bound into polymer matrices, offers a pathway to mitigate environmental concerns by reducing leaching and improving the material's lifecycle profile. Furthermore, ongoing research into TBBPA derivatives that offer improved performance or reduced environmental impact creates new avenues for product innovation and market penetration. Opportunities also lie in expanding TBBPA's application into niche segments that prioritize fire safety above all else, and in emerging markets where industrialization and infrastructure growth are accelerating, potentially with less stringent initial regulatory frameworks for certain chemicals. Strategic investments in green chemistry and advanced manufacturing techniques can unlock sustainable growth prospects for TBBPA within a responsible framework, thereby shaping the future of this essential flame retardant.

Segmentation Analysis

The Tetrabromobisphenol A (TBBPA) market is comprehensively segmented to provide granular insights into its diverse applications, product types, and end-use industries. This segmentation allows for a detailed understanding of market dynamics, growth drivers, and specific challenges within each category, crucial for strategic planning and competitive analysis. The primary segmentation categories include application areas such as epoxy resins, polycarbonates, and PBT resins, which represent the largest consumption sectors. Further differentiation is made by product type, distinguishing between standard TBBPA and its various derivatives, reflecting advancements in chemical modification to address evolving performance and environmental requirements. Finally, the market is analyzed across key end-use industries, including electronics and electrical, construction, and transportation, highlighting the sector-specific demand patterns and regulatory influences that shape TBBPA consumption.

- By Application:

- Epoxy Resins: Utilized extensively in printed circuit boards (PCBs) for flame retardancy, where TBBPA is chemically reacted into the resin matrix for durable fire protection. This segment is the largest consumer due to the rapid expansion of the electronics industry.

- Polycarbonates: TBBPA is used as an additive or reactive flame retardant in polycarbonate plastics, commonly found in electronic housings, automotive components, and various consumer goods requiring high impact strength and fire resistance.

- PBT Resins (Polybutylene Terephthalate): Employed in electrical connectors, automotive parts, and various engineering plastics, TBBPA enhances the flame retardant properties of PBT, ensuring compliance with stringent safety standards in these critical applications.

- ABS Resins (Acrylonitrile Butadiene Styrene): TBBPA is incorporated into ABS formulations for applications in consumer electronics, automotive interiors, and appliance housings where a balance of toughness, aesthetics, and fire safety is required.

- Unsaturated Polyesters: Used in construction materials, electrical components, and composite structures, TBBPA helps these resins meet fire safety codes, particularly in applications exposed to potential fire hazards.

- Others: This segment includes smaller applications such as textile coatings, adhesives, sealants, and various specialty polymers where specific flame retardant properties are necessary.

- By Type:

- Standard Grade TBBPA: The primary form of TBBPA, used directly as an additive or reacted into polymers, meeting baseline flame retardancy requirements for a broad range of applications.

- TBBPA Derivatives: Modified forms of TBBPA, such as TBBPA-bis(2-hydroxyethyl ether) or TBBPA-carbonate oligomers, designed to enhance specific properties like thermal stability, compatibility with certain polymers, or to reduce migration, often acting as reactive flame retardants.

- By End-Use Industry:

- Electronics & Electrical: The dominant end-use industry, encompassing printed circuit boards, electronic housings, connectors, and wire and cable insulation, driven by the global demand for electronic devices and appliances.

- Construction: TBBPA is utilized in insulation materials, roofing membranes, structural composites, and various building materials to comply with fire safety regulations and enhance structural integrity during fire events.

- Transportation: Applied in automotive interiors, aerospace components, and railway systems to reduce flammability, protecting passengers and critical infrastructure from fire hazards.

- Textiles: Used in fabric coatings for furniture, drapery, and industrial textiles to provide fire resistance, particularly in commercial and public spaces where safety standards are rigorous.

- Furniture: Incorporated into foams, upholstery, and plastic components for furniture to meet fire safety standards, crucial for both residential and commercial furnishings.

- Others: Includes applications in paints & coatings, adhesives, and various industrial materials where fire protection is a critical performance requirement.

Value Chain Analysis For Tetrabromobisphenol A Market

The value chain for the Tetrabromobisphenol A (TBBPA) market is a multi-tiered process, commencing with the sourcing of fundamental raw materials and culminating in its integration into diverse end-use products. The upstream segment of the value chain is dominated by the extraction and production of key precursors: bromine and bisphenol A. Bromine is typically derived from brine solutions found in underground reservoirs or seawater, involving complex chemical processes to ensure purity and sufficient supply. Bisphenol A, an organic compound, is synthesized from acetone and phenol. These raw material suppliers form the foundational layer, providing the essential chemical building blocks for TBBPA manufacturing. Fluctuations in the prices and availability of these raw materials directly impact the production costs and profitability of TBBPA manufacturers, necessitating robust procurement strategies and long-term contracts.

Midstream in the value chain are the TBBPA manufacturers, who synthesize TBBPA from bromine and bisphenol A through various bromination processes. These manufacturers invest heavily in R&D to optimize production efficiency, ensure product purity, and develop advanced TBBPA derivatives that meet evolving market demands and regulatory requirements, such as reactive forms that minimize environmental concerns. Following the manufacturing stage, compounders and formulators play a crucial role by blending TBBPA with various polymers and additives to create customized flame retardant formulations. These formulations are tailored to specific end-application requirements, ensuring optimal performance, processability, and compliance with industry standards. Their expertise in material science is vital for integrating TBBPA effectively into complex polymer matrices, enhancing its flame retardant capabilities for downstream applications.

The downstream segment involves the distribution and ultimate consumption by end-product manufacturers. Distribution channels can be both direct and indirect. Direct distribution often involves TBBPA manufacturers supplying large quantities directly to major end-users, such as integrated electronics manufacturers or large chemical compounders, fostering strong client relationships and offering technical support. Indirect distribution involves a network of distributors, agents, and specialty chemical suppliers who cater to a broader base of smaller and medium-sized enterprises (SMEs) across various industries like construction, automotive, and furniture. These channels facilitate market reach, warehousing, and localized customer service. Ultimately, end-product manufacturers in sectors such as electronics, construction, and transportation integrate these TBBPA-containing materials into their final products, ranging from printed circuit boards and building insulation to automotive components, thereby completing the value chain and bringing fire-safe products to the consumer market.

Tetrabromobisphenol A Market Potential Customers

The Tetrabromobisphenol A (TBBPA) market serves a broad and diverse range of potential customers, primarily driven by the imperative for enhanced fire safety across various industrial and commercial applications. The largest and most consistent customer base resides within the electronics and electrical industry, specifically printed circuit board (PCB) manufacturers. These companies are critical for the global production of electronic devices, from consumer gadgets like smartphones and laptops to complex industrial control systems and data center equipment. TBBPA, integrated into the epoxy resins used for PCBs, is indispensable for meeting strict flammability standards, ensuring the safety and reliability of electronic components. The continuous evolution and expansion of the electronics sector worldwide guarantee a sustained demand from these key players, who prioritize performance and regulatory compliance in their material specifications.

Beyond electronics, a significant segment of potential customers includes plastic compounders and resin producers. These entities specialize in formulating and manufacturing various types of plastics, such as polycarbonates, ABS, HIPS, and PBT, which are then supplied to diverse end-use industries. TBBPA is incorporated into these plastic compounds to impart flame retardancy, making them suitable for applications in automotive interiors, appliance housings, consumer goods, and electrical enclosures. These customers value TBBPA for its efficiency in achieving desired fire resistance ratings without significantly compromising the mechanical properties or processability of the base polymer. Their need for versatile, high-performance flame retardant additives ensures they remain a substantial and growing customer segment for TBBPA suppliers, particularly as product safety standards become more rigorous across various consumer products.

Furthermore, the construction and transportation sectors represent increasingly important customer segments for TBBPA. In construction, TBBPA finds use in fire-resistant insulation panels, roofing materials, and structural composites, serving manufacturers of building materials who must adhere to stringent fire codes for residential, commercial, and industrial structures. Within the transportation industry, including automotive, aerospace, and rail, manufacturers of interior components, wire coatings, and specialized parts utilize TBBPA-containing materials to enhance passenger safety and meet fireworthiness regulations. These customers often have unique requirements for durability, weight, and specific flame retardancy performance, driving demand for specialized TBBPA formulations. The continuous global investment in infrastructure and the drive for safer transport solutions ensure these industries will remain significant potential customers for TBBPA, seeking innovative solutions to balance performance, cost, and regulatory compliance.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.52 billion |

| Market Forecast in 2033 | USD 2.10 billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Albemarle Corporation, ICL-IP, Shandong Brother Sci.&Tech Co., Ltd., Jiangsu Yoke Technology Co., Ltd., Kingboard Chemical Holdings Ltd., Lanxess AG, Jordan Bromine Company Ltd. (JBC), Shouguang Fukang Pharmaceutical Co., Ltd., Weifang Longda Intermediate Co., Ltd., Xiamen Jinhongfa Chemical Co., Ltd., Tokyo Chemical Industry Co., Ltd. (TCI), Great Lakes Solutions (now part of Lanxess), Chemtura Corporation (now part of Lanxess), BASF SE (for related products), Dow Chemical Company (for related products), AkzoNobel N.V. (for related products), SABIC (for related products), Covestro AG (for related products), DSM (for related products), Solvay S.A. (for related products). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tetrabromobisphenol A Market Key Technology Landscape

The technology landscape for the Tetrabromobisphenol A (TBBPA) market is characterized by a blend of established production methodologies and continuous innovation driven by performance demands and evolving environmental regulations. The core production technology involves the bromination of bisphenol A, typically carried out through direct bromination reactions in various solvents. Key technological advancements in this area focus on optimizing reaction conditions, such as temperature, pressure, and catalyst use, to maximize yield, purity, and process efficiency while minimizing energy consumption and byproduct formation. Manufacturers are increasingly adopting advanced analytical techniques, including High-Performance Liquid Chromatography (HPLC) and Gas Chromatography-Mass Spectrometry (GC-MS), to ensure the precise quality control and characterization of TBBPA, critical for its demanding applications in electronics and other high-performance materials.

Beyond synthesis, a significant portion of technological development is centered on improving the environmental profile and application versatility of TBBPA. This includes the development of reactive TBBPA derivatives, where the TBBPA molecule is chemically integrated into the polymer matrix rather than merely being blended as an additive. Technologies like TBBPA-bis(2-hydroxyethyl ether) or TBBPA-carbonate oligomers aim to reduce leaching, improve thermal stability, and enhance compatibility with specific resins, thereby addressing concerns about environmental persistence and bioaccumulation. These reactive forms represent a crucial technological shift, enabling TBBPA to meet stricter regulatory requirements while maintaining its superior flame retardancy performance, particularly in high-durability applications such like printed circuit boards and engineering plastics. This focus on chemical modification is paramount for the long-term sustainability of TBBPA in the market.

Furthermore, the technology landscape extends to the development of sophisticated compounding and formulation techniques. These technologies allow for the precise incorporation of TBBPA into various polymer systems, ensuring homogeneous dispersion and optimal flame retardant efficacy at the lowest possible loading levels. Innovations in polymer processing equipment and methodologies are crucial for handling TBBPA-containing compounds effectively, from extrusion to injection molding. There is also a growing emphasis on green chemistry principles in TBBPA production, exploring solvent-free bromination processes or catalysts that reduce hazardous waste. Additionally, technologies related to recycling and end-of-life management for TBBPA-containing materials are emerging, aiming to recover and reuse valuable resources, further enhancing the sustainability credentials of the TBBPA market and aligning with the broader circular economy initiatives within the chemical industry.

Regional Highlights

- Asia Pacific: The Asia Pacific region stands as the dominant market for Tetrabromobisphenol A, primarily propelled by the robust and continuously expanding electronics manufacturing sector in countries like China, South Korea, Taiwan, and Japan. The region's rapid industrialization, extensive infrastructure development, and a substantial consumer electronics market create immense demand for fire-resistant materials, making TBBPA a critical component. While regulatory oversight is increasing, some areas still offer more flexibility compared to Western counterparts, contributing to the region's production and consumption leadership. The presence of numerous TBBPA manufacturers and compounders further solidifies Asia Pacific's strategic importance in the global market.

- North America: North America represents a mature yet significant market for TBBPA, characterized by stringent fire safety standards, particularly in the construction and transportation industries. The region exhibits a strong emphasis on research and development, focusing on high-performance applications and the exploration of reactive flame retardant solutions to mitigate environmental concerns. While the market faces pressure from environmental advocacy and a push towards halogen-free alternatives, TBBPA continues to be utilized in specialized electronics and engineering plastics where its efficacy and cost-effectiveness remain unparalleled. Innovation in sustainable chemistry and closed-loop systems is a key trend in this region.

- Europe: The European TBBPA market operates under some of the world's most rigorous environmental and health regulations, notably REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances). This regulatory landscape has led to a significant shift towards reactive forms of TBBPA that are chemically bonded into polymers, reducing their potential for migration and environmental impact. Despite the regulatory pressures, demand persists in high-value applications such as professional electronics, specialized construction materials, and automotive components, where adherence to strict fire safety codes is paramount. European companies are leaders in developing sophisticated TBBPA derivatives and recycling technologies.

- Latin America: The Latin American market for TBBPA is an emerging region demonstrating steady growth, driven by increasing industrialization, urbanization, and expanding infrastructure projects. Countries such as Brazil and Mexico are experiencing growth in their electronics assembly and automotive manufacturing sectors, translating into higher demand for flame retardant materials. While regulatory frameworks are still evolving in some parts of the region, the adoption of international safety standards is gradually increasing, which in turn boosts the consumption of TBBPA in construction and consumer goods. Economic development and foreign investment are key factors influencing TBBPA market expansion here.

- Middle East and Africa (MEA): The MEA region presents a developing market for TBBPA, with growth primarily influenced by substantial investments in construction, infrastructure development, and nascent manufacturing industries. Rapid urbanization and government initiatives to diversify economies away from oil are fostering new industrial bases that require fire-safe materials. While the overall market size is smaller compared to other regions, there is significant potential for growth as industrial and fire safety standards evolve and the demand for commercial and residential buildings, along with basic electronics, increases across key countries like Saudi Arabia, UAE, and South Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tetrabromobisphenol A Market.- Albemarle Corporation

- ICL-IP

- Shandong Brother Sci.&Tech Co., Ltd.

- Jiangsu Yoke Technology Co., Ltd.

- Kingboard Chemical Holdings Ltd.

- Lanxess AG

- Jordan Bromine Company Ltd. (JBC)

- Shouguang Fukang Pharmaceutical Co., Ltd.

- Weifang Longda Intermediate Co., Ltd.

- Xiamen Jinhongfa Chemical Co., Ltd.

- Tokyo Chemical Industry Co., Ltd. (TCI)

- Great Lakes Solutions (now part of Lanxess)

- Chemtura Corporation (now part of Lanxess)

- BASF SE

- Dow Chemical Company

- AkzoNobel N.V.

- SABIC

- Covestro AG

- DSM

- Solvay S.A.

Frequently Asked Questions

What is Tetrabromobisphenol A (TBBPA) and its primary function?

Tetrabromobisphenol A (TBBPA) is a brominated organic compound primarily used as a flame retardant. Its main function is to inhibit the combustion process in materials by releasing bromine radicals that scavenge highly reactive hydrogen and hydroxyl radicals in the flame, thereby preventing or delaying ignition and reducing the rate of flame spread. TBBPA is crucial for enhancing the fire safety of a wide range of products, most notably in printed circuit boards (PCBs) and various plastic components within the electronics, construction, and transportation industries. It can be incorporated as an additive or, increasingly, as a reactive component chemically bound within the polymer matrix.

What are the main applications driving the TBBPA market growth?

The primary applications fueling TBBPA market growth are found in the electronics and electrical industry, particularly in the manufacturing of printed circuit boards (PCBs) for consumer electronics, industrial equipment, and telecommunications. TBBPA is indispensable here for meeting stringent fire safety standards. Additionally, significant demand arises from the construction sector, where it's used in insulation and building materials, and from the automotive industry for interior components. The continuous expansion of these sectors, coupled with evolving fire safety regulations globally, ensures sustained demand for TBBPA to enhance product safety and compliance. The shift towards reactive TBBPA forms also contributes to its continued relevance in these critical applications.

What are the environmental and regulatory challenges facing the TBBPA market?

The TBBPA market faces significant environmental and regulatory challenges, primarily due to concerns about brominated flame retardants' potential for persistence, bioaccumulation, and toxicity in the environment. Regulations such as the European Union's REACH and RoHS directives aim to restrict the use of certain hazardous substances, including some brominated compounds. These concerns push manufacturers to seek alternatives or to develop more environmentally benign forms of TBBPA, such as reactive grades that are chemically integrated into polymers to minimize leaching. Compliance with these evolving global environmental standards and public perception of chemical safety are ongoing challenges that necessitate continuous innovation and responsible stewardship within the industry.

How do reactive TBBPA forms differ from additive forms, and why are they gaining importance?

Reactive TBBPA forms differ from additive forms in that they are chemically integrated into the polymer structure during the manufacturing process, becoming a permanent part of the material. In contrast, additive TBBPA is merely blended into the polymer and can potentially leach out over time. Reactive forms are gaining importance because they address environmental and health concerns associated with additive flame retardants by significantly reducing migration, improving long-term flame retardancy, and enhancing the material's thermal stability. This chemical bonding minimizes the compound's release into the environment during the product's lifecycle and at end-of-life, making them a more sustainable and compliant option under tightening global regulations, particularly in sensitive applications like electronics.

What is the future outlook for the Tetrabromobisphenol A market considering alternatives?

The future outlook for the Tetrabromobisphenol A market is characterized by continued demand in critical applications while simultaneously navigating increasing pressures for more sustainable alternatives. While the market faces competition from halogen-free flame retardants, TBBPA's superior performance in specific high-demand areas like printed circuit boards, where it offers unparalleled flame retardancy and thermal stability, ensures its ongoing relevance. The market's future will be shaped by a dual strategy: significant investment in developing reactive TBBPA derivatives that mitigate environmental concerns and continuous innovation to optimize production processes for greater sustainability. While growth may be tempered by regulatory shifts and the rise of alternatives, TBBPA is expected to maintain a robust position in applications where its specific advantages remain indispensable, especially with advancements in green chemistry and recycling technologies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager