Thickener Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438288 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Thickener Market Size

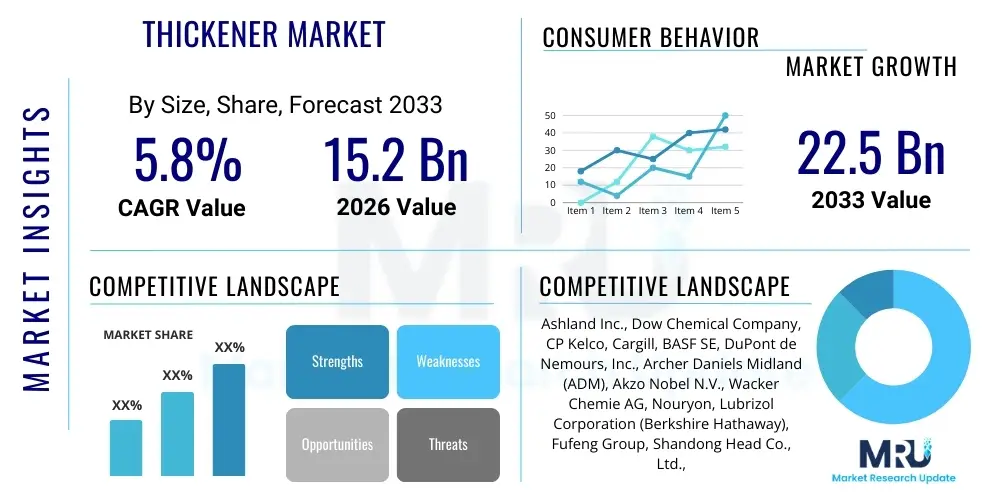

The Thickener Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 15.2 Billion in 2026 and is projected to reach USD 22.5 Billion by the end of the forecast period in 2033. This robust growth trajectory is primarily underpinned by increasing demand across high-volume industrial applications, particularly in food and beverage stabilization, pharmaceuticals, and highly specialized personal care products where texture and stability are paramount performance indicators.

Market expansion is also supported by the shift toward natural and sustainable thickening agents, driven by evolving consumer preferences and stricter regulatory mandates concerning synthetic additives. The demand for rheology modifiers capable of functioning effectively in diverse chemical environments—such as high shear, extreme pH, or elevated temperatures—further fuels innovation and market valuation. The geographic disparity in growth rates, with Asia Pacific exhibiting the fastest expansion, reflects accelerating industrialization and rising per capita consumption of processed foods and consumer goods in developing economies.

Thickener Market introduction

The Thickener Market encompasses a diverse range of chemical substances, primarily polymers, utilized to increase the viscosity of liquid systems without significantly altering other physical properties. These substances, often referred to as rheology modifiers or hydrocolloids, play a critical role in determining the texture, stability, suspension, and flow behavior of numerous commercial products. They achieve thickening by forming complex internal structures, such as molecular entanglement networks or physical associations, within the liquid medium. This functionality is essential for product efficacy and consumer acceptability across multiple sectors, ensuring that formulations maintain homogeneity, prevent phase separation, and provide the desired sensory experience.

Major applications of thickeners span the entire industrial landscape, including food and beverage processing, where they are used to modify mouthfeel, stabilize emulsions, and prevent sedimentation in sauces, dairy products, and baked goods. In the pharmaceutical sector, thickeners are vital for formulating stable suspensions, controlled-release matrix systems, and palatable oral syrups. Furthermore, they are extensively used in paints and coatings to prevent pigment settling and ensure uniform application consistency, and in cosmetics and personal care products, such as creams and shampoos, to achieve the desired luxurious texture and product stability on the shelf.

The core benefit derived from thickeners is improved product performance and longevity. Driving factors for market growth include the rising global population and subsequent demand for processed foods, significant investments in infrastructure and construction necessitating high-performance coatings, and continuous innovation in drug delivery systems requiring precise rheological control. The growing emphasis on convenience foods, stable pharmaceuticals, and environmentally friendly, high-solid coatings further solidifies the essential nature of thickeners in modern manufacturing processes. The versatility of thickeners allows formulators to tailor products precisely to specific functional requirements, contributing directly to higher efficiency and better end-user satisfaction.

- Product Description: Substances (polymers, hydrocolloids) used to increase viscosity and control the rheological behavior of liquid systems.

- Major Applications: Food stabilization, pharmaceuticals (suspensions/gels), paints & coatings (anti-sagging/pigment suspension), personal care (texture modification).

- Benefits: Improved stability, enhanced mouthfeel/texture, prevention of phase separation, controlled flow properties, and extended shelf life.

- Driving Factors: Rising demand for processed foods, growth in pharmaceutical and cosmetic industries, and technological advancements in synthetic polymer chemistry.

Thickener Market Executive Summary

The Thickener Market is characterized by intense competitive dynamics and a rapid shift toward bio-based and sustainable product lines. Current business trends indicate a strong focus on strategic mergers and acquisitions among key players to consolidate market share and integrate specialized technological expertise, particularly in high-performance synthetic thickening agents and specialized cellulosic derivatives. Furthermore, research and development efforts are heavily concentrated on creating thickeners that offer multi-functional benefits, such as combined thickening, emulsifying, and stabilizing properties, thereby simplifying formulations and reducing production costs for end-users. Regulatory compliance, particularly concerning food safety and environmental impact, continues to shape product innovation and market entry strategies across all geographies.

Regionally, the Asia Pacific (APAC) stands out as the primary engine of growth, propelled by robust economic expansion, rapid urbanization, and significant growth in its manufacturing and processed food sectors, especially in China and India. North America and Europe, while mature, maintain strong market shares driven by high-value applications in pharmaceuticals and advanced personal care, alongside stringent regulatory frameworks favoring high-quality, certified thickeners. The demand in Latin America and the Middle East & Africa (MEA) is accelerating, reflecting increasing penetration of modern food processing techniques and rising consumer expenditure on packaged goods, creating new opportunities for market penetration by global suppliers.

Segment trends highlight the dominance of natural thickeners, such as starch and hydrocolloids (e.g., Xanthan Gum and Carrageenan), due to consumer preference for clean labels and natural ingredients, particularly within the Food & Beverage segment. However, synthetic thickeners, including polyacrylates and polyethylene glycols, maintain strong traction in industrial applications like coatings and construction chemicals, where high performance, cost-efficiency, and consistency are critical. The Paints & Coatings application segment demonstrates consistent growth, driven by global construction activity and the increasing use of water-based, environmentally friendly coating systems that rely heavily on specialized rheology modifiers for performance optimization.

AI Impact Analysis on Thickener Market

User queries regarding the impact of Artificial Intelligence (AI) on the Thickener Market frequently center on predictive formulation, optimization of production processes, and the development of novel rheology modifiers. Key themes revolve around how AI can accelerate R&D timelines, specifically in modeling complex polymer interactions and predicting viscosity performance under various environmental conditions (temperature, shear rate, pH). Users are concerned about the implementation costs and the expertise required to integrate AI-driven algorithms for quality control and batch consistency, especially in continuous manufacturing environments. Expectations are high regarding AI's ability to minimize raw material waste, optimize reaction kinetics during synthesis of synthetic thickeners, and personalize ingredient recommendations based on desired end-product texture and stability profiles, leading to faster commercialization cycles for specialized thickeners.

AI’s potential for transforming the thickener industry lies primarily in its ability to manage and interpret vast datasets generated during materials testing and application studies. Traditional formulation development is time-consuming and heavily reliant on trial-and-error methodologies. By leveraging machine learning and generative design, companies can simulate thousands of possible formulations in silico, predicting properties such as shear thinning, yield stress, and thermal stability before expensive physical lab work begins. This capability drastically reduces time-to-market for new or improved thickening agents and ensures greater consistency in high-volume production batches, which is a major quality concern for industrial buyers.

Furthermore, AI algorithms are becoming instrumental in supply chain optimization for raw materials used in thickener production, particularly natural hydrocolloids, whose supply often fluctuates based on agricultural factors. Predictive maintenance in manufacturing facilities and the optimization of energy consumption during the drying and milling processes of thickener powders are also areas where AI offers substantial operational efficiency improvements. The integration of AI-powered sensors and data analytics ensures that the quality and functional performance of the final thickener product adhere strictly to customer specifications, enhancing overall market reliability and competitiveness.

- Accelerated R&D: AI models predict optimal polymer structures and concentration levels for specific rheological targets, reducing formulation time.

- Process Optimization: Machine learning enhances batch consistency, optimizes reaction parameters for synthetic thickeners, and predicts equipment failures.

- Quality Control: Real-time data analysis ensures strict adherence to viscosity and stability specifications, minimizing off-spec product runs.

- Supply Chain Management: AI predicts fluctuations in raw material availability (e.g., natural gums), optimizing inventory and sourcing strategies.

- Personalized Formulation: Generating data-driven recommendations for thickener selection based on specific end-product performance requirements.

DRO & Impact Forces Of Thickener Market

The dynamics of the Thickener Market are heavily influenced by a critical interplay of drivers, restraints, and opportunities. Key drivers include the exponential growth in the global population demanding higher volumes of processed and convenience foods, which heavily rely on thickeners for stability and texture. Simultaneously, the burgeoning pharmaceutical industry, particularly the development of complex oral suspensions and topical drug delivery systems, necessitates high-purity, specialized rheology modifiers. The continuous transition from solvent-based to water-based coatings and adhesives in the construction and automotive sectors acts as a massive driver, as water-based systems require advanced thickeners to maintain viscosity and prevent sagging during application. These collective forces provide a robust foundation for consistent market growth and innovation.

However, the market faces significant restraints. Stringent regulatory scrutiny regarding the safety and origin of food-grade and pharmaceutical-grade thickeners often leads to complex and expensive approval processes, particularly in highly regulated markets like the EU and North America. Fluctuations in the prices and availability of natural raw materials, such as specific seeds or algae required for hydrocolloids, due to climate change or geopolitical issues, present inherent supply chain volatility. Furthermore, the complexity involved in formulating multi-component systems, where thickeners must interact favorably with other additives (like surfactants, salts, or emulsifiers), can sometimes limit widespread adoption of newer, specialized products.

Opportunities in the market primarily reside in the development of sustainable, naturally derived, and clean-label thickeners that address consumer demand for health-conscious ingredients. Significant potential exists in catering to the specialized needs of emerging applications, such as 3D printing inks, enhanced oil recovery (EOR) operations, and highly efficient agricultural formulations, all of which require precise rheological control. The development of next-generation synthetic polymers that offer superior salt and pH tolerance, combined with exceptional shear stability, will open up premium market segments and allow manufacturers to capture higher margins, mitigating the impact of existing restraints and fostering long-term market expansion.

Segmentation Analysis

The Thickener Market is broadly segmented based on the product type, source, application, and functionality, allowing for a detailed examination of sector-specific trends and demands. The core distinction lies between natural, synthetic, and modified natural thickeners. Natural thickeners, derived primarily from biological sources such as plants, animals, or microorganisms (e.g., starches, cellulose, guar gum), dominate the volume and are favored in the food and pharmaceutical sectors due to their perceived safety and clean-label appeal. Synthetic thickeners, manufactured through chemical processes (e.g., polyacrylates, polyethylene oxides), are characterized by high performance, stability, and versatility, making them essential in industrial coatings, construction, and oilfield chemicals.

The Application segment is the most crucial determinant of market valuation. The Food & Beverage sector represents the largest consumer, driven by the need for texture enhancement, gelling, and stabilization in beverages, dairy, and processed meats. The Paints & Coatings segment follows closely, where thickeners are essential for adjusting rheology to optimize brushability, roller application, and anti-settling properties. Pharmaceuticals and Cosmetics are high-value segments demanding highly purified and specialized grades, often requiring modified or premium synthetic thickeners to ensure compatibility with active ingredients and specific delivery systems.

Further segmentation by Functionality often highlights performance characteristics such as shear-thinning behavior, yield stress capability, and thermal stability. The selection criteria vary significantly across end-user industries; for instance, high shear-thinning thickeners are preferred in sprayable coatings, while high yield stress thickeners are vital for maintaining particle suspension in industrial drilling muds and consumer lotions. Understanding these segmented demands is critical for manufacturers to tailor their product portfolio and target strategic growth areas effectively, capitalizing on specialized industrial requirements.

- By Type:

- Natural Thickeners (Starches, Hydrocolloids, Cellulose Derivatives)

- Synthetic Thickeners (Polyacrylates, Polyurethanes, Associative Thickeners)

- Modified Natural Thickeners (Modified Starches, CMC, HPMC)

- By Source:

- Plant-Based

- Animal-Based

- Microbial

- Synthetic

- By Application:

- Food & Beverage

- Paints & Coatings

- Pharmaceuticals

- Cosmetics & Personal Care

- Oil & Gas

- Construction

- Adhesives & Sealants

- By Functionality:

- High Shear Rate Performance

- Yield Stress Agents

- Salt & pH Stable Thickeners

Value Chain Analysis For Thickener Market

The value chain for the Thickener Market begins with the highly diversified upstream segment involving the sourcing and processing of raw materials. For natural thickeners, this includes agricultural sourcing (e.g., guar seeds, wood pulp for cellulose derivatives, or microbial fermentation inputs). This stage is characterized by susceptibility to commodity price volatility and seasonal supply issues, demanding robust risk management strategies from manufacturers. For synthetic thickeners, the upstream segment involves petrochemical derivatives (monomers and specialized chemical reagents), where global oil and gas prices exert a direct influence on production costs. Effective upstream management focusing on sustainable sourcing and competitive long-term contracts is paramount for maintaining profitability across the value chain.

The core manufacturing and processing phase involves complex chemical synthesis (for synthetic products) or extraction, purification, and modification (for natural and modified natural products). This stage requires significant capital investment in reaction equipment, drying technology, and stringent quality control systems, particularly for pharmaceutical and food-grade products. Research and development activities, focusing on improving functional properties like solubility, stability, and cost-effectiveness, are integrated into this stage. Manufacturers often aim for vertical integration or strategic alliances with raw material suppliers to enhance control over quality and cost structures, thereby capturing maximum value within the chain.

The downstream segment involves distribution, sales, and end-user application. Distribution channels are varied, including direct sales to major industrial users (e.g., large coating manufacturers or pharmaceutical giants) and indirect sales through specialized chemical distributors and agents, who provide crucial localized technical support and smaller-volume delivery services. The effectiveness of the distribution network is crucial, especially in delivering high-value, specialized grades that require specific handling and storage conditions. End-users evaluate thickeners based on price, technical performance, consistency, regulatory compliance, and the level of technical support offered by the supplier, completing the loop of the market value chain.

Thickener Market Potential Customers

Potential customers for thickeners represent a broad and varied spectrum of industries, all sharing the fundamental requirement of controlling the viscosity and rheological behavior of their liquid formulations. The largest category of potential customers are multinational and regional Food & Beverage manufacturers, including producers of dairy, sauces, dressings, bakery fillings, and prepared meals. These buyers prioritize clean-label compliance, sensory impact (mouthfeel), and the ability of thickeners to prevent syneresis or sedimentation over extended shelf life, often demanding high-purity natural hydrocolloids and modified starches.

A second major customer segment consists of industrial manufacturers within the Paints, Coatings, and Construction sectors. These customers purchase specialized synthetic and associative thickeners (e.g., HEUR, HASE) to control application properties such as film build, sag resistance, and spatter during high-speed application. Specific construction chemical companies also utilize thickeners in cement additives, mortars, and tile adhesives to improve workability and water retention. For this group, technical performance, shear stability, and compatibility with other industrial additives (like pigments and dispersants) are the key purchasing criteria.

Further high-value customers include global Pharmaceutical and Personal Care companies. Pharmaceutical buyers require ultra-high-purity cellulosic and synthetic derivatives for manufacturing oral liquids, ophthalmic solutions, and transdermal patches, where consistency and inertness are critical for drug efficacy and safety. Cosmetics and Personal Care manufacturers, including producers of lotions, creams, and hair care products, seek thickeners that provide desirable sensorial attributes, emulsification stability, and compatibility with complex cosmetic ingredients, often driving demand for specialty polyacrylates and specific natural gums.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 15.2 Billion |

| Market Forecast in 2033 | USD 22.5 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ashland Inc., Dow Chemical Company, CP Kelco, Cargill, BASF SE, DuPont de Nemours, Inc., Archer Daniels Midland (ADM), Akzo Nobel N.V., Wacker Chemie AG, Nouryon, Lubrizol Corporation (Berkshire Hathaway), Fufeng Group, Shandong Head Co., Ltd., Ingredion Incorporated, Tate & Lyle PLC, Shin-Etsu Chemical Co., Ltd., Chemrez Technologies Inc., Sumitomo Seika Chemicals Co., Ltd., Global Bio-Chem Technology Group Company Limited, Kerry Group plc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Thickener Market Key Technology Landscape

The technology landscape within the Thickener Market is defined by continuous innovation focused on enhancing product efficiency, sustainability, and tailored functionality. A major technological focus involves advanced polymer synthesis techniques, particularly in the creation of associative thickeners (such as Hydrophobically Modified Alkali-Soluble Emulsions or HASE, and Hydrophobically Modified Ethoxylated Urethanes or HEUR). These synthetic technologies allow for viscosity modification through reversible hydrophobic associations, offering superior performance in water-borne systems, crucial for modern, low-VOC coatings. Ongoing research aims at designing polymers with predictable and controllable yield stress profiles, enabling formulators to achieve specific textural goals with minimal additive load, thereby reducing cost and formulation complexity.

In the domain of natural thickeners, biotechnological advancements, especially in microbial fermentation and enzymatic modification, are driving the development of novel hydrocolloids. Precision fermentation allows for the sustainable, large-scale production of high-quality gums like Xanthan and Gellan, bypassing the supply volatility associated with traditional agricultural sourcing. Furthermore, enzymatic modification techniques are being utilized to enhance the functional characteristics of existing natural starches and cellulose, improving their solubility, reducing retrogradation tendencies, and broadening their operational pH and temperature range for complex food and pharmaceutical applications. This focus on controlled structural alteration significantly expands the utility of bio-based materials.

Emerging technologies also include the use of nanotechnology and microencapsulation for specialized thickening agents. These methods involve encapsulating or structuring rheology modifiers at the nanoscale to improve dispersion stability and control the release of active ingredients in applications such as controlled drug delivery or specialized drilling fluids. The integration of high-throughput screening and computational chemistry is accelerating the discovery phase, allowing R&D teams to model and optimize the interaction of thickeners with various solvents and dispersed phases much more quickly than conventional methods. Overall, the technology trajectory points towards multi-functional, high-purity, and environmentally sound rheology modification solutions.

Regional Highlights

The global Thickener Market exhibits distinct characteristics and growth momentum across different geographical regions, reflecting varying industrialization levels, consumer demands, and regulatory environments. Asia Pacific (APAC) currently holds the dominant position in terms of market share and is projected to experience the fastest growth throughout the forecast period. This rapid expansion is fueled by massive urbanization, burgeoning middle-class populations leading to increased consumption of packaged foods and cosmetics, and robust infrastructure development requiring substantial volumes of coatings and construction chemicals. Countries such as China and India are focal points due to their immense manufacturing capabilities and large consumer bases.

North America and Europe represent mature markets characterized by high per capita consumption and sophisticated regulatory standards. Growth in these regions is primarily driven by innovation in high-value segments, particularly specialty pharmaceuticals, nutraceuticals, and premium personal care products that require high-grade, certified thickeners. The strong emphasis on sustainability and clean labels in European markets is driving demand for certified organic and highly purified natural thickeners. Manufacturers in these regions often focus on product differentiation through superior technical performance and compliance with stringent food and drug administration guidelines, maintaining a strong position in terms of value capture.

Latin America (LATAM) and the Middle East and Africa (MEA) are emerging regions offering significant untapped market potential. Growth here is spurred by increasing foreign investment in manufacturing, improving standards of living, and the modernization of their food processing and construction industries. While currently smaller in volume, these regions present significant long-term opportunities for synthetic thickener suppliers targeting construction and oilfield chemical applications, and for natural thickener suppliers catering to rapidly expanding local food and beverage manufacturers seeking cost-effective stabilization solutions.

- Asia Pacific (APAC): Dominates market volume; driven by food processing, construction boom, and increasing industrial output in China and India.

- North America: High-value market focused on specialty pharmaceuticals, advanced personal care, and specialized coatings (high CAGR in niche segments).

- Europe: Driven by strict clean-label requirements, sustainability mandates, and high demand for specialized cellulosic derivatives and bio-based thickeners.

- Latin America (LATAM): Emerging market growth fueled by rising disposable incomes and expanding local food manufacturing.

- Middle East & Africa (MEA): Growth tied heavily to infrastructure projects, oil & gas industry demands (drilling fluids), and modernizing food industry.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Thickener Market.- Ashland Inc.

- Dow Chemical Company

- CP Kelco (A J.M. Huber Company)

- Cargill Incorporated

- BASF SE

- DuPont de Nemours, Inc.

- Archer Daniels Midland (ADM)

- Akzo Nobel N.V.

- Wacker Chemie AG

- Nouryon

- Lubrizol Corporation (A Berkshire Hathaway Company)

- Fufeng Group

- Shandong Head Co., Ltd.

- Ingredion Incorporated

- Tate & Lyle PLC

- Shin-Etsu Chemical Co., Ltd.

- Chemrez Technologies Inc.

- Sumitomo Seika Chemicals Co., Ltd.

- Global Bio-Chem Technology Group Company Limited

- Kerry Group plc.

Frequently Asked Questions

Analyze common user questions about the Thickener market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between natural and synthetic thickeners?

Natural thickeners, such as Xanthan Gum or Modified Starches, are derived from biological sources and are often preferred for food and clean-label applications. Synthetic thickeners, like polyacrylates (HASE), are chemically manufactured, offering superior stability, cost-efficiency, and targeted rheological performance in industrial coatings and detergents, often tolerating extreme pH and shear conditions better than their natural counterparts.

Which application segment drives the highest demand volume in the Thickener Market?

The Food & Beverage application segment currently drives the highest demand volume globally. Thickeners are essential for achieving desired texture, mouthfeel, and stability in diverse products including sauces, dairy items, and beverages. However, the Paints & Coatings sector is highly significant due to the mandatory inclusion of rheology modifiers in modern water-based, low-VOC formulations.

How is sustainability impacting the selection and manufacturing of thickening agents?

Sustainability is profoundly impacting the market by accelerating the demand for certified bio-based, biodegradable, and non-GMO thickeners. Manufacturers are investing heavily in technologies like precision fermentation to produce high-purity natural hydrocolloids sustainably, minimizing the environmental footprint and addressing the clean-label movement favored by consumers in developed economies.

What role do associative thickeners play in the coatings industry?

Associative thickeners (e.g., HEUR, HASE) are critical in the coatings industry, particularly for water-borne paints. They function by forming temporary hydrophobic networks that stabilize the viscosity under low shear (storage) while allowing viscosity reduction under high shear (application, like brushing or spraying), ensuring optimal flow, leveling, and film build without sagging.

What is the projected growth outlook for the Thickener Market in the Asia Pacific region?

The Asia Pacific region is projected to exhibit the fastest Compound Annual Growth Rate (CAGR) due to rapid industrialization, high levels of urbanization, and significant expansion in the food processing, pharmaceutical manufacturing, and construction sectors across major economies like China and India, making it the most dynamic regional market globally.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Paste Thickener Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Drum Thickener Market Statistics 2025 Analysis By Application (For Sludge Treatment, For Water Treatment, Others), By Type (Large-scale, Small-scale), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Central Drive Thickener Market Statistics 2025 Analysis By Application (Tailings, Counter Current Decantation (CCD), Others), By Type (Large-scale, Small-scale), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Paint Thickener Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Starch, Xanthan Gum, Carrageenan, Guar Gum, Locust Bean Gum, Gum Arabic, Others), By Application (Water Based Paint, Oil Based Paint), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager