Tire Changing Machines Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440177 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Tire Changing Machines Market Size

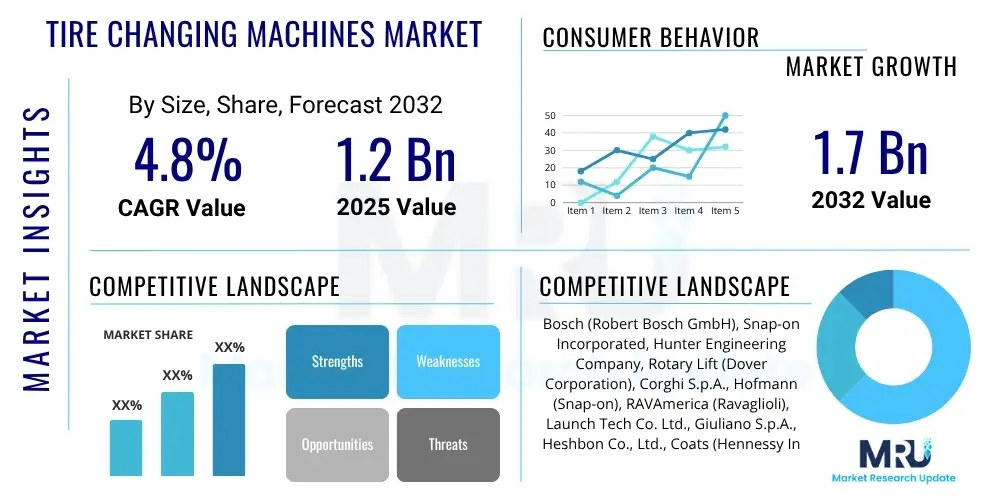

The Tire Changing Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.12 Billion in 2026 and is projected to reach USD 1.65 Billion by the end of the forecast period in 2033. This consistent growth trajectory is driven by the escalating global vehicle parc, the increasing complexity of modern tire designs, and the ongoing demand for efficient and safe tire maintenance services across various automotive sectors. The shift towards higher performance vehicles and larger diameter wheels further necessitates advanced equipment, underpinning the market's expansion.

Tire Changing Machines Market introduction

The Tire Changing Machines Market encompasses the global industry involved in the manufacturing, distribution, and utilization of specialized equipment designed for the mounting and dismounting of tires from vehicle wheels. These machines are critical tools within the automotive service ecosystem, ranging from basic manual models to highly automated, sophisticated systems that cater to a wide array of tire types, including those for passenger vehicles, commercial trucks, motorcycles, and off-road equipment. The primary function of these machines is to streamline the tire service process, enhance operational efficiency, and ensure the safety and longevity of tires and wheels. Major applications for tire changing machines are found in independent automotive repair shops, franchised dealerships, dedicated tire service centers, and fleet maintenance facilities. The benefits derived from these machines include significant time savings, reduced manual effort, minimization of wheel and tire damage during service, improved technician safety, and the ability to handle the increasing diversity and complexity of modern tire technologies such as run-flat tires and ultra-high-performance tires. Key driving factors propelling market growth include the steady expansion of the global vehicle fleet, the imperative for regular tire maintenance for safety and performance, technological advancements in tire and wheel design necessitating more capable equipment, and stringent automotive safety regulations that indirectly boost demand for professional tire services.

Modern tire changing machines have evolved considerably from their predecessors, incorporating features like pneumatic assists, leverless technology, and integrated wheel lifters, all aimed at enhancing ergonomics and productivity. The market is also being influenced by environmental considerations, with an increasing focus on energy-efficient designs and materials. As vehicle electrification gains momentum, the weight and torque characteristics of electric vehicles (EVs) are placing new demands on tire durability and service, consequently impacting the design and capabilities required for future tire changing equipment. This evolution ensures that tire changing machines remain an indispensable asset in the automotive aftermarket, adapting continuously to the changing landscape of vehicle technology and consumer expectations. The global infrastructure supporting automotive services further solidifies the foundational demand for this essential equipment, promoting continuous innovation and market penetration across diverse geographical regions.

Tire Changing Machines Market Executive Summary

The Tire Changing Machines Market is experiencing robust growth, driven by a confluence of evolving business trends, distinct regional dynamics, and significant segment-specific advancements. Business trends indicate a strong move towards automation and integration, with manufacturers focusing on smart machines that offer enhanced diagnostics, data connectivity, and user-friendly interfaces to address the skilled labor shortage and boost workshop efficiency. There's also a rising emphasis on ergonomic designs and safety features, recognizing the physical demands of tire service. Regionally, Asia Pacific is emerging as a dominant growth hub, propelled by rapidly expanding automotive markets, increasing disposable incomes, and the modernization of automotive service infrastructure. North America and Europe continue to be strong markets, characterized by demand for high-end, technologically advanced machines and replacements for aging equipment, driven by stringent safety standards and a focus on premium service. Segment-wise, the market is seeing increased adoption of automatic and leverless machines due to their efficiency and ability to handle complex wheel and tire assemblies without damage. The commercial vehicle segment is also growing, supported by robust logistics and transportation industries requiring heavy-duty, reliable tire changing solutions. These overarching trends paint a picture of a dynamic market poised for continued expansion and innovation.

Further market analysis reveals a concentrated effort by leading manufacturers to diversify their product portfolios, offering a spectrum of machines that cater to different price points and workshop capacities, from small independent garages to large multi-bay service centers. This strategy helps capture a broader customer base and maintain competitive advantage. The aftermarket service industry's resilience, even amidst economic fluctuations, provides a stable demand foundation for tire changing equipment, as tire replacement and maintenance are non-discretionary aspects of vehicle ownership. Moreover, the emergence of specialized tire service franchises and mobile tire service units is creating new avenues for equipment sales, particularly for compact and portable tire changers. Investment in research and development remains a cornerstone for market players, focusing on material science for enhanced durability, software integration for predictive maintenance, and modular designs that allow for upgrades and customization. This holistic approach across business, regional, and segment dimensions underscores the vibrant and adaptive nature of the tire changing machines market, indicating a promising outlook for stakeholders.

AI Impact Analysis on Tire Changing Machines Market

Common user questions regarding AI's impact on the Tire Changing Machines Market frequently revolve around automation capabilities, predictive maintenance, diagnostic accuracy, and the potential for reduced human intervention. Users are keen to understand how AI can make tire changing processes faster, safer, and more precise, especially with the increasing complexity of modern tire and wheel combinations. There's also considerable interest in how AI can integrate with existing workshop management systems, streamline inventory, and provide data-driven insights for improved operational efficiency. Concerns often include the initial investment cost, the need for specialized training for technicians to operate AI-enhanced equipment, and the reliability of AI algorithms in diverse real-world workshop environments. Ultimately, users expect AI to elevate the tire service experience by minimizing errors, optimizing workflow, and contributing to a more intelligent and proactive service model, thereby enhancing customer satisfaction and workshop profitability.

- Enhanced Automation and Precision: AI algorithms can optimize clamping pressure and bead breaking force, adapting dynamically to different tire types and sizes, reducing the risk of wheel or tire damage. This leads to more precise and consistent operations, particularly for sensitive or expensive wheel and tire assemblies, minimizing human error.

- Predictive Maintenance for Equipment: AI-powered sensors integrated into tire changing machines can monitor component wear, motor performance, and pneumatic system integrity, predicting potential failures before they occur. This allows for proactive maintenance scheduling, minimizing downtime, extending equipment lifespan, and reducing unexpected repair costs for workshops.

- Intelligent Diagnostics and Tire Analysis: AI can analyze tire wear patterns, balance data, and pressure sensor readings to provide more accurate diagnostic recommendations to technicians. This includes identifying issues such as uneven wear, misalignment, or structural damage, helping workshops offer more comprehensive and data-backed tire services.

- Optimized Workflow and Efficiency: AI can learn and optimize the sequence of tire changing operations based on historical data and real-time conditions, suggesting the most efficient steps for a given tire and wheel combination. This reduces cycle times, improves throughput, and allows technicians to service more vehicles in less time, directly impacting profitability.

- Integration with Workshop Management Systems: AI facilitates seamless data exchange between tire changing machines and broader workshop management software. This integration can automate inventory management for tires and parts, track service history for individual vehicles, and provide comprehensive reporting on workshop performance and technician productivity.

- Augmented Reality (AR) for Technician Training and Support: AI-driven AR overlays can provide real-time guidance to technicians during complex tire changes, displaying instructions, torque specifications, and diagnostic information directly on the wheel or machine. This can accelerate training for new staff and offer immediate support for challenging cases, enhancing skill sets.

- Data-Driven Insights for Business Optimization: AI can process vast amounts of operational data from multiple machines across a service network, identifying trends in tire types serviced, common issues encountered, and peak operational times. These insights enable strategic business decisions, such as optimizing staffing, inventory, and marketing efforts, to better meet customer demand.

- Safety Enhancements: AI can monitor the operational environment and technician movements around the machine, identifying potential safety hazards or incorrect procedures. It can provide alerts or even temporarily halt operations to prevent accidents, significantly improving workshop safety standards and reducing workplace injuries.

- Customization and Adaptability: AI allows tire changing machines to adapt more effectively to the increasing variety of tire and wheel designs, including specialized EV tires, run-flats, and large commercial vehicle tires. The machine can automatically adjust settings and programs to ensure optimal handling for each specific application, enhancing versatility.

- Reduced Learning Curve for Complex Operations: For less experienced technicians, AI can act as an intelligent assistant, guiding them through intricate procedures for difficult tire changes, such as those involving low-profile or stiff sidewall tires. This lowers the barrier to entry for performing advanced tire services, broadening the skill base within workshops.

DRO & Impact Forces Of Tire Changing Machines Market

The Tire Changing Machines Market is profoundly shaped by a dynamic interplay of drivers, restraints, and opportunities, collectively forming the core impact forces. Key drivers include the consistent growth in the global vehicle parc, which naturally escalates the demand for tire replacement and maintenance services across all vehicle types. This is further amplified by the continuous evolution of tire technologies, such as run-flat tires, ultra-high-performance tires, and larger diameter wheels, which necessitate more sophisticated and specialized changing equipment to prevent damage and ensure proper fitment. Additionally, the increasing focus on vehicle safety and performance by consumers and regulatory bodies mandates professional tire service, thereby bolstering demand for advanced machines. However, the market faces significant restraints, primarily the high initial investment cost associated with advanced tire changing machines, which can be a barrier for smaller independent workshops, especially in developing regions. The shortage of skilled technicians capable of operating and maintaining these intricate machines also poses a challenge, impacting adoption rates and efficiency. Economic downturns and fluctuations in automotive sales can temporarily dampen investment in new equipment, creating market volatility. Opportunities for growth are abundant, particularly in emerging markets where automotive penetration is rapidly increasing and infrastructure is being modernized. The trend towards greater automation and integration of smart technologies presents avenues for innovation and premium product offerings. Furthermore, the rising demand for EV-specific tire services, given their unique weight and torque characteristics, opens a niche for specialized equipment. These impact forces collectively dictate market expansion, technological innovation, and competitive strategies within the tire changing machines industry.

The impact forces within the market are multifaceted, extending beyond immediate supply and demand to encompass technological shifts and macroeconomic factors. The push for sustainability, for instance, is driving manufacturers to develop more energy-efficient machines and incorporate recyclable materials, aligning with global environmental objectives. This also creates opportunities for retrofitting older machines with newer, more eco-friendly components. Geopolitical stability and international trade agreements play a crucial role in the global distribution and pricing of these machines, affecting market accessibility and competitiveness. Moreover, the increasing consolidation among automotive service providers and tire manufacturers can influence purchasing decisions, favoring suppliers who can offer comprehensive solutions and strong aftermarket support. The aftermarket nature of tire changing machines means their demand is less susceptible to new vehicle sales cycles alone, benefiting from the sustained maintenance needs of the existing vehicle fleet. The evolving digital landscape also presents an opportunity for remote diagnostics and software updates for machines, enhancing their operational lifespan and functionality. Understanding these intricate impact forces is vital for stakeholders to navigate the market effectively, identify lucrative segments, and develop resilient business strategies that capitalize on emerging trends while mitigating potential risks.

Segmentation Analysis

The Tire Changing Machines Market is comprehensively segmented to provide granular insights into various product types, operational mechanisms, application areas, and end-user categories. This segmentation allows for a detailed understanding of market dynamics, enabling manufacturers to tailor their offerings and identify specific growth opportunities, while also helping service providers make informed purchasing decisions based on their specific needs and operational scales. The primary segmentation typically includes classifications by type, such as manual, semi-automatic, and automatic machines, which reflect varying levels of automation and technical sophistication. Further distinctions are made based on the design and operational features, including tilt-back column machines and swing-arm column machines, each offering unique advantages in terms of space efficiency and operational ease. Application-based segmentation often categorizes machines by the type of vehicle they service, such as passenger vehicles, commercial vehicles (light, medium, heavy-duty), and motorcycles, recognizing the specialized requirements of each. Moreover, end-user segmentation differentiates between independent repair shops, franchised automotive dealerships, specialized tire service centers, and fleet operators, acknowledging their distinct purchasing power, volume requirements, and service expectations. These detailed segmentations are crucial for strategic planning and competitive positioning within the diverse tire changing machines market landscape.

- By Type:

- Manual Tire Changers: Basic models requiring significant physical effort for bead breaking, mounting, and demounting, typically used in smaller shops or for low-volume applications. Characterized by simplicity and lower cost.

- Semi-Automatic Tire Changers: Incorporate pneumatic or hydraulic assistance for certain operations like clamping or bead breaking, reducing manual labor compared to fully manual machines. Offer a balance between automation and cost.

- Automatic Tire Changers: Feature higher levels of automation, often with pneumatic assists for most operations, automatic wheel clamping, and sometimes integrated wheel lifters. Enhance speed and reduce technician fatigue, suitable for high-volume shops.

- Leverless Tire Changers: A sub-category of automatic changers that eliminate the traditional tire lever, using specialized tools to mount and demount tires without direct contact between metal and rim. Ideal for delicate and expensive alloy wheels, as well as run-flat and ultra-high-performance tires.

- By Operation Mechanism:

- Pneumatic: Utilizes compressed air to power various functions, common across semi-automatic and automatic machines for clamping, bead breaking, and rotating.

- Hydraulic: Employed in heavier-duty machines, particularly for commercial vehicle tires, providing greater force for bead breaking and lifting heavy wheels.

- By Design:

- Tilt-Back Column: The mounting column tilts back to allow for easier access and placement of larger wheels onto the turntable. Popular for shops handling a wide variety of wheel sizes.

- Swing-Arm Column: The mounting column swings to the side, suitable for smaller workshops with limited space, as the machine's footprint remains compact during operation.

- By Application/Vehicle Type:

- Passenger Vehicle Tire Changers: Designed for cars, SUVs, and light trucks, often focusing on handling a wide range of rim diameters and tire profiles common in consumer vehicles.

- Commercial Vehicle Tire Changers: Robust machines built to handle the larger diameters, heavier weights, and tougher beads of truck, bus, and agricultural tires. May include features like integrated lifts and higher torque.

- Motorcycle Tire Changers: Specialized equipment with smaller clamping mechanisms and specific adaptors to accommodate motorcycle wheels and tires, ensuring no damage to delicate rims.

- Off-Road & Specialty Vehicle Tire Changers: Machines designed for construction equipment, forklifts, ATVs, and other non-standard vehicles, often requiring unique adaptors and high breaking forces.

- By End-User:

- Independent Repair Shops: A significant market segment, often opting for semi-automatic or automatic machines that offer a good balance of features and cost-effectiveness.

- Franchised Automotive Dealerships: Typically invest in high-end, fully automatic, and leverless machines to provide premium service and handle the latest vehicle models with delicate wheels.

- Specialized Tire Service Centers: Businesses solely focused on tire sales and service, often requiring multiple advanced machines to handle high volumes and diverse customer needs.

- Fleet Operators & Government Agencies: Maintain their own workshops for large fleets of vehicles (e.g., transport companies, municipal services), investing in durable, efficient machines capable of heavy-duty use.

- By Technology Level:

- Basic & Standard Models: Entry-level machines with core functionalities, suitable for workshops with budget constraints or lower service volumes.

- Advanced & Integrated Models: Include features like pneumatic wheel lifts, integrated inflation systems, USB ports for updates, and diagnostic capabilities, offering enhanced efficiency and versatility.

Value Chain Analysis For Tire Changing Machines Market

The value chain for the Tire Changing Machines Market is a complex ecosystem, beginning with upstream activities involving the sourcing of raw materials and the manufacturing of specialized components, and extending through various stages to the downstream distribution channels and ultimately to the end-users. Upstream analysis highlights a reliance on suppliers of high-quality steel, aluminum alloys, plastics, and electronic components, as well as pneumatic and hydraulic systems. Manufacturers of tire changing machines work closely with these suppliers to ensure the availability of durable, precision-engineered parts. Research and development activities also form a crucial part of the upstream segment, driving innovation in machine design, automation capabilities, and material science. These foundational elements directly influence the quality, performance, and cost-effectiveness of the final product, demanding robust supply chain management and quality control from machine manufacturers.

Downstream activities primarily involve the distribution, sales, and aftermarket support of tire changing machines. Manufacturers utilize both direct and indirect distribution channels to reach their diverse customer base. Direct channels include direct sales forces engaging with large dealerships or fleet operators, often providing bespoke solutions and extensive training. Indirect channels, which form a substantial part of the market, involve a network of authorized distributors, equipment wholesalers, and online retailers. These intermediaries play a vital role in market penetration, particularly for smaller workshops and across wider geographical areas, often bundling machines with other workshop equipment and offering localized support. After-sales services, including installation, training, maintenance, and spare parts supply, are critical components of the downstream value chain, significantly influencing customer satisfaction and brand loyalty. The effectiveness of these distribution and service networks is paramount for manufacturers to ensure broad market reach, prompt customer service, and sustained revenue streams throughout the product lifecycle.

Tire Changing Machines Market Potential Customers

The potential customers for tire changing machines represent a broad spectrum of entities within the automotive service and maintenance industry, all of whom require efficient and reliable equipment for tire mounting and demounting. These end-users are primarily driven by the need to service a growing global vehicle fleet, adhere to safety standards, and provide high-quality, expedient service to their clientele. The largest segment of potential customers includes independent automotive repair shops, which cater to a wide range of vehicles and often seek versatile, durable, and cost-effective machines that can handle diverse tire types without extensive specialized training. These shops rely on tire changers as fundamental tools for routine maintenance, tire rotations, and full tire replacements, making their continuous demand a cornerstone of the market.

Another significant customer segment comprises franchised automotive dealerships, which typically demand high-end, technologically advanced tire changing machines. These dealerships often service newer vehicles with sophisticated wheel and tire assemblies, including expensive alloy wheels and complex run-flat or low-profile tires, necessitating leverless or highly automated machines to prevent damage and ensure precision. Specialized tire service centers, which focus exclusively on tire sales, fitting, balancing, and repair, represent a high-volume customer base that requires robust, rapid, and often multiple tire changing units to maintain throughput. Furthermore, fleet operators—ranging from commercial trucking companies to public transport agencies and government vehicle pools—constitute a crucial customer group. These entities operate large fleets and maintain in-house service facilities, requiring heavy-duty, reliable tire changing equipment capable of handling commercial vehicle tires efficiently to minimize downtime and operational costs. The evolving landscape of mobile tire service providers also creates a growing niche for compact, portable, and versatile tire changing solutions, expanding the customer base beyond traditional brick-and-mortar workshops.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.12 Billion |

| Market Forecast in 2033 | USD 1.65 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Snap-on Incorporated (John Bean, Hofmann), Hunter Engineering Company, CORGHI S.p.A., RAVAGLIOLI S.p.A., Giuliano S.p.A., BOSCH GmbH (Beissbarth), Nussbaum Automotive Lifts GmbH, SICE S.p.A., Heshbon Co., Ltd., COATS Global, Tecnomotor S.p.A., Rotary Lift, Launch Tech Co., Ltd., BRIGHT Technology, Phoenix Automotive Equipment, BendPak Inc., Atlas Auto Equipment, CEMB S.p.A., Sicam S.r.l., Unite Automotive Equipment Co. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tire Changing Machines Market Key Technology Landscape

The Tire Changing Machines Market is continuously evolving with the integration of advanced technologies, aimed at enhancing efficiency, precision, safety, and versatility to meet the demands of modern vehicle and tire designs. A primary technological advancement is the widespread adoption of leverless technology, which eliminates the traditional tire iron to mount and demount tires without direct metal-to-rim contact. This innovation is crucial for protecting delicate alloy wheels and servicing complex, low-profile, or run-flat tires, which are prone to damage with conventional methods. Furthermore, sophisticated pneumatic and hydraulic control systems have become standard, providing precise and adjustable clamping pressures and bead breaking forces, ensuring tires are handled optimally regardless of their stiffness or size. The evolution also includes the development of integrated wheel lift systems, which automatically raise heavy wheel and tire assemblies to the correct working height, significantly reducing technician fatigue and preventing workplace injuries, thereby enhancing ergonomics and safety within the workshop.

Beyond mechanical and pneumatic improvements, the market is increasingly integrating digitalization and smart features. This includes touch-screen interfaces with intuitive controls, allowing for easier operation and program selection for different tire types. Sensor technology is becoming more prevalent, enabling machines to automatically detect rim diameter and tire width, and adjust operations accordingly. Connectivity, often through IoT (Internet of Things) integration, allows for machine diagnostics, software updates, and performance monitoring, contributing to predictive maintenance and improved asset management for workshops. Some advanced models are even incorporating diagnostic integration capabilities, where the tire changer can communicate with wheel balancers or alignment systems to provide a more holistic tire service solution. The future technological landscape points towards greater automation driven by artificial intelligence, autonomous operation for repetitive tasks, and enhanced material science in machine construction for increased durability and efficiency, positioning tire changing machines as central components in the intelligent workshop of tomorrow.

Regional Highlights

- North America: This region represents a mature yet robust market for tire changing machines, characterized by a high demand for advanced, fully automatic, and leverless models. The presence of a large vehicle parc, stringent safety regulations, and a strong emphasis on service quality drive consistent upgrades and replacements of existing equipment. The United States and Canada lead in adopting innovative technologies, supported by a significant number of independent repair shops, large automotive dealerships, and specialized tire service chains. The market here benefits from a preference for premium, durable equipment that offers high efficiency and minimizes the risk of wheel damage, catering to a sophisticated consumer base.

- Europe: Similar to North America, Europe is a well-established market with high demand for technologically advanced and eco-friendly tire changing solutions. Countries like Germany, Italy, France, and the UK are at the forefront of innovation, with a strong manufacturing base for automotive service equipment. The region places a significant emphasis on precision engineering, ergonomic design, and adherence to rigorous safety and environmental standards. The diverse vehicle market, including a large proportion of luxury and performance vehicles with specialized tires, fuels the adoption of leverless and high-capacity automatic machines. Eastern European countries, while having a slightly lower adoption rate of cutting-edge technology, are rapidly modernizing their automotive service infrastructure, presenting growth opportunities for a broader range of equipment.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region in the tire changing machines market, driven by the massive and expanding automotive industries in countries like China, India, Japan, and South Korea. Rapid urbanization, increasing disposable incomes, and the burgeoning middle class are leading to a surge in vehicle ownership and, consequently, demand for tire service equipment. While the market sees strong demand for basic and semi-automatic machines due to cost considerations, there's a growing inclination towards advanced automatic and leverless models, particularly in developed economies like Japan and South Korea, and increasingly in metropolitan areas of China and India. The sheer volume of new vehicle sales and the development of new automotive service infrastructure make APAC a crucial growth engine for the global market.

- Latin America: This region is characterized by a developing automotive aftermarket, with countries such as Brazil, Mexico, and Argentina being key contributors. The market for tire changing machines in Latin America is driven by the gradual modernization of workshops, increasing vehicle ownership, and the need to service a mixed fleet of new and older vehicles. There is a strong demand for cost-effective, durable semi-automatic machines, though automatic models are gaining traction in larger urban centers and for servicing newer vehicle models. Investments in infrastructure and an improving economic outlook are expected to further stimulate market growth, alongside increasing awareness regarding professional vehicle maintenance.

- Middle East and Africa (MEA): The MEA region is experiencing steady growth, primarily influenced by rapid infrastructure development, increasing vehicle sales, and the expansion of the automotive service sector, particularly in the Gulf Cooperation Council (GCC) countries. The demand for tire changing machines is propelled by the hot climate and diverse terrains, which necessitate frequent tire maintenance and replacement. While the market is varied, there's a growing preference for robust and reliable machines capable of handling both passenger and light commercial vehicle tires. Investment in luxury vehicles in some parts of the region also drives demand for advanced, wheel-friendly equipment. African countries are seeing foundational growth as vehicle fleets expand and basic service infrastructure develops.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tire Changing Machines Market.- Snap-on Incorporated (John Bean, Hofmann)

- Hunter Engineering Company

- CORGHI S.p.A.

- RAVAGLIOLI S.p.A.

- Giuliano S.p.A.

- BOSCH GmbH (Beissbarth)

- Nussbaum Automotive Lifts GmbH

- SICE S.p.A.

- Heshbon Co., Ltd.

- COATS Global

- Tecnomotor S.p.A.

- Rotary Lift

- Launch Tech Co., Ltd.

- BRIGHT Technology

- Phoenix Automotive Equipment

- BendPak Inc.

- Atlas Auto Equipment

- CEMB S.p.A.

- Sicam S.r.l.

- Unite Automotive Equipment Co. Ltd.

Frequently Asked Questions

What is a tire changing machine and why is it important?

A tire changing machine is a specialized piece of equipment used in automotive service centers to efficiently and safely mount and dismount tires from vehicle wheels. It is crucial because it reduces manual labor, prevents damage to wheels and tires, and significantly speeds up the tire service process, which is essential for vehicle safety and performance. Modern tire changers are designed to handle complex tire constructions and delicate wheel finishes with precision, supporting the evolving needs of the automotive industry.

What are the different types of tire changing machines available?

Tire changing machines are primarily categorized by their level of automation: manual, semi-automatic, and automatic. Manual machines require significant physical effort, while semi-automatic and automatic machines use pneumatic or hydraulic power to assist with operations like clamping, bead breaking, and rotation. A specialized type, leverless tire changers, eliminates traditional levers to protect delicate wheels and tires from damage, offering enhanced precision and efficiency, especially for modern, high-performance vehicles.

What factors should I consider when purchasing a tire changing machine?

When purchasing a tire changing machine, consider the types of vehicles and tires you will service (e.g., passenger, commercial, run-flat), your workshop's volume and space constraints, your budget, and the desired level of automation. Key features to evaluate include wheel diameter range, clamping force, bead breaking power, presence of a wheel lift, leverless technology, and overall durability. After-sales support, warranty, and spare parts availability are also critical considerations for long-term operational efficiency.

How do tire changing machines handle modern run-flat and low-profile tires?

Modern run-flat and low-profile tires, with their stiff sidewalls and delicate rims, require advanced tire changing machines equipped with specialized features. Leverless technology is particularly effective as it avoids direct metal-on-metal contact, preventing damage. Many advanced machines also include auxiliary assist arms, pneumatic presses, and precise clamping mechanisms to gently manipulate the tire bead without excessive force, ensuring safe and efficient service for these complex tire types.

What is the impact of AI and IoT on the future of tire changing machines?

AI and IoT are poised to revolutionize tire changing machines by introducing enhanced automation, predictive maintenance, and data-driven insights. AI can optimize operational sequences, adapt to different tire types, and provide intelligent diagnostics for tire wear. IoT connectivity enables remote monitoring, software updates, and seamless integration with workshop management systems, leading to improved efficiency, reduced downtime, and safer operations. These technologies will make tire service more precise, proactive, and less reliant on manual intervention.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager