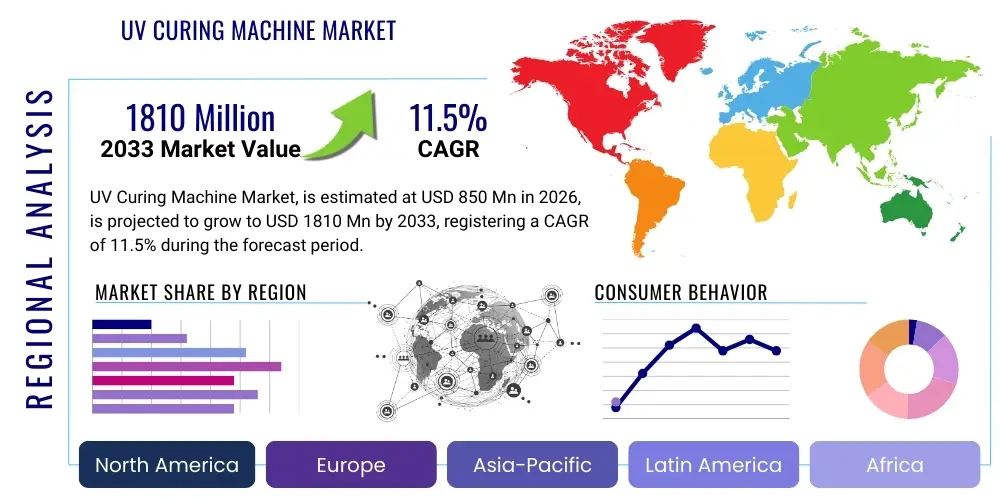

UV Curing Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436177 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

UV Curing Machine Market Size

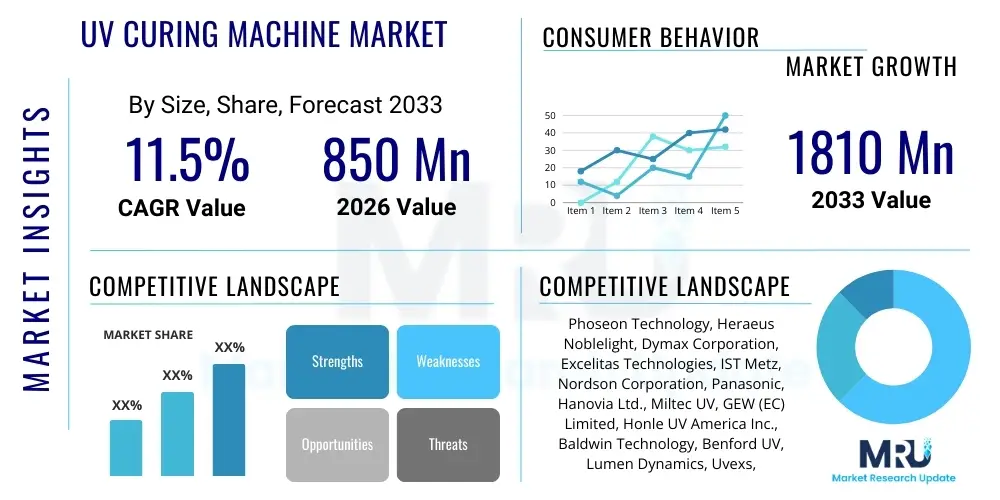

The UV Curing Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 11.5% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1810 Million by the end of the forecast period in 2033.

UV Curing Machine Market introduction

The UV Curing Machine Market encompasses specialized equipment designed to utilize ultraviolet light energy for instantly curing or drying inks, coatings, and adhesives. This technology fundamentally relies on photopolymerization, where reactive monomers and oligomers within a formulation immediately solidify upon exposure to specific UV wavelengths. UV curing systems offer a superior alternative to traditional thermal or air drying processes, providing immediate tack-free surfaces, significantly reduced processing times, and enhanced product durability. The machinery integrates components such as UV lamps (arc, microwave, or LED), power supplies, and reflective optics, configured for precise application environments ranging from small-scale laboratory settings to high-speed industrial production lines.

Major applications of UV curing technology span across the Printing and Packaging industry, particularly in flexible packaging, labels, and offset printing, where rapid throughput and exceptional scratch resistance are paramount. The electronics sector utilizes UV curing for bonding, encapsulation, and conformal coatings on Printed Circuit Boards (PCBs) and displays, demanding high precision and low heat emission, which UV LED systems effectively provide. Furthermore, the automotive industry employs these machines for curing durable, high-gloss clear coats and specialized adhesive applications. The integration of these systems enhances manufacturing efficiency and minimizes the production footprint, driving widespread adoption globally.

The principal driving factors accelerating market growth include stringent environmental regulations mandating the reduction of Volatile Organic Compounds (VOCs) emitted by solvent-based coatings and inks. UV formulations are typically 100% solids, eliminating harmful emissions. Additionally, the increasing demand for high-quality, durable finishes across consumer goods and industrial products, coupled with the rapid expansion of digital inkjet printing technologies that rely heavily on UV-curable inks, further supports the market trajectory. The ongoing technological migration towards highly energy-efficient and long-lasting UV LED curing solutions is perhaps the strongest underlying driver, providing compelling operational cost savings and superior process control.

UV Curing Machine Market Executive Summary

The UV Curing Machine Market is characterized by robust expansion driven primarily by industrial automation trends and the global shift toward sustainable manufacturing practices. Business trends indicate a strong move toward modular and scalable curing systems that can be easily integrated into existing manufacturing lines, favoring suppliers who offer comprehensive system integration and customization. Key market participants are focusing on developing high-irradiance UV LED arrays, which offer superior energy efficiency and spectral flexibility compared to traditional mercury vapor lamps. Strategic alliances and mergers, particularly between UV lamp manufacturers and digital printing equipment providers, are shaping the competitive landscape, emphasizing full-stack solutions for end-users seeking optimized curing performance and consistency.

Segment trends highlight the dominance of UV LED technology due to its environmental benefits, operational longevity, and reduced heat output, making it indispensable in temperature-sensitive applications like electronics and medical device manufacturing. While the Printing and Packaging application segment retains the largest market share owing to high-volume output requirements, the rapid adoption of UV technology in the Wood and Furniture industry for durable finishes and the Medical sector for sterile bonding are emerging as high-growth segments. Custom-engineered curing systems designed for complex 3D geometries are also experiencing burgeoning demand, indicating market maturity in specialized industrial contexts.

Regionally, Asia Pacific (APAC) stands as the undisputed leader in market size and growth rate, primarily fueled by the massive concentration of electronics manufacturing, automotive production, and packaging hubs in countries like China, Japan, and South Korea. North America and Europe maintain stable growth, driven by stringent environmental standards and continuous investment in advanced manufacturing techniques, focusing heavily on adopting high-end, automated UV systems for specialized industrial applications. The push for localized manufacturing and supply chain resilience post-2020 further solidified the demand for high-performance curing solutions across all major geographical regions, making market penetration and localized service crucial for global vendors.

AI Impact Analysis on UV Curing Machine Market

User inquiries regarding AI's influence on the UV Curing Machine Market frequently center on how these technologies can enhance process reliability, predict system failures, and automatically optimize curing parameters. Users are concerned with overcoming inconsistencies caused by variations in coating thickness, substrate type, and ambient environmental factors (temperature, humidity). Expectations are high for AI to deliver predictive maintenance schedules for expensive components like LED arrays or arc lamps, minimizing unexpected downtime. Furthermore, there is significant interest in using machine learning algorithms to fine-tune the UV dosage and speed based on real-time quality control feedback, thereby reducing waste and ensuring compliance with strict industrial standards, particularly in high-precision fields such as medical and semiconductor manufacturing. The key themes revolve around achieving 'smart curing'—a fully automated, self-regulating process that maintains peak efficiency and quality without constant human intervention.

- AI-driven Predictive Maintenance: Analyzing irradiance and temperature data to forecast lamp or LED array failure, scheduling preventative replacements, thus maximizing uptime.

- Real-time Process Optimization: Machine learning algorithms adjusting conveyor speed, UV intensity, and spectrum based on substrate feedback and real-time coating thickness measurements.

- Automated Quality Control (AQC): Utilizing computer vision and AI to detect microscopic curing defects (e.g., inadequate cross-linking or surface imperfections) immediately after the curing process.

- Energy Consumption Management: Employing AI to dynamically match energy input to minimum required curing levels, significantly reducing electricity costs while maintaining quality specifications.

- Recipe Management and Standardization: Creating and managing complex curing 'recipes' automatically across multiple machines and production sites, ensuring global operational consistency.

DRO & Impact Forces Of UV Curing Machine Market

The UV Curing Machine Market dynamics are powerfully shaped by interconnected Drivers (D), Restraints (R), Opportunities (O), and the resulting Impact Forces. The primary driver is the accelerating pressure from global regulatory bodies, such as the EPA and REACH, demanding the reduction of VOCs, making 100% solids UV-curable formulations highly attractive across industries. This environmental imperative combines with the fundamental technological advantage of UV curing—instantaneous processing speed—which significantly boosts production throughput and reduces work-in-progress inventory, thereby offering substantial economic incentives. These forces collectively create a high penetration rate environment, particularly in advanced manufacturing sectors where speed and precision are non-negotiable.

However, the market faces significant restraints, most notably the high initial capital expenditure associated with high-irradiance UV LED systems, which often presents a barrier to entry for smaller enterprises or those operating with tight budget constraints. Furthermore, the specialized training required for operating and maintaining these complex systems, coupled with the need for specialized UV-curable materials (which can sometimes be costlier than conventional materials), acts as a dampening force on overall market expansion. The limited effective curing depth of some UV systems also restricts their use in applications involving very thick coatings or opaque substrates, pushing manufacturers to seek customized dual-curing solutions (e.g., UV + thermal).

Opportunities for exponential growth lie in the continued penetration of UV LED technology into emerging markets, offering robust systems with lower long-term operational costs. Specifically, the development of UV curable materials for 3D printing and additive manufacturing presents a vast, untapped application space demanding precise energy control. The market is also heavily influenced by the competitive force of technology substitution, where continuous innovation in UV LED systems—offering new, specialized wavelengths (like UV-A, UV-B, or UV-C) for specific tasks—makes traditional arc lamps increasingly obsolete, pushing vendors towards sustained R&D investment to maintain market relevance and technical superiority.

Segmentation Analysis

The UV Curing Machine Market is rigorously segmented based on technology type, application, component structure, and end-use industry, allowing for precise market analysis tailored to specific industrial requirements. The technological landscape is dominated by the ongoing transition from conventional mercury vapor lamps to sophisticated UV LED arrays. This shift is critical because UV LEDs offer unparalleled advantages in terms of energy consumption, thermal management, and lifetime, although mercury lamps still maintain a strong position in high-volume, broad-spectrum applications like wide-format printing. The segmentation analysis confirms that industrial adopters are prioritizing long-term operational efficiency and environmental compliance when making procurement decisions, leading to disproportionate growth in the UV LED segment across nearly all regions.

- By Type: UV LED Curing Systems, UV Arc Lamp Curing Systems, UV Microwave Lamp Curing Systems.

- By Component: Lamps/LED Arrays, Reflectors, Ballasts/Power Supplies, Housing/System Integration, Control Systems (HMI/PLC).

- By Application: Printing & Packaging (Offset, Flexography, Screen Printing, Digital Printing), Automotive Coatings and Adhesives, Electronics (PCB Conformal Coating, Display Bonding), Medical and Healthcare (Sterile Bonding, Catheter Curing), Wood and Furniture Coatings, Industrial Metal and Plastic Coatings.

- By End-Use Industry: Consumer Goods Manufacturing, Industrial Manufacturing, Healthcare & Pharmaceuticals, Aerospace & Defense.

Value Chain Analysis For UV Curing Machine Market

The value chain for the UV Curing Machine Market begins with upstream activities focused heavily on the sourcing and manufacturing of specialized components, particularly high-purity quartz and high-power semiconductors required for UV lamps and LED arrays, respectively. This stage is characterized by high technical expertise and reliance on a limited number of specialized material suppliers. Manufacturers of UV curing equipment then engage in complex system integration, assembling lamps, cooling systems, optics, and power electronics into robust industrial machinery. The sophistication of the optics (reflectors and focusing lenses) and the power supply (ballasts or dedicated LED drivers) are critical differentiating factors at this manufacturing stage, demanding rigorous quality control and specialized engineering.

The midstream channel primarily involves two distinct distribution paths: direct sales to large Original Equipment Manufacturers (OEMs) and indirect sales through specialized system integrators and distributors. Direct sales are common when the UV curing system is a core, integrated part of a large production line (e.g., high-speed printing presses or automotive assembly lines), where the curing system vendor works closely with the OEM. Indirect distribution leverages regional distributors who provide localized service, spare parts inventory, and application support to smaller end-users, ensuring broader market penetration and immediate technical assistance, which is essential for minimizing production downtime.

Downstream activities center on the end-user adoption and integration of the machinery into existing production environments, often requiring specialized application engineering support provided by the manufacturers or distributors. The long-term profitability of the value chain is increasingly tied to after-sales service, including periodic maintenance, calibration, lamp/LED array replacement, and software updates. The shift toward subscription-based services or performance contracts for predictive maintenance represents an emerging trend in the downstream segment, maximizing the operational lifespan and efficiency of the high-value curing assets deployed across various highly demanding industries.

UV Curing Machine Market Potential Customers

The potential customer base for UV Curing Machines is exceptionally broad, spanning nearly all industrial sectors that require high-speed bonding, coating, or sealing processes. Primary customers include large-scale commercial printers and packaging converters (both flexible and rigid), who require instantaneous curing to handle high-throughput demands essential for cost-effective mass production. These buyers prioritize speed, system reliability, and low operational costs. Furthermore, specialized manufacturers in the electronics sector, particularly those involved in PCB assembly, semiconductor fabrication, and display manufacturing, constitute a vital customer segment, valuing the low heat emission and precise wavelength control offered by modern UV LED systems for sensitive components.

The automotive and aerospace industries represent another significant buyer segment, focusing on durable exterior coatings, high-strength structural bonding, and sealing gaskets. These customers demand systems that ensure material longevity and compliance with stringent performance specifications, often requiring highly customized curing zones. Medical device manufacturers, producing items like catheters, syringes, and specialty optics, require validated, precise curing processes, often in cleanroom environments, making them premium buyers who prioritize validation documentation and system repeatability. The diverse requirements across these sectors mean that successful vendors must offer a wide portfolio of products, ranging from large, integrated conveyor systems to compact, handheld spot curing tools.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1810 Million |

| Growth Rate | CAGR 11.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Phoseon Technology, Heraeus Noblelight, Dymax Corporation, Excelitas Technologies, IST Metz, Nordson Corporation, Panasonic, Hanovia Ltd., Miltec UV, GEW (EC) Limited, Honle UV America Inc., Baldwin Technology, Benford UV, Lumen Dynamics, Uvexs, DELO Industrial Adhesives, Atlantic Zeiser, American Ultraviolet. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

UV Curing Machine Market Key Technology Landscape

The key technology landscape of the UV Curing Machine Market is centered around the transition from broad-spectrum mercury vapor lamps to narrow-spectrum, high-intensity UV Light Emitting Diodes (LEDs). Traditional mercury arc lamps, including metal halide variants, provide high power and broad spectral output (UV-A, UV-B, UV-C), making them suitable for curing a wide range of chemistries and deep penetration requirements. However, they suffer from short lifespan, high heat generation, the presence of hazardous mercury, and significant power consumption, necessitating large cooling systems and specialized disposal protocols. Despite these drawbacks, their low initial cost and long-established use ensure their continued, albeit shrinking, presence in certain legacy applications.

The prevailing technological momentum belongs unequivocally to UV LED curing systems. These systems operate primarily in the UV-A range (typically 365 nm, 385 nm, 395 nm, and 405 nm), offering precise wavelength control that matches the photoinitiator requirements of specialized UV-curable formulations. Key advantages include instant on/off capabilities, minimal heat transfer to the substrate, exceptionally long operating life (tens of thousands of hours), and zero ozone or mercury emissions, aligning perfectly with sustainability goals. The continuous advancements in LED chip density and output intensity, coupled with sophisticated cooling and optical integration techniques, are expanding their application scope into previously mercury-dominated high-power areas like thick coatings and high-speed packaging printing.

Beyond the core lamp technology, peripheral innovations are equally crucial. These include inert atmosphere curing (using nitrogen purging) to eliminate oxygen inhibition, thereby improving surface cure quality, especially for highly reactive coatings. Furthermore, the development of dual-cure systems, combining UV energy with thermal or moisture curing mechanisms, addresses the limitations of UV light penetration for opaque or thick materials. Advancements in sensor technology and control systems (PLCs and HMI interfaces) allow for precise dose monitoring, closed-loop control of irradiance, and seamless integration into modern Industry 4.0 smart factory environments, optimizing overall curing consistency and data logging capabilities.

Regional Highlights

Regional dynamics play a crucial role in shaping the demand and adoption patterns within the UV Curing Machine Market, reflecting varying levels of industrialization, regulatory environments, and technological maturity across the globe.

- Asia Pacific (APAC): Dominates the global market, driven by its status as a major global manufacturing hub for electronics (especially PCBs and displays), automotive components, and consumer goods. Countries like China, India, and South Korea are witnessing massive infrastructural investments and rapid adoption of high-speed digital printing and automation technologies, creating unprecedented demand for high-throughput UV curing solutions, particularly UV LED systems.

- North America: Characterized by high technological maturity and stringent environmental regulations (mandating VOC reduction), pushing industrial sectors toward adopting highly efficient, advanced UV LED curing technology. The focus here is on specialty applications in medical device manufacturing, aerospace, and high-end industrial coatings, valuing precision and process validation over sheer volume.

- Europe: Exhibits steady growth, propelled by the strong presence of specialized machinery manufacturing and the robust European Union regulations (REACH), which accelerate the shift away from solvent-based systems. Germany, Italy, and the UK are key markets, emphasizing automation, energy efficiency, and sustainable manufacturing practices within the automotive, packaging, and wood coatings sectors.

- Latin America (LATAM): Represents an emerging market with increasing industrialization, particularly in Brazil and Mexico. Adoption is currently centered in the printing and packaging sectors, gradually transitioning from traditional technologies to more modern UV systems as local economies expand and labor costs increase, driving the need for automation.

- Middle East and Africa (MEA): Currently holds the smallest share but shows growth potential, particularly in the Middle East due to infrastructural projects and diversification away from oil economies. Demand is concentrated in specialized coatings for oil and gas pipelines, architectural finishes, and localized packaging production.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the UV Curing Machine Market.- Phoseon Technology

- Heraeus Noblelight

- Dymax Corporation

- Excelitas Technologies

- IST Metz

- Nordson Corporation

- Panasonic

- Hanovia Ltd.

- Miltec UV

- GEW (EC) Limited

- Honle UV America Inc.

- Baldwin Technology

- Benford UV

- Lumen Dynamics

- Uvexs

- DELO Industrial Adhesives

- Atlantic Zeiser

- American Ultraviolet

Frequently Asked Questions

Analyze common user questions about the UV Curing Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of UV LED curing over traditional mercury arc curing?

The primary advantage of UV LED curing is significantly reduced energy consumption and heat output, resulting in lower operational costs and the ability to process heat-sensitive substrates like thin plastics and certain electronic components without thermal damage. Additionally, UV LEDs are mercury-free, offer a longer operational lifespan, and provide instantaneous on/off capability, eliminating warm-up time.

How do environmental regulations impact the demand for UV Curing Machines?

Environmental regulations, particularly those concerning the reduction of Volatile Organic Compounds (VOCs), directly drive demand. UV-curable inks and coatings are typically 100% solids, meaning they contain virtually no solvents or VOCs, allowing manufacturers to comply with strict air quality standards while eliminating the need for expensive fume extraction and abatement systems, thus accelerating adoption.

Which application segment shows the fastest growth rate for UV Curing technology?

The Electronics segment, specifically for Printed Circuit Board (PCB) conformal coatings, encapsulation, and display bonding, is exhibiting the fastest growth rate. This growth is fueled by the demand for miniaturization, precise placement of adhesives, and the necessity for low-temperature processing, requirements uniquely met by high-precision UV LED systems.

What are the key differences between UV-A, UV-B, and UV-C curing processes?

These classifications refer to the wavelength range used: UV-A (315–400 nm) is most common for deep curing and bonding adhesives; UV-B (280–315 nm) is used for certain coatings and sterilization; and UV-C (200–280 nm) is highly effective for surface curing and potent germicidal applications. Most modern industrial curing occurs in the UV-A range due to the spectral requirements of standard photoinitiators.

What role does machine vision and AI play in modern UV curing processes?

Machine vision and AI enhance quality control and process reliability. AI algorithms analyze real-time irradiance data and visual feedback to detect curing defects, ensure consistent material coverage, and automatically adjust curing parameters (intensity and speed) to maintain optimal performance, minimizing waste and ensuring output quality standardization in high-speed manufacturing environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager