Zirconium Oxide Powder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434971 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Zirconium Oxide Powder Market Size

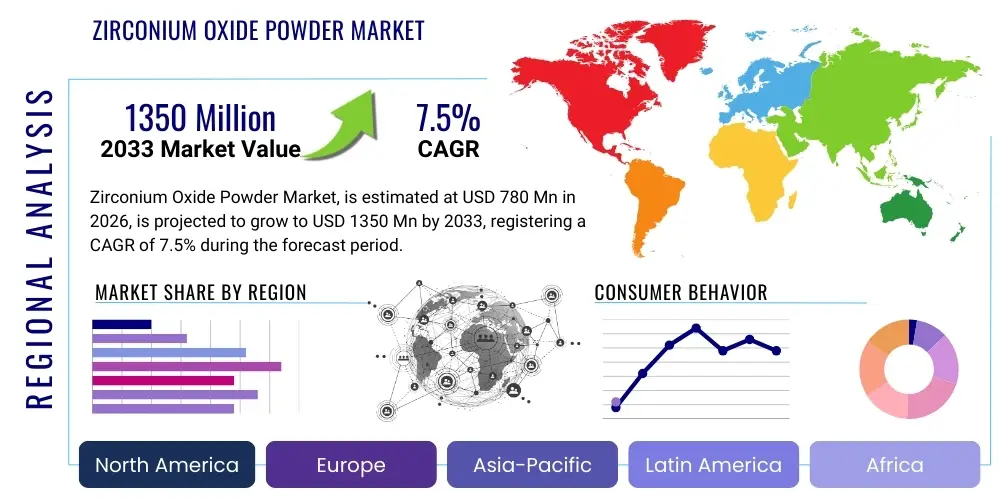

The Zirconium Oxide Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 780 Million in 2026 and is projected to reach USD 1350 Million by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the escalating demand for advanced ceramic materials across high-performance applications, particularly within the automotive, electronics, and biomedical sectors. Zirconium oxide, often referred to as zirconia, offers unparalleled thermal stability, mechanical strength, and chemical inertness, making it indispensable for harsh operating environments.

Zirconium Oxide Powder Market introduction

The Zirconium Oxide Powder Market encompasses the production and distribution of high-purity refractory materials synthesized primarily from zircon sand. Zirconium oxide (ZrO2) is renowned for its polymorphic nature, stabilizing into desirable crystalline phases such as tetragonal or cubic structures through the addition of dopants like yttria or magnesia. This material serves as a foundational component for advanced technical ceramics, high-temperature refractories, dental prosthetics, and catalytic converters, leveraging its exceptional hardness, fracture toughness, and low thermal conductivity. The core benefits driving its adoption include resistance to thermal shock, superior wear performance, and remarkable biocompatibility, positioning it as a preferred material over conventional metals and polymers in critical applications.

Major applications of zirconium oxide powder span from structural ceramics used in industrial pumps and valves to functional ceramics utilized in oxygen sensors and solid oxide fuel cells (SOFCs). The rising global emphasis on energy efficiency and stringent environmental regulations, particularly concerning vehicle emissions, significantly accelerates the demand for zirconia-based components. Furthermore, the burgeoning requirement for miniaturization and high reliability in electronic devices, such as multilayer ceramic capacitors (MLCCs) and thermal barrier coatings (TBCs) in gas turbines, reinforces the material's market trajectory. The driving factors are intrinsically linked to global industrial expansion, technological advancements in material science, and increasing healthcare expenditures promoting high-quality dental and orthopedic replacements.

The market landscape is characterized by constant innovation in particle size control and stabilization techniques, aiming to achieve specific material properties required by specialized end-users. Ultra-fine or nano-sized zirconium oxide powders are gaining traction due to their enhanced sintering characteristics and superior mechanical properties when integrated into nanocomposites. The high cost associated with raw material processing and purification remains a challenge, yet the superior performance metrics offered by zirconia consistently justify its economic viability in demanding high-value applications, ensuring steady market growth throughout the forecast period.

Zirconium Oxide Powder Market Executive Summary

The Zirconium Oxide Powder Market is witnessing robust growth, underpinned by significant technological advancements across multiple industrial sectors. Key business trends include the increasing vertical integration among market players to secure reliable access to high-grade zircon sand resources and the proliferation of strategic partnerships focused on developing specialized, stabilized zirconia formulations for next-generation energy and medical devices. Regionally, Asia Pacific maintains its dominance, primarily fueled by massive manufacturing output in China and the rapid expansion of the electronics and automotive industries in South Korea and Japan. North America and Europe demonstrate strong growth in niche segments, particularly in high-purity medical-grade zirconia and advanced SOFC components. Segment trends indicate a clear preference for yttria-stabilized zirconia (YSZ) due to its superior performance in oxygen sensors and electrolytes, while the application segment is increasingly weighted towards structural ceramics and the rapidly expanding dental materials sector, which benefits significantly from zirconia's aesthetic and mechanical attributes.

The macroeconomic environment provides a supportive backdrop for market expansion, with sustained investments in infrastructure, particularly in developing economies, driving the demand for high-performance refractories. However, the market faces constraints related to supply chain volatility exacerbated by geopolitical tensions affecting key raw material sourcing regions. Mitigation strategies involve geographical diversification of production facilities and the exploration of circular economy approaches to recycle zirconia from industrial waste streams. The market structure remains highly competitive, with established multinational corporations and specialized chemical producers striving for technological supremacy through patented processing methods, such as chemical precipitation and plasma spray techniques, offering tailored particle distributions for critical applications.

Further analysis reveals that the shift toward sustainable and eco-friendly manufacturing processes is becoming a critical differentiating factor. Companies investing in energy-efficient production of zirconia powders and minimizing environmental footprint are gaining a competitive edge, particularly in European markets governed by stringent environmental regulations. The long-term outlook remains highly positive, largely attributed to the irreplaceable role of zirconium oxide in foundational technologies related to decarbonization, advanced computing, and public health, guaranteeing its continued relevance in the material science ecosystem and projecting strong double-digit growth potential in specialized micro-markets like 3D printing feedstock and advanced battery components.

AI Impact Analysis on Zirconium Oxide Powder Market

User inquiries regarding the influence of Artificial Intelligence (AI) on the Zirconium Oxide Powder Market frequently revolve around optimizing synthesis processes, predicting material performance under extreme conditions, and enhancing quality control. Users are keen to understand how AI-driven predictive modeling can reduce the time and cost associated with discovering new stabilized zirconia formulations, and whether machine learning algorithms can minimize defects during high-temperature sintering. A significant concern is the integration of AI in managing complex global supply chains for zircon sand and ensuring traceability and quality consistency from raw material to final powder product. Expectations are high that AI will revolutionize R&D by simulating atomic-level interactions and accelerating the commercialization of novel zirconia-based composites, particularly those designed for extreme thermal environments or complex geometries achievable through additive manufacturing.

- AI optimizes synthesis protocols by determining precise temperature, pressure, and chemical ratios for consistent nanoparticle formation.

- Machine learning algorithms enhance quality control by analyzing microscopic images and spectroscopic data to detect impurities or particle size inconsistencies in real-time.

- Predictive modeling shortens R&D cycles for developing novel stabilized zirconia compositions by simulating performance metrics before physical experimentation.

- AI-driven supply chain management improves logistics, raw material inventory forecasting, and mitigates risks associated with volatile zircon sand sourcing.

- Implementation of AI in energy management optimizes the high-energy consuming steps of calcination and milling, reducing overall production costs.

DRO & Impact Forces Of Zirconium Oxide Powder Market

The Zirconium Oxide Powder Market is shaped by a powerful interplay of Drivers, Restraints, and Opportunities (DRO), collectively forming the fundamental Impact Forces determining its growth trajectory. The primary driver is the exponentially increasing global demand for high-performance ceramic materials, specifically fueled by the necessity for advanced thermal barrier coatings (TBCs) in aerospace and power generation turbines, and the rapid proliferation of solid oxide fuel cells (SOFCs) as efficient, clean energy sources. Furthermore, the expanding adoption of zirconia in the medical field, encompassing orthopedic implants and aesthetically superior dental restorative materials, provides consistent market uplift. However, significant restraints challenge market expansion, notably the high capital expenditure required for establishing advanced purification and processing facilities, and the volatility and geopolitical concentration of raw material (zircon sand) mining, leading to unpredictable supply chain economics. Opportunities primarily stem from innovation in nano-zirconia for specialized electronics and the integration of these materials into additive manufacturing (3D printing) technologies, enabling the creation of intricate, high-density ceramic parts, opening new avenues for customization and market penetration. These forces create a dynamic environment where technological superiority and supply chain resilience are key determinants of market leadership and sustained growth.

The impact forces analysis highlights that technological substitution, though currently limited due to zirconia's unique properties, poses a potential long-term constraint, particularly if lower-cost materials achieve comparable performance characteristics through advanced composite development. Conversely, the strict regulatory environment in developed regions (like the EU and North America) acts as an indirect driver, favoring high-purity, well-documented materials like medical-grade zirconia, effectively increasing the barrier to entry for lower-quality competitors. The most significant immediate impact force is the price elasticity of zircon sand, which directly affects the cost of goods sold for powder producers. Consequently, companies focused on resource efficiency and process optimization, such as developing plasma synthesis techniques that minimize waste, are better positioned to absorb these fluctuations and maintain profitability.

The long-term market dynamics suggest that the increasing push towards electric vehicles (EVs) and renewable energy systems presents dual opportunities: first, in advanced battery component protection, and second, in efficient energy conversion systems (SOFCs). The strategic imperative for market players is to diversify their product portfolio across various stabilization chemistries (e.g., Yttria, Magnesia, Ceria) to cater to diverse end-user specifications, ranging from high-toughness structural parts to highly conductive electrolyte membranes. Successfully navigating the complex intersection of high processing costs and burgeoning demand across critical national infrastructure sectors will define the competitive landscape over the next decade.

- Drivers: Growing demand for Solid Oxide Fuel Cells (SOFCs); increased adoption in biomedical applications (dental, orthopedic); robust expansion of the thermal barrier coatings (TBCs) sector in aerospace.

- Restraints: High manufacturing costs associated with ultra-high purity production; geopolitical concentration and price volatility of raw zircon sand; complexity in achieving uniform particle size distribution at commercial scale.

- Opportunity: Expansion into high-value 3D printing ceramic feedstock; development of nano-zirconia for advanced electronic components; strategic market penetration in emerging economies focusing on industrial infrastructure.

- Impact Forces: Technological innovation in stabilization techniques; stringent regulatory standards in medical and aerospace sectors; competitive threat from alternative high-performance ceramics (e.g., silicon nitride).

Segmentation Analysis

The Zirconium Oxide Powder Market is comprehensively segmented based on product type, stabilization method, application, and end-use industry, reflecting the diverse and specialized requirements of its consumers. Segmentation by product type primarily differentiates between high-purity zirconia (typically >99.9%) used in electronics and medical devices, and industrial-grade zirconia used in refractories and general ceramics. Stabilization methods are critical, as they dictate the material’s crystalline phase and subsequent physical properties, with yttria-stabilized zirconia (YSZ) dominating due to its use in structural and functional applications, followed by magnesia-stabilized and ceria-stabilized variations. Application segmentation covers crucial areas like structural ceramics, refractories, dental ceramics, and electronic components. Finally, the end-use industry segment focuses on major consuming sectors such as Automotive, Aerospace, Medical & Dental, Electronics & Electrical, and Chemicals & Petrochemicals, allowing for detailed market targeting and resource allocation based on industry-specific growth dynamics and performance criteria. This granular segmentation provides stakeholders with actionable insights into the highest-growth and highest-margin sub-markets.

- By Product Type:

- High Purity Zirconium Oxide (>99.9%)

- Industrial Grade Zirconium Oxide (99% - 99.9%)

- Nano Zirconium Oxide Powder

- By Stabilization Method:

- Yttria Stabilized Zirconia (YSZ)

- Magnesia Stabilized Zirconia (MSZ)

- Ceria Stabilized Zirconia (CSZ)

- Others (Calcium Stabilized Zirconia, etc.)

- By Application:

- Structural Ceramics (Wear parts, pump components)

- Functional Ceramics (Solid Oxide Fuel Cells, Oxygen Sensors)

- Refractories and Foundry Materials

- Abrasives and Polishing Media

- Thermal Barrier Coatings (TBCs)

- By End-Use Industry:

- Medical & Dental (Prosthetics, Implants)

- Automotive and Transportation

- Aerospace and Defense

- Electronics and Electrical

- Chemical and Petrochemical

- Energy and Environment (Fuel Cells)

Value Chain Analysis For Zirconium Oxide Powder Market

The value chain of the Zirconium Oxide Powder Market is highly intricate, starting with the upstream sourcing of raw materials, primarily zircon sand (ZrSiO4). Upstream activities involve mining, purification, and calcination of zircon sand to produce intermediate chemicals like zirconium oxychloride and subsequently, high-purity zirconia precursors. The quality and cost efficiency at this initial stage heavily dictate the final powder cost. Midstream operations focus on sophisticated powder synthesis techniques, such as chemical precipitation, hydrothermal synthesis, and plasma methods, which are crucial for achieving the desired particle size, morphology, and stabilization required by end-users. Distribution channels are twofold: direct sales to large, strategic customers like major automotive component manufacturers or ceramic fabricators, and indirect sales through specialized chemical distributors who manage inventory and supply to smaller, niche users, such as local dental laboratories or specialized R&D facilities. Downstream activities involve the fabrication of finished products, where powder is sintered or incorporated into composites by end-use manufacturers in sectors like aerospace, medical, and industrial machinery, marking the final value addition before reaching the consumer or industrial buyer.

The complexity of the value chain is heightened by the necessity for stringent quality control at every stage, particularly when producing medical or aerospace-grade zirconia. For instance, the transition from precursor chemicals to stabilized powder requires specialized, often proprietary, knowledge to ensure phase stability and eliminate trace impurities that could compromise mechanical integrity. Direct distribution channels are often preferred for high-volume, critical applications where technical support and quality traceability are paramount, enabling powder manufacturers to maintain tight control over product performance feedback loops. Indirect channels, conversely, offer better market reach and localized technical support in fragmented markets, proving essential for penetrating smaller industrial customer bases globally.

Profitability margins tend to be highest in the specialized midstream processing segment, where technological expertise in nano-powder synthesis and customization of stabilization chemistries creates significant intellectual property value. The downstream segment faces competitive pressures but benefits from the high replacement cost and long service life of zirconia-based components. Managing the upstream reliance on geographically concentrated zircon sand reserves remains the primary strategic challenge, compelling downstream players to secure long-term contracts and potentially invest in captive raw material processing capabilities to enhance supply security and cost control, thus stabilizing the entire market structure against commodity price volatility.

Zirconium Oxide Powder Market Potential Customers

Potential customers for zirconium oxide powder span a diverse range of high-technology, demanding industries that require materials capable of operating under extreme thermal, mechanical, and chemical stresses. The primary end-users include manufacturers of structural ceramics, who utilize zirconia for components like bearings, seals, cutting tools, and grinding media due to its exceptional hardness and wear resistance. A burgeoning customer base is found within the Medical and Dental sector, comprising prosthetic manufacturers, dental laboratories, and medical device companies requiring biocompatible and aesthetically pleasing materials for implants, crowns, bridges, and surgical tools. Furthermore, the Energy sector, specifically producers of Solid Oxide Fuel Cells (SOFCs) and advanced batteries, constitutes a critical customer segment, utilizing yttria-stabilized zirconia (YSZ) as the solid electrolyte material due to its high oxygen ion conductivity at elevated temperatures. The Aerospace and Automotive industries are constant consumers, procuring zirconia for high-performance thermal barrier coatings (TBCs) that protect engine components from extreme heat, thereby improving fuel efficiency and extending component lifespan. Each customer group demands tailored specifications, with the medical industry requiring ultra-high purity and traceability, while the energy sector prioritizes consistent ionic conductivity and mechanical stability.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 780 Million |

| Market Forecast in 2033 | USD 1350 Million |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Saint-Gobain ZirPro, Tosoh Corporation, Daiichi Kigenso Kagaku Kogyo Co., Ltd. (DKK), Innovnano, MEL Chemicals, KCM Corporation, Zirconia Sales (America) Inc., Solvay S.A., Orient Zirconic Ind. Sci & Tech Co., Ltd., Zircomet Ltd., Atlantic Equipment Engineers, Inc. (AEE), Showa Denko Materials Co., Ltd. (Resonac), Inframat Advanced Materials, Inc., Baikowski SAS, Reade International Corp., American Elements, H.C. Starck Solutions, CoorsTek, Inc., CeramTec GmbH, Vesuvius plc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Zirconium Oxide Powder Market Key Technology Landscape

The technological landscape of the Zirconium Oxide Powder Market is defined by the ongoing pursuit of achieving tighter control over particle morphology, size distribution, and phase purity, which directly impacts the mechanical and electrical properties of the final sintered product. Traditional methods, such as the basic chloride process, are being increasingly replaced or refined by advanced chemical synthesis routes. Key technologies include the high-purity Chemical Precipitation method, which allows for precise control over particle size, resulting in narrow size distribution powders essential for high-end biomedical and electronic applications. The Hydrothermal Synthesis route is gaining prominence for producing highly crystalline, fine powders at relatively low temperatures, reducing energy consumption and enabling better control over crystalline phase formation. Furthermore, advancements in Plasma Synthesis techniques, specifically radio-frequency (RF) plasma systems, facilitate the rapid production of ultra-fine, spherical, and non-agglomerated nano-zirconia powders, vital for advanced coatings and composite materials requiring superior packing density and sintering behavior.

Stabilization technology is central to market innovation. Yttria Stabilization remains the predominant method (producing YSZ) due to its reliability in maintaining the tetragonal phase, which imparts fracture toughness via transformation toughening. However, research is expanding into novel co-dopant systems and rare-earth element additions (such as cerium and scandium) to optimize ionic conductivity for SOFC electrolytes or enhance aging resistance in structural ceramics. The integration of advanced computational materials science, leveraging density functional theory (DFT) and machine learning, is accelerating the discovery and optimization of these stabilization chemistries, moving away from time-intensive trial-and-error experimentation. This computational approach minimizes resource usage and accelerates time-to-market for specialized zirconia formulations tailored for specific functional roles.

Moreover, the technologies related to post-synthesis processing are critical. Techniques such as spray drying, granulation, and advanced milling processes (like jet milling) are essential for converting synthesized powders into flowable, moldable, and sinterable ceramic feedstocks, particularly for complex shaping processes such as ceramic injection molding (CIM) and 3D printing (Additive Manufacturing). The successful commercialization of zirconia 3D printing feedstock relies heavily on developing highly uniform, spherical powders suitable for binder jetting and stereolithography (SLA) processes. Overall, the technological focus is shifting toward sustainable, continuous processing methods that yield high-quality, customizable powders with reduced environmental impact and superior material performance consistency, ensuring Zirconium Oxide maintains its pivotal role in advanced material engineering.

Regional Highlights

- Asia Pacific (APAC): APAC is the undisputed leader in the Zirconium Oxide Powder Market, driven by its massive manufacturing capabilities and rapid industrialization, particularly in China, Japan, South Korea, and India. China dominates both production and consumption, fueled by extensive investment in electronics (capacitors, sensors), automotive components, and the burgeoning infrastructure sector requiring high-performance refractories. Japan and South Korea lead in technological innovation, focusing on high-purity nano-zirconia for functional ceramics and advanced semiconductor processing equipment. The region benefits from lower manufacturing costs, but is increasingly pressured by environmental regulations necessitating cleaner production methods.

- North America: North America represents a mature, high-value market characterized by robust demand for specialized, highly regulated zirconia grades, particularly in the Aerospace, Defense, and Biomedical sectors. The region focuses heavily on R&D for next-generation applications, including advanced thermal barrier coatings for gas turbines and orthopedic implants. Key market drivers include stringent safety standards and high consumer willingness to pay for premium dental materials. The region relies heavily on imports for raw zircon sand but excels in advanced powder synthesis and fabrication technologies.

- Europe: Europe exhibits strong demand, driven by strict environmental regulations and high investment in clean energy technologies, particularly Solid Oxide Fuel Cells (SOFCs). Germany, France, and the UK are major consumers, utilizing zirconia extensively in automotive catalytic converters and industrial wear parts. The European market prioritizes sustainability and traceability, demanding high standards for powder composition and manufacturing process documentation. The region is a pioneer in implementing zirconia-based ceramics in luxury and high-performance automotive braking systems and industrial machinery.

- Latin America (LATAM): LATAM is an emerging market, primarily driven by expanding industrial activity, especially in mining, oil and gas, and refractories in Brazil and Mexico. The demand for zirconia is generally concentrated in industrial-grade applications, focused on durability and cost-effectiveness. Growth is steady but often linked to fluctuating commodity prices and infrastructure investment cycles. Opportunities exist in localized production facilities to cater to the growing demand for basic industrial ceramics.

- Middle East and Africa (MEA): The MEA market, especially the Gulf Cooperation Council (GCC) countries, shows increasing consumption of zirconia powder, predominantly in the petrochemical and power generation sectors for high-temperature refractory linings and thermal barrier coatings. Infrastructure projects and growing healthcare expenditure are gradually increasing the demand for high-end dental and medical zirconia. Market expansion is dependent on diversification strategies away from oil dependence, fostering local manufacturing capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Zirconium Oxide Powder Market.- Saint-Gobain ZirPro

- Tosoh Corporation

- Daiichi Kigenso Kagaku Kogyo Co., Ltd. (DKK)

- Innovnano

- MEL Chemicals

- KCM Corporation

- Zirconia Sales (America) Inc.

- Solvay S.A.

- Orient Zirconic Ind. Sci & Tech Co., Ltd.

- Zircomet Ltd.

- Atlantic Equipment Engineers, Inc. (AEE)

- Showa Denko Materials Co., Ltd. (Resonac)

- Inframat Advanced Materials, Inc.

- Baikowski SAS

- Reade International Corp.

- American Elements

- H.C. Starck Solutions

- CoorsTek, Inc.

- CeramTec GmbH

- Vesuvius plc

Frequently Asked Questions

Analyze common user questions about the Zirconium Oxide Powder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for Yttria Stabilized Zirconia (YSZ) in the current market?

The primary driver for YSZ demand is its critical role as the solid electrolyte material in high-efficiency Solid Oxide Fuel Cells (SOFCs) and its use in advanced oxygen sensors, benefiting from its superior ionic conductivity and phase stability at high temperatures, which supports the global shift toward clean energy solutions.

How does the volatility of zircon sand supply impact the profitability of zirconium oxide powder manufacturers?

Zircon sand is the essential raw material for ZrO2 production, and its supply is geographically concentrated, leading to high price volatility. This directly increases the cost of goods sold for powder manufacturers, often compressing operating margins unless supply chain resilience is secured through long-term contracts or vertical integration strategies.

In which end-use application is nano-zirconium oxide powder experiencing the fastest adoption rate?

Nano-zirconium oxide powder is seeing the fastest adoption in advanced biomedical applications, particularly in dental restorative materials and orthopedic implants, due to its enhanced mechanical properties, high density, improved aesthetics, and reduced grain size which prevents low-temperature degradation (LTD).

What are the major technological advancements shaping the Zirconium Oxide powder synthesis landscape?

Key technological advancements include the transition toward continuous synthesis methods like Hydrothermal and Plasma synthesis for better control over particle morphology and size distribution. Furthermore, the use of co-dopants (like ceria or scandia) and AI-driven computational modeling is accelerating the development of highly specialized, functional zirconia grades.

Which region holds the highest market share for Zirconium Oxide Powder and why?

Asia Pacific (APAC) holds the largest market share, primarily driven by China's dominant position in global manufacturing across the electronics, automotive, and industrial ceramics sectors, coupled with significant governmental and private investment in advanced material processing capabilities throughout the region.

The comprehensive analysis of the Zirconium Oxide Powder Market underscores its robust potential, intrinsically tied to global technological progression and the increasing need for high-performance, durable materials in critical infrastructure and high-tech industries. The ongoing push for energy efficiency, decarbonization, and advancements in medical technologies provides a perpetual catalyst for market growth. While supply chain vulnerability remains a challenge, strategic innovation in synthesis methods and product diversification across specialized applications ensures the long-term viability and expansion of the market. Detailed examination of the value chain reveals that control over raw material sourcing and proprietary stabilization technology are crucial competitive advantages for market leaders aiming to meet the exacting standards of the aerospace and biomedical sectors. The future landscape will be heavily influenced by the integration of digital technologies, such as AI, to optimize production and accelerate the development of next-generation zirconia formulations suitable for additive manufacturing and extreme environmental conditions, further cementing Zirconium Oxide's status as a critical material of the 21st century.

Furthermore, the competitive dynamic is shifting towards those players capable of offering vertically integrated solutions, from precursor chemical production to customized powder delivery, allowing them to better manage quality control and cost structures. The regional growth disparities reflect different adoption phases, with APAC focusing on volume and industrial scale, while North America and Europe prioritize specialized, high-margin, regulatory-compliant grades. The continued market evolution will necessitate substantial investment in sustainable processing technologies to comply with increasingly stringent global environmental standards, particularly those affecting the high-energy demanding steps of powder manufacturing, thereby differentiating innovative market leaders from traditional producers. This report provides a foundational framework for strategic decision-making in navigating the complexities and capturing the opportunities within this dynamic and essential materials market.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager