Aqua Ammonia Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434005 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Aqua Ammonia Market Size

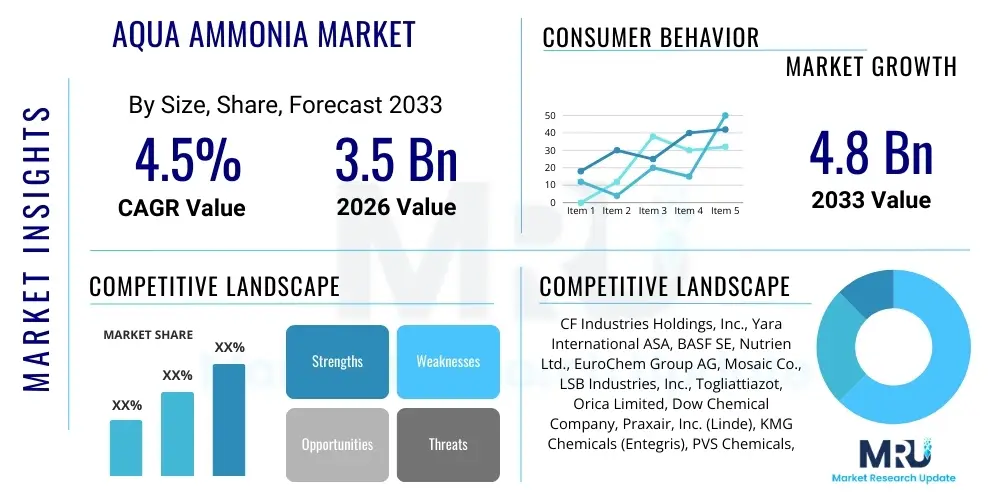

The Aqua Ammonia Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 4.8 Billion by the end of the forecast period in 2033.

Aqua Ammonia Market introduction

The Aqua Ammonia Market, encompassing the aqueous solution of ammonia (NH3), represents a vital segment within the global chemical and industrial landscape. Also known as ammonia solution, ammonia water, ammoniacal liquor, or liquid ammonia, this colorless liquid possesses a pungent odor and finds extensive application across various industries due to its efficacy as a chemical reagent, neutralizing agent, and nitrogen source. The inherent properties of aqua ammonia, particularly its ability to readily release ammonia gas upon heating and its effectiveness as a pH modifier, solidify its position in manufacturing processes ranging from pharmaceuticals to environmental protection. Market dynamics are strongly influenced by the stability of upstream natural gas prices, which directly impact ammonia production costs, and the increasing global demand for nitrogenous fertilizers and industrial cleaners.

The product is fundamentally utilized in several core industrial applications. In agriculture, it serves as an essential source of nitrogen for fertilizers, contributing significantly to crop yield enhancement, especially in regions with high agricultural output. Beyond agriculture, aqua ammonia is critical in environmental compliance, particularly in flue gas denitrification processes (Selective Catalytic Reduction, SCR, and Selective Non-Catalytic Reduction, SNCR) utilized to minimize nitrogen oxide (NOx) emissions from large industrial sources and power plants. Its use as a laboratory reagent and in specialized manufacturing processes, such as the production of pharmaceuticals, rubber, and explosives, provides diversified revenue streams, insulating the market from reliance on any single end-user sector. The increasing stringency of environmental regulations worldwide is acting as a major tailwind for the segment focused on NOx reduction.

Key driving factors propelling market expansion include the sustained growth of the global population, leading to increased demand for food and consequently greater usage of nitrogen fertilizers. Furthermore, the robust expansion of the refrigeration sector, particularly in commercial and industrial cold storage facilities where ammonia serves as an efficient refrigerant, contributes substantially to market volume. The benefits of utilizing aqua ammonia over anhydrous ammonia in certain applications, such as enhanced safety in handling and transportation due to lower vapor pressure, are accelerating its adoption. Conversely, the market must navigate regulatory complexities surrounding hazardous chemical handling and fluctuating feedstock costs, presenting both opportunities for process optimization and constraints on price stability.

Aqua Ammonia Market Executive Summary

The Aqua Ammonia Market is exhibiting steady expansion, primarily driven by robust demand from the agricultural and environmental sectors, positioning it as a mature yet growth-oriented chemical commodity market. Current business trends indicate a strong emphasis on supply chain resilience, particularly in the sourcing of natural gas feedstock, and the development of centralized storage facilities to minimize logistical costs and potential supply disruptions. Strategic investments are being observed in high-purity aqua ammonia production suitable for electronic applications and pharmaceutical synthesis, signaling a shift toward value-added specialized products alongside the traditional bulk commodity market. Furthermore, market players are actively exploring sustainable production methods, including green ammonia synthesis, to align with global decarbonization goals, although conventional production methods derived from fossil fuels still dominate the landscape.

Geographically, market growth is bifurcated, with Asia Pacific (APAC) maintaining dominance in terms of volume consumption, chiefly due to the expansive agricultural base and rapid industrialization in countries like China and India, which necessitate large volumes for fertilizer and environmental control purposes. North America and Europe, while representing slower volume growth, are focusing heavily on sophisticated environmental applications, such as large-scale SCR/SNCR deployment in power generation and industrial facilities, driving demand for high-concentration solutions. Regional trends also highlight evolving regulatory standards; Europe, for instance, emphasizes stricter emission limits, directly translating into greater demand for ammonia solutions in NOx abatement technologies, thereby maintaining premium pricing and technological advancements in the region.

Segmentation analysis underscores the dominance of the Industrial Grade segment by volume, fueled by its application across various manufacturing processes and water treatment. However, the Reagent Grade and Specialized Grade segments are anticipated to witness the highest Compound Annual Growth Rate (CAGR), reflecting the growing precision requirements in sectors like life sciences and semiconductor manufacturing, where impurities must be strictly controlled. The application segment remains heavily weighted towards agriculture and fertilizer production, but the chemical processing and NOx abatement segments are projected to gain market share due to global industrial expansion and increasingly stringent environmental mandates. These segment trends confirm a market characterized by high volume, low-margin bulk sales juxtaposed against lower volume, high-margin specialty sales, demanding diversified corporate strategies from key players.

AI Impact Analysis on Aqua Ammonia Market

User queries regarding the impact of Artificial Intelligence (AI) on the Aqua Ammonia Market primarily revolve around optimizing production efficiency, enhancing safety protocols, and predicting supply chain disruptions. Common concerns center on how AI and advanced data analytics can rationalize complex chemical manufacturing processes, which involve exothermic reactions and precise temperature and pressure controls. Users are keenly interested in whether predictive maintenance powered by AI can reduce unexpected downtime in ammonia synthesis plants and minimize the energy intensity inherent in production. Furthermore, there is significant exploration into AI's role in optimizing the logistics and storage of this hazardous material, improving routing and inventory management to reduce environmental and safety risks during transportation and handling. The overarching user expectation is that AI integration will lead to substantial cost reductions, improved product consistency, and a significant leap forward in operational safety within the traditionally conservative chemical industry.

The implementation of AI and Machine Learning (ML) algorithms is set to revolutionize key operational aspects of the Aqua Ammonia value chain, moving beyond traditional automation into predictive and self-optimizing systems. Specifically, AI-driven process modeling allows manufacturers to simulate complex reaction kinetics and optimize parameters for maximum yield while minimizing energy consumption, particularly crucial given the high energy demands of producing base ammonia. Furthermore, AI systems are being deployed to analyze sensor data from storage tanks and transportation units, providing real-time risk assessments concerning leaks, temperature fluctuations, or unauthorized access, thereby significantly enhancing compliance with safety and environmental regulations. This integration of digital technology positions the market for increased capital expenditure efficiency and improved reliability in the coming decade.

- AI-Powered Process Optimization: Utilizing machine learning for real-time adjustments of temperature, pressure, and catalyst ratios in ammonia synthesis to maximize yield and reduce energy consumption per metric ton.

- Predictive Maintenance: Deployment of AI algorithms to analyze equipment performance data, forecasting potential failures in compressors, pumps, and reactors, thereby minimizing costly unplanned downtime.

- Supply Chain and Logistics Optimization: ML models improving routing efficiency for transportation of aqua ammonia, optimizing inventory levels across distribution centers, and mitigating risks associated with volatile feedstock prices.

- Enhanced Safety Monitoring: AI-enabled video and sensor analytics providing early detection of leaks or anomalous operational behavior in storage facilities, leading to faster incident response times.

- Quality Control Automation: Application of computer vision and analytical tools for high-speed, accurate quality control testing, ensuring product purity standards are met for specialized applications.

DRO & Impact Forces Of Aqua Ammonia Market

The Aqua Ammonia Market is fundamentally shaped by a complex interplay of drivers, restraints, opportunities, and external impact forces that dictate its growth trajectory and competitive landscape. Primary market drivers include the pervasive global need for food security, which mandates increased application of nitrogen fertilizers derived from ammonia, coupled with increasingly strict governmental regulations worldwide targeting industrial NOx emissions, particularly from power generation and cement manufacturing. These factors provide a stable, long-term demand foundation. However, the market faces significant restraints, chiefly stemming from the volatility of natural gas prices—the primary feedstock—and the substantial capital investment required for establishing or expanding ammonia production facilities. Additionally, the corrosive and hazardous nature of aqua ammonia necessitates stringent handling and transportation protocols, adding to operational complexities and costs.

Opportunities within the market are predominantly centered on technological advancements and sustainability pivots. The transition towards green ammonia (produced using renewable energy) presents a considerable long-term opportunity, addressing both environmental concerns and potentially diversifying feedstock dependence away from natural gas. Furthermore, the burgeoning demand for high-purity aqua ammonia in specialized applications, such as high-grade reagents for semiconductor manufacturing and advanced pharmaceuticals, offers premium pricing and margin expansion for producers capable of meeting stringent quality specifications. These specialty applications, while smaller in volume, represent strategic growth areas less susceptible to commodity price cycles than the bulk fertilizer market. Focused investment in these niche areas allows companies to diversify their product portfolio and enhance overall market resilience.

Impact forces currently shaping the competitive environment include geopolitical instability affecting natural gas supply chains, the accelerating pace of energy transition policies globally, and the growing public scrutiny regarding industrial carbon footprints. The push for decarbonization is the most significant exogenous force, driving research into catalytic improvements and hydrogen integration into ammonia synthesis. Furthermore, the competitive intensity is moderated by high barriers to entry due to massive capital requirements and regulatory hurdles, concentrating market share among established global chemical manufacturers. The balance between necessary scale for cost efficiency and the flexibility to adapt to rapid technological shifts defines the success of key market players, making operational efficiency and strategic hedging against energy price fluctuations paramount to maintaining profitability.

Segmentation Analysis

The Aqua Ammonia Market is comprehensively segmented based on its Purity/Grade, End-Use Application, and Concentration Level, reflecting the diverse requirements of various industrial consumers. Analyzing these segments provides critical insights into market dynamics, price sensitivity, and growth potential across different end-user sectors. Purity levels, ranging from Industrial Grade to high-specification Reagent Grade, dictate the product's applicability and pricing structure, with higher purity products commanding a significant premium due to the rigorous purification processes involved and their use in sensitive manufacturing environments like electronics and pharmaceuticals. The segmentation is crucial for producers aiming to tailor production capabilities and marketing strategies to address specific industry needs effectively, optimizing capacity utilization across bulk commodity and specialty product lines.

The Application segment remains the largest and most influential in terms of volume. Agriculture and Fertilizer production continue to dominate consumption, utilizing aqua ammonia primarily for direct soil application or as an intermediate in producing complex fertilizers. However, segments such as NOx abatement (SCR/SNCR) and chemical processing are projected to demonstrate superior growth rates over the forecast period, fueled by global industrialization and increasingly enforced environmental standards. This segmentation divergence highlights a strategic imperative for market players: balancing the stability of the high-volume agricultural market with the dynamic, high-growth potential of the environmental compliance sector, requiring robust R&D investments in delivery and handling systems suited for power plants and large industrial emitters.

Concentration segmentation further details market preferences, typically ranging from 10% to 30% NH3 by weight. The 29% concentration is particularly prevalent in industrial cleaning, reagents, and some environmental applications due to its efficient balance of ammonia content and handling safety. The segmentation by concentration also heavily influences logistics and storage requirements, as lower concentrations are generally safer to transport but require greater volumes to deliver the equivalent amount of active nitrogen. Understanding these nuanced segmentation dynamics allows companies to structure their global distribution networks optimally, minimizing logistical costs while adhering to strict regional regulations governing the transport of hazardous liquids, ensuring product accessibility across diverse geographical markets.

- By Purity/Grade:

- Industrial Grade (High volume, general chemical processes, and bulk fertilizer use)

- Reagent Grade (Laboratory use, specialized synthesis, moderate purity requirements)

- Electronic Grade (High purity, critical for semiconductor and flat panel display manufacturing)

- Pharmaceutical Grade (Highest purity, used in drug synthesis and medical preparations)

- By Application:

- Agriculture and Fertilizer Production (Direct application and intermediate production)

- NOx Abatement (Selective Catalytic Reduction (SCR) and Selective Non-Catalytic Reduction (SNCR))

- Chemical Manufacturing and Processing (As a neutralizing agent, solvent, and chemical intermediate)

- Industrial Cleaning Agents (For cleaning heavy machinery and specialized equipment)

- Water Treatment (pH adjustment and disinfection)

- Refrigeration and HVAC (Absorption refrigeration systems)

- Pharmaceuticals and Healthcare

- Pulp and Paper Industry

- By Concentration:

- Below 20% Concentration

- 20% to 29% Concentration

- Above 29% Concentration

- By Distribution Channel:

- Direct Sales (Large industrial contracts)

- Distributors and Third-Party Logistics Providers

Value Chain Analysis For Aqua Ammonia Market

The value chain for the Aqua Ammonia Market is a sequential process starting with upstream raw material sourcing, moving through high-capital manufacturing, and concluding with complex downstream distribution to diverse end-user sectors. The upstream segment is dominated by the production of anhydrous ammonia, which relies heavily on natural gas (primarily via the Haber-Bosch process) or, increasingly, coal or renewable hydrogen as feedstock. Thus, the pricing and stability of the aqua ammonia market are intrinsically linked to global energy market volatility and the geopolitical environment impacting natural gas supply. Key upstream activities involve securing long-term feedstock contracts and managing the energy-intensive process of ammonia synthesis, where efficiency improvements and carbon capture technologies represent significant competitive differentiators. Strategic vertical integration into feedstock production provides substantial cost advantages to major players.

The core manufacturing stage involves dissolving the anhydrous ammonia gas into demineralized water to achieve the required concentration and purity levels. This stage demands stringent quality control, especially for high-purity grades like Electronic or Pharmaceutical grades, where contaminant removal is paramount. Producers must utilize specialized equipment, including corrosion-resistant reactors and purification systems, to ensure the final product adheres to customer specifications. Midstream activities also encompass large-scale storage, where robust infrastructure is necessary to safely contain the corrosive liquid before final packaging or bulk transfer. Operational excellence in this stage is critical for maintaining margins, as minor deviations in production costs or storage efficiency can significantly impact profitability given the commodity nature of the industrial grade product.

Downstream activities include packaging, distribution, and direct and indirect sales channels. Due to the hazardous classification of aqua ammonia, transportation—whether by rail car, tanker truck, or barge—is heavily regulated and requires specialized logistics expertise. Direct distribution typically serves large industrial consumers, such as major fertilizer blenders or power plants requiring bulk deliveries, facilitating customized supply agreements and tighter inventory control. Indirect distribution relies on regional distributors and chemical wholesalers who handle smaller volumes and provide last-mile delivery to diverse end-users, including small farms, municipal water treatment facilities, and specialty chemical manufacturers. This dual-channel approach ensures market penetration across all scale levels, with distribution efficiency being a core determinant of regional competitiveness.

Aqua Ammonia Market Potential Customers

The potential customer base for the Aqua Ammonia Market is exceptionally broad, spanning core industrial sectors and niche high-value applications, fundamentally driven by the need for a reliable, reactive source of nitrogen or a pH-modifying agent. The largest volume consumers remain the agricultural sector, specifically commercial farming enterprises and large-scale fertilizer blending operations that utilize the product as a direct nitrogen source to enhance crop yield, particularly for staple crops like corn, wheat, and rice. The stability of demand from this sector is high, linked closely to planting seasons and global food consumption trends. Strategic engagement with major agricultural cooperatives and fertilizer manufacturers is essential for securing consistent, high-volume orders, forming the financial backbone of the market.

Another rapidly expanding segment of high-potential customers includes thermal power generation facilities, cement manufacturers, glass furnaces, and large refineries that operate under strict air quality standards mandated by environmental regulatory bodies such as the EPA or European Environment Agency. These entities are mandated to utilize NOx abatement technologies, primarily SCR and SNCR, making them captive users of aqua ammonia or urea solution derivatives. The sustained need for compliance ensures stable and growing demand, particularly in industrialized regions where capacity expansion or modernization is occurring. For producers, establishing long-term service contracts, which include not only supply but also storage consultation and dosage optimization, strengthens customer relationships in this demanding sector.

Beyond these high-volume users, emerging high-value customers include companies operating in the electronics and life sciences industries. Semiconductor manufacturers require ultra-high purity aqua ammonia as a cleaning agent in microchip fabrication processes, where even trace impurities can render batches useless. Pharmaceutical companies use high-grade solutions as a chemical precursor or pH regulator in complex drug synthesis. These specialized customers represent premium markets characterized by rigorous quality auditing, long qualification cycles, and low tolerance for supply interruption, but offering significantly higher profit margins compared to industrial grade products. Targeting these segments requires specialized production facilities and dedicated technical sales support focused on stringent quality assurance protocols.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 4.8 Billion |

| Growth Rate | 4.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | CF Industries Holdings, Inc., Yara International ASA, BASF SE, Nutrien Ltd., EuroChem Group AG, Mosaic Co., LSB Industries, Inc., Togliattiazot, Orica Limited, Dow Chemical Company, Praxair, Inc. (Linde), KMG Chemicals (Entegris), PVS Chemicals, Inc., Shandong Hualu-Hengsheng Chemical Co., Ltd., Koch Industries, Inc., Sichuan Lutianhua Co., Ltd., Jiangsu Huachang Chemical Co., Ltd., China Petroleum & Chemical Corporation (Sinopec), Qatar Fertiliser Company (QAFCO). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aqua Ammonia Market Key Technology Landscape

The underlying technology landscape for the Aqua Ammonia Market is primarily defined by advancements in ammonia synthesis processes and subsequent purification and handling technologies. The foundational Haber-Bosch process remains the dominant method for producing the anhydrous ammonia precursor, but current technological innovation is focusing heavily on enhancing its efficiency through improved catalysts (e.g., ruthenium-based catalysts) and optimization of high-pressure/high-temperature reactor designs to minimize energy consumption, crucial for reducing operational costs and the carbon footprint. Furthermore, the industry is witnessing significant R&D in carbon capture and storage (CCS) integration within existing large-scale ammonia plants, allowing conventional production facilities to mitigate environmental impact while awaiting the full commercialization of greener alternatives. These incremental technological improvements aim to maintain the cost competitiveness of the commodity product.

A major disruptive force in the technology landscape is the emergence and scaling of sustainable ammonia production methods, often categorized as Green Ammonia (produced via electrolysis powered by renewable energy) and Blue Ammonia (produced with fossil fuels but incorporating substantial carbon capture). While still in nascent stages of commercial viability for bulk applications, these technologies are rapidly advancing, driven by international climate targets and increasing corporate commitments to Net Zero emissions. The technological shift involves significant investment in specialized electrolyzers and hydrogen generation infrastructure, fundamentally altering the upstream supply chain. Successful deployment of these technologies will not only change the feedstock dependency but also potentially qualify aqua ammonia derived from these sources for premium environmental certifications, opening new market opportunities in sustainability-conscious regions.

In the mid-to-downstream segment, technological advancements focus heavily on safety, purity, and delivery systems. For high-purity grades required by the electronics industry, technologies like advanced membrane filtration, ultra-purification systems, and continuous online monitoring are essential to ensure ppb (parts per billion) level control of contaminants like metals and particulate matter. Furthermore, sophisticated telemetry and sensor integration in transportation and storage tanks are now standard practice, leveraging the Internet of Things (IoT) to provide real-time data on temperature, pressure, and structural integrity. This focus on digital monitoring and safety infrastructure is critical for managing the regulatory risks associated with transporting and storing high concentrations of corrosive and toxic ammonia solutions, enhancing overall supply chain integrity and operational reliability.

Regional Highlights

- Asia Pacific (APAC)

- North America

- Europe

- Latin America (LATAM)

- Middle East and Africa (MEA)

The Asia Pacific region currently holds the largest market share in terms of volume and is anticipated to maintain the highest growth trajectory throughout the forecast period. This dominance is intrinsically linked to the immense agricultural requirements of countries like China, India, and Indonesia, which necessitate massive quantities of nitrogenous fertilizers to support large populations and intensive farming practices. The rapid industrialization and expansion of the power generation and manufacturing sectors in these nations further drive demand for aqua ammonia in environmental applications, primarily for compliance with increasingly stringent regional NOx emission standards. Significant government initiatives supporting infrastructure development and domestic food security programs continue to spur demand. Furthermore, APAC is a hub for global semiconductor manufacturing, driving a strong and rapidly expanding requirement for ultra-high purity Electronic Grade aqua ammonia, making it a critical strategic region for both bulk and specialty chemical producers. Investment in large-scale production facilities in coastal areas to facilitate both regional consumption and international export is a common trend.

North America represents a mature market characterized by high consumption in both agriculture and a robust industrial sector, particularly in the United States and Canada. Demand is stable, supported by large-scale mechanized farming operations and significant deployment of NOx abatement technologies across the vast network of gas-fired power plants, refineries, and industrial boilers. The market here is less driven by rapid volume growth and more by technological sophistication and safety standards. There is a strong emphasis on integrating advanced logistics and storage solutions to minimize risks associated with handling the product. Moreover, North America is a pioneer in the early adoption of blue and green ammonia projects, driven by abundant natural gas resources (for blue ammonia) and significant renewable energy infrastructure (for green ammonia), positioning the region to lead the technological shift towards sustainable ammonia production in the medium term. Regulatory certainty and high environmental compliance levels ensure continued demand from the industrial and power sectors.

The European market is distinguished by its leadership in environmental regulations and a strong focus on industrial decarbonization. Demand is predominantly driven by the pervasive application of SCR and SNCR technologies required to meet the European Union’s strict emission ceilings for nitrogen oxides. While agricultural demand is present, consumption is heavily moderated by the Common Agricultural Policy (CAP) and restrictions on excessive fertilizer use. The market is increasingly shifting towards higher-value, specialized applications and is highly sensitive to sustainability credentials. European producers are heavily invested in transitioning production towards green ammonia, often leveraging Nordic hydropower and wind assets. High energy costs and geopolitical risks related to natural gas supply pose structural challenges, leading to higher market pricing compared to other regions, but also incentivizing innovation in supply efficiency and sustainable sourcing. The focus is on quality, reliability, and low-carbon sourcing.

The Latin American market is exhibiting significant growth, primarily fueled by the expansion of large-scale commercial agriculture, particularly in Brazil and Argentina, which are major global exporters of soybeans, corn, and other commodities. The need for fertilizer inputs is rapidly increasing, driving bulk demand for aqua ammonia. While industrial and environmental application growth lags behind North America and Europe, investment in industrial infrastructure and power generation capacity is gradually increasing the demand for NOx abatement solutions. Key market challenges include fragmented logistics infrastructure and reliance on imports for base ammonia in several countries, presenting opportunities for local or regional production capacity expansion to secure stable supply chains and reduce reliance on international commodity pricing and shipping costs.

The MEA region presents a dual market scenario. The Middle East, benefiting from abundant, low-cost natural gas reserves, is a primary global hub for base ammonia production and export, positioning it as a critical upstream supplier to global markets. Local consumption is moderate but growing, driven by specialized applications in petrochemicals and industrial development projects. Africa, conversely, is characterized by rapidly developing agricultural sectors and increasing efforts to modernize farming techniques, leading to emerging demand for nitrogen fertilizers. The growth in Africa is heavily reliant on foreign direct investment in infrastructure and agricultural technology transfer. The future regional landscape is heavily skewed towards the Middle East leveraging its cheap energy to dominate green and blue ammonia exports due to the capacity for large-scale, low-carbon production.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aqua Ammonia Market.- CF Industries Holdings, Inc.

- Yara International ASA

- BASF SE

- Nutrien Ltd.

- EuroChem Group AG

- Mosaic Co.

- LSB Industries, Inc.

- Togliattiazot

- Orica Limited

- Dow Chemical Company

- Linde plc (formerly Praxair, Inc.)

- Entegris (formerly KMG Chemicals)

- PVS Chemicals, Inc.

- Shandong Hualu-Hengsheng Chemical Co., Ltd.

- Koch Industries, Inc.

- Sichuan Lutianhua Co., Ltd.

- Jiangsu Huachang Chemical Co., Ltd.

- China Petroleum & Chemical Corporation (Sinopec)

- Qatar Fertiliser Company (QAFCO)

- Mitsubishi Chemical Corporation

Frequently Asked Questions

Analyze common user questions about the Aqua Ammonia market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary safety considerations when handling and storing Aqua Ammonia?

Aqua Ammonia is corrosive and releases ammonia gas, necessitating strict safety protocols including specialized, corrosion-resistant storage tanks, adequate ventilation, and mandatory use of personal protective equipment (PPE) such as respirators and chemical-resistant clothing. Transport must adhere to stringent regulations covering hazardous materials, particularly regarding tank integrity and emergency response plans to mitigate risks associated with leaks and inhalation hazards.

How does the volatile price of natural gas influence the cost of Aqua Ammonia?

Natural gas is the primary feedstock for producing anhydrous ammonia via the Haber-Bosch process, which is the precursor for aqua ammonia. As such, natural gas prices directly correlate with production costs. Significant volatility in natural gas markets, often triggered by geopolitical events or supply chain disruptions, results in corresponding fluctuations in the final price of aqua ammonia, heavily impacting the profitability of producers who lack vertical integration or long-term hedging strategies.

Which end-use application is currently driving the highest growth rate for the Aqua Ammonia Market?

The highest growth rate is observed in the NOx Abatement segment, particularly through its use in Selective Catalytic Reduction (SCR) and Selective Non-Catalytic Reduction (SNCR) systems. This growth is driven by the global trend of increasing governmental enforcement of stricter air quality regulations aimed at reducing nitrogen oxide emissions from industrial boilers, power plants, and marine vessels.

What is the difference between Industrial Grade and Electronic Grade Aqua Ammonia, and why is the latter more expensive?

Industrial Grade is used for bulk applications like fertilizer and chemical processes, tolerating higher impurity levels. Electronic Grade requires ultra-high purity, with stringent limits (often parts per billion) on metal ions and particulates, necessary for cleaning wafers in semiconductor manufacturing. The higher cost stems from the complex, multi-stage purification technologies, specialized cleanroom handling, and rigorous quality assurance testing required to meet these extreme purity specifications.

Are Green Ammonia technologies expected to replace traditional Aqua Ammonia production methods within the forecast period?

While Green Ammonia (produced using renewable energy) represents a significant long-term opportunity and strategic goal for the industry, it is unlikely to fully replace conventional production within the 2026-2033 forecast period due to existing cost disparities and the immense capital required to scale up renewable hydrogen infrastructure. However, Green Ammonia will gain traction in specialty and premium markets driven by corporate sustainability mandates, coexisting with optimized conventional production.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Electronic Grade Aqua Ammonia Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Industrial Grade Aqua Ammonia Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Aqua Ammonia Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Industrial Grade Aqua Ammonia, Electronic Grade Aqua Ammonia, Pharma Grade Aqua Ammonia), By Application (Agriculture Industry, Rubber Industry, Leather Industry, Pharmaceutical Industry, Pulp and Paper Industry, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager