Copper Powder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433938 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Copper Powder Market Size

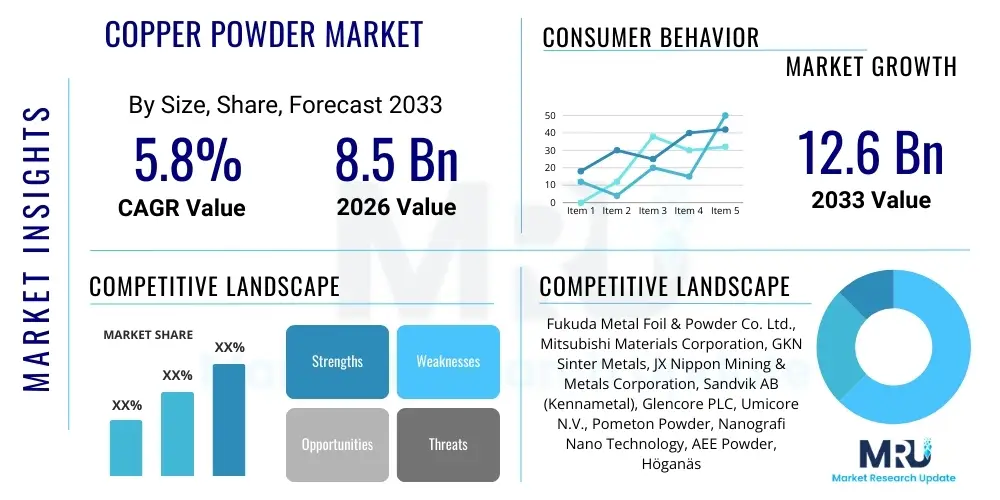

The Copper Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 8.5 Billion in 2026 and is projected to reach USD 12.6 Billion by the end of the forecast period in 2033.

Copper Powder Market introduction

The Copper Powder Market encompasses the production and distribution of fine particulate forms of copper, utilized extensively across high-growth industrial sectors due to copper’s excellent electrical conductivity, thermal properties, and corrosion resistance. Copper powders are manufactured through various methods, including atomization (water or gas), electrolysis, and chemical reduction, resulting in particles with distinct morphologies such as dendritic, spherical, or flaky, tailored for specific end-use requirements. This variety in particle structure allows copper powder to be deployed in applications demanding high precision and performance.

Major applications of copper powder include metallurgy (sintered parts, friction materials), electrical and electronic components (conductive inks, thermal management solutions, multilayer ceramic capacitors—MLCCs), chemical processes (catalysts), and increasingly, additive manufacturing (3D printing). The versatility of copper powder enables its integration into complex manufacturing processes where bulk copper cannot be utilized effectively. Its superior conductivity makes it indispensable in advanced electronics and electric vehicle (EV) battery systems, driving consistent demand growth.

The market expansion is fundamentally driven by the rapid global proliferation of electronics, the transition toward electrified transport, and technological advancements in powder metallurgy and additive manufacturing (AM). Key benefits include improved material efficiency, enabling the creation of intricate shapes with minimal waste, and superior performance characteristics in thermal and electrical applications. However, market dynamics are often influenced by the volatility of raw copper commodity prices and stringent environmental regulations governing production processes.

Copper Powder Market Executive Summary

The Copper Powder Market is characterized by robust growth stemming from the technological convergence of advanced manufacturing techniques and the increasing global focus on energy efficiency. Business trends highlight strategic capacity expansions, particularly in Asia Pacific, driven by the regional dominance in electronics manufacturing and electric vehicle production. Key industry players are concentrating on developing ultra-fine and nano-sized copper powders specifically optimized for conductive pastes and high-resolution 3D printing applications, thereby capturing high-value segments. The market structure remains moderately fragmented, with intensive R&D investments focused on improving powder consistency, purity, and flowability, which are critical parameters for modern industrial applications.

Regional trends indicate that Asia Pacific (APAC) holds the largest market share, largely due to massive infrastructure development, burgeoning consumer electronics production hubs in China and South Korea, and significant governmental push toward renewable energy technologies requiring copper components. North America and Europe are significant contributors, distinguished by high adoption rates of additive manufacturing technologies and demanding automotive industry standards. These regions are prioritizing electrolytic and atomized powders for electric motor components and advanced heat sinks, driving premium pricing for high-quality powders.

Segmentation trends show that the atomization method is the dominant production technology due to its cost-effectiveness and scalability in producing spherical powders ideal for 3D printing and advanced powder metallurgy. Application-wise, the electrical and electronics segment dominates, closely followed by the automotive sector, spurred by the mandatory inclusion of conductive components in EV infrastructure. Looking forward, the spherical copper powder sub-segment is expected to exhibit the fastest growth, underpinned by the accelerating adoption of laser powder bed fusion (L-PBF) and related additive manufacturing processes requiring high-density, free-flowing materials.

AI Impact Analysis on Copper Powder Market

Common user inquiries regarding the impact of Artificial Intelligence (AI) on the Copper Powder Market often revolve around operational efficiency, product quality prediction, and supply chain optimization. Users are keen to understand how machine learning models can optimize complex manufacturing processes, such as gas atomization, to reduce defects and energy consumption, leading to a more consistent output morphology and particle size distribution. Additionally, there is significant interest in how predictive analytics can manage the notorious volatility of raw copper pricing and mitigate supply chain risks, which are crucial factors affecting profitability in this market. The consensus suggests that AI is viewed primarily as a tool for enhancing precision metallurgy and securing procurement.

AI is transforming copper powder production by enabling sophisticated process control systems. Machine learning algorithms analyze real-time data collected from sensors within atomization chambers or electrolytic cells, adjusting parameters like temperature, flow rate, and gas pressure instantaneously. This level of fine-tuning is impossible manually, allowing producers to achieve tighter control over particle size, sphericity, and distribution width—attributes critical for high-performance applications like thermal management and specialized conductive inks. The adoption of AI-driven defect detection systems further minimizes waste, ensuring that only powders meeting rigorous quality standards proceed to packaging.

Furthermore, the integration of AI extends beyond the factory floor into market forecasting and material science R&D. Generative AI models are being used to simulate alloy compositions and predict their resulting powder properties, drastically shortening the development cycle for new copper-based materials designed for extreme conditions or novel applications. In market strategy, AI algorithms process massive datasets of geopolitical risk, commodity exchange rates, and end-user demand fluctuations, providing manufacturers with highly accurate projections necessary for strategic inventory management and proactive pricing adjustments, thereby stabilizing profitability margins against volatile input costs.

- AI optimizes atomization parameters (temperature, pressure) for precise particle size control.

- Machine learning improves yield rates by predicting and mitigating manufacturing defects in real-time.

- Predictive analytics enhances supply chain resilience against volatile raw copper commodity prices.

- AI-driven simulation accelerates the R&D of novel copper alloy powders for additive manufacturing.

- Automated vision systems utilize AI for faster and more accurate quality control checks (morphology, purity).

DRO & Impact Forces Of Copper Powder Market

The Copper Powder Market is propelled by significant macroeconomic drivers, primarily the global push towards electrification and digital transformation, countered by substantial constraints related to material costs and environmental regulatory burdens. Opportunities lie in the rapidly expanding fields of additive manufacturing and sustainable technology components, which demand high-purity, specialized powders. The critical impact forces include both the immediate demand elasticity driven by raw material price volatility and the long-term technological substitution risk posed by competing materials like aluminum or silver in specific conductive applications.

Major market drivers include the explosive demand from the automotive industry for electric vehicle components (motors, thermal interfaces, brake pads) and the continuous miniaturization of electronic devices, necessitating ultra-fine conductive inks and pastes. Furthermore, the expansion of green energy infrastructure, particularly solar panel busbars and specialized components for energy storage systems, generates consistent demand. Conversely, the high capital expenditure required for establishing advanced atomization or electrolytic production facilities acts as a significant restraint, limiting market entry for smaller players. The most pronounced constraint remains the fluctuating price of copper on the London Metal Exchange (LME), directly affecting the profitability and stability of manufacturers.

Opportunities are abundant in developing next-generation nano-copper powders for biomedical sensors, advanced catalysts, and highly efficient heat dissipation solutions in data centers. The rapid advancement and commercialization of metal 3D printing technologies provide a powerful long-term opportunity, as AM processes require custom-designed spherical copper powders. The primary impact forces affecting the market structure are the intensifying environmental scrutiny regarding heavy metal emissions and the pressure from major electronics manufacturers to adopt closed-loop recycling processes for copper powder waste, compelling producers to invest heavily in sustainable manufacturing techniques.

Segmentation Analysis

The Copper Powder Market is intricately segmented based on its manufacturing process, particle morphology, purity level, and diverse end-use applications. Understanding these segments is crucial for strategic positioning, as the requirements for high-density sintered parts differ significantly from those for low-viscosity conductive inks. Segmentation by type (e.g., dendritic, spherical) directly correlates with the suitability for specific applications; for instance, dendritic powders are preferred in lubrication and friction materials due to their high surface area, while spherical powders are optimized for rapid additive manufacturing processes where high flowability is essential.

Segmentation by manufacturing technology—primarily atomization (gas or water), electrolysis, and chemical reduction—defines the cost structure and purity profile of the final product. Atomized powders generally offer cost efficiency and scalable production, whereas electrolytic powders are renowned for their high purity and unique dendritic structure, making them ideal for specialized electronic applications. Purity levels, especially the demand for 99.99% or 5N copper, create a distinct premium segment driven by critical applications in semiconductors and aerospace where even trace impurities can lead to component failure.

- By Type

- Dendritic Copper Powder

- Spherical Copper Powder

- Flake Copper Powder

- Irregular Copper Powder

- By Manufacturing Process

- Atomization (Water and Gas)

- Electrolysis

- Chemical Reduction

- By Application

- Electrical and Electronics (Conductive Inks, PCBs, MLCCs)

- Automotive (Brake Pads, Motor Components, Bearings)

- Industrial/Powder Metallurgy (Sintered Parts, Friction Materials)

- Chemicals and Catalysts

- Additive Manufacturing (3D Printing)

- Defense and Aerospace

- By Purity Level

- Standard Grade (99.5% - 99.8%)

- High Purity Grade (99.9% - 99.99%)

Value Chain Analysis For Copper Powder Market

The value chain of the Copper Powder Market begins with the upstream segment involving the sourcing and refining of raw copper materials, typically copper cathode or scrap copper. Since copper powder quality is directly tied to the purity of the input material, stringent quality control at the mining and refining stages is crucial. Major global copper miners and commodity traders form the foundation of this segment, setting the baseline cost for the entire value chain. Efficiency in upstream processing, particularly leveraging energy-efficient smelting and refining techniques, directly impacts the overall production cost of the finished powder.

The core segment involves the specialized powder manufacturing processes, including atomization (gas or water), where molten copper is fragmented into fine particles, and electrolysis, where chemical deposition creates high-purity dendritic powders. This stage requires significant technological expertise and high capital investment in sophisticated machinery designed for controlled environments. Manufacturers often customize the powder based on particle size distribution (PSD), morphology, and surface properties, adding substantial value to the basic raw material. Quality assurance and certification are paramount at this juncture to meet industry-specific standards for automotive or electronics applications.

The downstream segment encompasses distribution and end-user consumption. Copper powder is typically distributed through a mix of direct sales channels, especially to large volume customers like major electronics OEMs, and indirect channels via specialized chemical and materials distributors who handle logistics and smaller quantity orders. End-users span diverse sectors—from large-scale sintering plants and additive manufacturing service bureaus to specialized producers of conductive pastes. The value realized downstream is dependent on the powder's ability to seamlessly integrate into complex manufacturing processes, such as laser powder bed fusion (L-PBF) or sophisticated printing techniques, underscoring the importance of high flowability and purity.

Copper Powder Market Potential Customers

The Copper Powder Market serves a highly diversified clientele, primarily comprising manufacturers across high-technology and heavy industrial sectors who rely on copper’s unique thermal and electrical characteristics. The largest volume buyers are those involved in the traditional powder metallurgy sector, producing sintered components such as bushings, bearings, and structural parts for general industrial machinery and white goods. These customers typically demand cost-effective, high-volume production of irregular or dendritic powders optimized for compaction and sintering processes.

A second major customer segment consists of global electronics manufacturers, including producers of printed circuit boards (PCBs), multilayer ceramic capacitors (MLCCs), and solar energy panels. These customers require ultra-fine, often nano-sized, spherical copper powders for developing advanced conductive inks and pastes used in precise deposition techniques. Their purchasing decisions are heavily influenced by particle purity, consistency, and thermal performance capabilities, driving demand for premium, high-specification products.

The fastest-growing segment of potential customers includes automotive OEMs and their tier-one suppliers, driven by the rapid shift toward electric vehicles (EVs). These customers purchase large volumes of specialized copper powders for thermal management systems (heat sinks), high-performance friction materials (brake pads), and critical components within EV motors and battery connection systems. Additionally, specialized 3D printing service bureaus and aerospace manufacturers represent a niche but highly profitable customer base, demanding customized, high-flow spherical copper powders capable of meeting stringent aerospace certification standards.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 8.5 Billion |

| Market Forecast in 2033 | USD 12.6 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Fukuda Metal Foil & Powder Co. Ltd., Mitsubishi Materials Corporation, GKN Sinter Metals, JX Nippon Mining & Metals Corporation, Sandvik AB (Kennametal), Glencore PLC, Umicore N.V., Pometon Powder, Nanografi Nano Technology, AEE Powder, Höganäs AB, Belmont Metals, ECKA Granules GmbH, Sumitomo Metal Mining Co., Ltd., Atlantic Equipment Engineers (AEE), PyroGenesis Canada Inc., Avocet Metal Powders, Technogenia S.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Copper Powder Market Key Technology Landscape

The Copper Powder Market is defined by several core manufacturing technologies, with atomization and electrolysis being the most dominant and technologically refined methods. Gas atomization, utilizing high-velocity inert gases like nitrogen or argon, is increasingly favored for producing highly spherical, fine powders crucial for high-end additive manufacturing applications. This process allows for precise control over particle morphology and bulk density, resulting in materials that exhibit excellent flow characteristics necessary for processes like Selective Laser Melting (SLM) and Electron Beam Melting (EBM). Recent technological advancements focus on closed-loop control systems and improved nozzle design to enhance yield and reduce energy consumption during atomization.

Electrolysis remains a crucial technology, particularly for manufacturing high-purity, dendritic copper powders. The electrolytic process involves the controlled deposition of copper onto a cathode plate, which is then mechanically scraped and pulverized. While requiring high energy input, this method yields powders with a unique, high surface area structure ideal for applications such as friction materials and specialized battery components. Innovation in this field is centered on developing proprietary electrolyte compositions and optimizing current densities to manipulate the resulting particle shape and size, catering specifically to the demanding specifications of the electronics industry.

Furthermore, the technology landscape is being significantly shaped by advancements in chemical reduction and nano-powder synthesis. Chemical reduction methods, such as the Polyol process, enable the synthesis of ultra-fine and nano-sized copper powders with narrow particle size distributions, highly sought after for conductive inks and catalysts. These nano-powders necessitate specialized handling and dispersion technologies to prevent oxidation and agglomeration. The integration of advanced testing equipment, including laser diffraction particle size analyzers and scanning electron microscopes (SEMs), forms a vital part of the quality assurance technology, ensuring that the increasingly stringent purity and morphological requirements of end-user industries are consistently met.

Regional Highlights

- Asia Pacific (APAC): APAC is the global leader in the Copper Powder Market, driven primarily by China’s massive electronics manufacturing base and its aggressive expansion in electric vehicle production. Countries like South Korea, Japan, and Taiwan are major consumers of high-purity copper powders for semiconductor packaging and advanced display technologies. India’s burgeoning infrastructure and renewable energy sector further solidify APAC's dominance. The region benefits from lower operational costs and a strong industrial ecosystem supporting both high-volume production and complex metallurgical requirements.

- North America: The North American market is characterized by high technological adoption, particularly in additive manufacturing (3D printing) for aerospace and automotive prototypes. The region demands specialized, highly consistent spherical copper powders. Robust R&D activities, especially in the US, focusing on advanced thermal management solutions for data centers and military applications, maintain a high-value segment for premium powder producers. Stringent quality requirements, such as NADCAP certification for aerospace components, drive innovation in powder quality and traceability.

- Europe: Europe is a mature market focusing heavily on sustainability and high-quality automotive components. Germany, France, and Italy are key consumers, particularly in sintered parts, friction materials, and high-performance motors for the European EV transition. European environmental regulations (REACH) place considerable pressure on manufacturers to adopt cleaner production technologies and enhance recycling capabilities. This regulatory environment favors high-ppurity electrolytic and atomized powders produced using sustainable practices.

- Latin America (LATAM): The LATAM market, while smaller, is growing steadily, primarily driven by mining infrastructure development and expanding domestic automotive component manufacturing in countries like Brazil and Mexico. Demand is largely concentrated in standard-grade powders for powder metallurgy and industrial applications, though increasing foreign investment in regional electronics assembly plants is gradually shifting the demand profile toward higher-specification powders.

- Middle East and Africa (MEA): Growth in the MEA region is nascent but promising, linked to substantial investments in energy infrastructure and diversification efforts away from oil dependence. The region requires copper powder mainly for oil and gas industry friction materials, industrial wear parts, and initial stages of electronics assembly. Future growth hinges heavily on developing domestic manufacturing capabilities and implementing planned large-scale renewable energy projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Copper Powder Market.- Fukuda Metal Foil & Powder Co. Ltd.

- Mitsubishi Materials Corporation

- GKN Sinter Metals

- JX Nippon Mining & Metals Corporation

- Sandvik AB (Kennametal)

- Glencore PLC

- Umicore N.V.

- Pometon Powder

- Nanografi Nano Technology

- AEE Powder

- Höganäs AB

- Belmont Metals

- ECKA Granules GmbH

- Sumitomo Metal Mining Co., Ltd.

- Atlantic Equipment Engineers (AEE)

- PyroGenesis Canada Inc.

- Avocet Metal Powders

- Technogenia S.A.

- Shandong Sinocera Functional Materials Co., Ltd.

- CNPC Powder Material Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Copper Powder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for spherical copper powder?

The primary driver is the rapid proliferation of Additive Manufacturing (3D Printing) technologies, such as Laser Powder Bed Fusion (L-PBF). Spherical morphology ensures high flowability and optimal packing density, which are essential prerequisites for successful, high-resolution 3D printing of complex copper parts.

How does the electrolytic process differ from the atomization process for producing copper powder?

Electrolytic processes yield highly pure, dendritic (irregular shaped) powders suitable for friction materials and specialized battery components, focusing on high surface area. Atomization (gas or water) produces spherical or irregular powders, scalable for mass production, and is favored for conductive inks and powder metallurgy due to better flow characteristics.

Which application segment holds the largest share in the Copper Powder Market?

The Electrical and Electronics segment holds the largest market share. This dominance is driven by the use of copper powder in conductive pastes, thermal management solutions, printed circuit boards (PCBs), and multilayer ceramic capacitors (MLCCs) required for consumer electronics and telecommunications infrastructure.

What are the main challenges facing copper powder manufacturers?

The chief challenges include managing the high volatility and unpredictable fluctuation in the price of raw copper commodities, meeting increasingly stringent environmental compliance standards related to heavy metal production, and overcoming the high capital costs associated with establishing state-of-the-art production facilities.

What role does nano-copper powder play in the future market growth?

Nano-copper powder is crucial for next-generation applications requiring ultra-fine precision and performance, such as highly efficient flexible electronics, advanced biomedical sensors, and superior thermal interface materials. Its unique characteristics enable the miniaturization and enhanced functionality of electronic components.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Atomizing Copper Powder Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- High Purity Copper Powder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Copper Powder Market Statistics 2025 Analysis By Application (Electronic Industry, Chemical Industry, Mechanical Industry, Coating Industry), By Type (Electrolytic copper powder, Water mist of copper powder, Ultra-fine copper powder, Copper alloy powder), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Ultra Fine Copper Powder Market Statistics 2025 Analysis By Application (Electronic, Chemical, Mechanical, Pharmaceutical), By Type (Nano Copper Particles Powder, Micro Copper Particles Powder), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Atomizing Copper Powder Market Statistics 2025 Analysis By Application (Metallurgy Industry, Chemical Industry, Electronic Materials, Diamond Tools), By Type (Water Atomization Technology, Gas Atomization Technology), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager