Modified Wood Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440447 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Modified Wood Market Size

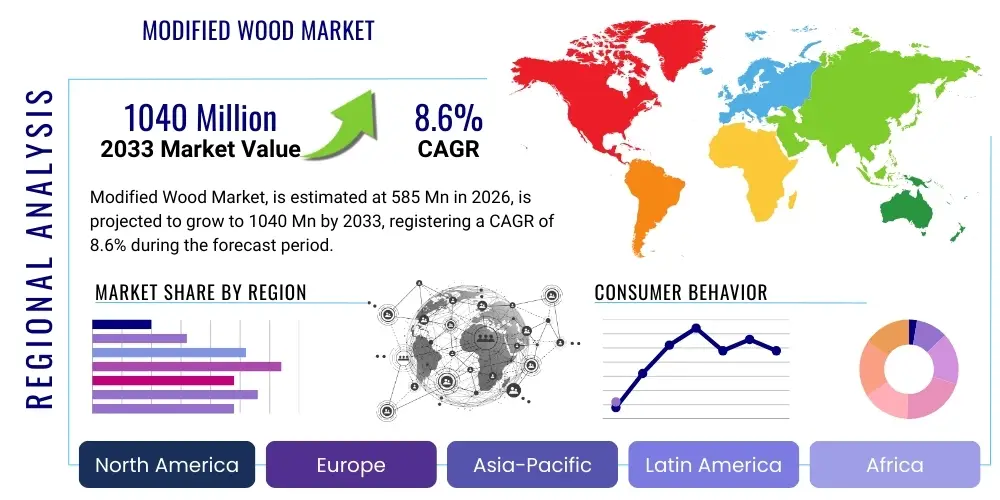

The Modified Wood Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.6% between 2026 and 2033. The market is estimated at 585 Million USD in 2026 and is projected to reach 1040 Million USD by the end of the forecast period in 2033.

Modified Wood Market introduction

The modified wood market encompasses timber products that have undergone physical, chemical, or thermal treatments to enhance their inherent properties, thereby improving durability, dimensional stability, biological resistance, and aesthetic appeal. These modifications transform ordinary wood species into high-performance materials suitable for demanding applications, often rivaling or surpassing the capabilities of tropical hardwoods or synthetic alternatives. The primary objective of wood modification is to overcome natural limitations such as susceptibility to decay, insect attack, moisture absorption, and warping, extending the service life of wood products without relying on traditional, often environmentally harmful, chemical preservatives. Key product descriptions include thermally modified wood, acetylated wood, furfurylated wood, and polymer-impregnated wood, each employing distinct processes to alter the wood's cell wall structure or composition. Major applications span a wide array of sectors, notably in outdoor construction for decking, siding, and facades, where exposure to harsh environmental conditions necessitates superior performance. Furthermore, modified wood finds significant use in flooring, both interior and exterior, outdoor furniture, marine applications, and other specialized architectural and design elements where longevity and low maintenance are paramount. The benefits of modified wood are manifold, including enhanced longevity, reduced need for maintenance, improved resistance to fungal decay and insect infestation, increased dimensional stability which minimizes swelling and shrinking, and often an attractive, uniform appearance. Critically, many modification processes are environmentally friendly, utilizing non-toxic chemicals or simply heat, aligning with global sustainability trends and consumer demand for green building materials. The market is driven by several key factors, prominently the increasing demand for sustainable and durable building materials, stringent environmental regulations restricting the use of conventional wood preservatives, a growing preference for natural aesthetics in construction, and continuous innovation in wood modification technologies that improve cost-effectiveness and performance.

Modified Wood Market Executive Summary

The Modified Wood Market is experiencing robust growth, propelled by a confluence of evolving business trends, regional dynamics, and segment-specific advancements. A prominent business trend is the intensifying focus on sustainability and circular economy principles, driving manufacturers to invest in eco-friendly modification processes and source wood from certified sustainable forests. This has led to strategic collaborations between technology providers and wood processors, aiming to optimize production efficiency and expand product portfolios. Furthermore, there is a clear trend towards customization and design flexibility, with modified wood being increasingly specified by architects and designers for its aesthetic versatility and long-term performance in bespoke projects. Regional trends reveal significant market expansion in Europe, which has historically been at the forefront of adopting advanced wood technologies dueer to stringent environmental regulations and a strong emphasis on sustainable construction practices. North America is also witnessing accelerated growth, driven by a buoyant residential construction sector and increasing consumer awareness regarding the benefits of durable, low-maintenance outdoor living solutions. The Asia Pacific region is emerging as a critical growth hub, fueled by rapid urbanization, infrastructure development, and a rising middle class with disposable income to invest in premium building materials. Within segmentation, thermally modified wood and acetylated wood currently dominate the market due to their established performance characteristics and commercial viability, but furfurylated and polymer-impregnated variants are gaining traction due to continuous research and development yielding enhanced properties for niche applications. The decking and siding segments remain the largest application areas, reflecting the primary consumer demand for durable exterior solutions, while flooring and outdoor furniture segments are demonstrating high growth rates, indicative of diversifying market penetration. Overall, the executive summary underscores a market characterized by innovation, environmental consciousness, and expanding geographical and application footprints, positioning modified wood as a pivotal material in the global push for sustainable and resilient construction.

AI Impact Analysis on Modified Wood Market

User questions regarding the impact of Artificial Intelligence (AI) on the Modified Wood Market frequently revolve around optimizing production efficiency, enhancing quality control, improving supply chain management, and predicting market demand. There is a strong user interest in how AI can contribute to more sustainable practices and foster innovation in material science within this sector. Users often seek to understand how AI algorithms can analyze complex data from the modification processes to ensure consistent product quality, minimize waste, and identify opportunities for energy savings. Concerns are also raised about the implementation costs and the technical expertise required to integrate AI solutions into existing manufacturing infrastructure.

The key themes emerging from this analysis include the potential for AI to revolutionize the precision and consistency of wood modification, transforming a traditionally experience-based process into a data-driven science. Users anticipate that AI can enable predictive maintenance for machinery, optimize parameters for thermal and chemical treatments in real-time, and even guide the selection of raw wood based on its structural properties for specific end-use applications. Furthermore, expectations are high for AI's role in market forecasting, allowing manufacturers to respond proactively to demand shifts and manage inventory more effectively, thereby reducing operational risks and improving profitability. The integration of AI is seen as a crucial step towards creating smarter factories and more sustainable product lifecycles in the modified wood industry.

However, the widespread adoption of AI also brings considerations regarding data privacy, cybersecurity, and the need for a skilled workforce capable of operating and interpreting AI-driven systems. Addressing these concerns will be critical for the successful deployment of AI technologies. The market anticipates that AI will not only streamline current operations but also unlock new possibilities in developing novel wood modification techniques and customizing product performance to unprecedented levels, ultimately driving market growth and competitive differentiation.

- AI-driven optimization of modification parameters for enhanced consistency and material performance.

- Predictive maintenance for machinery, reducing downtime and operational costs in manufacturing facilities.

- Automated quality control systems using computer vision to identify defects and ensure product standards.

- Advanced demand forecasting and supply chain optimization for efficient resource allocation and inventory management.

- Development of new material formulations and modification techniques through AI-accelerated R&D.

- Enhanced sustainability through AI-guided waste reduction and energy consumption optimization.

- Real-time monitoring of environmental conditions during wood treatment processes for precise control.

DRO & Impact Forces Of Modified Wood Market

The Modified Wood Market is profoundly shaped by a dynamic interplay of drivers, restraints, opportunities, and inherent impact forces. Key drivers fueling market expansion include the surging global demand for sustainable, durable, and low-maintenance building materials, particularly in exterior applications like decking, siding, and outdoor furniture. Stringent environmental regulations, which increasingly restrict the use of conventional chemical wood preservatives, significantly push manufacturers and consumers towards eco-friendly modified wood alternatives. Furthermore, a growing aesthetic preference for natural wood visuals, combined with a desire for superior performance against decay, insects, and dimensional instability, bolsters the market. Technological advancements in modification processes, making them more efficient and cost-effective, also serve as a crucial driver. However, the market faces notable restraints, primarily the higher initial cost of modified wood products compared to traditional untreated timber or some composite materials, which can deter price-sensitive consumers or large-scale projects operating on tight budgets. Limited awareness among some end-users and specifiers about the long-term benefits and performance characteristics of modified wood, as well as the perception of a niche product, also act as a drag on wider adoption. Supply chain complexities, especially concerning the availability of specific wood species suitable for modification and the scalability of specialized treatment facilities, present additional challenges. Opportunities for growth are abundant, particularly in emerging economies with rapidly expanding construction sectors and an increasing environmental consciousness. Continuous research and development into novel modification techniques, using biomass-derived chemicals or advanced thermal processes, offer avenues for cost reduction, performance enhancement, and broadening the range of suitable wood species. Niche applications, such as marine environments, architectural facades, and high-performance flooring, represent lucrative segments for specialized modified wood products. The integration of modified wood into prefabricated construction and modular building solutions also presents a significant growth opportunity. The inherent impact forces, such as the material's superior resistance to pests like termites and fungi, exceptional weather resilience against moisture and UV degradation, and its appealing natural aesthetics, fundamentally enhance its value proposition and drive its competitive advantage over alternatives. These combined factors critically influence market dynamics, investment decisions, and the trajectory of innovation within the modified wood industry.

Segmentation Analysis

The modified wood market is comprehensively segmented to provide a detailed understanding of its diverse components, offering insights into varying product types, applications, and end-use industries across different geographical regions. This segmentation allows for precise market analysis, enabling stakeholders to identify key growth areas, understand competitive landscapes, and formulate targeted business strategies. The market is primarily broken down by the type of modification process employed, the specific applications where modified wood is utilized, the end-user industries that consume these products, and the geographical regions driving demand. Each segment reflects unique characteristics, technological requirements, and market dynamics that collectively define the overall modified wood landscape. Understanding these distinctions is crucial for identifying market entry points, product development priorities, and effective marketing channels, ensuring that market players can cater to specific needs and capitalize on emerging trends. The granular segmentation helps in assessing the impact of regulatory changes, technological advancements, and consumer preferences on individual market components, providing a holistic view of the industry's structure and potential for expansion.

- By Type

- Thermally Modified Wood: Wood treated at high temperatures in an oxygen-free environment to alter cell structure.

- Acetylated Wood: Wood modified with acetic anhydride, replacing hydroxyl groups with acetyl groups to reduce water absorption.

- Furfurylated Wood: Wood impregnated with furfuryl alcohol, which polymerizes within the wood cells to enhance hardness and durability.

- Impregnated Wood:

- Resin-modified Wood: Wood infused with various resins to improve density, hardness, and stability.

- Polymer-modified Wood: Wood treated with polymers that fill cell voids, enhancing mechanical properties and water resistance.

- Densified Wood: Wood subjected to heat and pressure to increase density and hardness.

- By Application

- Decking: For outdoor patios, terraces, and walkways, valued for durability and weather resistance.

- Siding: Exterior cladding for residential and commercial buildings, chosen for aesthetic appeal and protection.

- Flooring:

- Indoor Flooring: Durable and stable options for interior spaces.

- Outdoor Flooring: High-performance solutions for balconies, patios, and garden paths.

- Furniture:

- Indoor Furniture: Stable and visually appealing options for interiors.

- Outdoor Furniture: Weather-resistant and long-lasting furniture for exterior use.

- Construction:

- Structural Construction: For load-bearing applications where enhanced strength and stability are required.

- Non-structural Construction: For decorative elements, trim, and other architectural features.

- Marine Applications: For boat building, docks, and piers, where water resistance and decay prevention are critical.

- Automotive Interiors: Lightweight yet durable wood elements for vehicle interiors.

- Musical Instruments: For enhanced acoustic properties and stability in instrument construction.

- Others: Includes landscaping elements, garden products, and specialized crafts.

- By End-Use Industry

- Residential Construction: Single-family homes, multi-family dwellings, and renovations.

- Commercial Construction: Office buildings, retail spaces, hotels, and public infrastructure.

- Industrial Applications: Specialized uses in manufacturing, transport, and other industrial settings.

- DIY & Home Improvement: Products sold directly to consumers for personal projects.

- Automotive: Manufacturers incorporating modified wood in vehicle components.

- Marine: Shipbuilders and repair facilities utilizing modified wood.

- By Region

- North America: U.S., Canada, Mexico.

- Europe: Germany, UK, France, Italy, Spain, Nordic Countries, Rest of Europe.

- Asia Pacific: China, Japan, India, South Korea, Australia, ASEAN Countries, Rest of APAC.

- Latin America: Brazil, Argentina, Rest of Latin America.

- Middle East & Africa: GCC Countries, South Africa, Rest of MEA.

Value Chain Analysis For Modified Wood Market

The value chain for the Modified Wood Market is a complex yet integrated network, encompassing raw material sourcing, intricate modification processes, distribution, and eventual end-use, each stage adding significant value to the final product. Upstream analysis begins with the sustainable sourcing of suitable wood species, predominantly from responsibly managed forests. This involves negotiations with timber suppliers, adherence to certifications like FSC or PEFC, and initial processing such as sawing, drying, and grading of logs into sawn timber. The choice of wood species is critical, as different woods respond uniquely to various modification techniques, influencing the final product's properties and cost. Midstream activities are centered around the actual modification processes, including thermal treatment, acetylation, furfurylation, or impregnation with resins or polymers. This stage requires specialized equipment, technical expertise, and precise process control to achieve the desired enhancements in durability, stability, and aesthetic quality. Quality control at this stage is paramount to ensure consistency and compliance with performance standards. Downstream analysis focuses on the distribution and market penetration of modified wood products. This involves primary processing of modified timber into specific formats like decking boards, siding panels, or flooring planks, followed by packaging and logistics. The distribution channels are diverse, ranging from direct sales to large-scale construction companies and industrial clients to indirect channels through wholesalers, distributors, timber merchants, and retail outlets catering to DIY enthusiasts and smaller contractors. Digital platforms and e-commerce are increasingly playing a role in connecting manufacturers with end-users and designers, expanding market reach and facilitating easier product selection. Direct distribution ensures greater control over pricing and customer relationships, often utilized for high-volume or custom orders, while indirect channels provide broader market coverage and cater to diverse customer segments, albeit with shared margins. The efficiency and effectiveness of this entire value chain, from sustainable forest management to seamless delivery to the end-user, are crucial determinants of competitiveness and profitability within the modified wood market, continuously seeking optimization through technological integration and strategic partnerships to enhance material flow and market response.

Modified Wood Market Potential Customers

The Modified Wood Market targets a diverse and expanding base of potential customers who prioritize durability, sustainability, aesthetics, and low maintenance in their material choices. The primary end-users and buyers of modified wood products span across the construction, architectural, and design sectors, alongside individual consumers engaged in home improvement projects. Major potential customers include large-scale residential and commercial construction companies seeking high-performance, long-lasting materials for exterior applications such such as facades, cladding, decking, and outdoor structures. Architects and interior designers are significant influencers and direct specifiers, recommending modified wood for its aesthetic versatility, natural appeal, and compliance with green building standards in various projects, from residential dwellings to public buildings and hospitality venues. Furniture manufacturers, particularly those specializing in outdoor furniture, constitute a crucial customer segment, valuing modified wood for its resistance to weathering, fungi, and insects, which translates to extended product lifespan and reduced warranty claims. Moreover, marine construction companies and boat builders represent a niche but significant customer group, where the exceptional water resistance and dimensional stability of modified wood make it an ideal choice for docks, jetties, and boat components, offering a sustainable alternative to tropical hardwoods. DIY enthusiasts and homeowners form another growing segment, purchasing modified wood for personal home renovation projects, including garden decking, pergolas, fences, and outdoor living spaces, driven by the desire for durable, attractive, and low-maintenance solutions. As sustainability becomes a core purchasing criterion globally, any customer segment that previously relied on conventional treated wood or tropical hardwoods is a potential convert to modified wood, given its superior environmental profile and enhanced performance attributes. These diverse customer segments underscore the broad applicability and growing acceptance of modified wood as a premium, sustainable building and design material across various industries.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | 585 Million USD |

| Market Forecast in 2033 | 1040 Million USD |

| Growth Rate | 8.6% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Accoya (Titan Wood), Kebony, Lunawood, Thermory, UPM-Kymmene (WISA Wood), Sioo Wood Protection, ArborWood (Accsys Technologies), Plank & Hide Co., Vureh, Lignia Wood Company, Resysta, New Age Wood, Foreco, Goodfellow Inc., Oy SWM-Wood Ltd., Fritz Kohl Furnierwerk, IRO Timber, Woodsafe Timber Protection, W.E.B. Wärmepumpen und Energieberatung GmbH, Koppers Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Modified Wood Market Key Technology Landscape

The Modified Wood Market is underpinned by a diverse and continuously evolving technological landscape, with several key modification processes driving innovation and product differentiation. At the forefront is thermal modification, a process involving heating wood to high temperatures (typically 180-230 °C) in an oxygen-deprived environment. This technology significantly alters the wood's chemical structure, reducing its hygroscopicity, improving dimensional stability, and increasing resistance to decay and insects without using harmful chemicals. Kiln drying and vacuum-thermal treatment are common methods within this category, yielding products with enhanced durability and a distinct darker coloration. Another critical technology is acetylation, where wood is reacted with acetic anhydride. This process permanently changes the wood's cell wall chemistry by replacing hydroxyl groups with acetyl groups, making the wood less attractive to moisture and microorganisms. Acetylated wood is highly stable, durable, and boasts an exceptional service life, maintaining its natural appearance or allowing for consistent painting. Furfurylation represents another advanced chemical modification technique, involving the impregnation of wood with furfuryl alcohol, a bio-based monomer derived from agricultural waste. Under specific conditions, the furfuryl alcohol polymerizes within the wood cell walls, leading to increased density, hardness, fungal resistance, and dimensional stability. This process often results in a darker wood tone and a harder surface. Impregnation technologies, utilizing various resins or polymers, are also pivotal. Resin-modified wood involves injecting thermosetting resins into the wood's cellular structure, which then cure to create a more dense, strong, and stable material. Similarly, polymer-modified wood uses a range of synthetic or bio-based polymers to fill voids and reinforce the wood, enhancing its mechanical properties and resistance to environmental degradation. Finally, densification technologies, which combine heat and pressure to compress wood fibers, increase the material's density, hardness, and strength. These diverse technologies collectively enable manufacturers to tailor modified wood properties for specific applications, address performance gaps of untreated timber, and align with the growing demand for sustainable, high-performance materials. Ongoing research focuses on developing new bio-based modifying agents, optimizing process efficiencies, and reducing the energy consumption associated with these advanced wood treatments, thereby further expanding the market's technological frontier and competitive edge.

Regional Highlights

- North America: This region is witnessing significant growth, driven by a robust residential construction sector and increasing consumer demand for durable, low-maintenance outdoor living products. The U.S. and Canada are key markets, with a growing awareness of the environmental benefits and performance advantages of modified wood over traditional treated lumber.

- Europe: A mature and leading market for modified wood, characterized by stringent environmental regulations, high sustainability standards, and a strong preference for natural and long-lasting building materials. Nordic countries (Finland, Sweden) and Central Europe (Germany, France) are at the forefront of innovation and adoption, especially for decking, siding, and facade applications.

- Asia Pacific (APAC): The fastest-growing region, propelled by rapid urbanization, infrastructure development, and a rising middle class seeking premium and sustainable building solutions. China, India, Japan, and Australia are key contributors, with increasing investment in green buildings and a growing appreciation for modified wood's durability in diverse climates.

- Latin America: An emerging market with growing potential, driven by expanding construction activities and an increasing awareness of sustainable building practices. Countries like Brazil and Mexico are showing burgeoning interest in modified wood for both residential and commercial projects as an alternative to deforestation-linked tropical hardwoods.

- Middle East & Africa (MEA): This region is poised for gradual growth, influenced by large-scale construction projects, especially in the GCC countries, and an increasing focus on sustainable development. The demand is emerging from luxury construction and hospitality sectors seeking durable and aesthetically appealing exterior wood solutions capable of withstanding harsh desert climates.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Modified Wood Market.- Accoya (Titan Wood)

- Kebony

- Lunawood

- Thermory

- UPM-Kymmene (WISA Wood)

- Sioo Wood Protection

- ArborWood (Accsys Technologies)

- Plank & Hide Co.

- Vureh

- Lignia Wood Company

- Resysta

- New Age Wood

- Foreco

- Goodfellow Inc.

- Oy SWM-Wood Ltd.

- Fritz Kohl Furnierwerk

- IRO Timber

- Woodsafe Timber Protection

- W.E.B. Wärmepumpen und Energieberatung GmbH

- Koppers Inc.

Frequently Asked Questions

Analyze common user questions about the Modified Wood market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is modified wood and how does it differ from traditional treated wood?

Modified wood refers to timber that has undergone specific physical, chemical, or thermal treatments to enhance its inherent properties, primarily improving durability, dimensional stability, and resistance to biological degradation without necessarily relying on traditional, often toxic, chemical preservatives. Unlike pressure-treated wood, which typically impregnates timber with biocides to prevent decay, modified wood alters the wood's cell structure or chemistry at a fundamental level. For instance, thermally modified wood uses only heat and steam, while acetylated wood chemically changes cell wall components, making the wood itself less appealing to fungi and insects and less prone to swelling or shrinking. This fundamental alteration results in a more stable, durable, and often environmentally friendlier product compared to many chemically treated alternatives. The modification process enhances the wood's natural characteristics, leading to a product that is not only robust and long-lasting but also typically safer to handle and dispose of, aligning with growing ecological concerns. The improved dimensional stability of modified wood significantly reduces warping, cupping, and checking, problems commonly associated with traditional timber, making it an excellent choice for demanding exterior applications. Furthermore, the aesthetic qualities are often enhanced, with thermal modification imparting a rich, uniform color, and acetylation preserving the natural look while improving performance. These distinctions underscore why modified wood is increasingly preferred by architects, builders, and homeowners seeking high-performance, sustainable, and visually appealing wood solutions.

What are the primary benefits and disadvantages of using modified wood in construction?

The primary benefits of using modified wood in construction are numerous and compelling. Firstly, enhanced durability is a significant advantage, as modified wood exhibits superior resistance to fungal decay, insect infestation, and rot, often achieving durability classifications comparable to the most resilient tropical hardwoods. This extended service life reduces the need for frequent replacement and maintenance. Secondly, improved dimensional stability is a key benefit, as the modification processes reduce the wood's ability to absorb moisture, thereby minimizing swelling, shrinking, warping, and checking, which are common issues with untreated timber. This stability makes modified wood ideal for demanding exterior applications like decking and siding. Thirdly, many modified wood products are environmentally friendly, utilizing non-toxic treatments or bio-based chemicals, making them a sustainable choice that aligns with green building certifications and consumer demand for eco-conscious materials. Modified wood often requires no further chemical treatment, resulting in safer handling and disposal. Fourthly, it offers excellent aesthetic appeal, with some processes imparting a beautiful, uniform color, while others preserve the natural wood look, offering versatility in design. Lastly, its low maintenance requirements mean less time and money spent on upkeep over its long lifespan. However, there are some disadvantages. The initial cost of modified wood is generally higher than that of traditional untreated or standard pressure-treated lumber, which can be a barrier for some projects. While processes are improving, limited awareness and availability in certain regions can also pose challenges. Some modified wood types may also be slightly more brittle or harder to work with than their unmodified counterparts, requiring specific tools or installation techniques. Despite these drawbacks, the long-term value, performance, and environmental benefits often outweigh the initial investment and minor installation considerations, making modified wood a preferred choice for high-quality, sustainable construction.

How do different types of wood modification technologies impact product performance?

Different wood modification technologies fundamentally alter the wood's properties in unique ways, leading to distinct performance characteristics tailored for various applications. Thermal modification, for instance, uses high heat and steam to break down hemicelluloses within the wood cell walls. This reduces the wood's hygroscopicity (ability to absorb moisture) and consequently improves dimensional stability by up to 50-70%, making the wood highly resistant to warping, swelling, and shrinking. It also enhances resistance to decay and insects, granting high durability, and imparts a uniform, dark brown color. However, thermal modification can slightly reduce the wood's bending strength, making it more brittle. Acetylation, on the other hand, involves chemically reacting wood with acetic anhydride, permanently replacing hydroxyl groups with acetyl groups. This chemical change significantly reduces water absorption and makes the wood cells less digestible for fungi and insects, resulting in exceptional durability and dimensional stability that often surpasses even tropical hardwoods. Acetylated wood retains its natural color or can be easily painted and is highly stable in diverse environments. Its strength properties are largely maintained or even improved. Furfurylation, a process involving impregnation with bio-based furfuryl alcohol, polymerizes within the wood cell walls. This significantly increases the wood's density, hardness, and strength, alongside providing excellent fungal resistance and dimensional stability. Furfurylated wood typically has a rich, darker color and is often chosen for its robust mechanical properties. Polymer impregnation involves infusing the wood with various resins or polymers, filling the cell voids and strengthening the entire structure. This process drastically improves hardness, density, and stability, making the wood highly durable and suitable for high-wear applications, often without significantly altering its appearance unless a colored polymer is used. Each technology offers a specific balance of durability, stability, aesthetic change, and mechanical properties, allowing manufacturers and specifiers to choose the optimal modified wood product for specific end-use requirements, from exterior decking to high-performance flooring or marine applications.

Is modified wood truly sustainable and environmentally friendly compared to other materials?

Modified wood is generally considered a highly sustainable and environmentally friendly material, especially when compared to traditional alternatives like tropical hardwoods, plastics, or conventionally treated lumber. The sustainability stems from several key aspects. Firstly, the raw material, timber, typically comes from sustainably managed forests, often certified by organizations like FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification), ensuring responsible forestry practices and reforestation. This contrasts sharply with the often unsustainable logging of tropical rainforests for exotic hardwoods. Secondly, many modification processes themselves are environmentally benign. For example, thermal modification uses only heat and steam, avoiding any synthetic chemicals or heavy metals, making the resulting wood safe to handle and dispose of, and recyclable at the end of its life. Acetylation utilizes acetic anhydride, which reacts cleanly with the wood, and the by-product, acetic acid, is often reused or safely neutralized. Furfurylation employs furfuryl alcohol, a bio-based chemical derived from agricultural waste, further enhancing its eco-credentials. These processes significantly reduce the need for traditional wood preservatives, which often contain toxic chemicals that can leach into the environment and pose health risks. Thirdly, the extended lifespan of modified wood contributes significantly to its sustainability. By making wood much more durable and resistant to decay, it reduces the frequency of replacement, conserving resources and minimizing waste. This longevity also lowers the carbon footprint associated with manufacturing and transporting new materials. When compared to high-embodied energy materials like concrete, steel, or plastics, modified wood typically has a lower environmental impact throughout its lifecycle. Its natural origin, non-toxic modification, and recyclability firmly position modified wood as a leading choice for sustainable construction and design, aligning with global efforts to reduce environmental impact and promote a circular economy. The ongoing innovation in developing even greener modification agents and processes further solidifies its position as a truly sustainable material.

What are the long-term cost implications and maintenance requirements for modified wood products?

The long-term cost implications and maintenance requirements for modified wood products represent a significant advantage over many traditional materials, despite a potentially higher initial purchase price. While the upfront investment for modified wood is typically greater than for untreated softwood or conventionally pressure-treated timber, this premium is often offset by substantial savings over the product's lifespan. The primary factor contributing to these long-term savings is the significantly enhanced durability and resistance to decay, fungi, and insects that modified wood offers. This extended service life, often exceeding 25-50 years depending on the modification type and application, means fewer replacements are needed over time, directly reducing material and labor costs associated with repair or renewal. Furthermore, modified wood typically exhibits superior dimensional stability, minimizing issues like warping, cupping, and cracking. This stability contributes to lower maintenance needs, as structural integrity is maintained more consistently, preventing common problems that would otherwise require costly repairs or adjustments. In terms of ongoing maintenance, modified wood generally requires far less intervention compared to conventional wood. Many modified wood products do not require painting, sealing, or frequent chemical treatments to maintain their performance. If left untreated, most modified woods will naturally weather to a silver-grey patina, similar to untreated hardwoods, without compromising their core durability. If a specific color or finish is desired, periodic reapplication of stains or oils may be necessary, but this is primarily for aesthetic preservation rather than structural protection. The absence of toxic chemical preservatives also makes modified wood safer for handling during installation and less hazardous to the environment during its use and eventual disposal, potentially reducing future environmental remediation costs. When evaluating the total cost of ownership, including initial material cost, installation, maintenance, and replacement cycles, modified wood often presents a more economically favorable solution over the long term, offering superior performance and reduced hassle, making it a sound investment for durable and sustainable projects.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Thermally Modified Wood Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Thermally Modified Wood Boards Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Modified Wood Market Size Report By Type (Thermally Modified Wood, Chemical Modified Wood), By Application (Interior Applications, Exterior Applications), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Thermally Modified Wood Market Statistics 2025 Analysis By Application (Residential, Commercial), By Type (Thermo-S, Thermo-D, Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Thermally Modified Wood Boards Market Statistics 2025 Analysis By Application (Commercial, Residential), By Type (Thermo-S, Thermo-D), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager