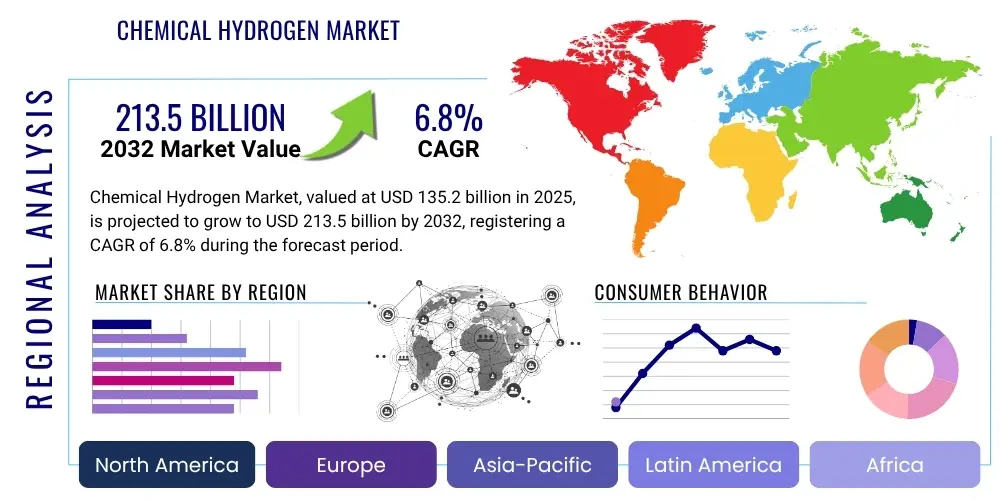

Chemical Hydrogen Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429216 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Chemical Hydrogen Market Size

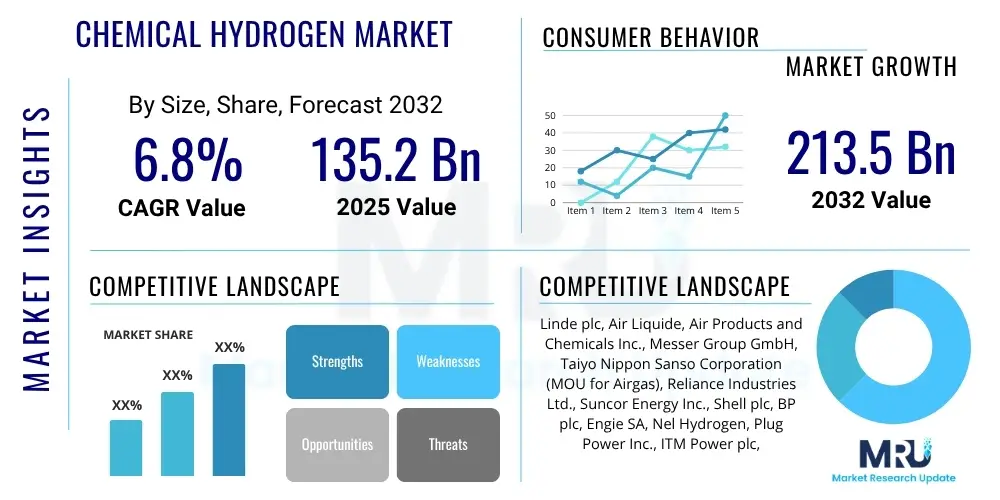

The Chemical Hydrogen Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 135.2 billion in 2025 and is projected to reach USD 213.5 billion by the end of the forecast period in 2032.

Chemical Hydrogen Market introduction

The Chemical Hydrogen market encompasses the production, distribution, and consumption of hydrogen specifically for industrial applications, where it serves as a crucial chemical feedstock rather than primarily for energy generation. This market is distinct from the broader energy hydrogen market, though there is increasing convergence due to decarbonization efforts. Chemical hydrogen is primarily utilized in processes like ammonia synthesis, methanol production, petroleum refining, and various chemical manufacturing activities. The versatility of hydrogen as a chemical agent, capable of reducing, hydrogenating, and serving as a raw material, underpins its indispensable role across numerous industrial sectors globally.

The product, chemical hydrogen, is typically produced through various methods, with Steam Methane Reforming (SMR) being the most dominant due to its cost-effectiveness and established infrastructure. However, the market is witnessing a significant shift towards cleaner production methods such as electrolysis (producing green or blue hydrogen) driven by stringent environmental regulations and corporate sustainability targets. The purity and delivery form of hydrogen are critical, with pipeline distribution, compressed gas cylinders, and liquid hydrogen tankers being common modes. Major applications include fertilizer production (ammonia), solvent and plastic manufacturing (methanol), and hydrotreating processes in refineries to remove impurities from fuels. As industries seek to reduce their carbon footprint, the demand for sustainably produced chemical hydrogen is accelerating, reshaping the supply chain and technological landscape.

The benefits of chemical hydrogen extend beyond its primary function as a chemical input. It facilitates the production of essential goods that underpin modern society, from food (fertilizers) to plastics and clean fuels. Driving factors for this market include the sustained growth of industrial sectors, particularly in developing economies, increasing demand for petrochemicals, and the global imperative for decarbonization. Policies promoting cleaner industrial processes and investments in hydrogen infrastructure are further catalyzing market expansion. The technological advancements in hydrogen production, storage, and transportation are also significant drivers, enhancing efficiency and reducing costs, thereby broadening its applicability and market penetration.

Chemical Hydrogen Market Executive Summary

The Chemical Hydrogen market is experiencing dynamic growth, driven by an escalating demand from key industrial sectors coupled with a global push towards decarbonization. Business trends indicate a robust increase in investments in hydrogen production facilities, particularly those leveraging cleaner technologies such as electrolysis for green hydrogen and carbon capture for blue hydrogen. Companies are actively forming strategic partnerships to develop integrated hydrogen ecosystems, encompassing production, storage, and distribution. There is a clear trend towards optimizing production costs through technological innovation and scaling up operations, aiming to make cleaner hydrogen more competitive with traditional fossil-fuel-based methods. Furthermore, the market is characterized by significant mergers and acquisitions activity as established players and new entrants seek to consolidate market share and expand their technological capabilities.

Regional trends highlight distinct growth patterns and strategic priorities. Asia Pacific, led by countries like China, India, and Japan, remains a dominant market due to its vast industrial base and ambitious national hydrogen strategies focused on both energy and industrial applications. Europe is rapidly advancing with strong regulatory support, extensive investment in green hydrogen projects, and the establishment of cross-border hydrogen pipelines, positioning itself as a leader in sustainable hydrogen development. North America is also witnessing substantial growth, particularly in the US, driven by tax credits and incentives aimed at boosting clean hydrogen production and infrastructure. The Middle East and Africa (MEA) are emerging as significant potential exporters of green hydrogen, leveraging abundant renewable energy resources, while Latin America is exploring its potential for hydrogen production, particularly for export markets.

Segmentation trends reveal that while Steam Methane Reforming (SMR) currently accounts for the largest share of chemical hydrogen production, its relative dominance is expected to decrease over the forecast period as electrolysis gains traction. The application segment continues to be dominated by ammonia production for fertilizers and methanol synthesis, but refineries are also a substantial and consistent consumer. Emerging applications in direct reduced iron (DRI) for steel production and other industrial processes are set to become significant growth areas. The end-use industry analysis shows sustained demand from the chemical and petrochemical sectors, with increasing adoption in the energy and transportation sectors as hydrogen's role in the broader energy transition solidifies. The focus across all segments is on achieving greater efficiency, lower costs, and reduced environmental impact, which is fostering innovation in every part of the value chain.

AI Impact Analysis on Chemical Hydrogen Market

User inquiries regarding the impact of Artificial Intelligence on the Chemical Hydrogen Market frequently revolve around optimizing production efficiency, reducing operational costs, enhancing safety, and improving supply chain resilience. Users are keen to understand how AI can address the inherent complexities of hydrogen production, particularly for novel methods like electrolysis, and how it can facilitate better integration of variable renewable energy sources. There is also significant interest in AI's role in predictive maintenance for critical infrastructure and in demand forecasting to ensure stable supply chains, thereby tackling concerns about the high capital expenditure and operational challenges associated with scaling up clean hydrogen technologies. The overarching expectation is that AI will be a transformative force, making the hydrogen economy more viable and sustainable.

- AI for process optimization: Real-time monitoring and control of hydrogen production units (e.g., electrolyzers, SMR units) to maximize efficiency and purity, minimizing energy consumption and waste.

- Predictive maintenance: Utilizing AI algorithms to analyze sensor data from pumps, compressors, and reactors to predict equipment failures, enabling proactive maintenance and reducing downtime.

- Supply chain management: Optimizing logistics for hydrogen storage and transportation, including route optimization for tankers and real-time inventory management across distribution networks.

- Demand forecasting: AI-driven models to accurately predict hydrogen demand from various industrial end-users, ensuring optimal production scheduling and preventing supply-demand mismatches.

- Safety and risk management: AI systems for continuous monitoring of facilities to detect leaks, anomalies, or potential hazards, enhancing operational safety and regulatory compliance.

- Integration of renewable energy: AI algorithms to manage the intermittency of renewable energy sources (wind, solar) for electrolysis, ensuring stable and cost-effective green hydrogen production.

- Research and development acceleration: AI and machine learning to accelerate the discovery of new catalyst materials, improve membrane technologies, and enhance overall hydrogen production methods.

DRO & Impact Forces Of Chemical Hydrogen Market

The Chemical Hydrogen market is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, alongside significant impact forces. Key drivers include the escalating global commitment to decarbonization and net-zero emissions targets, which position hydrogen as a crucial element in achieving sustainable industrial processes. Additionally, the growing demand from established end-use sectors like ammonia production, methanol synthesis, and petroleum refining continues to underpin market growth. Government policies and incentives, such as tax credits for clean hydrogen production and funding for infrastructure development, are providing substantial impetus for market expansion. Furthermore, technological advancements in hydrogen production efficiency, storage solutions, and distribution networks are steadily reducing costs and enhancing the feasibility of hydrogen adoption across diverse applications, thereby fueling its market penetration and growth.

However, several restraints impede the market's full potential. The high capital expenditure associated with establishing new clean hydrogen production facilities, especially for electrolysis, remains a significant barrier. The comparatively high production cost of green hydrogen, when contrasted with conventional fossil-fuel-based methods like SMR without carbon capture, poses a challenge for widespread adoption, particularly in cost-sensitive industries. Infrastructure limitations for hydrogen storage, transportation, and distribution are another major restraint, requiring substantial investment and time to develop. Safety concerns related to hydrogen's flammability and difficulty in containment also necessitate stringent regulatory frameworks and advanced safety technologies, adding to the overall cost and complexity of project implementation.

Opportunities for growth are abundant within the Chemical Hydrogen market. The development of innovative storage and transportation technologies, such as liquid organic hydrogen carriers (LOHCs) and solid-state hydrogen storage, promises to enhance efficiency and reduce logistics costs. The emergence of new end-use applications, particularly in direct reduced iron (DRI) for green steel production, heavy-duty transportation (fuel cells), and power generation, offers substantial avenues for market diversification and expansion. Furthermore, the potential for cross-sectoral integration, where hydrogen acts as an energy carrier and a chemical feedstock, presents unique synergies and market opportunities. The increasing focus on regional and international collaborations to establish robust hydrogen supply chains and trade corridors also represents a significant growth enabler, fostering economies of scale and accelerating market maturity.

Segmentation Analysis

The Chemical Hydrogen market is comprehensively segmented to provide a detailed understanding of its varied dynamics, encompassing different production methods, diverse applications, and numerous end-use industries. This segmentation allows for granular analysis of market trends, technological preferences, and demand drivers across the hydrogen value chain. The primary segments reflect the evolution from conventional fossil-fuel-based hydrogen production to advanced, cleaner methods, and highlight the critical industrial processes that rely on hydrogen as a key input. Understanding these segments is crucial for stakeholders to identify growth opportunities, develop targeted strategies, and navigate the complex landscape of the chemical hydrogen industry, aligning with both economic objectives and sustainability goals.

- By Production Method

- Steam Methane Reforming (SMR)

- Electrolysis (Alkaline, PEM, SOEC)

- Coal Gasification

- Partial Oxidation of Hydrocarbons

- Biomass Gasification

- Others (e.g., Thermochemical Cycles, Photocatalysis)

- By Application

- Ammonia Production

- Methanol Production

- Petroleum Refining (Hydrotreating, Hydrocracking)

- Direct Reduced Iron (DRI) for Steel Production

- Hydrogenation of Fats and Oils

- Electronics Manufacturing

- Chemical Synthesis (e.g., Aniline, Cyclohexane)

- Pharmaceuticals

- Glass Manufacturing

- By End-Use Industry

- Chemical and Petrochemical

- Refineries

- Metals and Mining

- Food and Beverage

- Electronics

- Pharmaceuticals

- Glass

- Power Generation

- Transportation (emerging, but chemical use in fuel synthesis)

Value Chain Analysis For Chemical Hydrogen Market

The value chain for the Chemical Hydrogen market is intricate, involving multiple stages from raw material sourcing to end-user consumption. Upstream activities primarily involve the procurement of feedstocks essential for hydrogen production. For conventional methods like Steam Methane Reforming (SMR), this includes natural gas. For electrolysis, it involves securing a reliable and cost-effective supply of water and electricity, with a growing emphasis on renewable electricity sources for green hydrogen. Coal gasification relies on coal, while biomass gasification uses agricultural residues or dedicated energy crops. The efficiency and environmental footprint of these upstream processes significantly impact the overall sustainability and cost-competitiveness of the final hydrogen product, driving innovation in renewable energy integration and sustainable feedstock sourcing.

Midstream operations focus on the actual production, purification, and initial storage of hydrogen. This stage involves various technologies such as SMR, partial oxidation, coal gasification, and electrolysis. Following production, hydrogen undergoes rigorous purification processes to meet the specific purity requirements of different industrial applications, which can range from standard industrial grade to ultra-high purity for electronics and fuel cells. Storage solutions are also critical here, including compressed gas in cylinders or tanks, liquid hydrogen in cryogenic tanks, and emerging solid-state storage technologies. The choice of production method and storage solution is dictated by factors such as feedstock availability, energy costs, environmental regulations, and the specific demands of the end-user, emphasizing the need for flexible and scalable infrastructure.

Downstream activities encompass the distribution, delivery, and eventual consumption by end-users. Hydrogen is transported through various channels: pipelines for large-volume, continuous supply to industrial clusters, tube trailers for compressed gas over shorter distances, and cryogenic tankers for liquid hydrogen over longer hauls. The distribution network involves terminals, refueling stations (for some emerging transport applications), and direct delivery to industrial sites. Direct sales often occur via dedicated pipelines to large industrial complexes like ammonia plants or refineries, ensuring a steady and integrated supply. Indirect channels may involve third-party distributors who aggregate and deliver hydrogen in smaller quantities to diverse customers. The efficiency and cost-effectiveness of these distribution channels are paramount for market penetration, impacting the delivered price of hydrogen and its competitiveness against alternative chemical feedstocks.

Chemical Hydrogen Market Potential Customers

Potential customers for chemical hydrogen are predominantly large industrial entities across a spectrum of sectors, where hydrogen serves as an indispensable raw material or processing agent. The primary buyers include chemical and petrochemical manufacturers, particularly those involved in the production of ammonia for fertilizers and methanol for various downstream chemical products like formaldehyde and acetic acid. These industries require vast, continuous supplies of high-purity hydrogen, making them foundational customers for the market. The consistent demand from these sectors ensures a stable base for hydrogen producers and drives significant investment in supply infrastructure, emphasizing long-term contractual relationships and reliable delivery mechanisms.

Refineries represent another major segment of potential customers, utilizing hydrogen extensively in hydrotreating processes to remove sulfur, nitrogen, and other impurities from crude oil derivatives, as well as in hydrocracking to convert heavy crude oil fractions into lighter, more valuable products like gasoline and diesel. As environmental regulations concerning fuel quality become more stringent globally, the demand for hydrogen in refining processes is expected to remain robust. Furthermore, the metals and mining industry, particularly steel manufacturers, are increasingly exploring hydrogen for direct reduced iron (DRI) processes to produce green steel, offering a significant growth avenue as industries aim to decarbonize their operations. This shift towards hydrogen-based steelmaking could redefine a substantial portion of the demand landscape for chemical hydrogen.

Beyond these dominant segments, a diverse array of industries constitutes potential customers. The food and beverage sector uses hydrogen for the hydrogenation of fats and oils in margarine and cooking oil production. The electronics industry demands ultra-high purity hydrogen for semiconductor manufacturing and annealing processes. Pharmaceutical companies use hydrogen in various synthesis reactions, and glass manufacturers utilize it for flame polishing and atmosphere control. As new industrial applications emerge, driven by technological advancements and the imperative for cleaner production, the customer base for chemical hydrogen is poised for further diversification and expansion, encompassing even niche, high-value-added sectors that prioritize purity and environmental benefits.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 135.2 billion |

| Market Forecast in 2032 | USD 213.5 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Linde plc, Air Liquide, Air Products and Chemicals Inc., Messer Group GmbH, Taiyo Nippon Sanso Corporation (MOU for Airgas), Reliance Industries Ltd., Suncor Energy Inc., Shell plc, BP plc, Engie SA, Nel Hydrogen, Plug Power Inc., ITM Power plc, thyssenkrupp AG, Siemens Energy AG, Cummins Inc., Fortescue Future Industries, Saudi Aramco, ExxonMobil, Mitsubishi Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Chemical Hydrogen Market Key Technology Landscape

The technological landscape of the Chemical Hydrogen market is characterized by a blend of mature, dominant processes and rapidly evolving, innovative solutions, all aimed at improving efficiency, reducing costs, and enhancing sustainability. Steam Methane Reforming (SMR) remains the cornerstone of hydrogen production due to its established infrastructure and cost-effectiveness. However, significant advancements in SMR now incorporate Carbon Capture, Utilization, and Storage (CCUS) technologies to produce "blue hydrogen," thereby mitigating its carbon footprint. Research continues on optimizing catalyst performance and reactor design to increase hydrogen yield and reduce energy consumption in SMR plants, ensuring its continued relevance in a decarbonizing world.

Electrolysis technologies are witnessing rapid innovation, driven by the global push for "green hydrogen" production using renewable electricity. Alkaline electrolyzers, a mature technology, are being scaled up for large industrial applications, while Proton Exchange Membrane (PEM) electrolyzers are gaining traction due to their compact size, rapid response to intermittent renewable power, and high efficiency. Solid Oxide Electrolyzer Cells (SOEC) are another promising technology, operating at high temperatures and capable of co-producing hydrogen and syngas, offering higher electrical efficiency when integrated with industrial waste heat. Advancements in electrode materials, membrane designs, and system integration are continuously reducing the capital costs and operational expenditures of these electrolyzers, making green hydrogen increasingly competitive.

Beyond SMR and electrolysis, other emerging technologies are also shaping the market. Biomass gasification offers a renewable pathway to hydrogen production, converting organic matter into syngas which can then be purified to yield hydrogen. Pyrolysis of natural gas, a process that produces "turquoise hydrogen" and solid carbon, is being explored for its potential to avoid CO2 emissions. Furthermore, research into photocatalytic and photoelectrochemical water splitting aims to develop direct solar-to-hydrogen conversion methods, promising extremely low-carbon production at potentially reduced costs in the long term. These diverse technological pathways highlight the market's dynamic nature and the ongoing pursuit of economically viable and environmentally sustainable hydrogen production methods for chemical applications.

Regional Highlights

- Asia Pacific: The largest and fastest-growing market for chemical hydrogen, driven by extensive industrialization, particularly in China, India, and Southeast Asian nations. High demand from ammonia, methanol, and refining sectors, coupled with significant investments in clean hydrogen production and infrastructure. Government support for hydrogen strategies in countries like Japan, South Korea, and Australia is accelerating adoption.

- Europe: A leading region in the transition to clean hydrogen, supported by ambitious decarbonization targets, robust policy frameworks (e.g., EU Hydrogen Strategy), and substantial funding for green and blue hydrogen projects. Germany, the Netherlands, France, and Spain are key players, focusing on developing integrated hydrogen value chains and cross-border pipeline networks.

- North America: Experiencing strong growth propelled by government incentives such as the Inflation Reduction Act (IRA) in the US, which offers significant tax credits for clean hydrogen production. High demand from refineries and chemical industries, alongside increasing investments in electrolysis and carbon capture technologies, particularly in states with abundant natural gas and renewable energy resources.

- Middle East and Africa (MEA): Emerging as a critical region for green and blue hydrogen production, leveraging vast renewable energy potential (solar in MEA) and abundant natural gas reserves (Middle East). Countries like Saudi Arabia, UAE, and Oman are investing heavily in large-scale clean hydrogen export projects, aiming to become global suppliers to industrial markets.

- Latin America: Demonstrating growing interest in developing its hydrogen economy, particularly leveraging abundant renewable energy resources (e.g., wind in Chile, hydropower in Brazil). Initial focus on pilot projects and export potential, with countries like Chile and Brazil positioning themselves for green hydrogen production for both domestic industrial use and international markets.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Chemical Hydrogen Market.- Linde plc

- Air Liquide

- Air Products and Chemicals Inc.

- Messer Group GmbH

- Taiyo Nippon Sanso Corporation (MOU for Airgas)

- Reliance Industries Ltd.

- Suncor Energy Inc.

- Shell plc

- BP plc

- Engie SA

- Nel Hydrogen

- Plug Power Inc.

- ITM Power plc

- thyssenkrupp AG

- Siemens Energy AG

- Cummins Inc.

- Fortescue Future Industries

- Saudi Aramco

- ExxonMobil

- Mitsubishi Corporation

Frequently Asked Questions

What is chemical hydrogen and its primary uses?

Chemical hydrogen refers to hydrogen produced and utilized as a feedstock in industrial processes. Its primary uses include ammonia synthesis for fertilizers, methanol production, and hydrotreating in petroleum refineries to remove impurities from fuels.

Which production method currently dominates the chemical hydrogen market?

Steam Methane Reforming (SMR) currently dominates the chemical hydrogen market due to its cost-effectiveness and well-established infrastructure, though cleaner methods like electrolysis are rapidly gaining market share.

How is AI impacting the efficiency of chemical hydrogen production?

AI impacts efficiency by optimizing production processes, enabling predictive maintenance for equipment, improving supply chain logistics, and providing accurate demand forecasting, thereby reducing operational costs and downtime.

What are the main drivers for the growth of the chemical hydrogen market?

Key drivers include global decarbonization initiatives, increasing demand from industries like chemical manufacturing and refining, robust government support and incentives for clean hydrogen, and continuous technological advancements.

Which region leads in chemical hydrogen consumption and why?

Asia Pacific leads in chemical hydrogen consumption, primarily due to its vast industrial base in countries like China and India, which have high demand from sectors such as fertilizers, petrochemicals, and refining.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Captive Chemical Hydrogen Generation Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Chemical Hydrogen Generation Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager