Milling Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430245 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Milling Machine Market Size

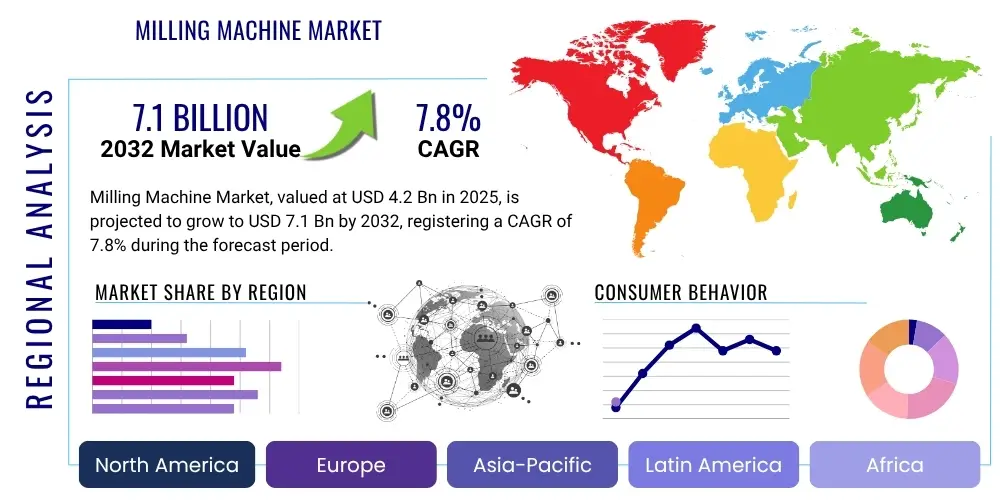

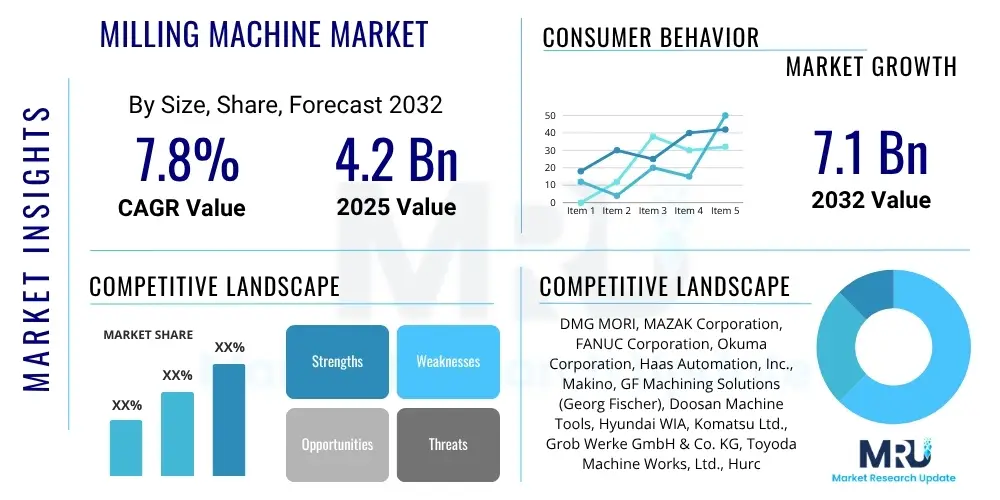

The Milling Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at $4.2 Billion in 2025 and is projected to reach $7.1 Billion by the end of the forecast period in 2032.

Milling Machine Market introduction

The global industrial landscape relies heavily on advanced milling machines for precision manufacturing across a multitude of sectors. These versatile machine tools are fundamental to shaping materials, creating complex geometries, and ensuring extremely tight tolerances in components for various critical applications. Milling machines, which utilize a rotating cutter to remove material from a workpiece often held stationary, perform a wide range of operations including slotting, planing, drilling, and contouring. The market spans from conventional manual machines to highly sophisticated Computer Numerical Control (CNC) systems, offering unparalleled flexibility and accuracy.

Major applications for milling machines are prevalent in industries such as automotive, aerospace, medical device manufacturing, general engineering, tool and die making, electronics, and energy sectors. The primary benefits derived from these machines include high precision, exceptional repeatability, versatility in handling different materials and part designs, efficiency in material removal, and significant reduction in labor costs through automation. Key driving factors propelling this market include the increasing global demand for precision components, the rapid rise of advanced manufacturing techniques, broader industrial automation trends, robust growth in automotive and aerospace production, and the escalating demand for customized and complex manufacturing solutions that only advanced milling can provide.

Milling Machine Market Executive Summary

The Milling Machine Market is undergoing significant transformation, primarily driven by a global shift towards automation and smart manufacturing practices, marked by the strong integration of Internet of Things (IoT) and Artificial Intelligence (AI) into machine operations. Current business trends indicate a concentrated effort by manufacturers to develop and implement multi-axis CNC machines and hybrid manufacturing solutions, which combine subtractive and additive processes, to address increasingly intricate production demands. Despite these advancements, the market continues to navigate global supply chain disruptions and fluctuating raw material prices, which significantly influence production timelines and overall market stability, compelling companies to adopt more resilient sourcing strategies and localized manufacturing where feasible.

Regionally, Asia Pacific stands as the leading market, fueled by robust manufacturing growth in economies such as China and India, alongside proactive government initiatives aimed at promoting widespread industrialization and technological adoption. North America and Europe, while mature, are significant adopters of advanced CNC technologies, primarily driven by their sophisticated aerospace, defense, and medical device sectors, which demand high precision and innovation. Latin America and the Middle East and Africa (MEA) are emerging as growth markets, experiencing an upward trajectory propelled by substantial investments in infrastructure development, economic diversification efforts, and a burgeoning manufacturing base that increasingly requires modern machining capabilities to compete globally. These regions represent significant opportunities for expansion and technological dissemination.

Segmentation analysis highlights the dominance of CNC milling machines, which account for the largest market share due to their superior precision, enhanced automation capabilities, and ability to handle complex tasks with minimal human intervention. Vertical milling machines are widely adopted for general-purpose machining across various industries, offering a balance of flexibility and cost-effectiveness. Conversely, horizontal milling machines are gaining traction for heavy-duty applications, particularly in large-scale industrial manufacturing, owing to their robust design and efficient chip evacuation. Furthermore, the software and services segments, encompassing CAD/CAM solutions, simulation software, and comprehensive after-sales support, are experiencing accelerated growth as integral components of holistic manufacturing solutions, crucial for maximizing machine uptime and optimizing operational efficiency in modern production environments.

AI Impact Analysis on Milling Machine Market

Common user questions regarding the impact of AI on the Milling Machine Market frequently center on how artificial intelligence can significantly enhance operational efficiency, enable predictive maintenance, and ensure superior part quality throughout the manufacturing process. Users are keen to understand the practical applications of AI in optimizing tool paths, reducing cycle times, and minimizing material waste. Conversely, concerns often revolve around the substantial initial investment required for AI integration, the necessary learning curve for existing operators, and the critical importance of data security and intellectual property protection within increasingly connected manufacturing ecosystems. Expectations are notably high for AI to revolutionize automation, leading to unprecedented levels of precision and consistency, effectively minimizing human error, and ultimately contributing to more sustainable and cost-effective production methodologies across various industries.

- Enhanced predictive maintenance, significantly reducing machine downtime and extending lifespan.

- Optimized tool path generation and adaptive process parameters for superior machining efficiency.

- Real-time quality control and anomaly detection, preventing defects and ensuring consistent output.

- Improved machine utilization and energy efficiency through intelligent scheduling and power management.

- Automated programming and adaptive machining capabilities, simplifying complex tasks.

- Faster prototyping and reduced material waste through advanced simulation and optimization.

- Advanced robotics integration for fully automated material handling and machine tending, boosting productivity.

DRO & Impact Forces Of Milling Machine Market

The Milling Machine Market's growth is primarily driven by the escalating demand for industrial automation across manufacturing sectors, the critical requirement for high-precision engineering components in sophisticated applications, and continuous technological advancements in machine design and control systems, including multi-axis CNC and integrated additive manufacturing capabilities. These drivers collectively push the boundaries of what is achievable in modern fabrication. However, the market faces significant restraints such as the high initial investment costs associated with acquiring advanced milling machines, which can be prohibitive for small and medium-sized enterprises. Additionally, a persistent shortage of skilled labor proficient in operating and programming complex CNC systems poses a bottleneck, alongside the inherent cyclical nature of key end-use industries, which can lead to fluctuating demand and uncertainty.

Opportunities within the market are abundant, particularly in the rapid industrialization of emerging economies that are actively investing in manufacturing infrastructure, presenting new avenues for market penetration. The widespread adoption of Industry 4.0 solutions, encompassing IoT, AI, and digital twin technologies, offers a transformative potential for optimizing entire production lines. Furthermore, the increasing demand for lightweight, high-performance materials in critical sectors like aerospace and defense mandates specialized milling capabilities, opening niches for innovative machine development. The market is also shaped by several impact forces including the relentless trend of globalization, fostering competitive pressures and cross-border collaborations. Technological innovation acts as a constant catalyst, pushing for higher efficiency and precision. Environmental regulations increasingly favor more efficient and sustainable manufacturing processes, while prevailing economic conditions significantly influence capital expenditure and investment decisions across industries, directly affecting market dynamics.

Segmentation Analysis

The Milling Machine Market is comprehensively segmented based on key attributes such as machine type, the underlying technology employed, the specific application areas, and the diverse end-use industries it serves. This granular segmentation provides critical insights into the market's structure, allowing for a detailed analysis of competitive landscapes, identifying niche growth opportunities, and understanding the varying demands and preferences across different operational categories. By dissecting the market along these dimensions, stakeholders can gain a nuanced perspective on technological adoption rates, regional consumption patterns, and the strategic imperatives that drive investment and innovation within the sector. This approach facilitates a targeted understanding of market dynamics, enabling more informed decision-making for manufacturers, suppliers, and investors.

- By Machine Type:

- Vertical Milling Machine

- Horizontal Milling Machine

- Universal Milling Machine

- Other Machine Types (e.g., Gantry Milling Machine, Turret Milling Machine)

- By Technology:

- CNC Milling Machine

- Conventional/Manual Milling Machine

- By Axis Type:

- 3-Axis

- 4-Axis

- 5-Axis

- Multi-Axis (Greater than 5-Axis)

- By Application:

- Die Mold Manufacturing

- Precision Parts Machining

- General Machining Operations

- Prototyping and Toolmaking

- Others (e.g., Medical Implants, Turbine Blades)

- By End-Use Industry:

- Automotive Industry

- Aerospace and Defense

- Electronics and Semiconductor

- Medical and Healthcare

- Energy (Oil and Gas, Power Generation)

- General Manufacturing and Job Shops

- Heavy Industry

- Educational and Research Institutions

- Others (e.g., Marine, Agriculture)

Value Chain Analysis For Milling Machine Market

The value chain for the Milling Machine Market is a complex ecosystem encompassing several critical stages, beginning with robust upstream activities that include the sourcing of diverse raw materials such as specialized steels, cast iron, aluminum alloys, and various electronic components and precision mechanical parts from a global network of suppliers. These materials form the foundational elements for constructing high-performance machines. Machine manufacturers then undertake the intensive processes of design, engineering, assembly, and rigorous testing of milling machines, where advanced technologies, software integration, and stringent quality control are paramount to ensure the production of reliable and efficient equipment that meets international standards and customer specifications. This stage also involves substantial research and development efforts to innovate and differentiate products in a competitive market.

The downstream segment of the value chain is characterized by an intricate network of distribution channels responsible for delivering the finished milling machines to end-users globally. This often involves a blend of direct sales channels, where manufacturers engage directly with large enterprise clients or specialized project implementers for bespoke solutions, and indirect sales channels, which leverage regional distributors, dealers, and value-added resellers for broader market penetration and localized support. Post-sales services, including comprehensive installation, preventive and corrective maintenance, technical support, spare parts supply, and operator training, are integral components of the value proposition. These services ensure operational efficiency, maximize machine uptime, and contribute significantly to overall customer satisfaction and loyalty. The effectiveness of these channels is crucial for market reach and sustaining long-term customer relationships.

Milling Machine Market Potential Customers

Potential customers for milling machines represent a broad and diverse spectrum of manufacturing and engineering enterprises that share a fundamental requirement for precision material removal, intricate part fabrication, and robust toolmaking capabilities. This extensive customer base includes large-scale automotive manufacturers needing high-volume component production and specialized engine parts, aerospace and defense contractors producing safety-critical components with exacting tolerances for aircraft and weaponry, and medical device companies necessitating ultra-high precision implants and surgical instruments. Electronics firms fabricating intricate circuit board components and semiconductor molds also form a significant segment, demanding machines capable of micro-level machining.

Beyond these highly specialized industries, general engineering workshops, custom job shops, and fabrication facilities constitute a substantial segment of buyers, utilizing milling machines for a wide range of tasks from custom part production to repair and maintenance operations. Additionally, educational institutions, vocational training centers, and research and development laboratories are important customers, acquiring milling machines for teaching purposes, experimental work, and prototyping new designs. The driving forces behind these diverse purchases are often the need for customized parts, rapid prototyping capabilities, efficient mass production of complex geometries, and the imperative for accuracy and reliability in manufacturing processes across all scales of operation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $4.2 Billion |

| Market Forecast in 2032 | $7.1 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | DMG MORI, MAZAK Corporation, FANUC Corporation, Okuma Corporation, Haas Automation, Inc., Makino, GF Machining Solutions (Georg Fischer), Doosan Machine Tools, Hyundai WIA, Komatsu Ltd., Grob Werke GmbH & Co. KG, Toyoda Machine Works, Ltd., Hurco Companies, Inc., HERMLE AG, Chiron Group, Zayer S.A., Soraluce, Index-Werke GmbH & Co. KG, Feeler (Fair Friend Group), EMCO Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Milling Machine Market Key Technology Landscape

The Milling Machine Market's technological landscape is characterized by a relentless pursuit of enhanced precision, increased speed, greater automation, and improved operational intelligence. Central to this evolution are advanced Computer Numerical Control (CNC) systems that have evolved to offer multi-axis capabilities, ranging from 3-axis to 4-axis, 5-axis, and even more complex multi-axis configurations. These advancements enable the machining of exceptionally intricate and complex geometries with superior accuracy and surface finish, crucial for demanding industries such as aerospace and medical. The pervasive integration of Industry 4.0 principles, including the Internet of Things (IoT) for real-time monitoring and advanced data analytics, is becoming a standard feature, facilitating predictive maintenance, optimizing production flows, and enabling remote diagnostics and control across distributed manufacturing environments.

Furthermore, the market is witnessing the emergence and increasing adoption of hybrid manufacturing solutions, which seamlessly combine traditional subtractive milling with additive manufacturing (3D printing) processes. This integration allows for the creation of intricate prototypes and highly specialized components with internal geometries previously impossible, reducing both material waste and production lead times. Cloud-based manufacturing platforms and digital twin technology are also gaining significant traction, enabling virtual simulation and comprehensive optimization of milling processes before any physical material is cut. This leads to substantial reductions in trial-and-error, faster product development cycles, and improved overall efficiency. The continuous development of advanced cutting tools, innovations in materials science for both workpieces and machine components, and sophisticated CAD/CAM software further support the market's technological progression, expanding the range of applications for milling machines and driving efficiency throughout the entire manufacturing ecosystem. Robotics integration for automated loading and unloading operations is also enhancing productivity and safety in modern milling environments.

Regional Highlights

- Asia Pacific: This region holds a dominant position in the global Milling Machine Market, primarily driven by rapid industrialization, high manufacturing output, and significant investments in advanced manufacturing technologies across countries like China, India, Japan, and South Korea. The automotive, electronics, and general manufacturing sectors are key contributors.

- Europe: A mature and highly sophisticated market characterized by high precision engineering capabilities and a strong presence in the aerospace, medical, and high-end automotive industries. Countries such as Germany, Italy, and Switzerland lead in innovation and R&D for advanced milling solutions, focusing on automation and digitalization.

- North America: This market is driven by continuous technological advancements, robust demand from critical sectors like aerospace and defense, medical devices, and custom fabrication. The United States and Canada are key players, with a strong emphasis on automation, high-value manufacturing, and the adoption of smart factory initiatives.

- Latin America: An emerging market experiencing growth fueled by expanding automotive manufacturing (particularly in Mexico and Brazil), increasing investments in infrastructure development, and a growing general manufacturing base. The region is gradually adopting more advanced machining technologies to enhance competitiveness.

- Middle East and Africa (MEA): A nascent but rapidly growing market, propelled by economic diversification efforts in oil-dependent economies, substantial infrastructure projects, and increasing investments in localized manufacturing and processing industries across the region, particularly in the GCC countries and South Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Milling Machine Market.- DMG MORI

- MAZAK Corporation

- FANUC Corporation

- Okuma Corporation

- Haas Automation, Inc.

- Makino

- GF Machining Solutions (Georg Fischer)

- Doosan Machine Tools

- Hyundai WIA

- Komatsu Ltd.

- Grob Werke GmbH & Co. KG

- Toyoda Machine Works, Ltd.

- Hurco Companies, Inc.

- Yamazaki Mazak Corporation

- HERMLE AG

- Chiron Group

- Zayer S.A.

- Index-Werke GmbH & Co. KG

- Soraluce

- Feeler (Fair Friend Group)

Frequently Asked Questions

What are the primary advantages of CNC milling machines over conventional ones?

CNC milling machines offer superior precision, exceptional repeatability, and enhanced automation, enabling the production of highly complex geometries with minimal human intervention, significantly reduced errors, and greater operational efficiency compared to manual operations.

Which industries are the largest consumers of milling machines globally?

The automotive, aerospace and defense, medical devices, electronics and semiconductor, and general manufacturing sectors are the largest consumers, primarily driven by their critical need for high-precision components, complex part fabrication, and advanced material processing capabilities.

How is Industry 4.0 impacting the Milling Machine Market landscape?

Industry 4.0 significantly impacts the market by fostering the integration of IoT, AI, and data analytics, leading to the development of smart factories with enhanced automation, predictive maintenance, real-time monitoring, optimized production processes, and greater overall operational intelligence.

What are the key challenges faced by manufacturers in the Milling Machine Market?

Key challenges include the high initial investment costs for acquiring advanced machines, a persistent shortage of skilled labor required to operate complex CNC systems, and the imperative to rapidly adapt to evolving technological advancements and fluctuating global raw material prices.

What future trends are expected to shape the Milling Machine Market?

Future trends include the increased adoption of multi-axis and hybrid manufacturing solutions, greater integration of AI and machine learning for process optimization, the widespread development of cloud-based manufacturing platforms, and a growing emphasis on sustainable and energy-efficient machining processes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Road Milling Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Rocker Milling Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Rice Milling Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Rocker Milling Machine Market Statistics 2025 Analysis By Application (Automobile Industry, Shipping Industry, Equipment Manufacturing Industry), By Type (Vertical Milling Machine, Horizontal Milling Machine), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Cold Milling Machine Market Statistics 2025 Analysis By Application (Asphalt Road, Concrete Road), By Type (Small Cold Milling Machine, Medium Cold Milling Machine, Large Cold Milling Machine), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager