Plier Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429846 | Date : Nov, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Plier Market Size

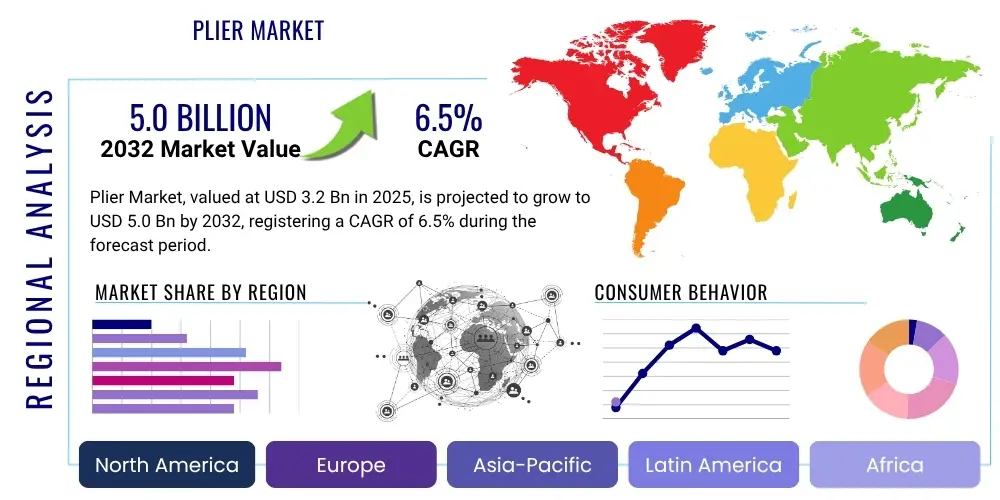

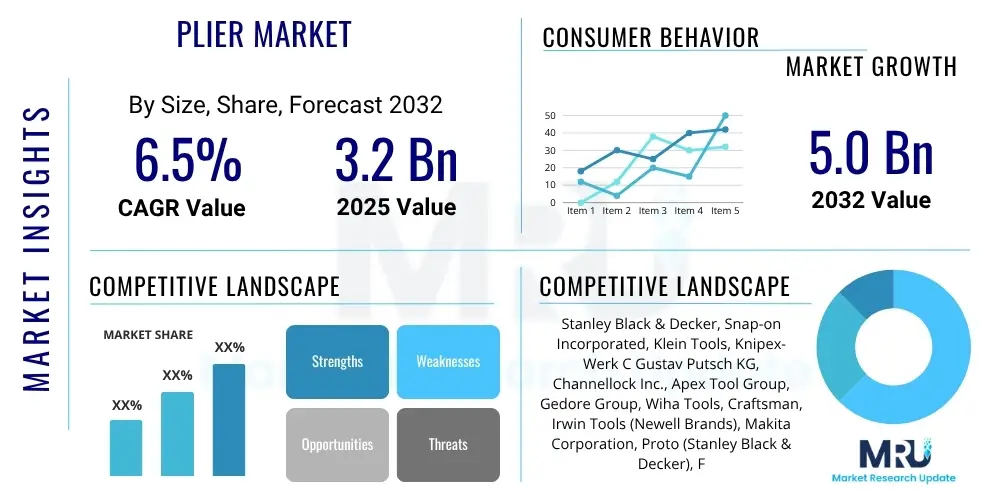

The Plier Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032. The market is estimated at USD 3.2 Billion in 2025 and is projected to reach USD 5.0 Billion by the end of the forecast period in 2032.

Plier Market introduction

The plier market encompasses a wide array of hand tools designed for gripping, cutting, bending, and twisting various materials. Pliers are fundamental implements across numerous industries and household applications, providing mechanical advantage and precision for tasks that would otherwise be difficult or impossible by hand alone. The market's stability is underpinned by the essential nature of these tools in construction, automotive repair, electronics manufacturing, plumbing, and general maintenance.

Key product descriptions within this market include combination pliers, cutting pliers (diagonal, end, and flush), gripping pliers (slip-joint, tongue-and-groove, locking), needle-nose pliers, and specialized variants such as crimping, circlip, and fencing pliers. Each type is engineered with specific jaw configurations and leverage mechanisms to optimize performance for its intended application. The benefits of modern pliers extend beyond basic functionality, incorporating ergonomic designs, insulated handles for electrical safety, and durable materials that enhance user comfort, reduce fatigue, and ensure longevity.

The market is primarily driven by several macroeconomic and industry-specific factors. Continuous growth in the global construction sector, particularly in emerging economies, fuels demand for robust hand tools. The expanding automotive industry, both in manufacturing and aftermarket services, consistently requires specialized pliers. Furthermore, the burgeoning DIY culture, coupled with increasing disposable incomes and a rising propensity for home improvement projects, significantly contributes to market expansion. Industrial maintenance and repair operations across manufacturing facilities also represent a substantial and stable demand segment for various plier types, emphasizing durability and precision.

Plier Market Executive Summary

The plier market demonstrates a resilient growth trajectory, primarily influenced by ongoing industrialization, infrastructural development, and a strong global emphasis on both professional trades and household DIY activities. Business trends indicate a focus on material innovation, ergonomic design improvements, and the integration of smart manufacturing processes to enhance product quality and production efficiency. Companies are increasingly investing in research and development to offer specialized tools that cater to evolving industry demands, such as insulated pliers for electrical work and multi-functional tools for versatility.

Regional trends highlight dynamic shifts in market dominance and growth rates. Asia Pacific is poised for significant expansion, driven by rapid urbanization, substantial investments in construction, and a thriving manufacturing sector, particularly in countries like China and India. North America and Europe, while representing mature markets, maintain consistent demand owing to established industrial bases, a robust professional trades workforce, and a strong consumer base for premium and specialized tools. These regions also lead in adopting advanced manufacturing techniques and sustainable practices, influencing global product standards.

Segmentation trends reveal a growing preference for application-specific tools, suggesting a move away from generic options towards specialized pliers that offer enhanced precision and safety for complex tasks. The professional/industrial end-user segment continues to be a dominant revenue generator, valuing durability, reliability, and brand reputation. Concurrently, the residential/DIY segment is expanding, propelled by accessibility through e-commerce platforms and a general increase in home repair and hobbyist activities. The rise of online retail channels is also reshaping distribution strategies, offering greater reach and convenience for both manufacturers and consumers.

AI Impact Analysis on Plier Market

The integration of Artificial Intelligence (AI) in the plier market is not about intelligent pliers themselves, but rather about revolutionizing the processes surrounding their manufacturing, distribution, and design. Common user questions often revolve around whether AI can make pliers smarter, or how it improves their production. The overarching theme is that AI's influence is predominantly indirect, acting as an enabler for greater efficiency, precision, and predictive capabilities throughout the plier industry value chain, ensuring better product availability, quality, and responsiveness to market demands. Users are keen to understand how traditional tools can benefit from advanced technological ecosystems.

AI's impact spans several critical areas, from optimizing the supply chain to enhancing production line efficiency and even informing product design through data analytics. Predictive analytics powered by AI can forecast demand with higher accuracy, minimizing inventory costs and reducing stockouts. In manufacturing, AI-driven quality control systems can detect defects in raw materials or finished products much faster and more consistently than human inspection, leading to superior product quality. Moreover, machine learning algorithms can analyze vast datasets to identify optimal material compositions or ergonomic designs, pushing the boundaries of traditional tool engineering without making the plier itself an AI-powered device. These applications translate into more durable, efficient, and cost-effective tools for the end-user, even if the AI is 'behind the scenes'.

- Enhanced Demand Forecasting: AI algorithms analyze historical sales data, seasonal trends, and economic indicators to predict future plier demand with greater accuracy, optimizing inventory management and production schedules.

- Optimized Manufacturing Processes: AI-powered predictive maintenance for machinery on production lines reduces downtime, while machine vision systems ensure precise quality control during forging, machining, and assembly.

- Supply Chain Efficiency: AI optimizes logistics, routing, and warehouse management, ensuring timely delivery of raw materials and finished products, reducing transportation costs and lead times.

- Material Science and Design Optimization: AI can simulate and analyze various material compositions and ergonomic designs, helping engineers develop more durable, lighter, and user-friendly pliers.

- Customization and Personalization: AI-driven data analysis of customer preferences can inform the development of specialized plier sets or customizable options, catering to niche market demands.

DRO & Impact Forces Of Plier Market

The plier market is influenced by a complex interplay of Drivers, Restraints, Opportunities, and broader Impact Forces that shape its trajectory. Key drivers include a consistently growing global construction industry, fueled by urbanization and infrastructure development projects, which directly translates into higher demand for hand tools. The robust expansion of the automotive sector, both in vehicle manufacturing and aftermarket repair services, provides a stable market for specialized pliers. Furthermore, the increasing prominence of the DIY culture worldwide, coupled with rising disposable incomes and a desire for home improvement, significantly bolsters the residential segment. The essential nature of pliers in industrial maintenance and repair operations across various manufacturing sectors also serves as a fundamental demand driver, underscoring their indispensability.

However, the market also faces several restraints. Volatility in raw material prices, particularly for steel alloys, can impact manufacturing costs and, consequently, product pricing and profit margins. Intense competition from both established global brands and local manufacturers, especially in emerging markets, can lead to price wars and market saturation. The availability of alternative power tools or specialized equipment for specific tasks might limit the demand for traditional hand pliers in certain applications. Economic slowdowns or recessions can adversely affect consumer spending on non-essential tools and reduce industrial activity, thereby restraining market growth. Additionally, stringent quality and safety regulations, while beneficial for consumers, can increase manufacturing complexities and costs for producers.

Opportunities for growth are abundant, particularly in emerging markets where industrialization and infrastructure development are still in their nascent stages, presenting untapped potential. The adoption of smart manufacturing technologies, including automation and advanced analytics, offers opportunities to enhance production efficiency and product quality. The development of customizable and multi-functional tools caters to evolving user preferences for versatility and efficiency. Expanding e-commerce platforms offer manufacturers new avenues for reaching a broader customer base, including direct-to-consumer sales. Niche applications, such as specialized pliers for aerospace, medical device assembly, or renewable energy installations, also present avenues for product diversification and market expansion. Overall, technological advancements in material science and ergonomic design continue to create avenues for product innovation, enhancing user experience and tool longevity.

Segmentation Analysis

Segmentation analysis is crucial for understanding the diverse dynamics within the Plier Market, enabling manufacturers and marketers to tailor products and strategies to specific customer needs and market opportunities. This comprehensive approach categorizes the market based on various attributes, providing granular insights into demand patterns, competitive landscapes, and growth prospects across different user groups and product types. By breaking down the broader market into more manageable segments, companies can identify their most profitable customer bases and develop highly targeted offerings, optimize distribution channels, and refine their marketing messages to resonate effectively with each segment.

The primary dimensions for segmenting the plier market include the specific type of plier, its major application areas, the materials used in its construction, the intended end-user, and the sales channels through which it is distributed. Each segment carries distinct characteristics regarding consumer preferences, price sensitivity, performance requirements, and regional demand variations. For example, professional end-users in the automotive or electrical sectors prioritize durability, precision, and safety certifications, often leading to a willingness to invest in premium tools. Conversely, the residential or DIY segment might prioritize versatility and affordability. Analyzing these segments individually helps in forecasting market trends, identifying underserved niches, and strategically positioning new product launches to maximize market penetration and revenue generation.

- By Type

- Combination Pliers

- Cutting Pliers

- Diagonal Cutting Pliers

- End Cutting Pliers

- Flush Cutting Pliers

- Gripping Pliers

- Slip Joint Pliers

- Tongue-and-Groove Pliers

- Locking Pliers (Vise-Grip style)

- Needle-Nose Pliers

- Flat-Nose Pliers

- Specialty Pliers

- Crimping Pliers

- Circlip Pliers

- Fencing Pliers

- Water Pump Pliers

- Electronic Pliers

- By Application

- Automotive

- Electrical and Electronics

- Construction

- Plumbing

- General Industrial

- DIY and Household

- Telecommunications

- By Material

- Carbon Steel

- Chrome Vanadium Steel

- Stainless Steel

- Other Alloys

- By End-User

- Professional and Industrial

- Residential and DIY

- By Sales Channel

- Offline Retail (Hardware Stores, Supermarkets, Specialty Stores)

- Online Retail (E-commerce Platforms)

- Distributors and Wholesalers

- Direct Sales to Industrial Clients

Value Chain Analysis For Plier Market

The value chain for the plier market begins with the upstream activities, primarily involving the sourcing and processing of raw materials. This initial stage is dominated by suppliers of high-grade steel alloys, such as carbon steel, chrome vanadium steel, and stainless steel, which are critical for the durability and strength of pliers. These materials undergo processes like forging, heat treatment, and precision machining to form the basic components of the tools. Additionally, suppliers of plastics and rubbers are integral for manufacturing ergonomic handles and insulated grips, which contribute significantly to user comfort and safety. The efficiency and cost-effectiveness at this upstream level directly influence the final product quality and price, making strong supplier relationships and effective raw material procurement vital.

Moving downstream, the value chain encompasses the manufacturing, assembly, and distribution of finished plier products to end-users. After fabrication, components are assembled, inspected for quality, and often branded. Distribution channels are diverse, ranging from direct sales to large industrial clients and government agencies, to indirect channels that utilize a network of wholesalers, distributors, and retailers. This multi-tiered distribution strategy ensures market penetration across various end-user segments. Large hardware store chains, specialty tool shops, and a growing number of e-commerce platforms serve as critical conduits for reaching professional tradespeople and residential DIY enthusiasts alike, facilitating broad market access and product availability.

The distribution landscape is characterized by a mix of traditional brick-and-mortar retail and increasingly dominant online platforms. Direct sales channels are often employed for large volume industrial orders, allowing manufacturers to build strong relationships with corporate clients. Indirect channels, through distributors and wholesalers, play a crucial role in aggregating products from multiple manufacturers and supplying them to a fragmented retail market. Online retail has revolutionized product accessibility, offering convenience and broader selection to consumers, while simultaneously challenging traditional retail models to adapt. Effective management of these channels is paramount for optimizing reach, reducing logistical costs, and ensuring competitive pricing, ultimately driving market share and profitability within the plier market.

Plier Market Potential Customers

The plier market serves a vast and diverse customer base, categorized primarily by their professional needs or personal usage. Professional and industrial end-users represent a significant segment, encompassing individuals and businesses whose daily operations rely heavily on durable, precise, and often specialized plier types. This group includes automotive technicians who require specific pliers for engine work, electricians needing insulated tools for safety, plumbers using tongue-and-groove pliers for pipework, and construction workers utilizing various types for bending, cutting, and fastening. Manufacturing facilities across diverse sectors, from electronics to heavy machinery, also constitute a core segment, demanding high-quality tools for assembly, maintenance, and repair operations.

Beyond the professional sphere, residential and do-it-yourself (DIY) enthusiasts form another substantial customer segment. These buyers typically seek versatile, easy-to-use, and affordable pliers for a wide array of household repairs, maintenance tasks, and hobby projects. The growth of the DIY culture, particularly in developed economies, contributes significantly to this segment's demand. From minor electrical fixes and plumbing adjustments to crafting and gardening, pliers are indispensable tools found in nearly every household toolbox. The demand from this segment is often influenced by factors such as product accessibility, marketing campaigns, and price points, making retail and online channels crucial for engagement.

Additionally, educational institutions and vocational training centers represent potential customers, procuring pliers for hands-on training programs in trades like carpentry, automotive repair, and electronics. Government agencies, including military and public works departments, also acquire various types of pliers for equipment maintenance, infrastructure projects, and field operations. The diverse applications and fundamental utility of pliers ensure a broad appeal across these varied customer groups, each with unique requirements regarding tool specifications, durability, and brand loyalty. Understanding these distinct customer profiles is key to effective product development, pricing strategies, and marketing efforts in the plier market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 3.2 Billion |

| Market Forecast in 2032 | USD 5.0 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Stanley Black & Decker, Snap-on Incorporated, Klein Tools, Knipex-Werk C Gustav Putsch KG, Channellock Inc., Apex Tool Group, Gedore Group, Wiha Tools, Craftsman, Irwin Tools (Newell Brands), Makita Corporation, Proto (Stanley Black & Decker), Facom (Stanley Black & Decker), Fujiya Co Ltd, Tolsen Tools, Great Neck Saw Manufacturers, Milwaukee Tool (Techtronic Industries), Tekton, Crescent Tools (Apex Tool Group), Bahco (SNA Europe) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Plier Market Key Technology Landscape

The plier market, while rooted in traditional hand tool manufacturing, continuously evolves through the integration of advanced technological processes and material science innovations. The key technology landscape is dominated by sophisticated metallurgical techniques crucial for producing high-strength and durable tools. This includes the precise selection and treatment of alloy steels, such as chrome vanadium steel and high-carbon steel, which undergo rigorous forging processes to achieve optimal grain structure and mechanical properties. Heat treatment technologies, including induction hardening and tempering, are vital for enhancing the toughness, wear resistance, and overall longevity of the plier jaws and cutting edges, ensuring they can withstand demanding professional use without deformation or premature wear.

Beyond material science, ergonomic design principles play a significant role in modern plier manufacturing. Technology in this area focuses on developing handle designs that reduce user fatigue, provide a secure grip, and enhance leverage. This often involves multi-component grips made from specialized plastics and rubbers that offer cushioning and slip resistance. Furthermore, advancements in insulation technology are critical for electrical pliers, where multi-layer insulation systems are engineered to meet stringent safety standards, protecting users from electrical shock. Precision machining techniques, often utilizing Computer Numerical Control (CNC) equipment, are employed to ensure the accurate alignment of jaw surfaces and smooth operation of pivot points, which are paramount for the functionality and precision of the tool.

Another important aspect of the technology landscape involves anti-corrosion coatings and surface treatments. These technologies, ranging from chrome plating to black oxide finishes, are applied to protect the metal components from rust and environmental degradation, thereby extending the tool's lifespan and maintaining its aesthetic appeal. The integration of multi-functional capabilities, such as built-in wire strippers or bolt cutters into a single plier, represents an ongoing trend driven by technological innovation to offer greater utility and convenience. While pliers are fundamentally mechanical tools, their manufacturing process is increasingly benefiting from advanced engineering, materials science, and design methodologies to meet the evolving demands for performance, safety, and user comfort in both professional and residential applications.

Regional Highlights

- North America: A mature market characterized by strong demand from well-established construction, automotive, and manufacturing industries. High adoption of premium and specialized tools, driven by professional trades and a significant DIY consumer base. The region exhibits a stable growth pattern with a focus on quality and innovation.

- Europe: Dominated by stringent quality standards and a strong preference for high-performance, ergonomically designed tools. Germany, France, and the UK are key contributors, with robust manufacturing sectors and a focus on specialized industrial applications. Emphasis on insulated and safety-compliant tools.

- Asia Pacific (APAC): The fastest-growing region, propelled by rapid industrialization, extensive infrastructure development projects, and a booming construction sector in countries like China, India, and Southeast Asian nations. A large manufacturing base and increasing disposable incomes contribute to both professional and residential demand.

- Latin America: An emerging market experiencing growth due to urbanization, increased construction activities, and expanding automotive industries in Brazil, Mexico, and Argentina. The region presents significant opportunities for market penetration, with a rising demand for affordable yet reliable tools.

- Middle East and Africa (MEA): Marked by substantial infrastructure investments, particularly in the construction and oil and gas sectors, driving demand for industrial-grade pliers. Economic diversification efforts and increasing urbanization are fostering growth, though political stability and economic conditions can influence market dynamics.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Plier Market.- Stanley Black & Decker

- Snap-on Incorporated

- Klein Tools

- Knipex-Werk C Gustav Putsch KG

- Channellock Inc.

- Apex Tool Group

- Gedore Group

- Wiha Tools

- Craftsman

- Irwin Tools (Newell Brands)

- Makita Corporation

- Proto (Stanley Black & Decker)

- Facom (Stanley Black & Decker)

- Fujiya Co Ltd

- Tolsen Tools

- Great Neck Saw Manufacturers

- Milwaukee Tool (Techtronic Industries)

- Tekton

- Crescent Tools (Apex Tool Group)

- Bahco (SNA Europe)

Frequently Asked Questions

What factors are primarily driving the growth of the Plier market?

The Plier market's growth is primarily driven by expanding global construction activities, robust demand from the automotive industry, the increasing popularity of DIY culture, and sustained needs from industrial maintenance and repair operations across various sectors.

How does the segmentation by type impact the Plier market?

Segmentation by plier type, such as combination, cutting, or gripping pliers, allows manufacturers to cater to specific applications and user requirements, influencing product development, marketing, and pricing strategies for specialized tasks.

Which regions are most significant for Plier market demand and growth?

Asia Pacific is the fastest-growing region due to rapid industrialization and infrastructure development, while North America and Europe remain significant mature markets with stable demand for high-quality and specialized tools.

What is the role of technology in modern Plier manufacturing?

Technology plays a crucial role through advanced metallurgy for durability, ergonomic designs for user comfort, precision machining for accuracy, and insulated handle technologies for safety, constantly improving tool performance and longevity.

Who are the key end-users or potential customers for Plier products?

Key end-users include professional tradespeople such as electricians, plumbers, and automotive technicians, as well as residential DIY enthusiasts, manufacturing facilities, and government agencies, each with distinct requirements for their tools.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Party and Event Rental Supplier Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Tongue Groove Plier Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Composite Plier Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Silicon Photomultiplier Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Procurement Outsourcing Services Market Size Report By Type (Business Process Outsourcing Services, Category Management, Source Management, Procurement Management, Supplier Management, Procure to Pay, Consulting Services), By Application (Marketing Related Services, IT Related Services, HR Related Services, Facilities Management & Office Services, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Statistics, Trends, Outlook and Forecast 2025-2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager